A kind of non-normal distribution aluminum hydroxide powder and its preparation method and application

An aluminum hydroxide, normal distribution technology, used in epoxy resin glue, polymer adhesive additives, adhesive types, etc., can solve the problems of low viscosity, anti-precipitation and mutual repulsion, and reduce production costs. , Improve the fusion performance, improve the mutually exclusive effect of low viscosity and anti-settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of described non-normal distribution aluminum hydroxide powder comprises the following steps:

[0025] A. Pulverization: Use a raw powder pulverizer to pulverize aluminum hydroxide to obtain aluminum hydroxide powders of 2 μm and 18 μm;

[0026] B. Screening: Use a powder classifying vibrating sieve at room temperature to screen aluminum hydroxide powders of 2 μm and 18 μm at 960 times / min to ensure that the particle size of the powder is uniform;

[0027] C. Mixing: Add 2μm and 18μm aluminum hydroxide powders into a 360° rotary mixer according to the mass ratio and mix them. The mixing temperature is 90±2℃, and they are mixed for 2±0.5h. After mixing evenly, aluminum hydroxide with non-normal distribution is obtained. pink.

[0028] The application of the non-normal distribution aluminum hydroxide powder is to use the non-normal distribution aluminum hydroxide powder as a filler for the preparation of two-component epoxy resin electronic potting...

Embodiment 1

[0052] The aluminum hydroxide powder with non-normal distribution is formed by mixing aluminum hydroxide powder with a particle size of 2 μm and aluminum hydroxide powder with a particle size of 18 μm, and the mixing mass ratio of the two is 2:1.

[0053] The specific preparation method is:

[0054] A. Pulverization: Use a raw powder pulverizer to pulverize aluminum hydroxide to obtain aluminum hydroxide powders of 2 μm and 18 μm;

[0055] B. Screening: Use a powder classifying vibrating sieve at room temperature to screen aluminum hydroxide powders of 2 μm and 18 μm at 960 times / min to ensure that the particle size of the powder is uniform;

[0056] C. Mixing: Add 2 μm and 18 μm aluminum hydroxide powders into a 360° rotary mixer in a mass ratio of 2:1 and mix them at a mixing temperature of 90±2°C. After mixing for 2 hours, aluminum hydroxide powders with non-normal distribution can be obtained.

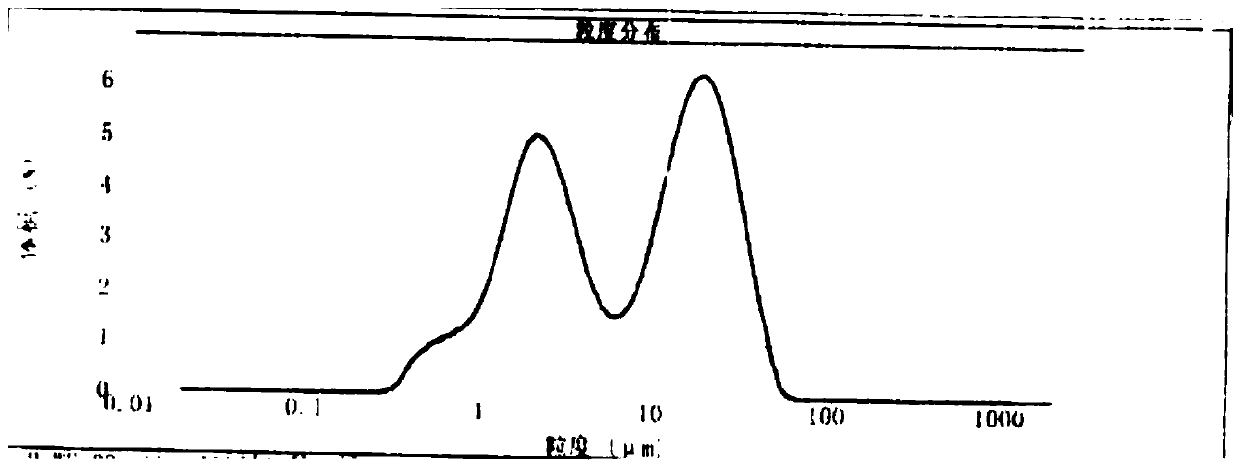

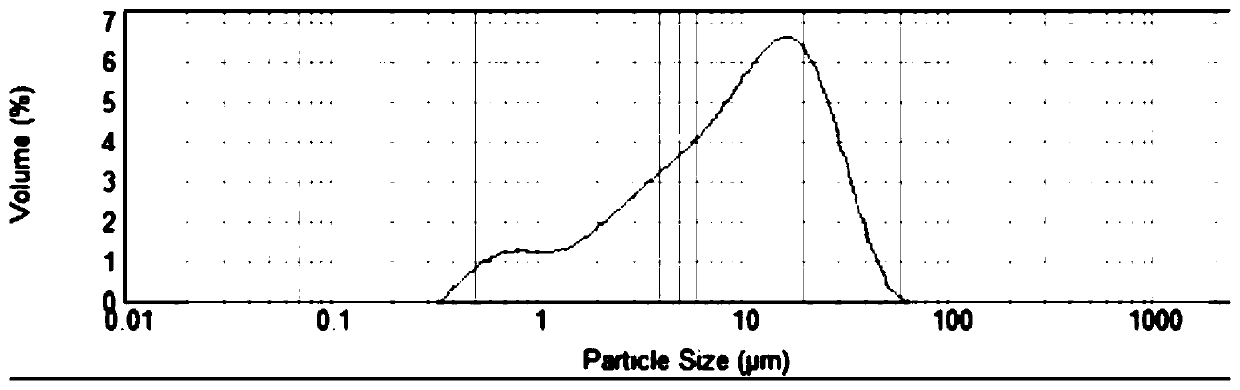

[0057] Use LS-POP (9) laser particle size analyzer to carry out particle size...

Embodiment 2~ Embodiment 5

[0059] The formula of the non-normal distribution aluminum hydroxide powder of embodiment 2~embodiment 5 is shown in Table 1, and its preparation method is identical with the preparation method among the embodiment 1.

[0060] Table 1 Formula and average particle size of aluminum hydroxide powder with non-normal distribution

[0061]

[0062] Note: The particle size distribution chart test instrument and test method, the average particle size calculation method are the same as in Example 1, and the particle size distribution chart shows that the products of Example 2 to Example 5 all contain two high absorption peaks.

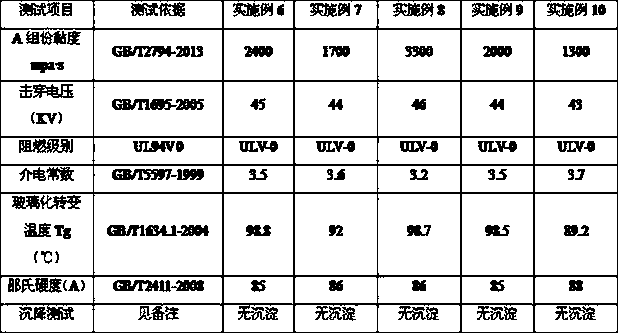

[0063] Next, the aluminum hydroxide powder with non-normal distribution prepared in Examples 1 to 5 was used as a filler and mixed with the base resin to prepare a simple version of component A, and to conduct viscosity and settling performance tests.

[0064] 1. Test method

[0065] Take five parts of 50g of commercially available E51 epoxy resin as the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com