High-thermal-conductive epoxy resin composition and preparation method thereof

A technology of epoxy resin and phenolic epoxy resin, which is applied in the field of high thermal conductivity epoxy resin composition and preparation, can solve the problems of complicated preparation process, high difficulty and high cost, and achieves simple preparation process, low production cost and high component cost. uncomplicated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

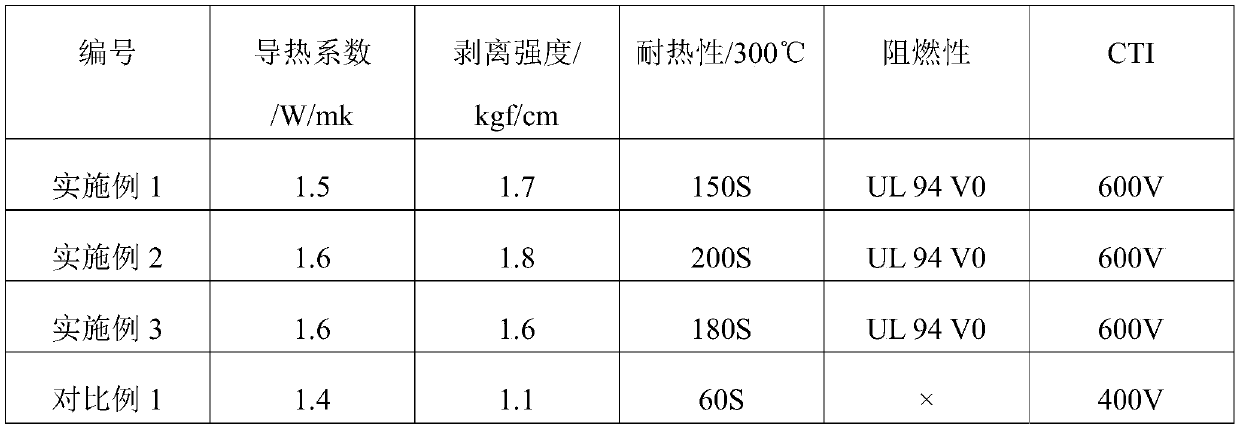

Examples

Embodiment 1

[0047] This example provides a high thermal conductivity epoxy resin composition, including the following components in parts by weight:

[0048] 20 parts of epoxy resin, 5 parts of curing agent, 65 parts of filler, 20 parts of flame retardant, and 15 parts of solvent.

[0049] Wherein, the epoxy resin is a mixture of bisphenol A epoxy resin and bisphenol F epoxy resin in a mass ratio of 1:1.

[0050] The bisphenol A epoxy resin is GelR28E (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 185g / eq), and the bisphenol F epoxy resin is FX7900 (Hunan Jiashengde, epoxy equivalent: 200g / eq).

[0051] The curing agent is 4,4-diaminodiphenyl sulfone.

[0052] The filler is a mixture of alumina and boria in a mass ratio of 1:1.

[0053]The flame retardant is a mixture of aluminum hydroxide and silicon dioxide in a mass ratio of 1:1.

Embodiment 2

[0056] This example provides a high thermal conductivity epoxy resin composition, including the following components in parts by weight:

[0057] 20 parts of epoxy resin, 8 parts of curing agent, 65 parts of filler, 20 parts of flame retardant, and 15 parts of solvent.

[0058] Wherein, the epoxy resin is a mixture of bisphenol A epoxy resin, bisphenol F epoxy resin, biphenyl type epoxy resin and naphthalene ring type epoxy resin.

[0059] Bisphenol A epoxy resin is GelR28E (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 185g / eq), bisphenol F epoxy resin is FX7900 (Hunan Jiashengde, epoxy equivalent: 200g / eq), biphenyl The type epoxy resin is NC-3000 (Nippon Kayaku, epoxy equivalent: 280g / eq), and the naphthalene ring type epoxy resin is NPTE4000 (Hunan Jiashengde, epoxy equivalent: 225g / eq).

[0060] The curing agent is dicyandiamide.

[0061] The filler is a mixture of alumina and boria in a mass ratio of 1:1.

[0062] The flame retardant is a mixture of alum...

Embodiment 3

[0065] This example provides a high thermal conductivity epoxy resin composition, including the following components in parts by weight:

[0066] 20 parts of epoxy resin, 8 parts of curing agent, 65 parts of filler, 20 parts of flame retardant, and 15 parts of solvent.

[0067] Among them, the epoxy resin is bisphenol A epoxy resin, bisphenol F epoxy resin, biphenyl type epoxy resin, naphthalene ring type epoxy resin and novolac epoxy resin in a mass ratio of 2:0.5:0.5:0.5: A mix of 2.5.

[0068] Bisphenol A epoxy resin is GelR28E (Hongchang Electronic Materials Co., Ltd., epoxy equivalent: 185g / eq), bisphenol F epoxy resin is FX7900 (Hunan Jiashengde, epoxy equivalent: 200g / eq), biphenyl Type epoxy resin is NC-3000 (Nippon Kayaku, epoxy equivalent: 280g / eq), naphthalene ring type epoxy resin is NPTE4000 (Hunan Jiashengde, epoxy equivalent: 225g / eq), novolac epoxy resin is SQCN702 produced by Shandong Shengquan Chemical Co., Ltd.

[0069] The curing agent is a 1:1 compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com