Semiconductor quantum dot doped polymer dispersed liquid crystal containing Ag nanoparticles

A nanoparticle, dispersed liquid crystal technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of polymer-dispersed liquid crystal structure damage, inability to prepare random lasers, and the luminous band is not easy to change. , to achieve the effect of broad commercialization prospects, less harsh preparation conditions, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A polymer-dispersed liquid crystal doped with semiconductor quantum dots containing Ag nanoparticles, prepared from the following components in parts by mass:

[0041]

[0042] Wherein, the nematic liquid crystal includes the following components in parts by mass:

[0043]

[0044]

[0045] The semiconductor quantum dots are ZnCdSeS / ZnS semiconductor quantum dots.

[0046] The particle size of the Ag nanoparticles was 80 nm.

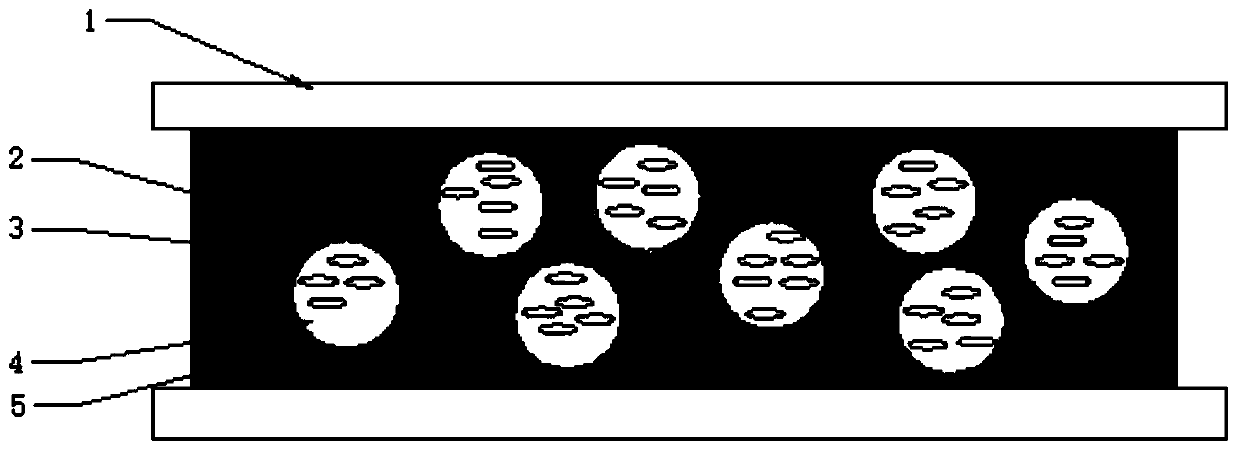

[0047] The above-mentioned semiconductor quantum dot doped polymer dispersed liquid crystal containing Ag nanoparticles is prepared by the following method:

[0048] (1) Nematic liquid crystal, photosensitive polymer polymethyl methacrylate, ZnCdSeS / ZnS semiconductor quantum dots and photoinitiator phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide were heated at 50°C Stir in the dark for 5 minutes to form a mixed solution, then add Ag nanoparticles with a particle size of 80 nm into the mixed solution, perform ultrasonic dispersion for 1...

Embodiment 2

[0059] A semiconductor quantum dot-doped polymer-dispersed liquid crystal with Ag nanoparticles as a scatterer, prepared from the following components in parts by mass:

[0060]

[0061] Wherein, the nematic liquid crystal includes the following components in parts by mass:

[0062]

[0063] The semiconductor quantum dots are ZnCdSeS / ZnS semiconductor quantum dots.

[0064] The particle diameter of the Ag nanoparticles was 50 nm.

[0065] The above-mentioned semiconductor quantum dot doped polymer dispersed liquid crystal containing Ag nanoparticles is prepared by the following method:

[0066] (1) Stir nematic liquid crystal, photosensitive polymer polymethyl acrylate, ZnCdSeS / ZnS semiconductor quantum dots and photoinitiator 2-hydroxy-methylphenylpropan-1-ketone at 50°C in the dark for 5 minutes to form a mixed solution , and then Ag nanoparticles with a particle size of 50 nm were added to the mixed solution, followed by ultrasonic dispersion for 1 min, and then mec...

Embodiment 3

[0071] A polymer-dispersed liquid crystal doped with semiconductor quantum dots containing Ag nanoparticles, prepared from the following components in parts by mass:

[0072]

[0073] Wherein, the nematic liquid crystal includes the following components in parts by mass:

[0074]

[0075] The semiconductor quantum dots are ZnCdSeS / ZnS semiconductor quantum dots.

[0076] The particle size of the Ag nanoparticles was 20 nm.

[0077] The above-mentioned semiconductor quantum dot doped polymer dispersed liquid crystal containing Ag nanoparticles is prepared by the following method:

[0078] (1) Stir nematic liquid crystal, photosensitive polymer polyaminoacrylate, ZnCdSeS / ZnS semiconductor quantum dots and photoinitiator benzoin dimethyl ether at 50°C for 5min in the dark to form a mixed solution, and then mix the particles with a particle size of 20nm After the Ag nanoparticles were added into the mixed solution, ultrasonic dispersion was performed for 1 min, and then me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com