Polymer dispersed liquid crystal and preparation method and application

A technology of dispersing liquid crystals and polymers, which is applied in the field of quantum dots, can solve the problems of inconvenient preparation of random lasers, difficulty in changing the light emission band, and high laser emission threshold, and achieve broad commercialization prospects, less harsh preparation conditions, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

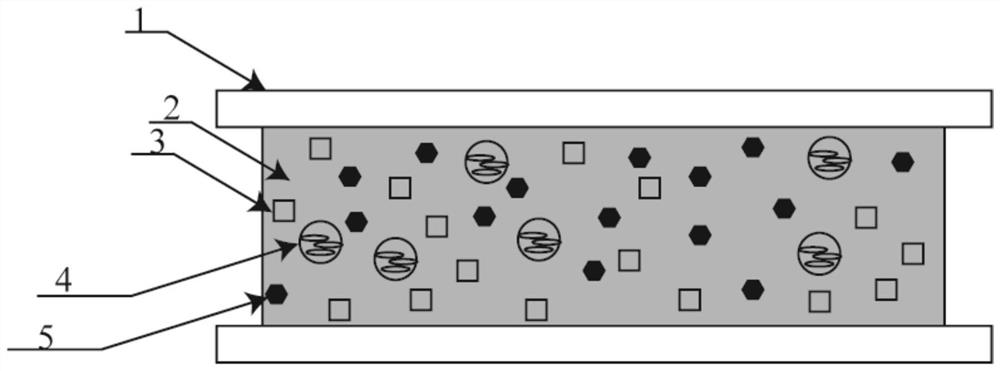

[0048] A kind of polymer dispersion liquid crystal, it is made by following composition:

[0049]

[0050] Wherein, the nematic liquid crystal includes the following components in parts by mass:

[0051]

[0052]

[0053] Wherein, the silver content of the nano-silver loaded graphene is 45wt%, the average lateral dimension is 5 μm, and the average longitudinal dimension is 0.8 μm;

[0054] The above-mentioned polymer dispersed liquid crystal is prepared by the following method:

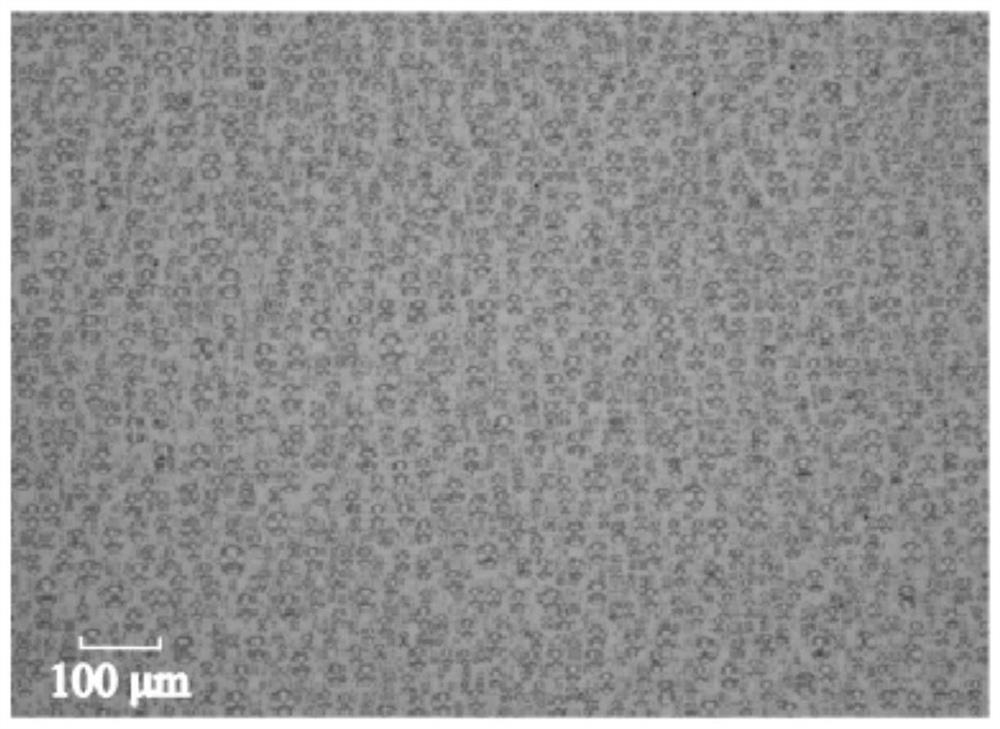

[0055] (1) The above-mentioned nematic liquid crystal, photosensitive polymer polymethyl methacrylate, ZnCdSeS / ZnS semiconductor quantum dot and photoinitiator phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide were mixed at 50 Stir in the dark for 5 min at °C to form a mixed solution.

[0056] (2) After nano-silver-loaded graphene was added to the mixed solution, ultrasonic dispersion was carried out for 1.5 h, and then mechanically stirred for 2 h at 50° C. under the condition of avoiding ...

Embodiment 2

[0065] A kind of polymer dispersion liquid crystal, it is made by following composition:

[0066]

[0067] Wherein, the nematic liquid crystal includes the following components in parts by mass:

[0068]

[0069] Wherein, the silver content of the nano-silver loaded graphene is 35wt%, the average lateral dimension is 6 μm, and the average longitudinal dimension is 0.9 μm;

[0070] The above-mentioned polymer dispersed liquid crystal is prepared by the following method:

[0071] (1) The above-mentioned nematic liquid crystal, photosensitive polymer polymethyl acrylate, CsPbBr 3 The perovskite semiconductor quantum dots and the photoinitiator 2-hydroxy-methylphenylpropan-1-ketone were stirred at 50° C. for 5 minutes in the dark to form a mixed solution.

[0072] (2) After nano-silver-loaded graphene was added into the mixed solution, ultrasonic dispersion was carried out for 1 h, and then mechanically stirred for 1 h at 50° C. under the condition of avoiding light to obt...

Embodiment 3

[0077] A kind of polymer dispersion liquid crystal, it is made by following composition:

[0078]

[0079]

[0080] Wherein, the nematic liquid crystal includes the following components in parts by mass:

[0081]

[0082] Wherein, the silver content of the nano-silver loaded graphene is 30wt%, the average lateral dimension is 6 μm, and the average longitudinal dimension is 1.1 μm;

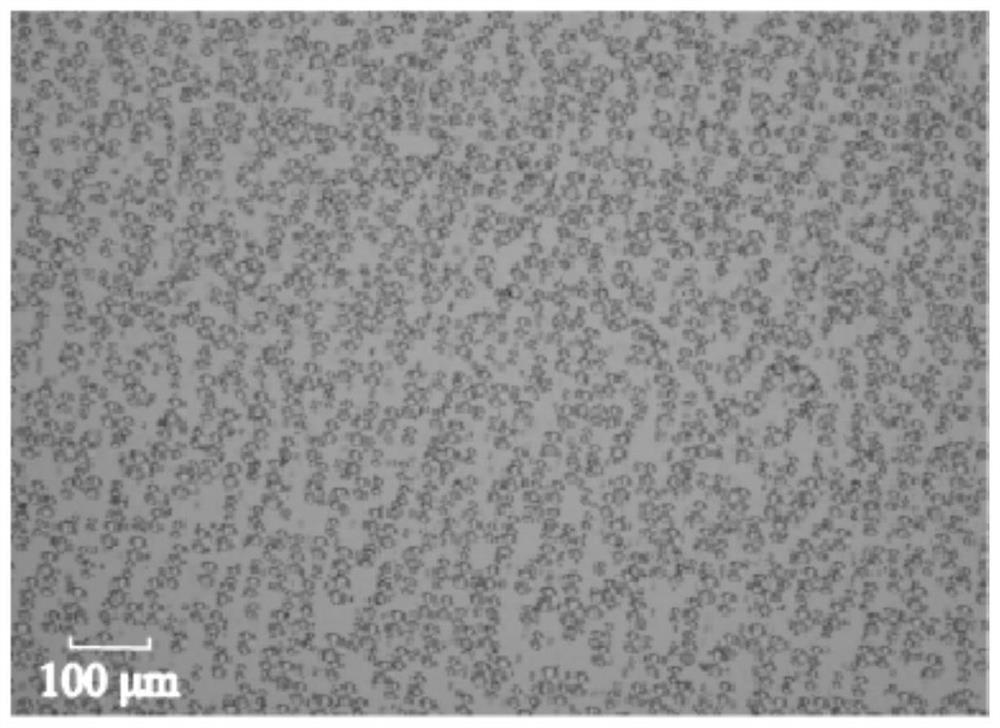

[0083] The above-mentioned polymer dispersed liquid crystal is prepared by the following method:

[0084] (1) Stir the above-mentioned nematic liquid crystal, photosensitive polymer polyaminoacrylate, ZnCdSeS / ZnS semiconductor quantum dots and photoinitiator benzoin dimethyl ether at 50° C. in the dark for 5 minutes to form a mixed solution.

[0085] (2) After nano-silver-loaded graphene was added into the mixed solution, ultrasonic dispersion was performed for 1 h, and then mechanically stirred for 2 h at 50° C. under the condition of avoiding light to obtain solution A.

[0086] (3) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com