Manufacturing method for ultra-long and ultra-thick circular plate

A manufacturing method and arc plate technology, which are applied to manufacturing tools, arc welding equipment, auxiliary devices, etc., can solve the problems of poor mechanical properties of arc plates, large machining workload, and high mold manufacturing costs, and reduce manufacturing costs. , Improve welding quality, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

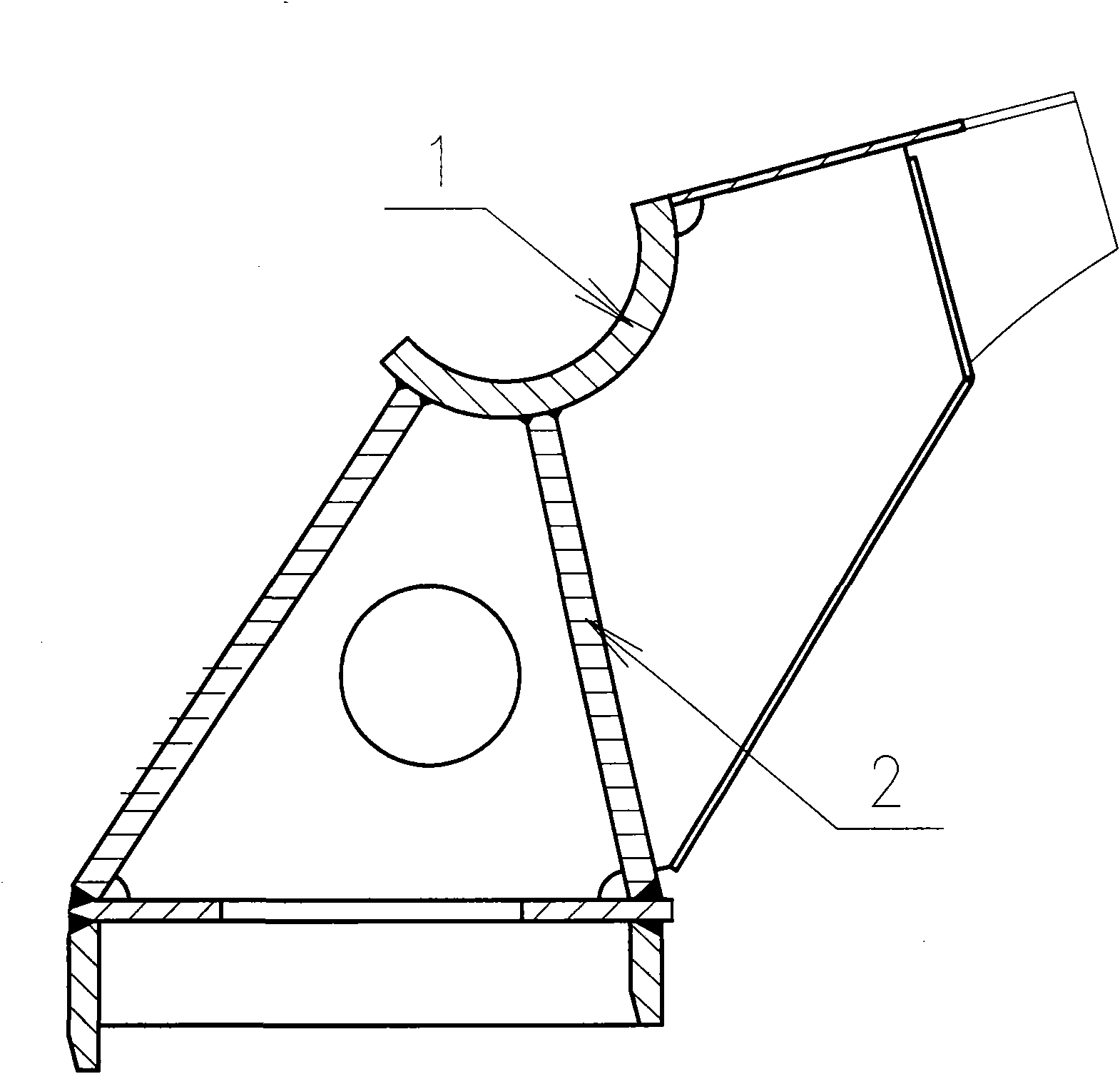

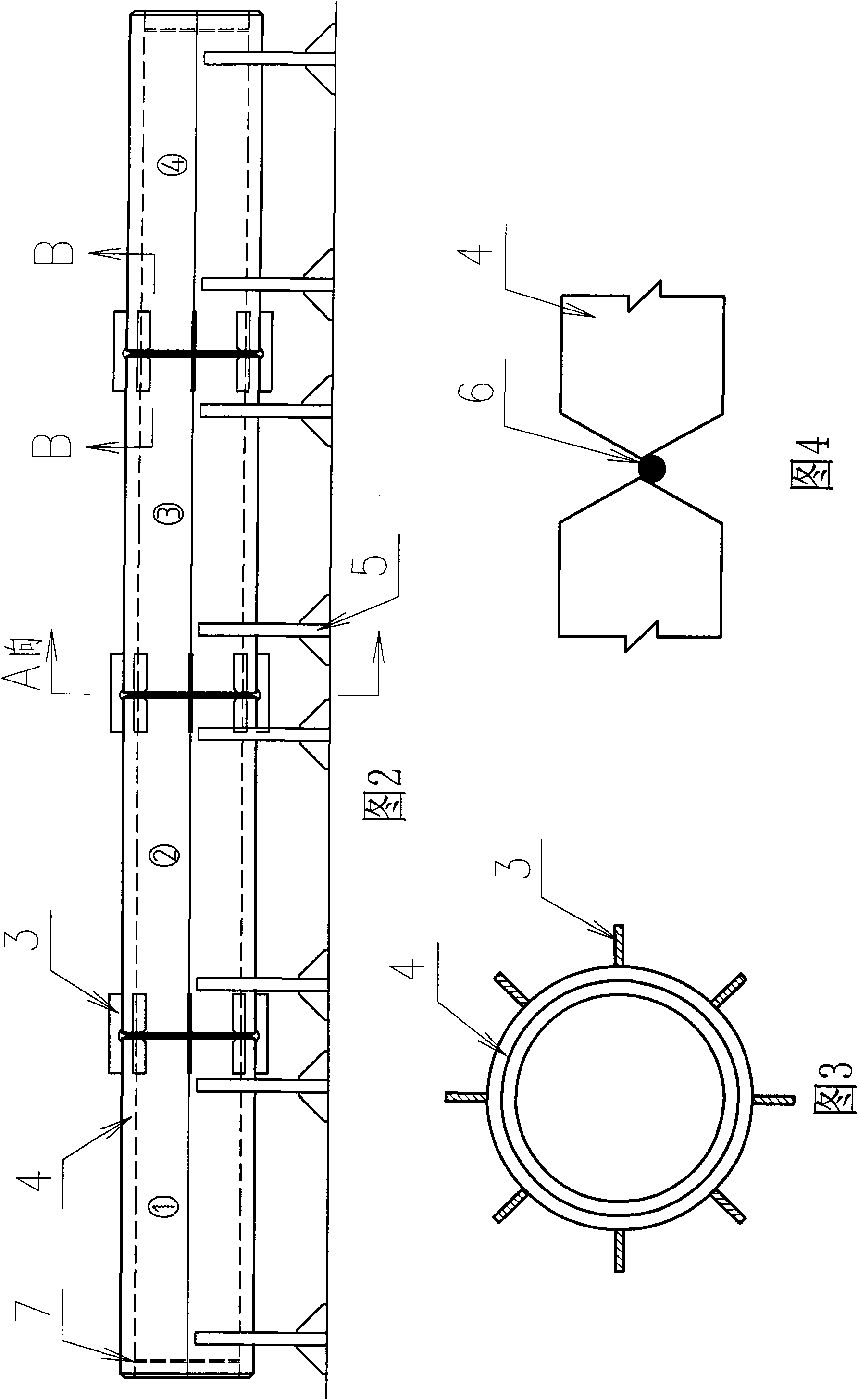

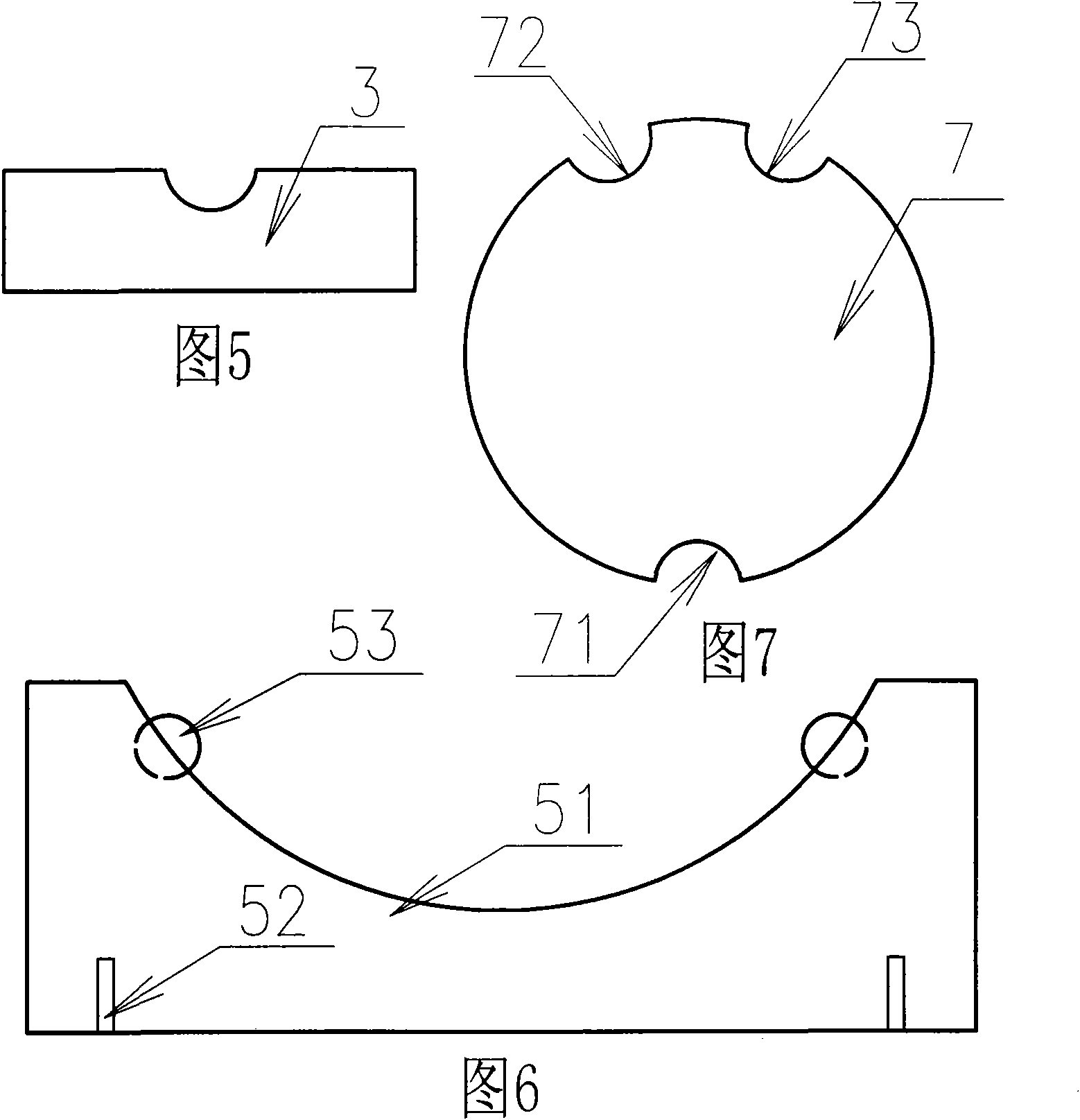

[0032] exist image 3 Shown in is to forge four section steel cylinder 4 at first, in figure 2 1. cylinder, 2. cylinder, 3. cylinder and 4. cylinder are used to indicate that four sections of cylinder 4 are connected together to prepare for welding. Each section of cylinder 4 is machined with a machine tool respectively, and the inner circle radius of the cylinder is 440 mm, the thickness is 120 mm, the length is 3 meters, and the surface roughness is 6.3, and the groove is machined at the end of the cylinder, such as Figure 4 shown. Put the cylinder ② and the cylinder ③ on the rolling tire frame 5, the structure of the rolling tire frame is as follows: Image 6 Shown: two small brackets 52 are respectively connected to the bottom of the tire frame plate 51, the upper end of the tire frame plate 51 is in the shape of an arc, the inner diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com