Patents

Literature

41results about How to "Reduce weld defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

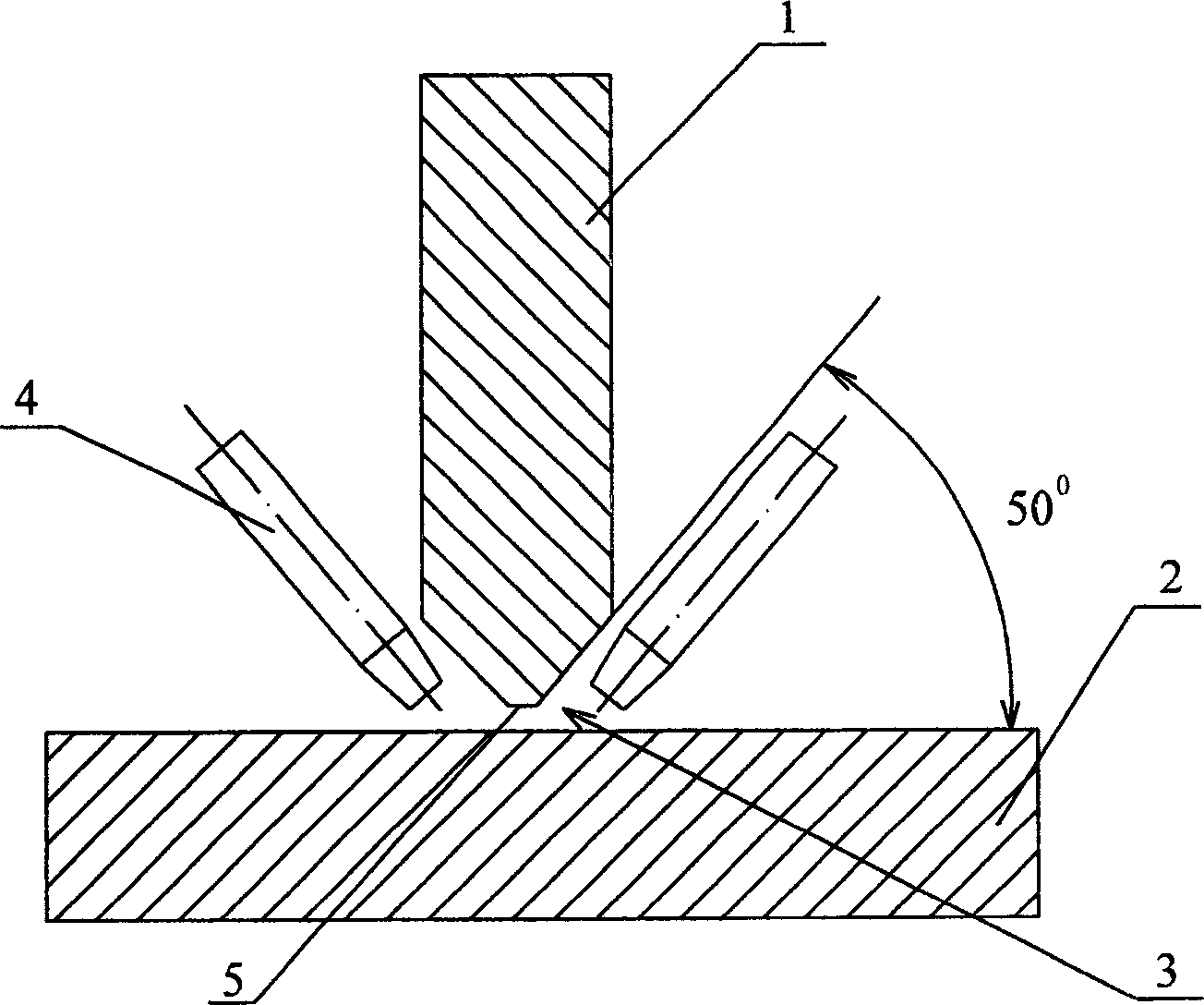

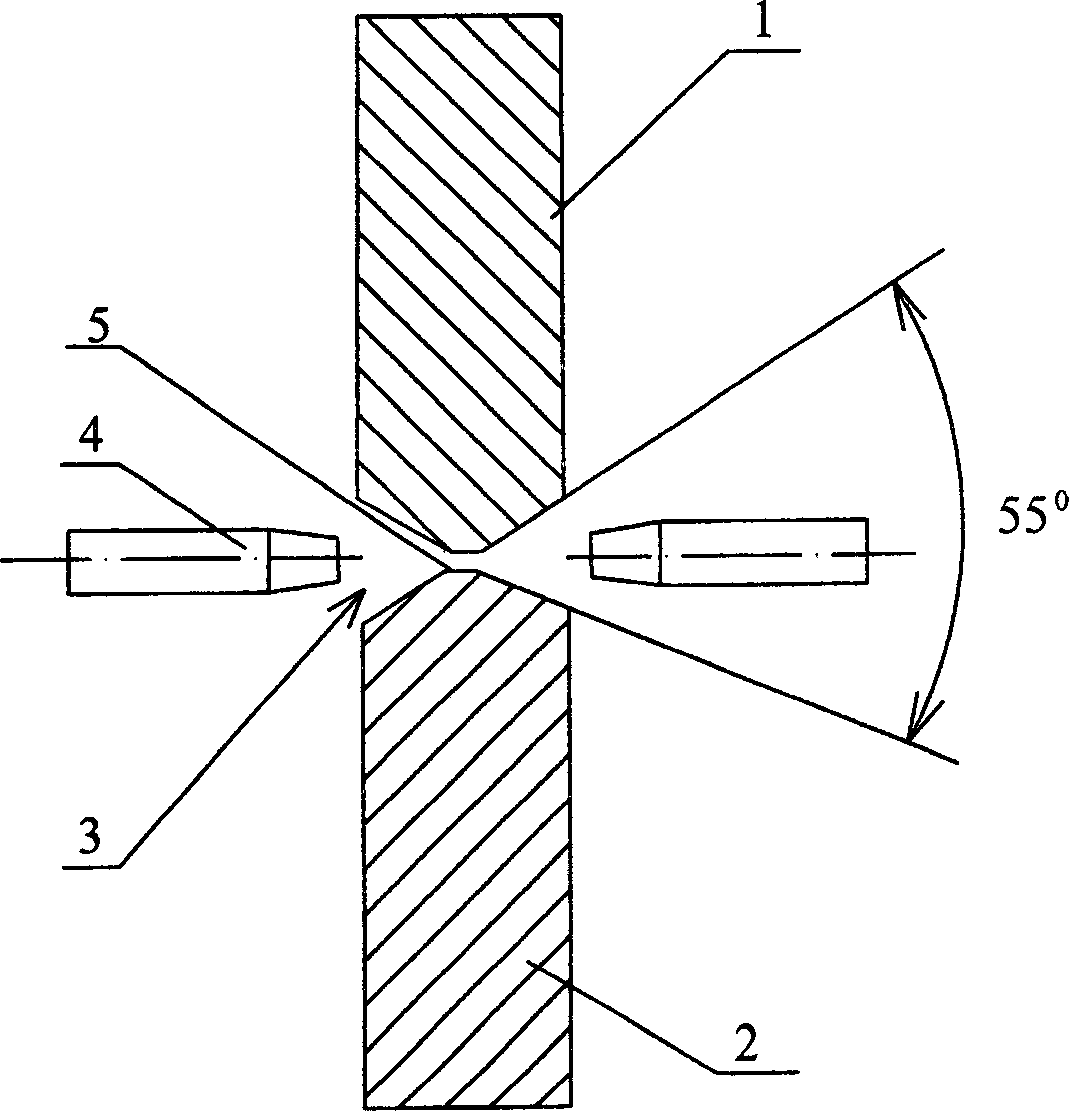

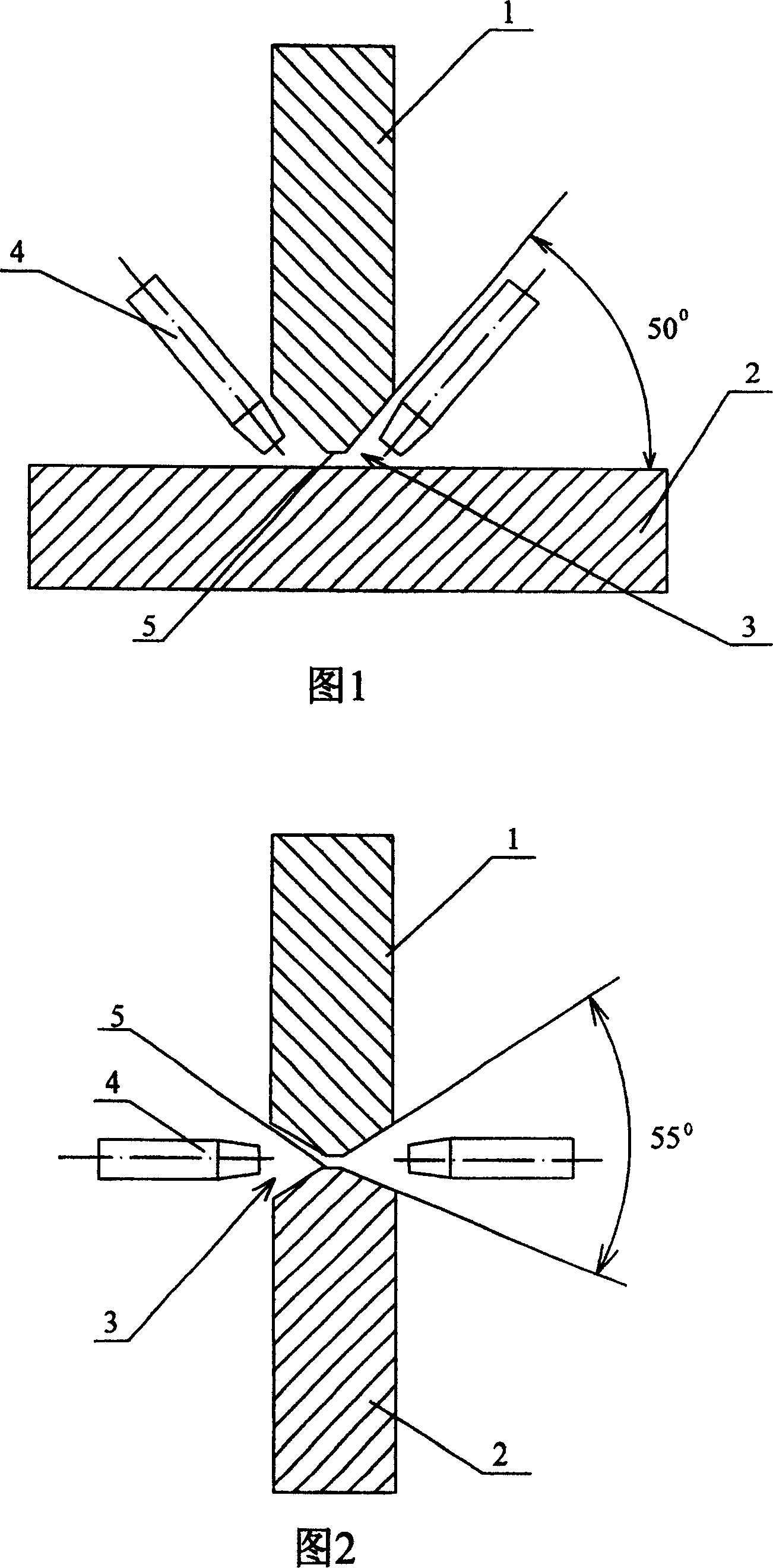

Double sides double arc welding method

ActiveCN1603045AReduce stressGuarantee welding qualityArc welding apparatusWorkpiece edge portionsJoint stressWelding deformation

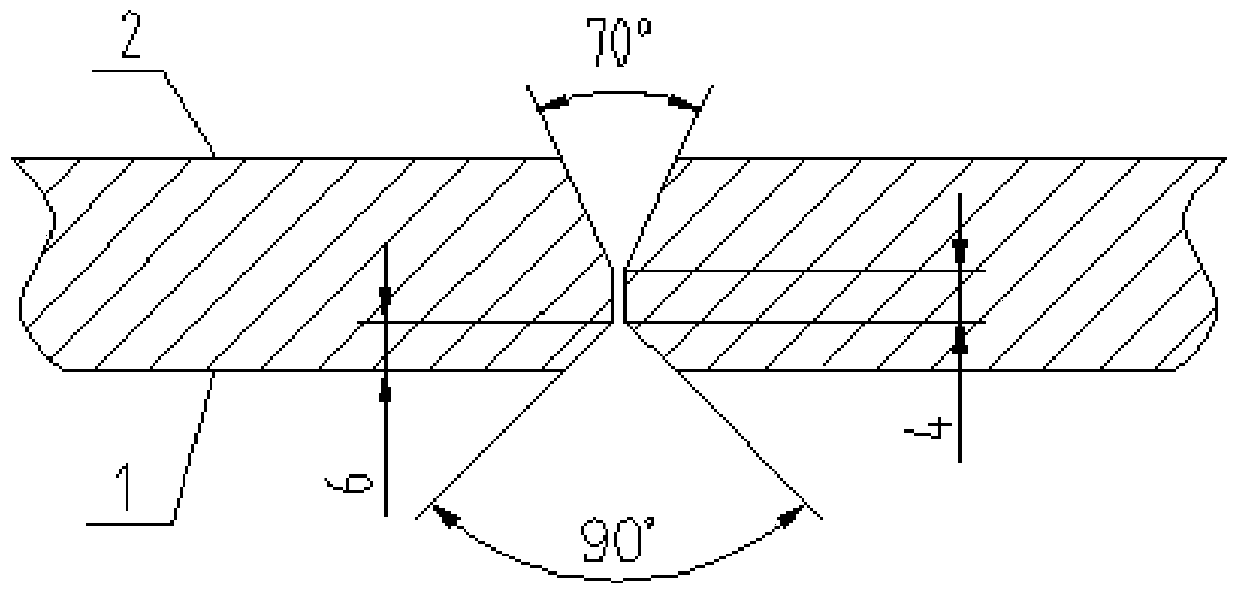

The invention relates to a double side dual-arc welding method. It includes the following steps that the work-piece connection part waited for welding is made both sides welding groove; the both sides welding groove and its both sides surface is ground and cleaned out before the welding; the two independent electric arcs elicited by two welding guns of the two welding machines are conducted both sides dual-arc symmetry bottoming welding respectively at the both sides welding groove; after the bottoming welding, the two independent electric arcs are conducted both sides dual-arc filling welding respectively at the both sides welding groove. The invention avoids the carbon arc-air gouging back gouging process, simplifies the welding process, so that the automation welding can be realized. It avails to practice gas shielded welding, ensure the welding quality, reduce the welding deformation, and decrease joint stress. The method can apply to important metal structural parts welding.

Owner:渤海造船厂集团有限公司

Method for producing aluminum plate-fin heat exchanger

InactiveCN1943973AHigh strengthLow strength, good cleaning qualityDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesShielding gasNitrogen

The process of producing aluminum plate-fin heat exchanger includes the steps of blanking, washing, mounting, brazing, argon arc welding and pressure test. The present invention adopts numerically controlled lathe with high machining precision for blanking; ultrasonic washing for high washing efficiency and high washing quality; continuous high purity nitrogen protected brazing for high brazing quality; and argon arc welding with welding robot for high welding quality and high production efficiency.

Owner:管保清 +1

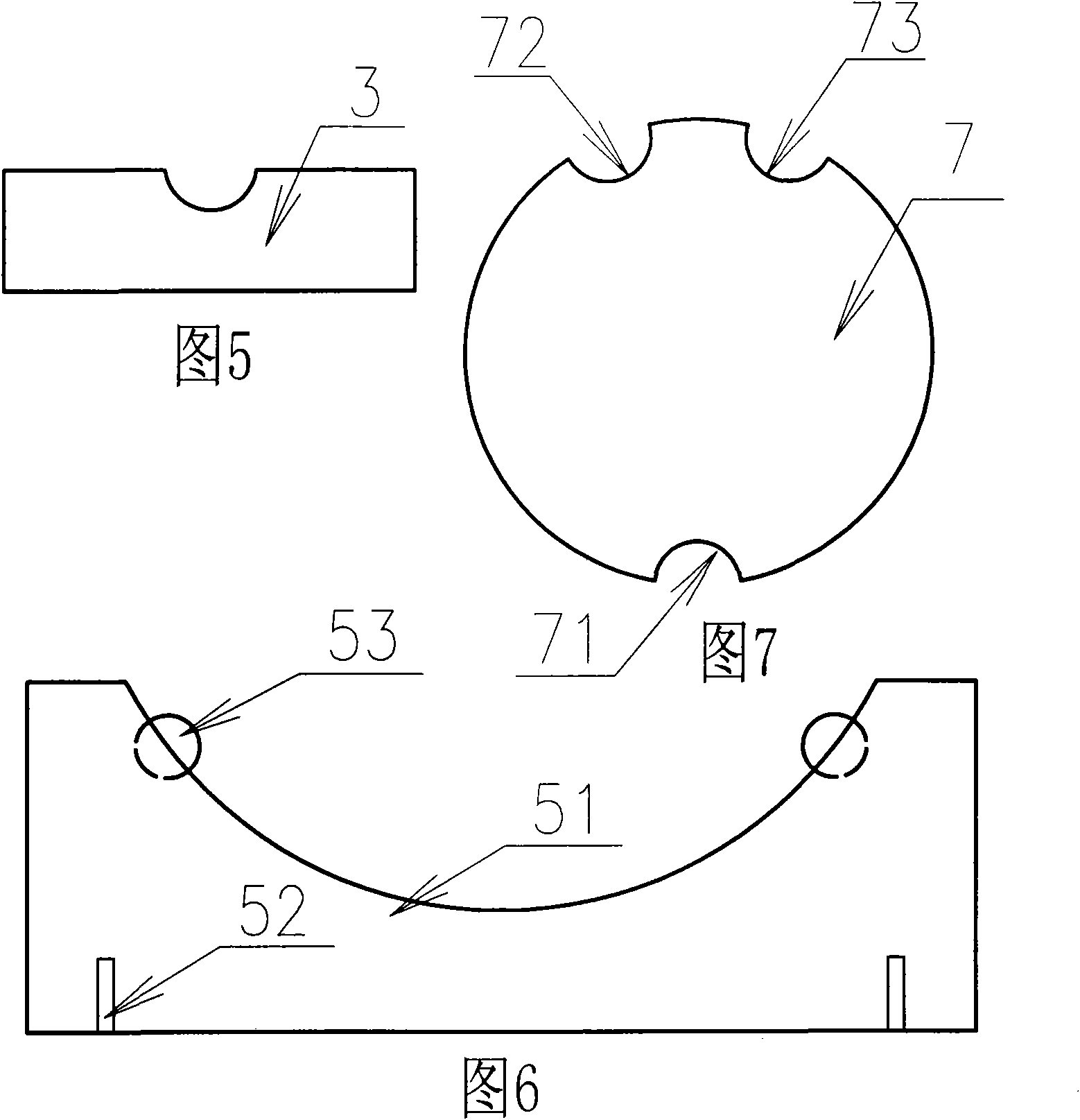

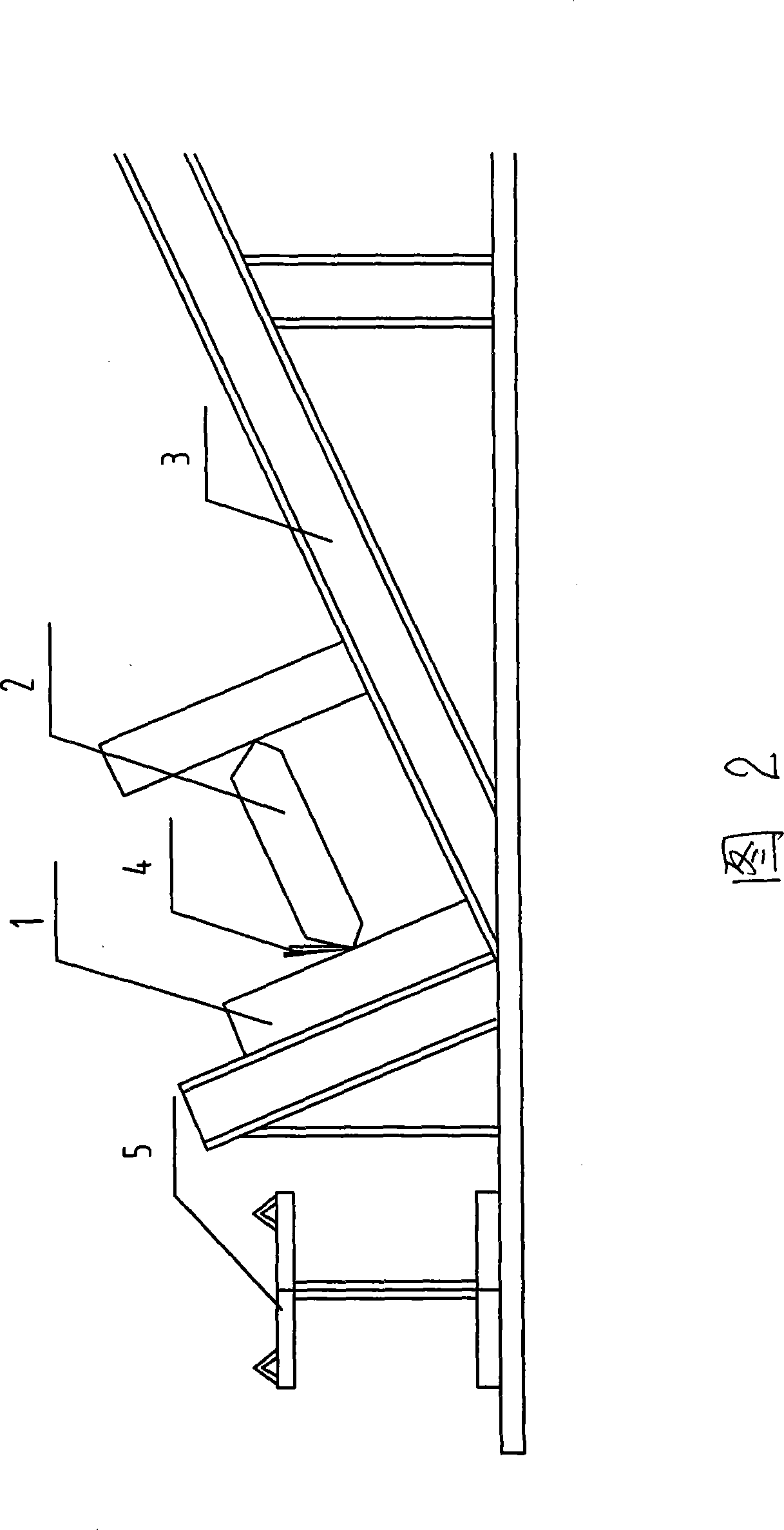

Manufacturing method for ultra-long and ultra-thick circular plate

ActiveCN101579700AImprove mechanical propertiesReduce stressWelding/cutting auxillary devicesArc welding apparatusChemical industryButt welding

A manufacturing method for ultra-long and ultra-thick circular plate is suitable for the steel circular plate which has a length more than 10 meters and has a thickness more than 100 millimeters. The method comprises the following steps: forging a plurality of segments of ultra-thick cylinders; carrying out mechanical processing to make the inner diameter, the wall thickness and the surface roughness accord with the requirements; and processing bevels at two ends. The invention is characterized in that the plurality of segments after procession are placed on a rolling jig bed 5; an interface part is fixed with a fixing plate; then the butt welding is performed after the bevels are added with ceramic gaskets 6; the long cylinder is prepared; the cutting is performed; and the ultra-long ultra-thick circular plate with the required dimension is manufactured. The invention has the advantageous of capability of manufacturing the ultra-long and ultra-thick circular plate with the length of more than 10 meters and the thickness of more than 100 millimeters, having high mechanical property of the manufactured plate, and having simple and convenient manufacturing method, easy operation and reduced manufacturing cost. The manufacturing method for ultra-long and ultra-thick circular plate can be widely used in the watercraft manufacturing industry and other mechanical chemical industry.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

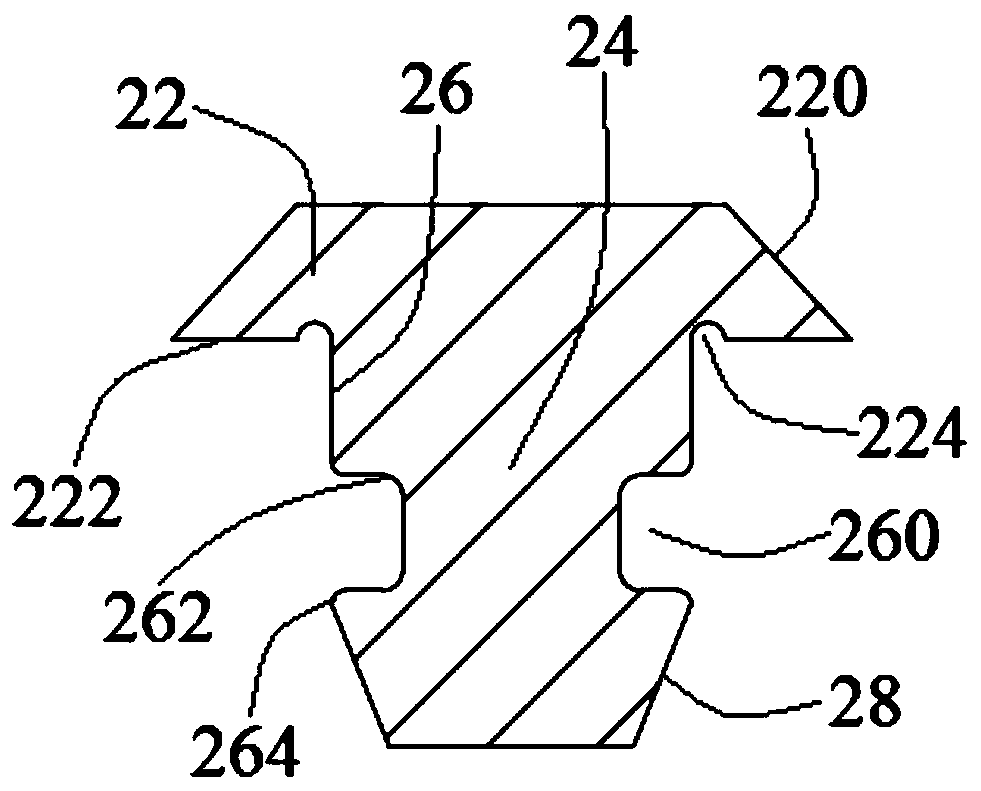

Laser welding fixture and method

ActiveCN108941907ADoes not block the spin welding processGuaranteed face to faceWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

The invention discloses a laser welding fixture and method. The laser welding fixture comprises a supporting rod, a positioning plate, U-shaped rotation arms and pressure covers; the supporting rod isarranged in the vertical direction, and the top end of the supporting rod is provided with the positioning plate in the horizontal direction; the upper surface of the positioning plate is provided with a storage groove, and the two sides of the positioning plate are provided with the U-shaped rotation arms; the pressure covers are installed on the U-shaped rotation arms; and driving devices are installed on the lower portions of the U-shaped rotation arms and used for driving the U-shaped rotation arms to rotate and do vertical reciprocating motion. The laser welding method comprises the following steps that a laser welding head is started, the U-shaped rotation arms on the fixture are started to rotate at the same time, and thus, the U-shaped rotation arms of the fixture rotate while thewelding head does rotary welding so that welding of an annular welding zone can be achieved at a time through the welding head; and a pressure sensor on the fixture can measure the pressure value applied to the pressure covers. According to the laser welding device and method, the welding sealing performance is good, and the welding efficiency is high.

Owner:SHENZHEN DADE LASER TECH CO LTD

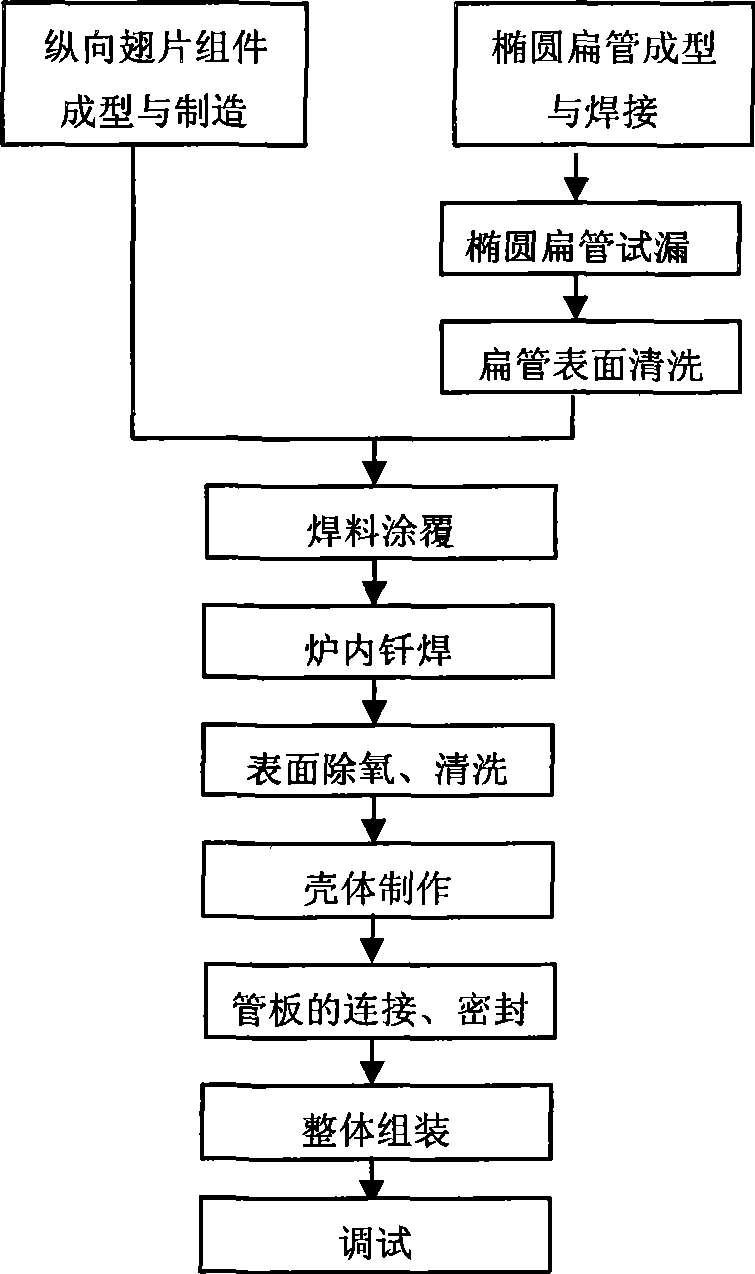

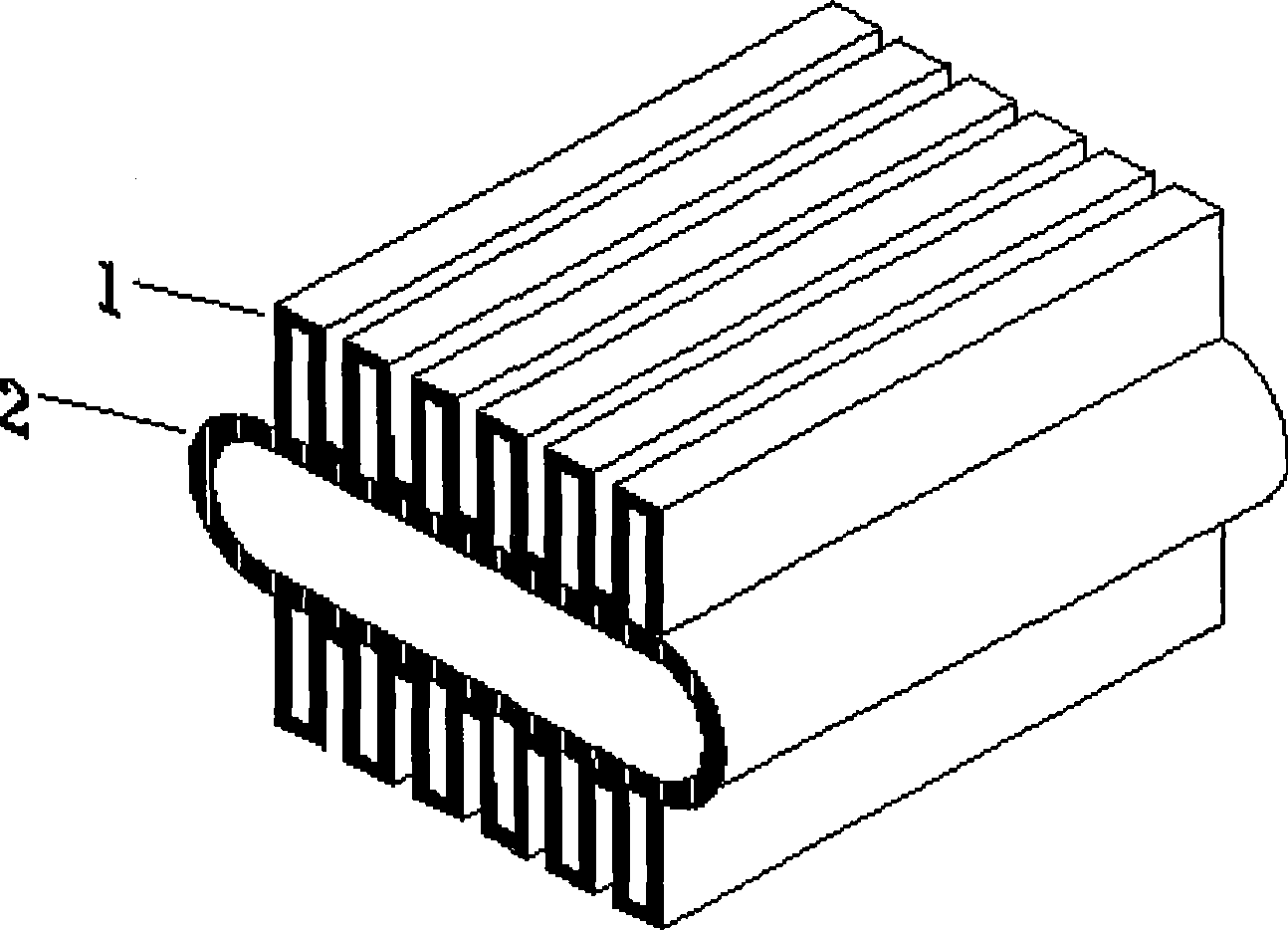

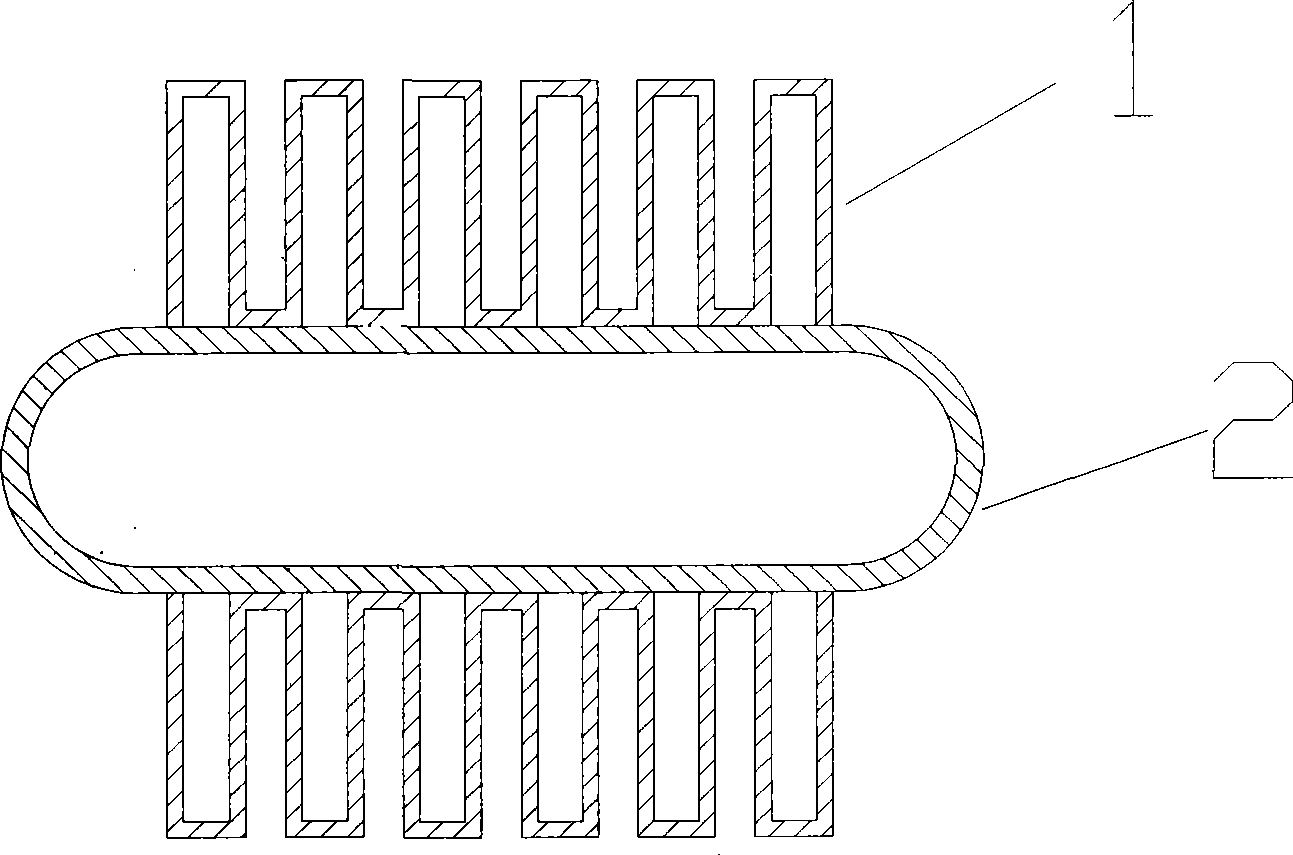

Axial fin flat pipe heat exchanger and manufacturing method thereof

InactiveCN101368800AReduce resistanceIncrease the circulation areaWelding/cutting media/materialsSoldering mediaPlate heat exchangerFlue gas

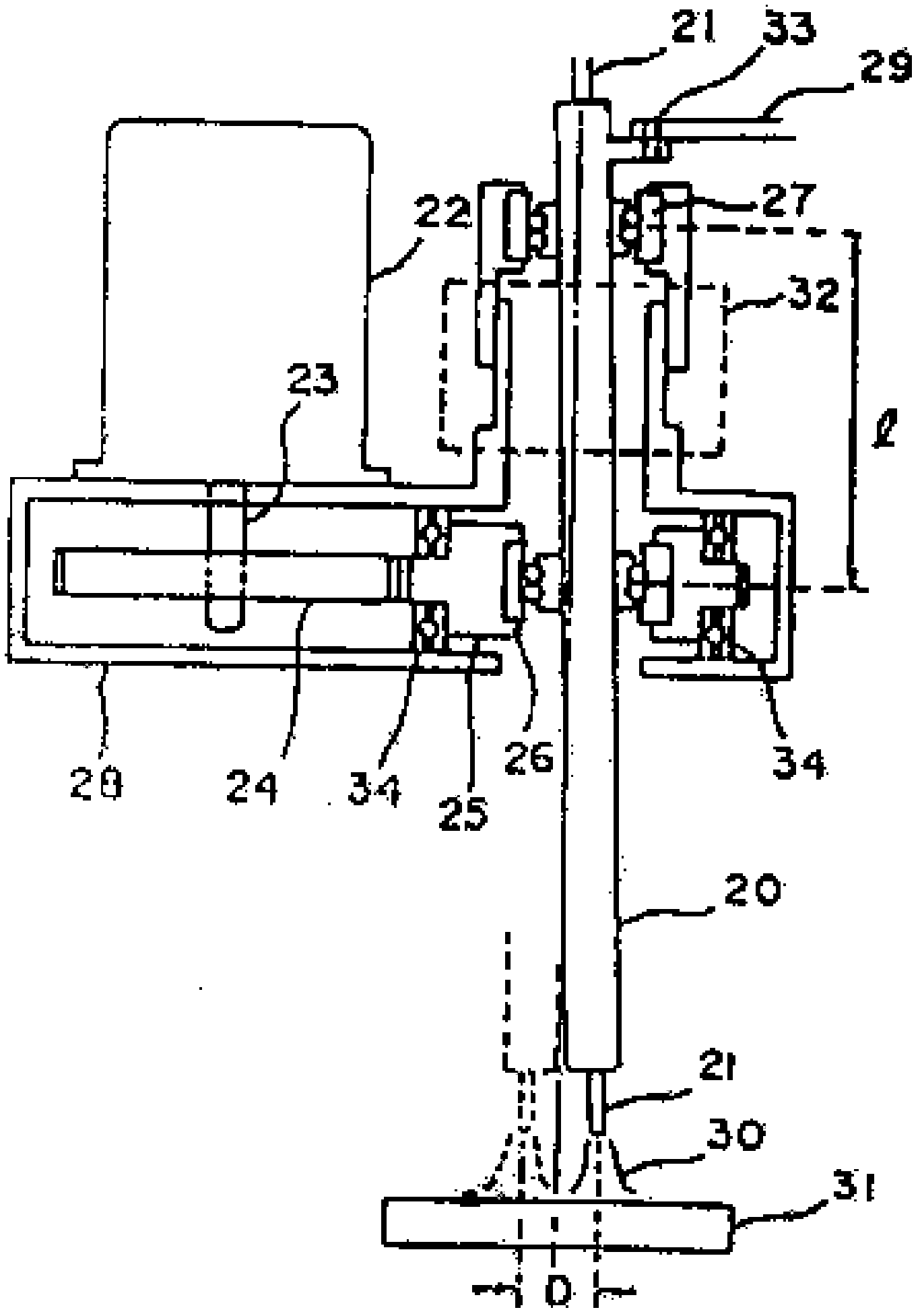

The invention relates to a vertical finned flat tube heat exchanger, which is composed of a flat tube (1) and a group of rectangular fins (2) through welding; the flat tube (1) is shaped as a runway which is arc at both ends and straight in the middle; and the fins (2) are distributed in parallel around the straight edge of the flat tube (1) and along the vertical direction of the heat exchanger. The manufacturing method comprises the following steps: (1), producing the flat tube (1) and the fins (2); (2), cleaning the surfaces of the flat tube (1) and the fins (2), and then coating the solder; (3), welding; (4), cleaning the brazing agent residues; (5), removing the oxides and oily substances on the weldment surface; and (6), producing a shell body, collecting and sealing the tube plate, and completing the overall assembly debugging. The invention improves the heat exchange efficiency, reduces the flue gas resistance, increases the cross-section flow area and does not easily get ash deposited and scaled, which is easy in maintenance; besides, the production efficiency is significantly improved and the corrosion resistance is good so as to reduce the costs.

Owner:DONGHUA UNIV +1

Aqueous cleaning low-temperature welding paste and preparation method thereof

ActiveCN102398122ADesign scienceReasonable ratioWelding/cutting media/materialsSoldering mediaActive agentAlloy

The invention discloses aqueous cleaning low-temperature welding paste and a preparation method thereof. The welding paste comprises the following components in percentage by weight: 85 to 90 percent of soldering alloy powder, and 10 to 15 percent of scaling powder, wherein the soldering alloy powder consists of the following components in percentage by weight: 36 to 44 percent of Pb, 18 to 22 percent of Bi and the balance of Sn; and the scaling powder is formed by mixing 2 to 10 weight percent of active agent, 1 to 10 weight percent of pasting agent, 20 to 30 weight percent of wetting agent, 2 to 10 weight percent of thixotropic agent, and 50 to 70 weight percent of solvent and the total percentage of all components is 100 percent. The welding paste is suitable for various welding processes, is high in welding speed, does not damage components, does not contain halogen and does not have corrosiveness, and residues are few after welding.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

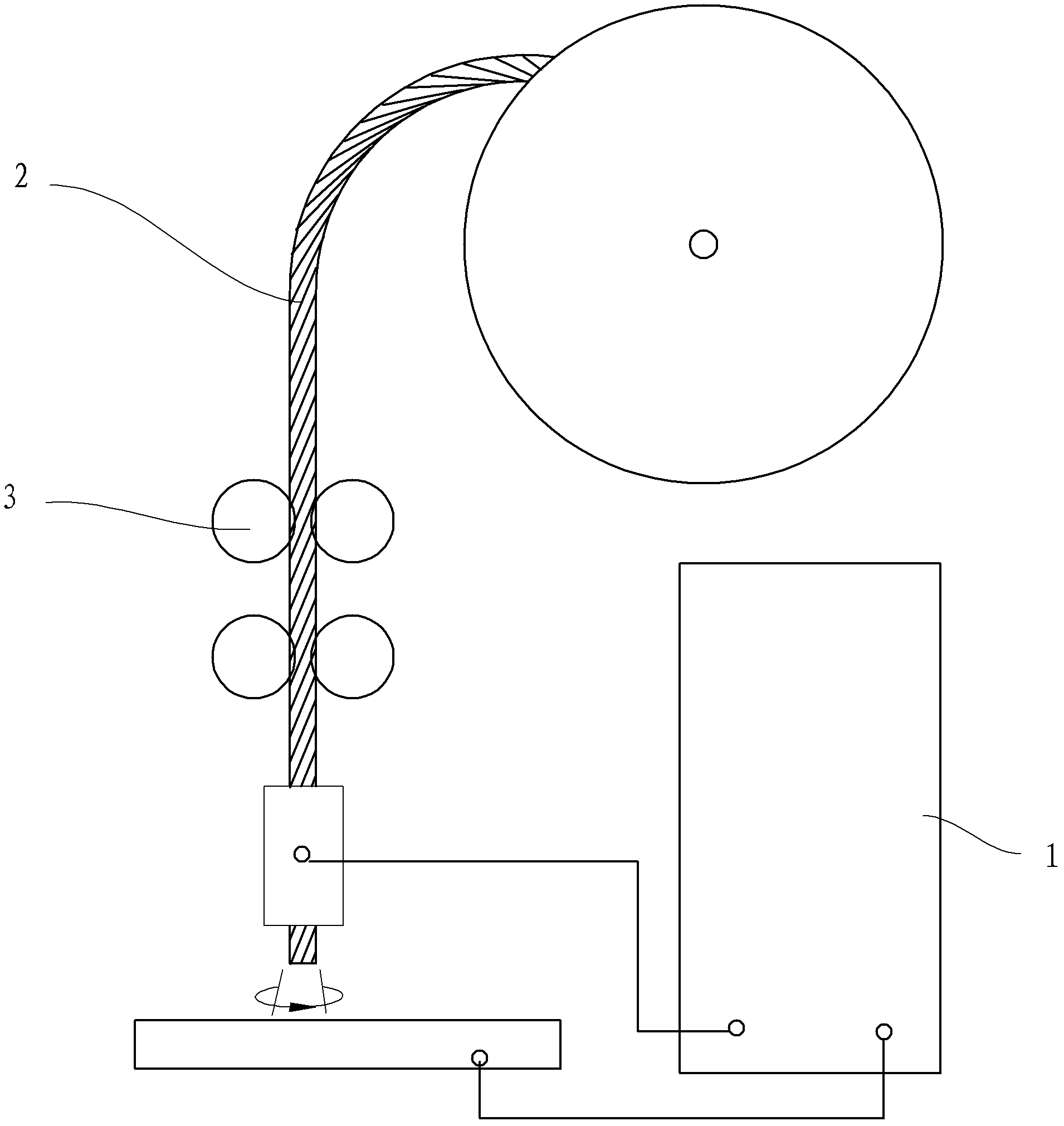

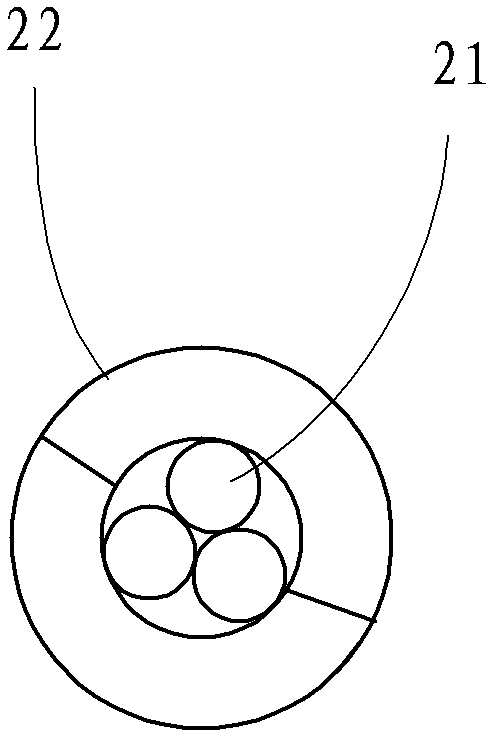

Multi-wire rotating arc welding

InactiveCN102615391AWidely used valueImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsMetal alloyMolten bath

The invention relates to an arc welding, in particular to a multi-wire rotating arc welding, which is a rotating arc welding utilizing welding wires wound in a certain helical angle, automatically formed in the welding process and having stirring effects on a molten bath. The multi-wire rotating arc welding not only improves welding melting efficiency but also enables welding line metal alloy to be even in component, and grain refinement is achieved.

Owner:时振

Steel pipe end rounding device

The invention relates to the field of pipe machining, and discloses a steel pipe end rounding device. The device comprises a movable base, a supporting assembly and a rounding mechanism, wherein the rounding mechanism comprises an outer rounding assembly and an inner rounding assembly; the inner rounding assembly comprises a main shaft, an inner disc and inner diameter rounding rollers, wherein the inner disc is of a disc-shaped structure, and the main shaft and the inner disc are coaxially arranged and connected; at least one group of inner diameter rounding rollers are arranged on the innerdisc; the outer rounding assembly comprises an outer disc and outer diameter rounding rollers, wherein the outer disc is annular, is concentric with the inner disc, and sleeves the exterior of the inner disc; and at least one group of outer diameter rounding rollers are arranged on the outer disc. According to the steel pipe end rounding device, rolling systems are formed on the inner wall and theouter wall of a steel pipe correspondingly, and meanwhile rolling rounding is conducted at the same time, so that longitudinal creases are effectively prevented from appearing on the surface of a pipe end in the rounding process. The device is high in work efficiency and suitable for mass production of welded steel pipes, the ovality of the pipe end shaped through the device is smaller than or equal to 0.3%, and the rounding effect is good.

Owner:SHANGHAI TIAN YANG STEEL TUBE

Vertical down surfacing welding method capable of realizing aesthetic welding joint and low dilution rate

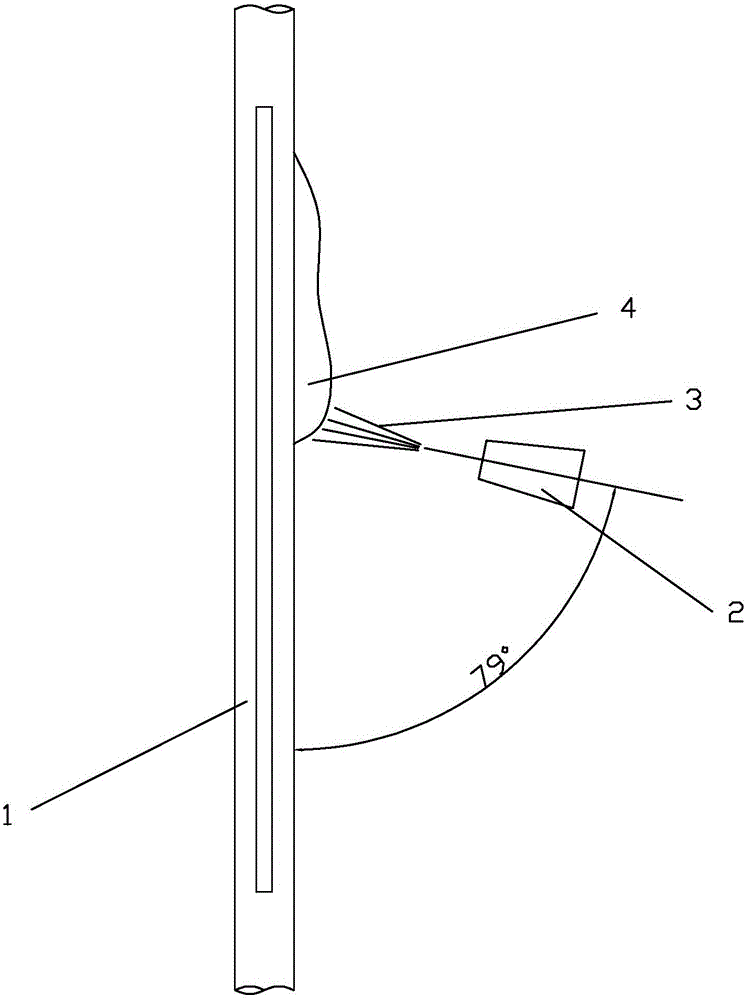

InactiveCN104999165AStable and continuous qualityImprove fusionArc welding apparatusMetal working apparatusWire rodWelding power supply

The invention discloses a vertical down surfacing welding method capable of realizing aesthetic welding joint and low dilution rate, wherein an impulse consumable electrode inert gas arc welding source is adopted; a pipe is placed vertically, a welding gun points to an oblique upper direction and forms an included angle of 75 to 80 degrees with the vertical direction, and the electric arc ejected by the welding gun blows to a weld pool; the welding gun performs reciprocated swing horizontally, the swing frequency is 500 to 900 times per minute, and the swing width is 5 to 9mm; the welding current is 120 to 180 A, the welding voltage is 22 to 25V, the wire feed rate is 6 to 8 meters per minute, and elongation of a wielding wire rod is controlled to be 10 to 15mm; the moving down speed of the welding gun is 600 to 1200 millimeters per minute. The vertical down surfacing welding method provided by the invention can enable the welding joint to be continuous and smooth, and thin and aesthetic, and is shallow in depth of fusion and low in dilution rate, the welding wires are saved, and the cost is lowered.

Owner:POURIN WELDING ENG

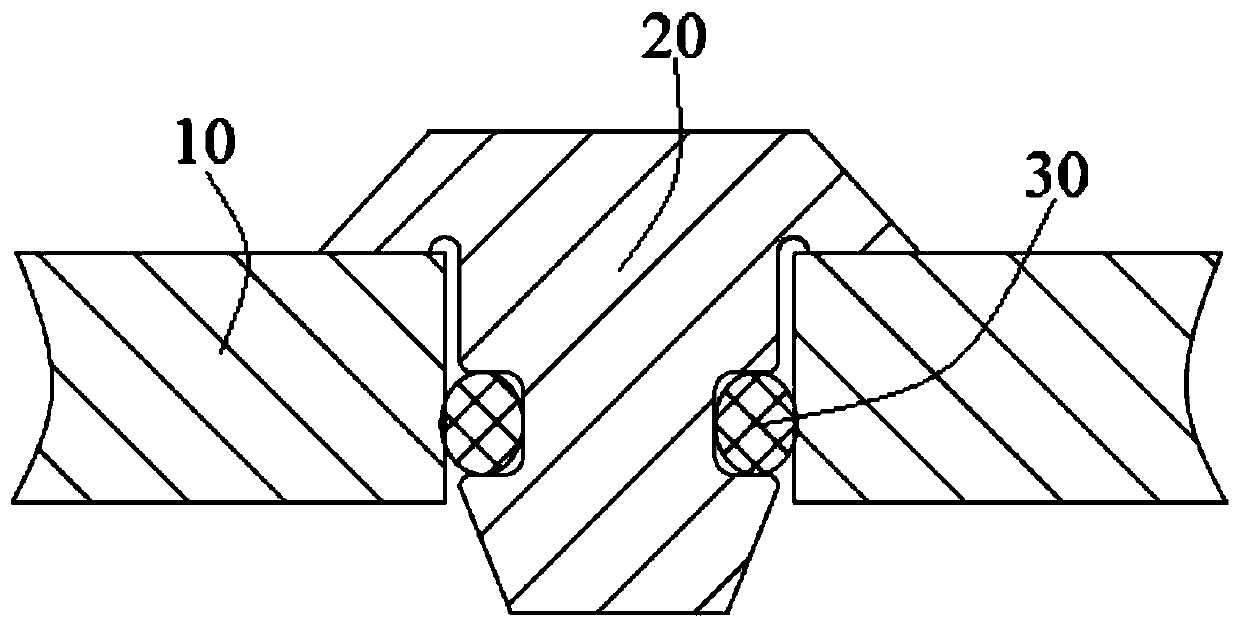

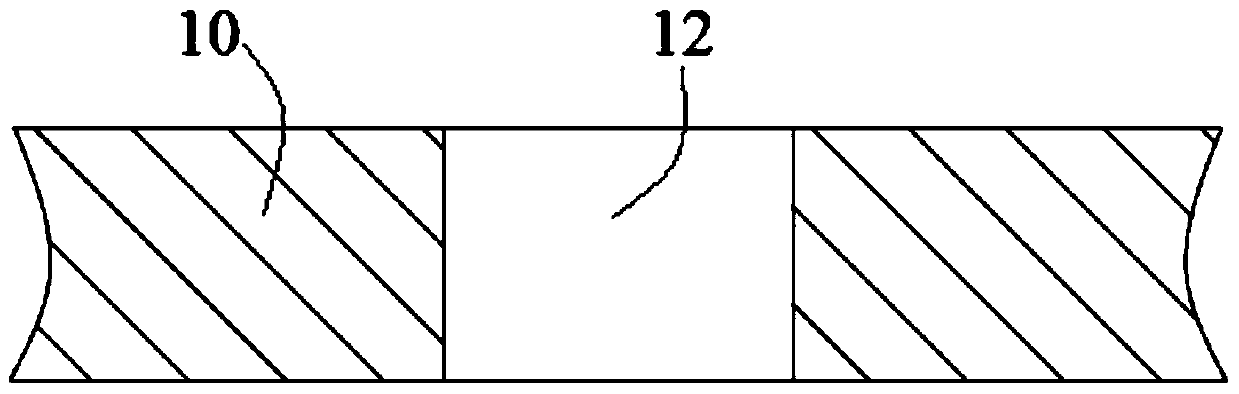

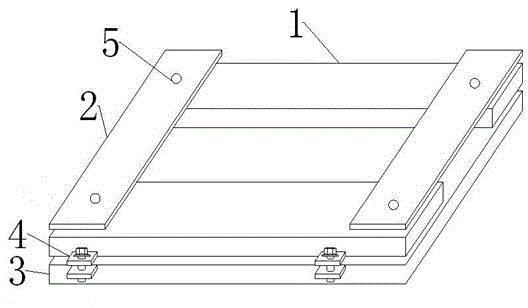

Welding seam positioning device and welding method using welding seam positioning device

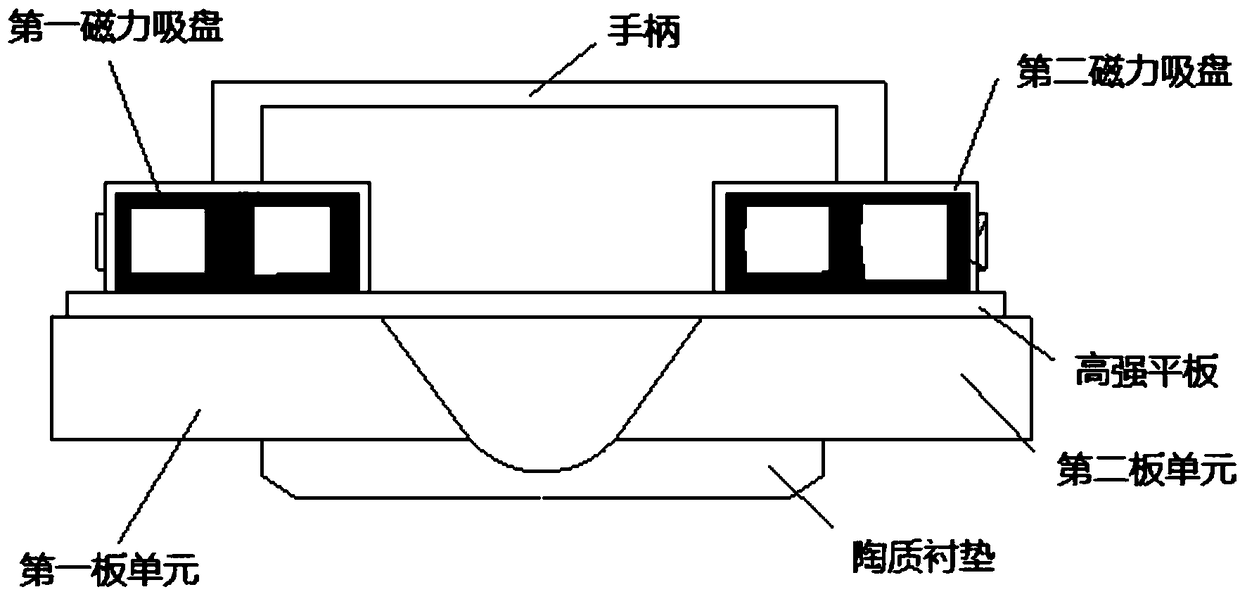

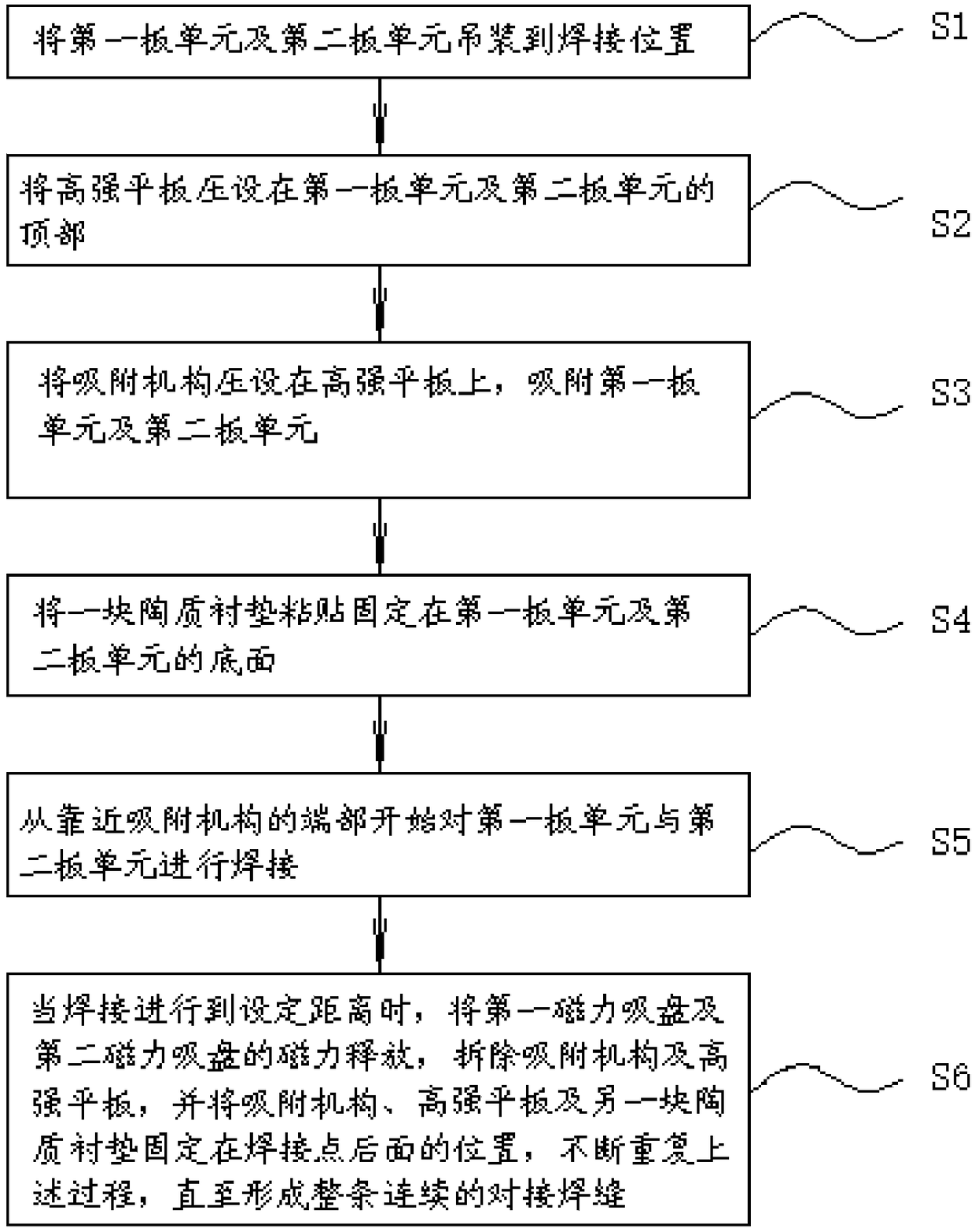

InactiveCN108115259AAvoid the wrong side problemAvoid risk of sabotageWelding/cutting auxillary devicesAuxillary welding devicesSheet steelWeld seam

The invention relates to a welding seam positioning device and a welding method using the welding seam positioning device. The welding seam positioning device comprises a ceramic liner, a high-strength flat plate and a suction mechanism; the ceramic liner is fixed at the bottoms of a first plate unit and a second plate unit; the high-strength flat plate is pressed at the tops of the first plate unit and the second plate unit, and the suction mechanism comprises a first magnetic suction cup, a second magnetic suction cup and a handle fixedly connected with the first magnetic suction cup and thesecond magnetic suction cup. The welding method comprises the steps that the high-strength flat plate is pressed at the tops of the first plate unit and the second plate unit, the first plate unit and the second plate unit are sucked and tightly attached to the bottom surface of the high-strength flat plate through the first magnetic suction cup and the second magnetic suction cup of the suctionmechanism, the ceramic liner is fixed at the bottoms of the first plate unit and the second plate unit, and then welding starts to be conducted. By means of the welding seam positioning device and thewelding method, welding seams are continuous, the welding defects are effectively reduced, the risk of damaging base materials of steel plates is avoided, and the automation degree is significantly increased.

Owner:WUCHUAN HEAVY ENG

Cleaning-free lead-based high-temperature soldering paste and preparation method thereof

ActiveCN107297582AHigh melting pointGood welding performanceWelding/cutting media/materialsSoldering mediaMetal coatingWorking life

The invention discloses cleaning-free lead-based high-temperature soldering paste and a preparation method thereof and belongs to the technical field of hybrid integrated circuits. The soldering paste is prepared from, by weight, 85%-90% of brazing filler metal alloy powder and 10%-15% of brazing flux. The brazing filler metal alloy powder is prepared from, by weight, 15.5%-16.5% of Sn, 7.0%-8.0% of Sb, 0.8-1.2% of Ag and the balance Pb. The brazing flux is prepared from, by weight, 5%-10% of activator, 5%-10% of paste forming agent, 20%-30% of wetting agent, 5%-10% of thixotropic agent and 40%-65% of solvent. The cleaning-free lead-based high-temperature soldering paste is prepared through the steps of brazing filler metal alloy smelting, brazing filler metal alloy powder preparation, brazing flux preparation and soldering paste preparation. The soldering paste is high in melting temperature, has good wettability for a metal coating, and is good in brazing manufacturability, long in working life and suitable for soft brazing of electronic device silver cladding, gold cladding and copper.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

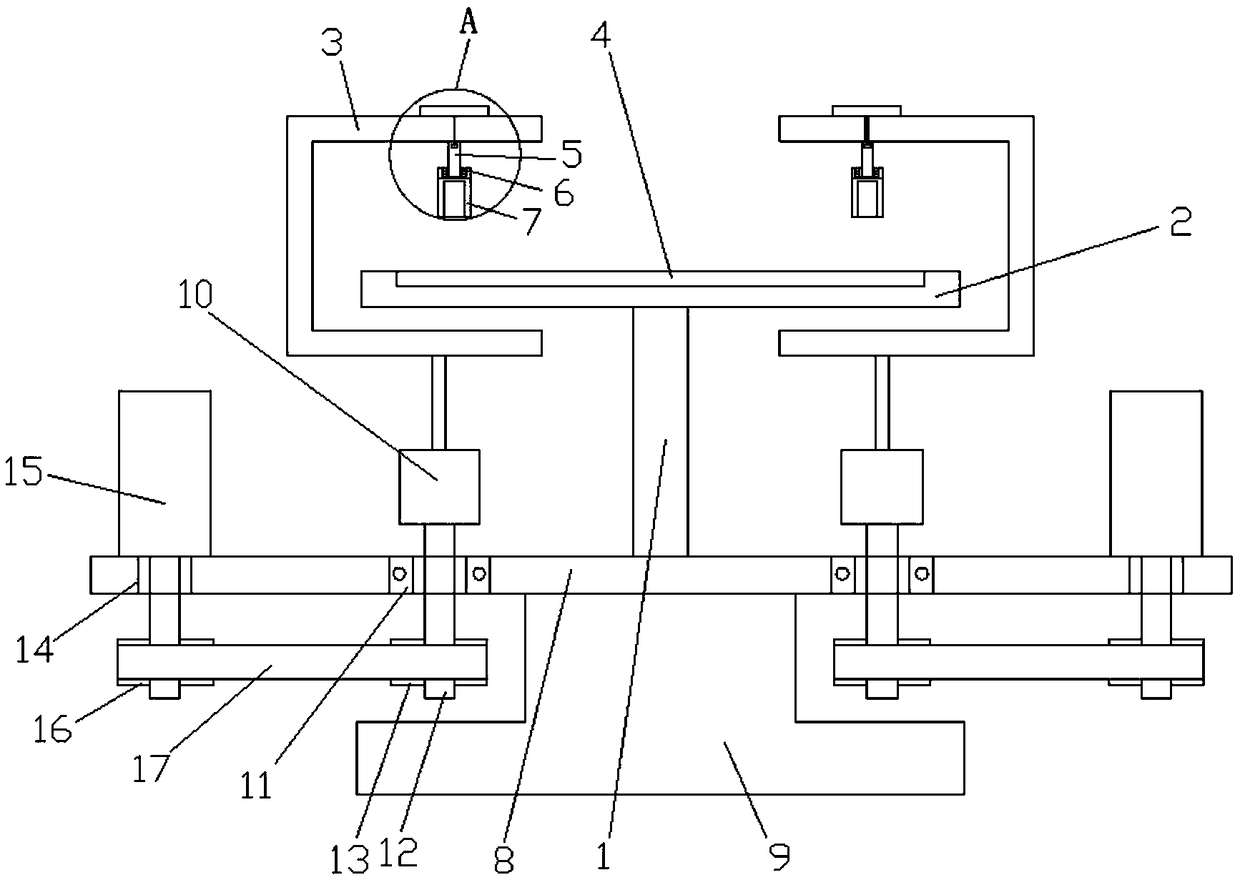

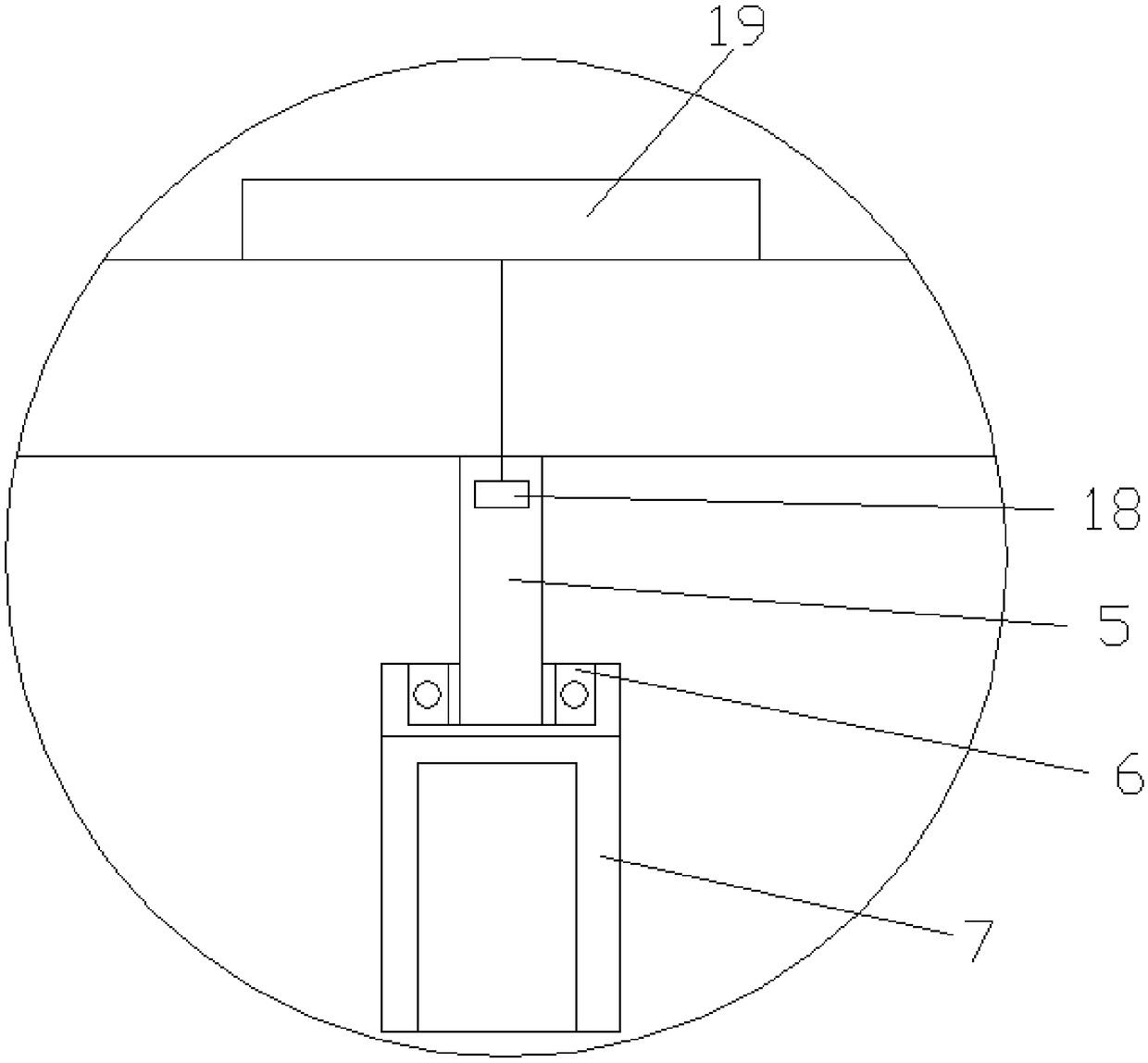

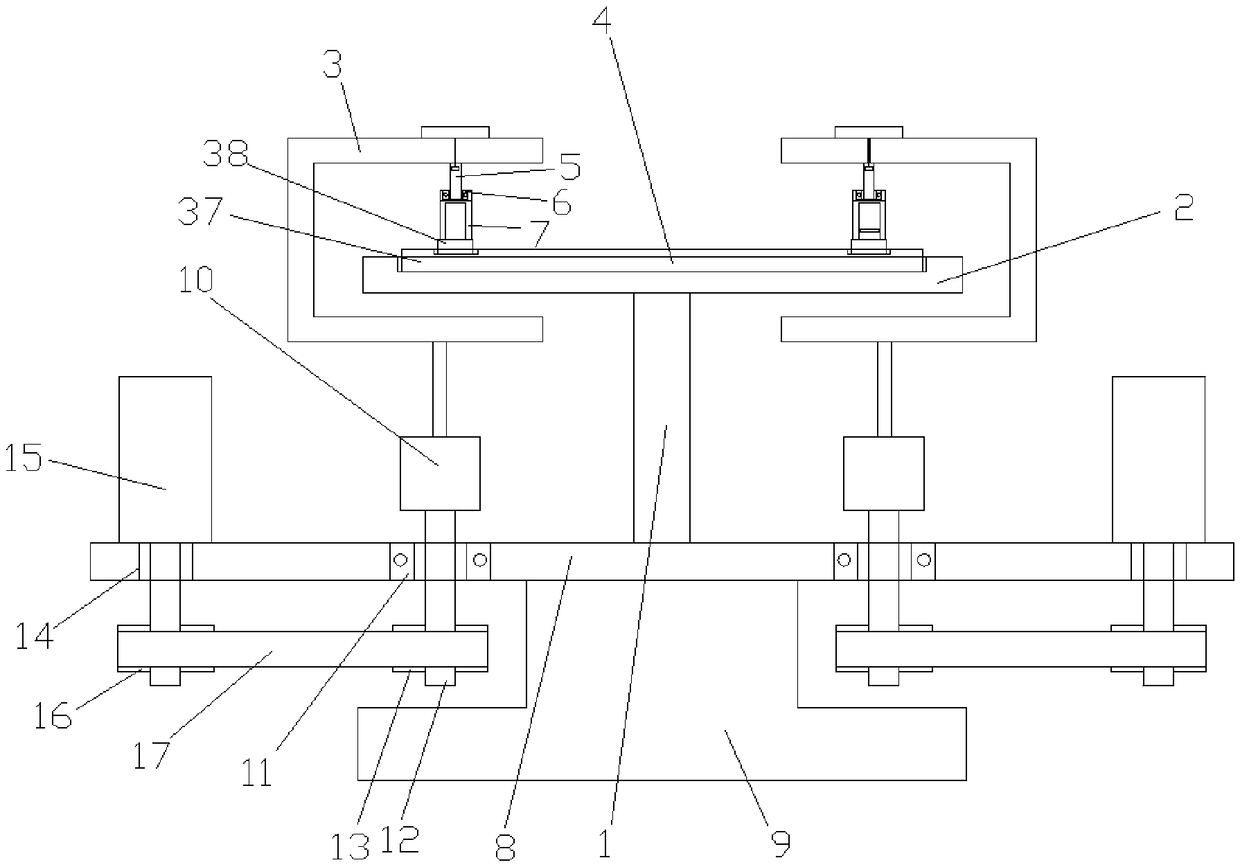

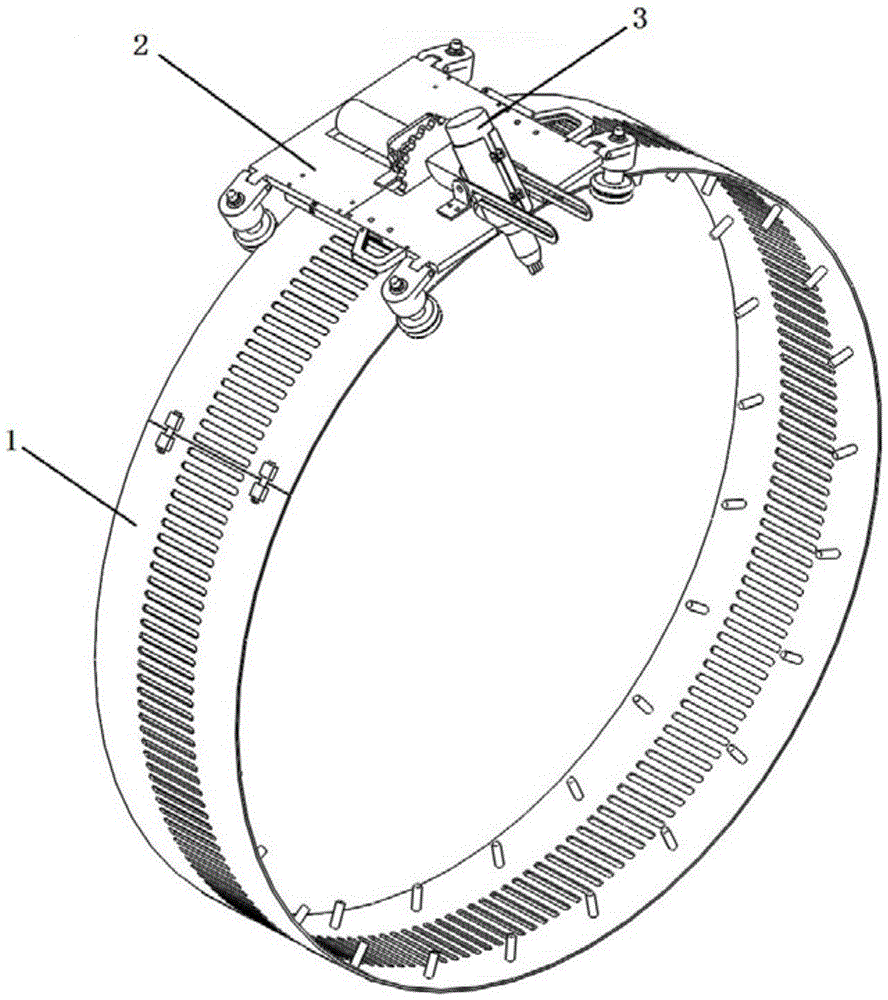

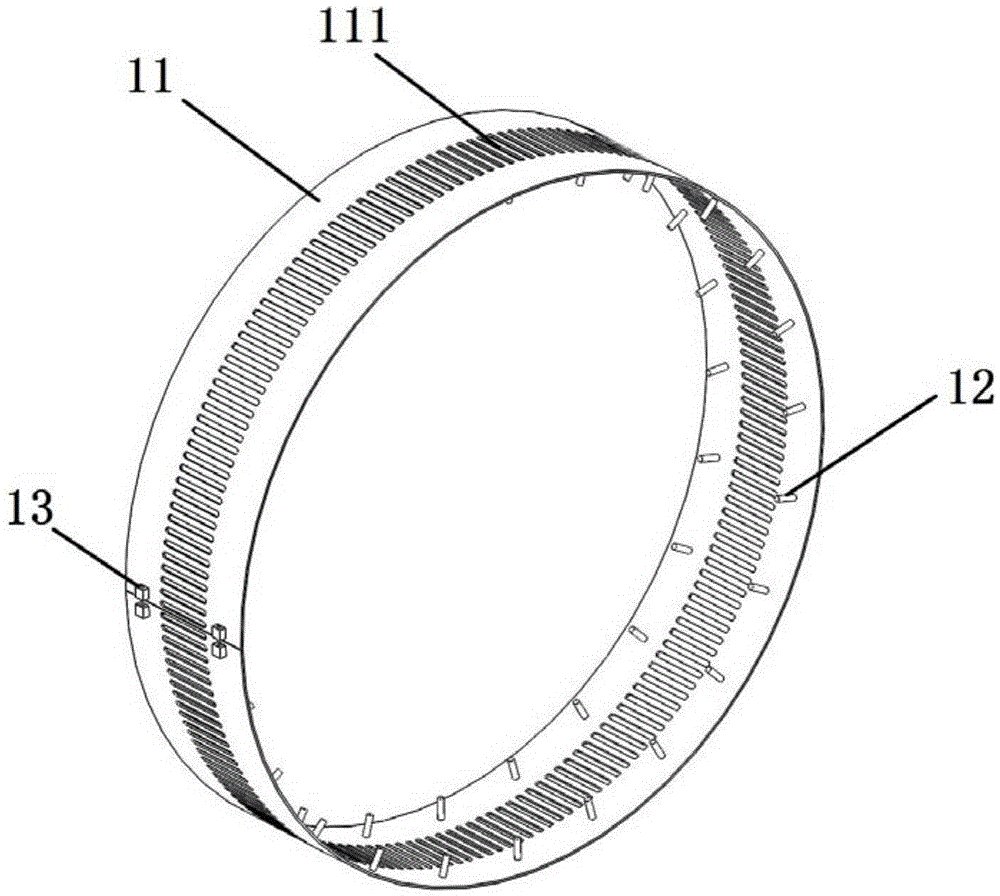

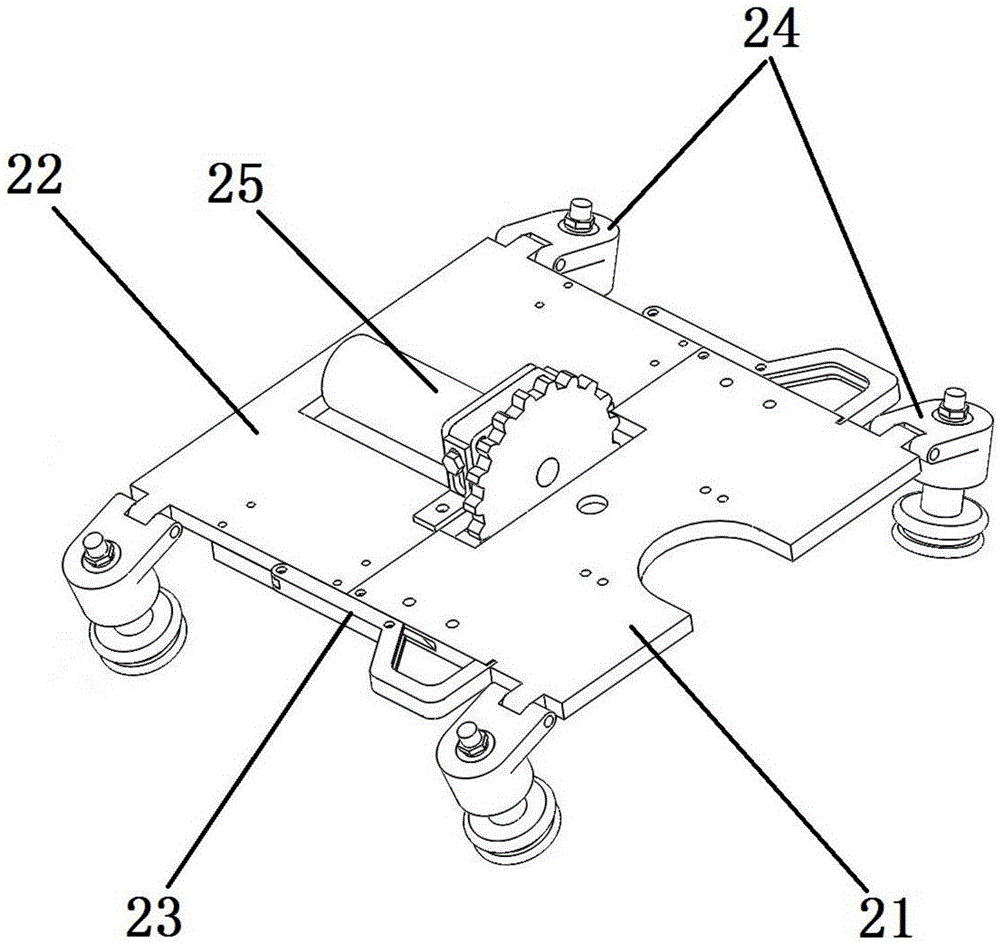

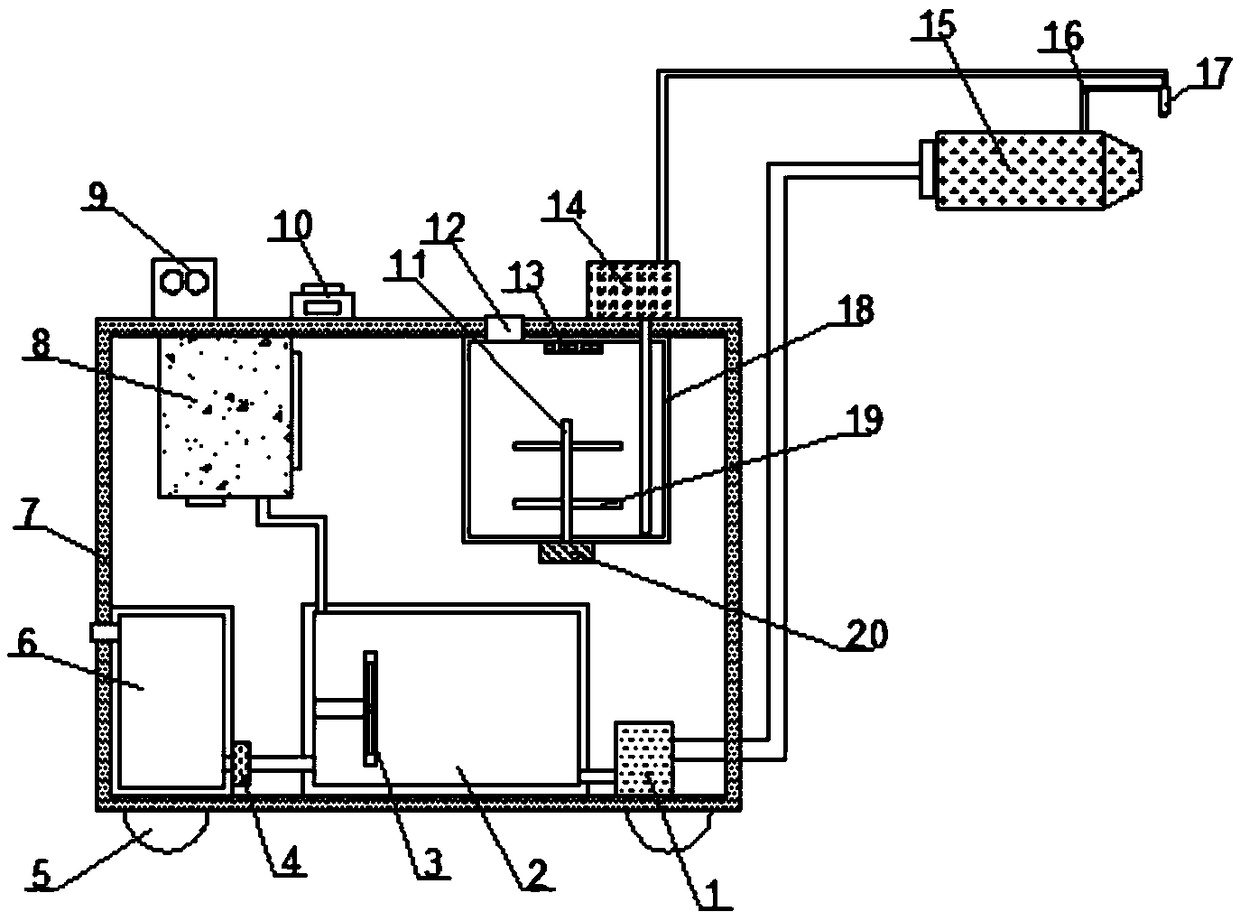

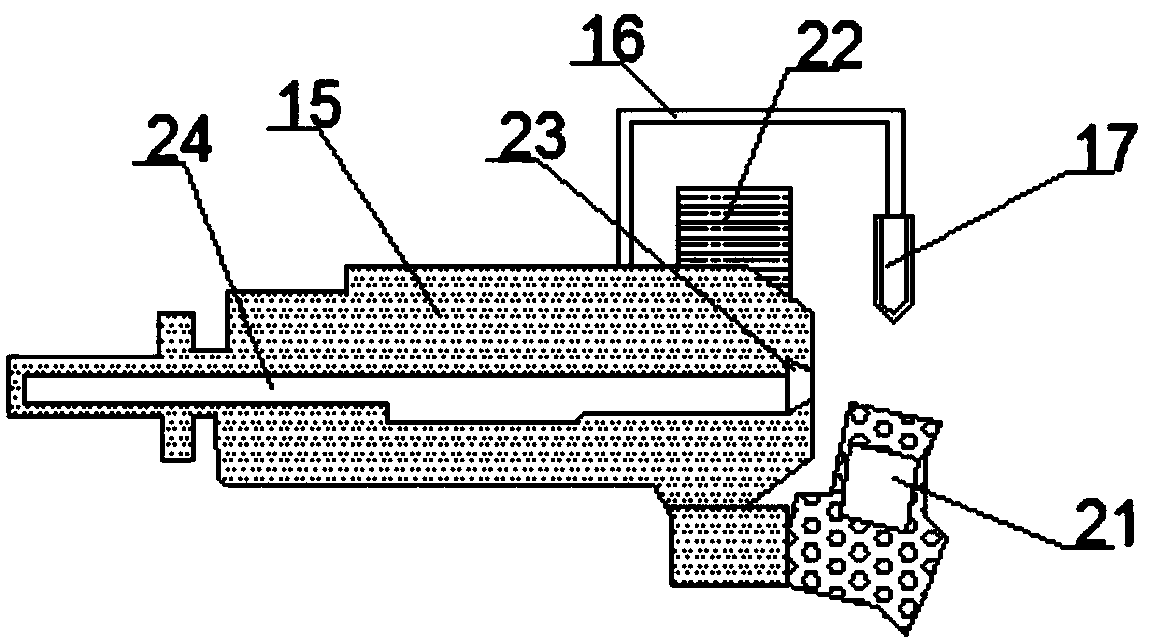

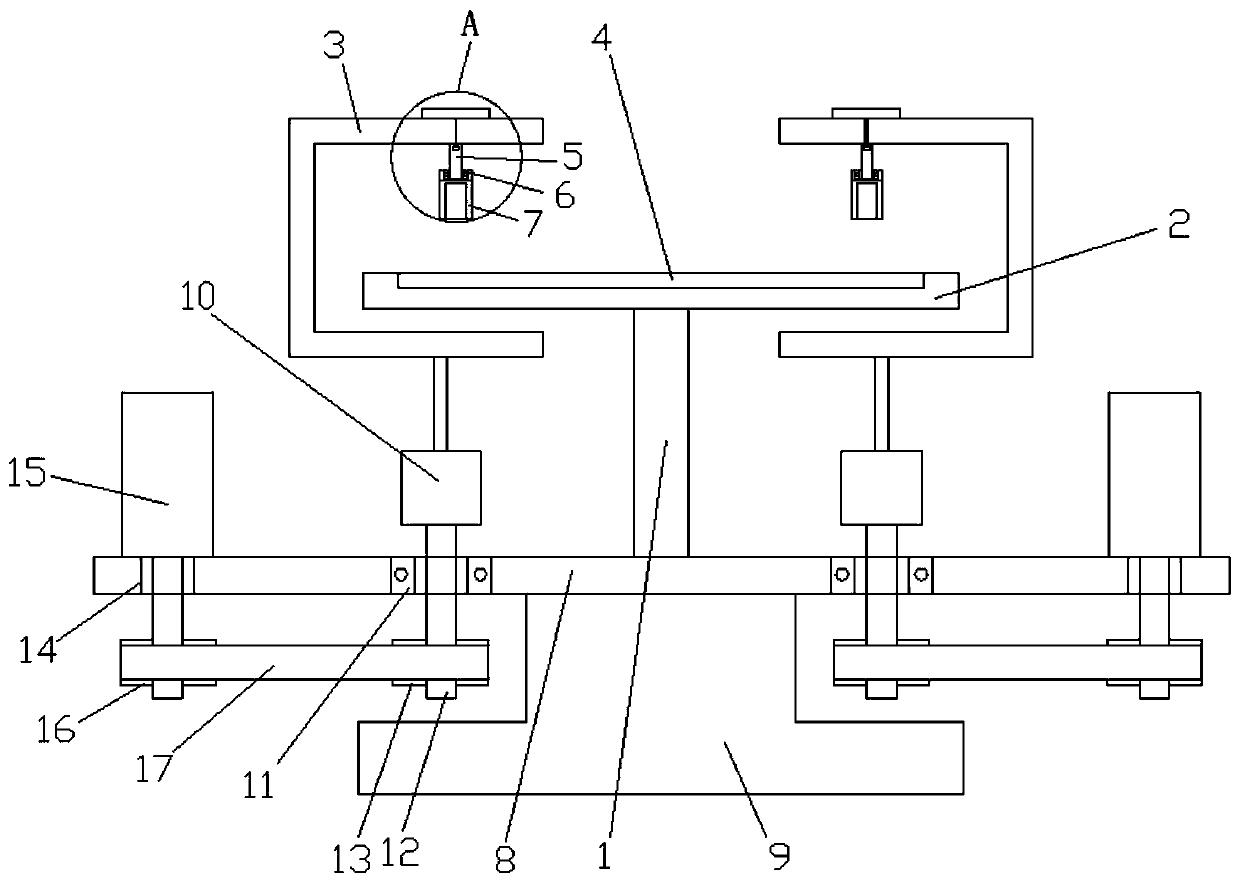

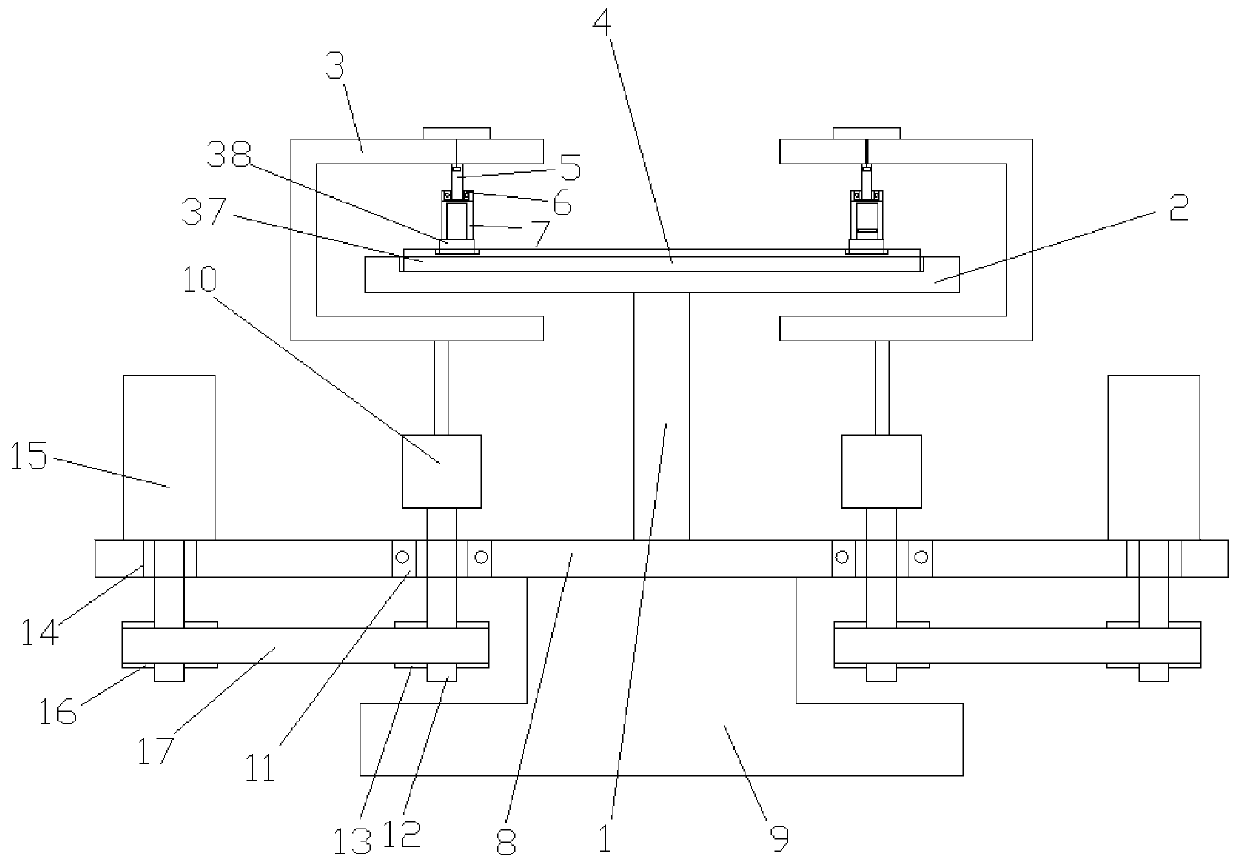

Automatic ultrasonic impact device for girth weld

InactiveCN103952531BReduce residual stressImprove processing efficiencyStress distributionStress relieving

The invention belongs to the field of metal welding, and particularly relates to an automatic ultrasonic impact device for a circumferential weld, which is used for improving stress distribution of a welded joint of the circumferential weld of a pipeline and a pressure vessel, and improving overall performance of the welded joint. The device comprises an annular guide rail, a traveling mechanism and a stress relieving mechanism, wherein the annular guide rail surrounds and is fixed outside the pipeline or the pressure vessel, and is used for supporting the traveling mechanism, the traveling mechanism is installed on the annular guide rail and can conduct a circular motion around the annular guide rail, and the stress relieving mechanism is fixed at one side of the traveling mechanism, and can respectively relieve the stress of weld toes at two sides of the circumferential weld through ultrasonic impact under the driving of the traveling mechanism. The device can complete the work of relieving the stress of the circumferential weld of the pipeline and the pressure vessel through ultrasonic impact, reduces weld defect, eliminates residual stress at the weld toes, and improves the post-weld treatment efficiency; in addition, the device is simple to assemble and disassemble, can be regulated according to different pipe diameters, and is applicable to stress relieving of the circumferential welds of different pipe diameters.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

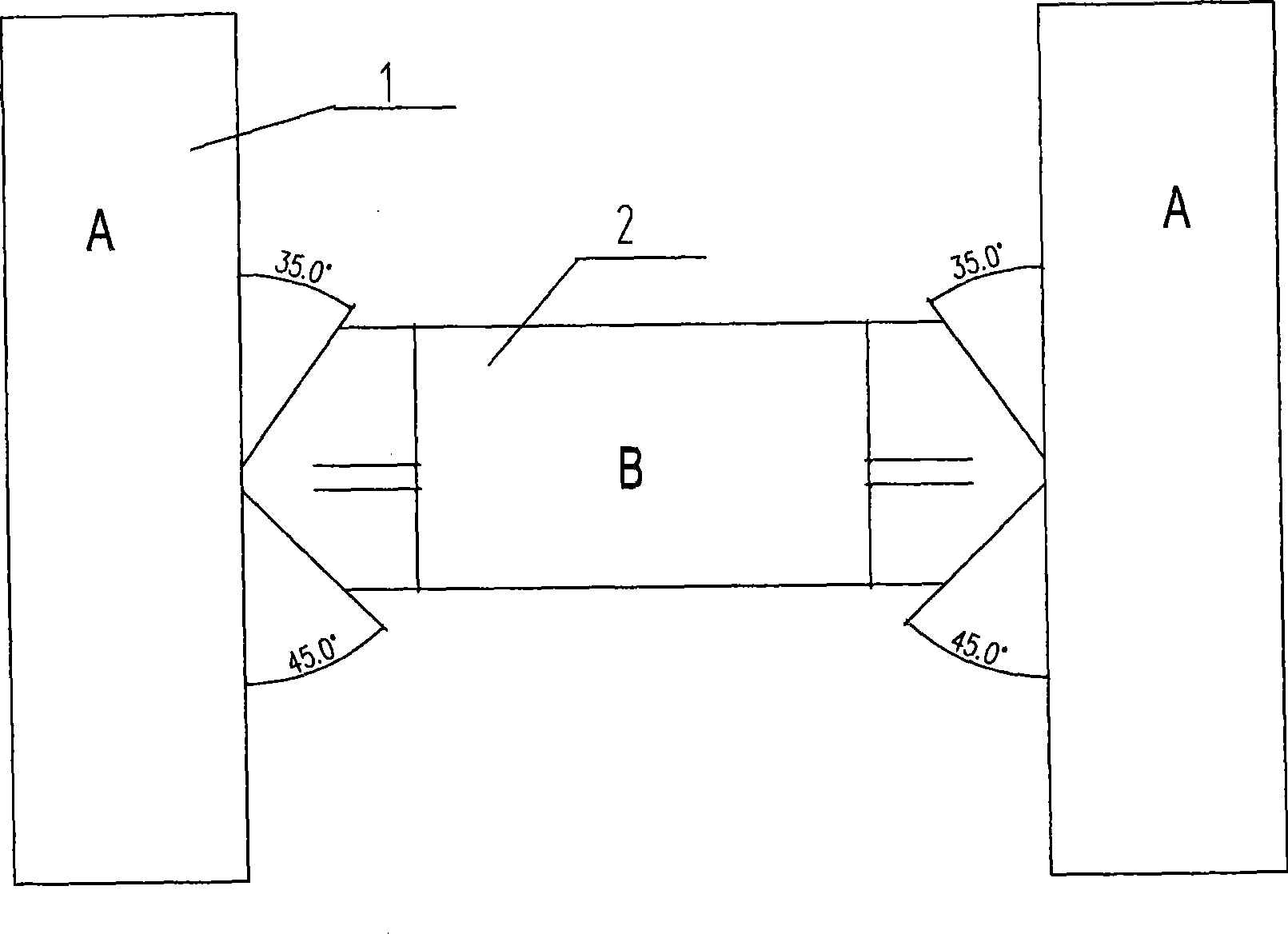

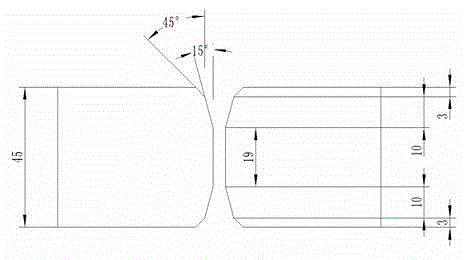

Welding process of union melt welding small divided edge

InactiveCN101412145AFast welding speedGuaranteed Progress RequirementsArc welding apparatusEconomic benefitsEngineering

The invention relates to a welding process, in particular to an automatic submerged arc welding small groove welding process. The welding process comprises the following steps: a groove is cut on a welding piece, the angle of one side of the groove is 35 degrees, and the angle of other side of the groove is 45 degrees; the H pair group of the welding piece is performed, and the welding piece is fixed by the spot adhibiting method, and the spot adhibiting fixing welding seam is arranged on the 45-degree side of the groove; the welding piece is welded, the 35-degree side of the groove is firstly welded, when one-third of the 35-degree side of the groove is welded, the root part of the 45-degree side of the groove is cleaned, after the cleaning, the welding continues, through the repeatedly staggered welding, the weld pass is completely filled. Compared with the prior art, the welding process has the advantages of reducing the welding time, improving the welding speed of the workpiece, ensuring the scheduling requirements on a project, reducing the filler level of weld metal, saving one-third of welding materials, directly improving actual economic benefits and reducing the welding deformation; moreover, because the angle of the groove is reduced, the welding process also has the advantages of reducing the pre-heating width of the welding seam, lowering the defect of the welding seam and lowering the repair cost.

Owner:MCC JINGTANG CONSTR

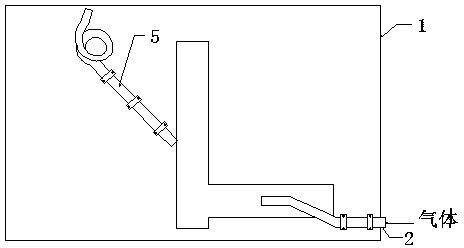

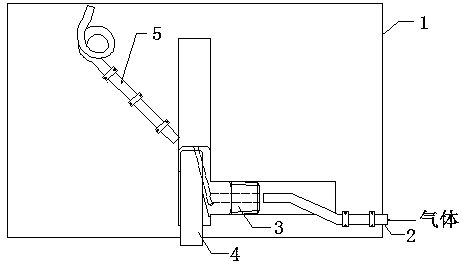

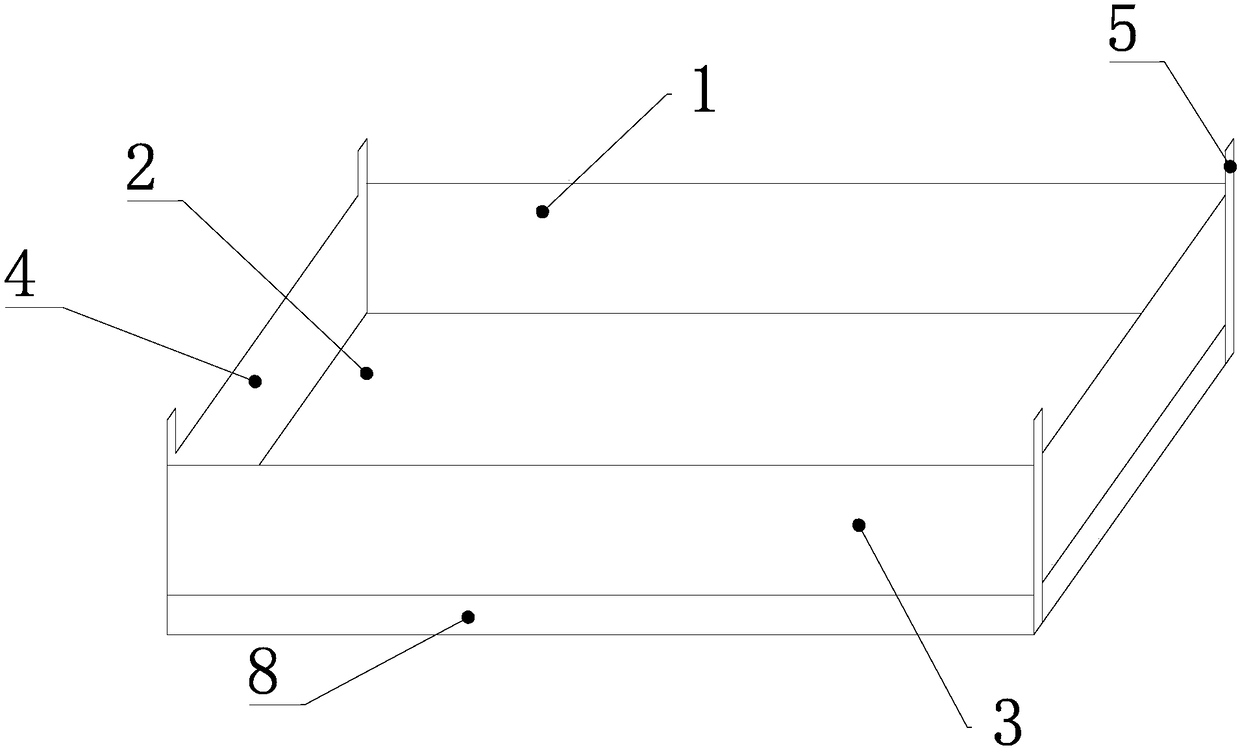

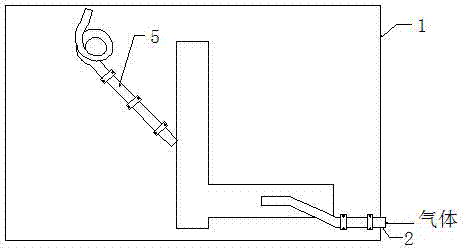

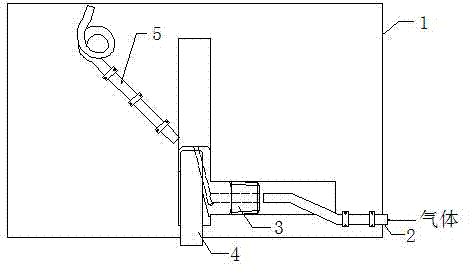

Device and method for welding bourdon tube for pressure gauge

ActiveCN103737215AAvoid cloggingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses a device and a method for welding a bourdon tube for a pressure gauge, and belongs to the field of pressure gauge production. The device comprises a base, a gas feeding tube, a water ejection tube, a first groove and a second groove, wherein the first groove and the second groove are formed in the base; one end of the second groove is vertically connected with the first groove; the gas feeding tube is fixed on the base; one end of the gas feeding tube is arranged in the second groove; the water ejection tube is arranged on the base. By the adoption of the device, a gas can be supplied in welding, so that through holes are prevented from being blocked, and meanwhile due to arrangement of the water ejection tube, weld seams can be conveniently cooled down, and meanwhile due to addition of special substances in water in the welding method, the anticorrosion effect can be achieved, and the welding defects can be greatly reduced.

Owner:MAANSHAN NAITE INSTR TECH

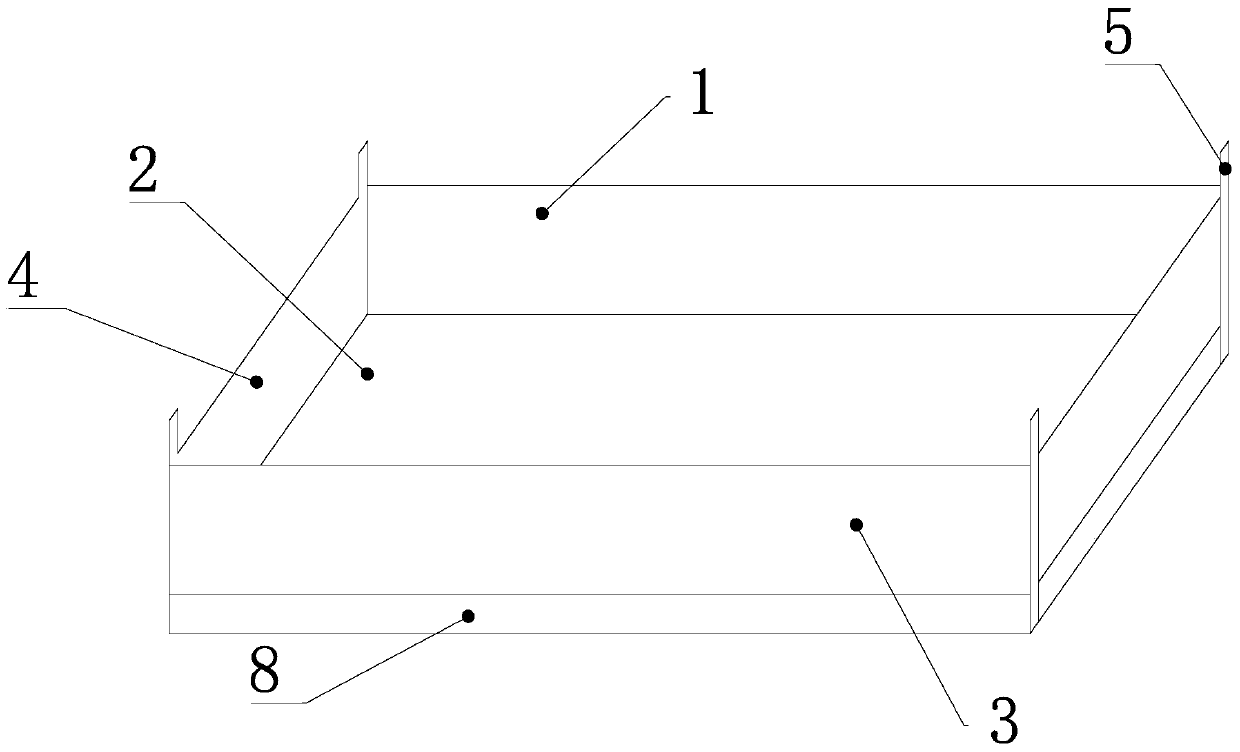

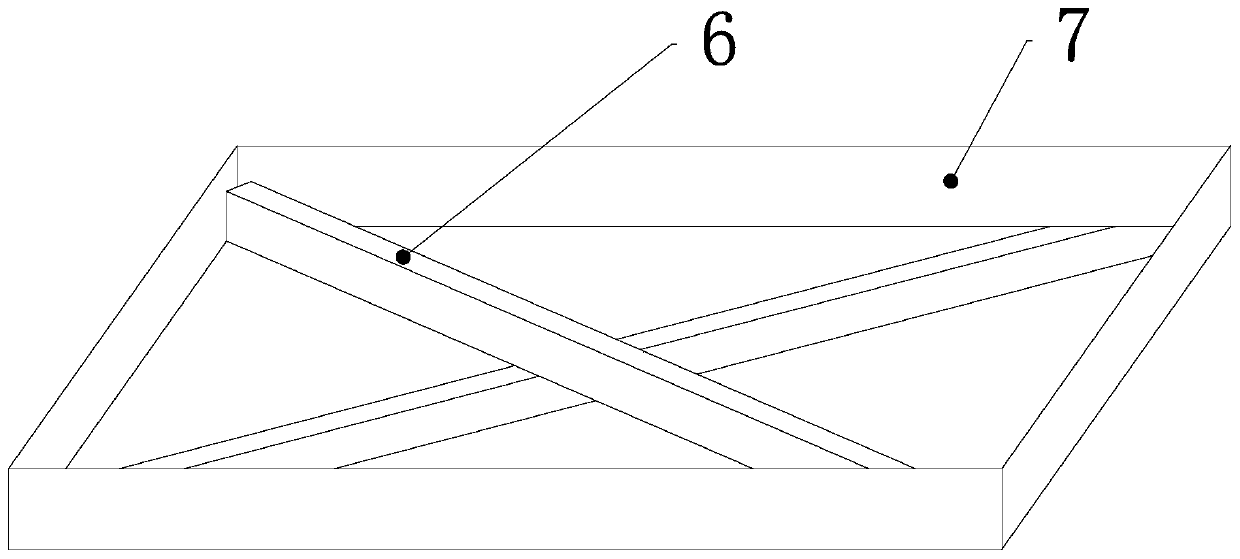

Welding technology of fully-enclosed aluminum alloy anti-roll multifunctional cabinet

ActiveCN108296609AImprove corrosion resistanceReduce weightArc welding apparatusWelding/soldering/cutting articlesSheet steelTruck

The invention belongs to the technical field of an aluminum alloy welding and relates to a welding technology of a fully-enclosed aluminum alloy anti-roll multifunctional cabinet externally arranged at a heavy truck. The fully-enclosed aluminum alloy anti-roll multifunctional cabinet comprises a bottom plate, a top plate, a rear plate and side plates; the top plate is fixedly arranged on the frontside of the bottom plate; the rear plate is fixedly arranged on the rear side of the bottom plate;, the side plates are fixedly arranged on the left side and right side of the bottom plate correspondingly; a cuboid is defined by the bottom plate, the top plate, the rear plate and the side plates; lifting lug plates are fixedly arranged at the four corners of the cuboid; a door plate is buckled onthe four corners of the cuboid; reinforcing ribs are arranged at the four corners of the door plate in a crossed manner; and a bottom section is fixedly arranged under the bottom plate. In the welding process, the top plate, the rear plate and the bottom plate are welded with the side plates correspondingly, the bottom section is welded with the bottom plate, the lifting lug plates are welded with side plates and the bottom section, and door plate is welded with the reinforcing ribs at four welding stages correspondingly, so that the problems that energy conservation and emission reduction are not facilitated and the corrosion resistance can not meet the requirement since an existing vehicle-mounted multifunctional cabinet and anti-roll beams, which are made of carbon steel and steel plate materials, are heavy are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

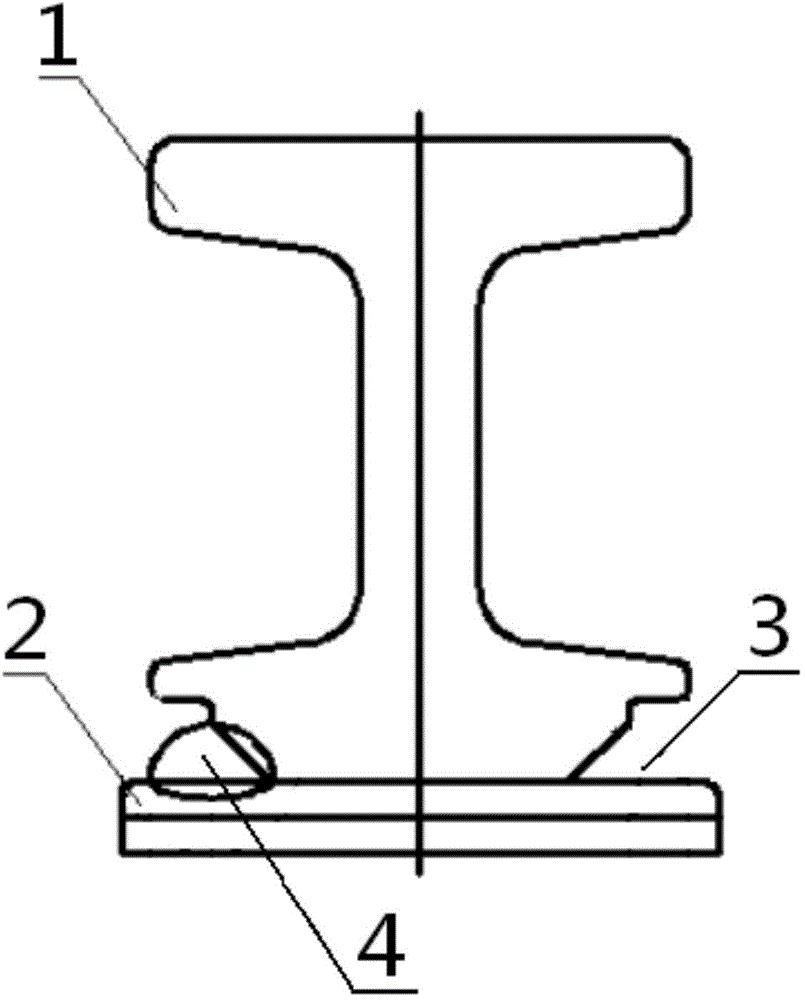

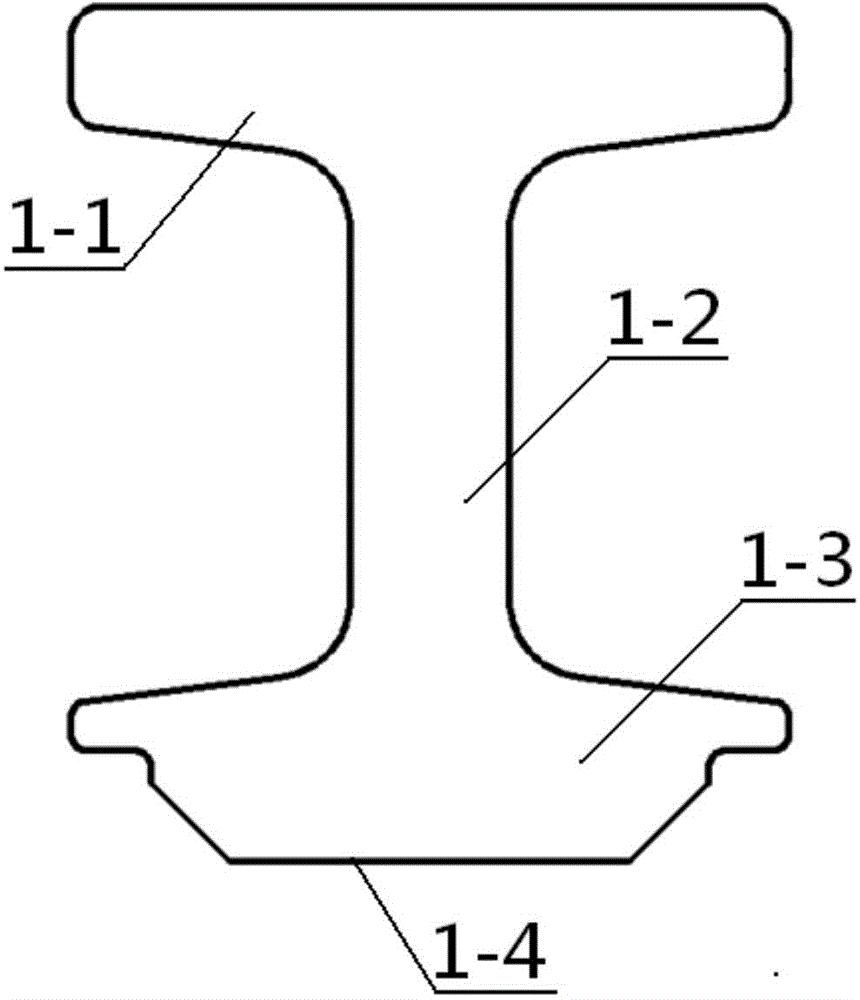

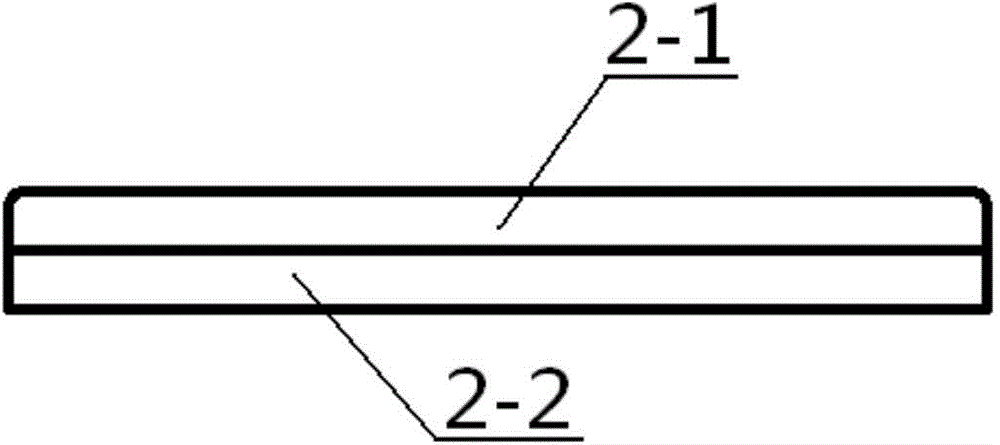

Aluminum alloy guide rail and welding method thereof

ActiveCN104613304AOptimizing welding process parametersReduce welding distortionElongated constructional elementsArc welding apparatusCopperWelding deformation

The invention discloses an aluminum alloy guide rail. The aluminum alloy guide rail comprises an I beam and an aluminum-copper composite board welded and fixed to one end face of the I beam. The aluminum-copper composite board is welded in an explosive welding mode. The I beam is an integrally-extruded aluminum profile and comprises a top board, a web and a bottom board. The bottom board is in an inverted cone shape. A platform is arranged on the lower bottom face of the bottom board. Triangular welding grooves are formed among the two sides of the platform, the I beam and the aluminum-copper composite board, and the height of the triangular welding grooves ranges from 3 mm to 7 mm. The length of the I beam and the aluminum-copper composite board ranges from 2.8 mm to 3.3 mm, the width of the I beam ranges from 40 mm to 50 mm, the height of the I beam ranges from 50 mm to 60 mm, the thickness of the aluminum-copper composite board ranges from 5 mm to 7 mm, the width of the aluminum-copper composite board ranges from 40 mm to 50 mm, and the thickness difference of an aluminum board and a copper board of the aluminum-copper composite board is not larger than 1 / 5. The invention further discloses a method for welding the guide rail. The aluminum alloy guide rail is high in weld joint quality and small in welding deformation.

Owner:忠旺(辽阳)铝模板制造有限公司

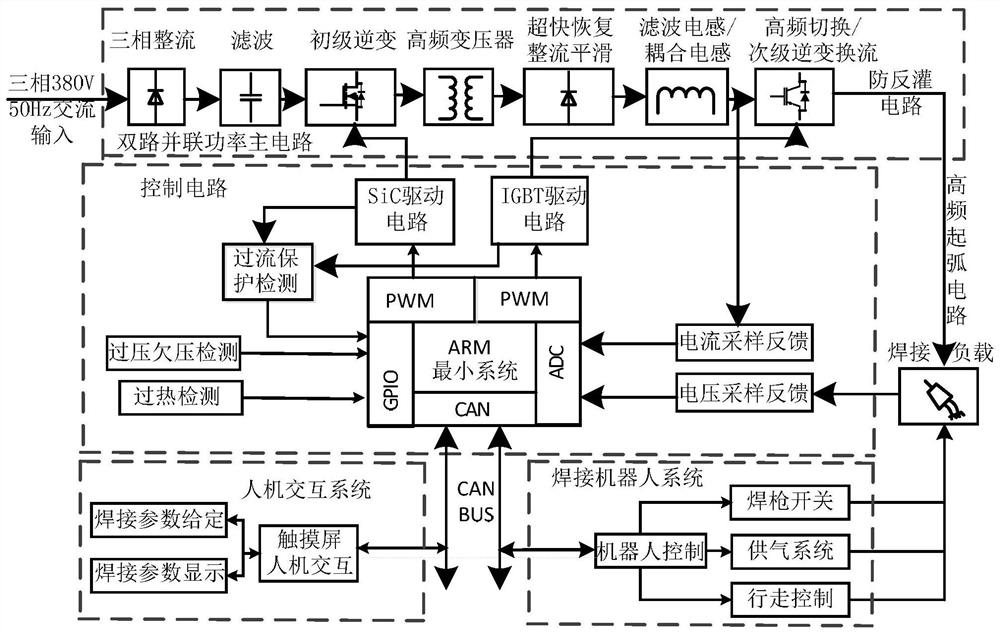

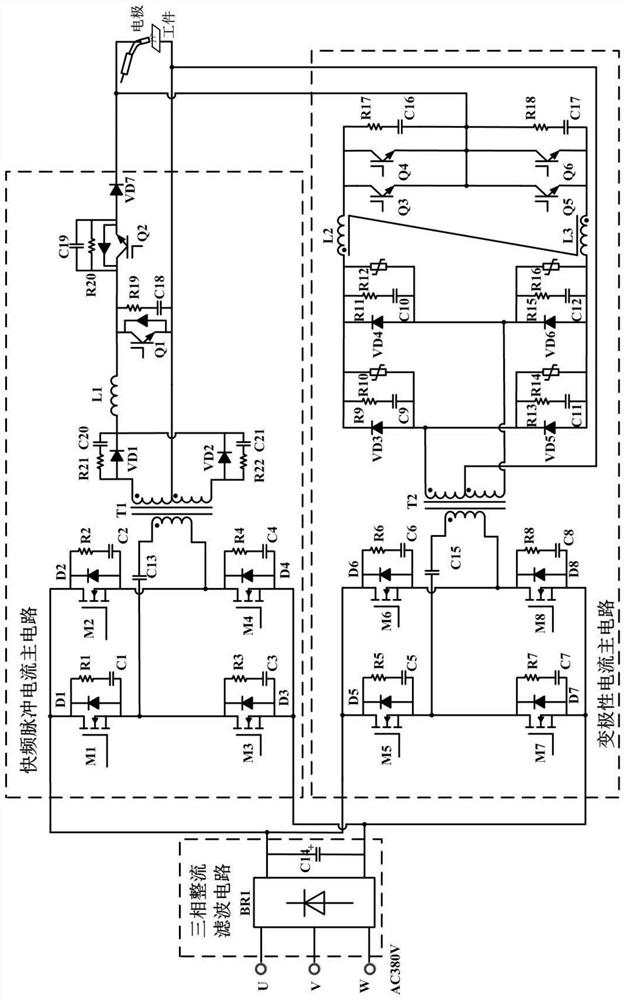

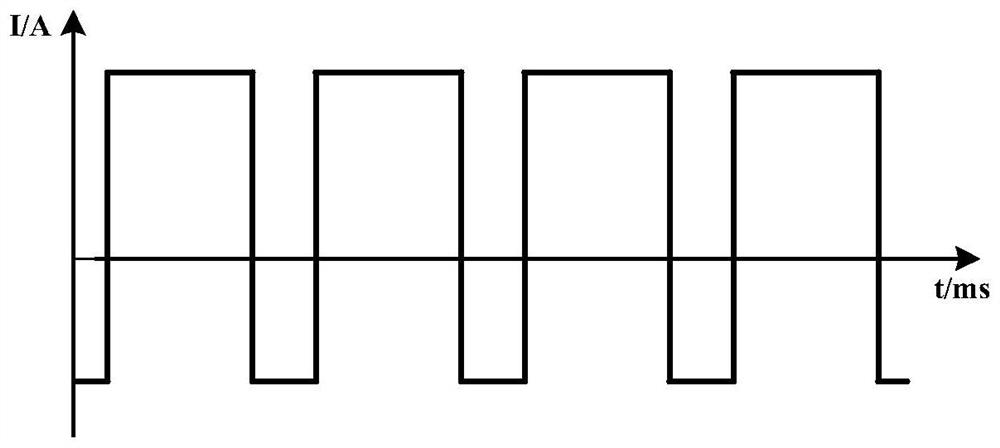

Fast frequency-variable polarity TIG welding power source and system based on SiC module

ActiveCN114654049AImprove energy efficiencyIncrease inverter frequencyEfficient power electronics conversionArc welding apparatusWelding power supplyHemt circuits

The invention provides a fast frequency variable polarity TIG welding power source and system based on a SiC module. The welding power source comprises a double-path parallel power main circuit, a control circuit and a man-machine interaction system. The double-path parallel power main circuit comprises a three-phase rectification filter circuit, a fast frequency pulse current main circuit and a variable polarity current main circuit; each of the fast frequency pulse current main circuit and the variable polarity current main circuit comprises a primary inverter circuit, a high-frequency transformer and an ultrafast recovery rectification smoothing circuit which are connected in sequence; the fast-frequency pulse current main circuit further comprises a filter inductor and a high-frequency switching circuit which are sequentially connected behind the ultra-fast recovery rectifying and smoothing circuit. The variable polarity current main circuit further comprises a coupling inductor and a secondary inverse current conversion circuit which are sequentially connected behind the ultrafast recovery rectification smoothing circuit. The welding power source can reduce the size, is high in dynamic response speed, low in switching loss, high in energy efficiency and stable and distortionless in output waveform, and can improve the welding quality.

Owner:SOUTH CHINA UNIV OF TECH

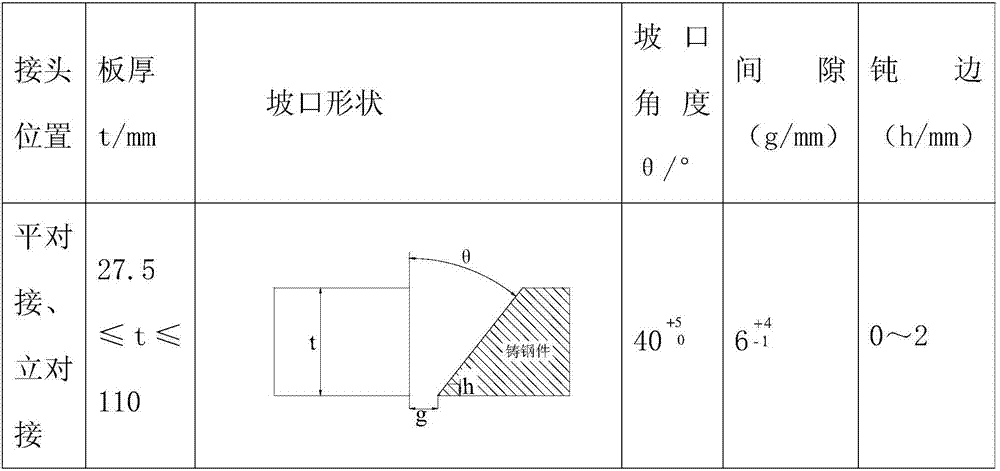

Welding method for low-temperature steel casting and marine plate

InactiveCN106964912AQuality improvementImprove low temperature impact performanceWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneThermal treatment

The invention discloses a welding method for a low-temperature steel casting and a marine plate. The welding method comprises the steps that S10, materials are prepared, namely the low-temperature steel casting and the marine plate are provided; the low-temperature steel casting is firstly chamfered and then is subjected to thermal treatment; the marine plate is not chamfered; S20, preheating is performed before welding, and the welded plates are preheated to 100 DEG C; S30, welding is performed; and multi-layer weld beads are arranged; each layer starts from the marine plate and ends at the low-temperature steel casting until the whole weld beads are finished. The low-temperature steel casting is chamfered before thermal treatment, and through thermal treatment, stress at chamfers is eradicated, so that welding quality is improved; the low-temperature steel casting and the marine plate are preheated before welding, and thermal preservation is performed during welding, so that welding joint defects are decreased after welding through the special arrangement of the weld beads; low-temperature impact performance of the welding joints and heat-affected areas is effectively improved; welding quality is ensured; and the welding joints can withstand low-temperature impact test at 60 DEG C after welding.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Double sides double arc welding method

ActiveCN1330449CSimplify the welding processImplement automated weldingArc welding apparatusWorkpiece edge portionsEngineeringJoint stress

Owner:中国船舶集团渤海造船有限公司

Lithium-ion battery liquid injection hole sealing structure

ActiveCN107359304BEasy to detectEasy to weldCell component detailsStructural engineeringLithium-ion battery

The invention provides a lithium ion battery liquid injection hole sealing structure, which includes a top cover plate, a sealing ring and a weldable sealing nail; a straight wall liquid injection hole is opened on the top cover plate; the sealing nail includes an insertion injection hole The nail body in the liquid hole and the nail cap welded to the top cover plate; the sealing ring is fixed on the nail body of the sealing nail and is located between the top cover plate and the sealing nail. Compared with the prior art, the sealing structure of the liquid injection hole of the lithium ion battery of the present invention realizes the advantages of easy welding, less weld defects, high production efficiency and easy detection of the weld by assembling the seal ring and the seal nail into an integrated seal nail. .

Owner:CONTEMPORARY AMPEREX TECH CO

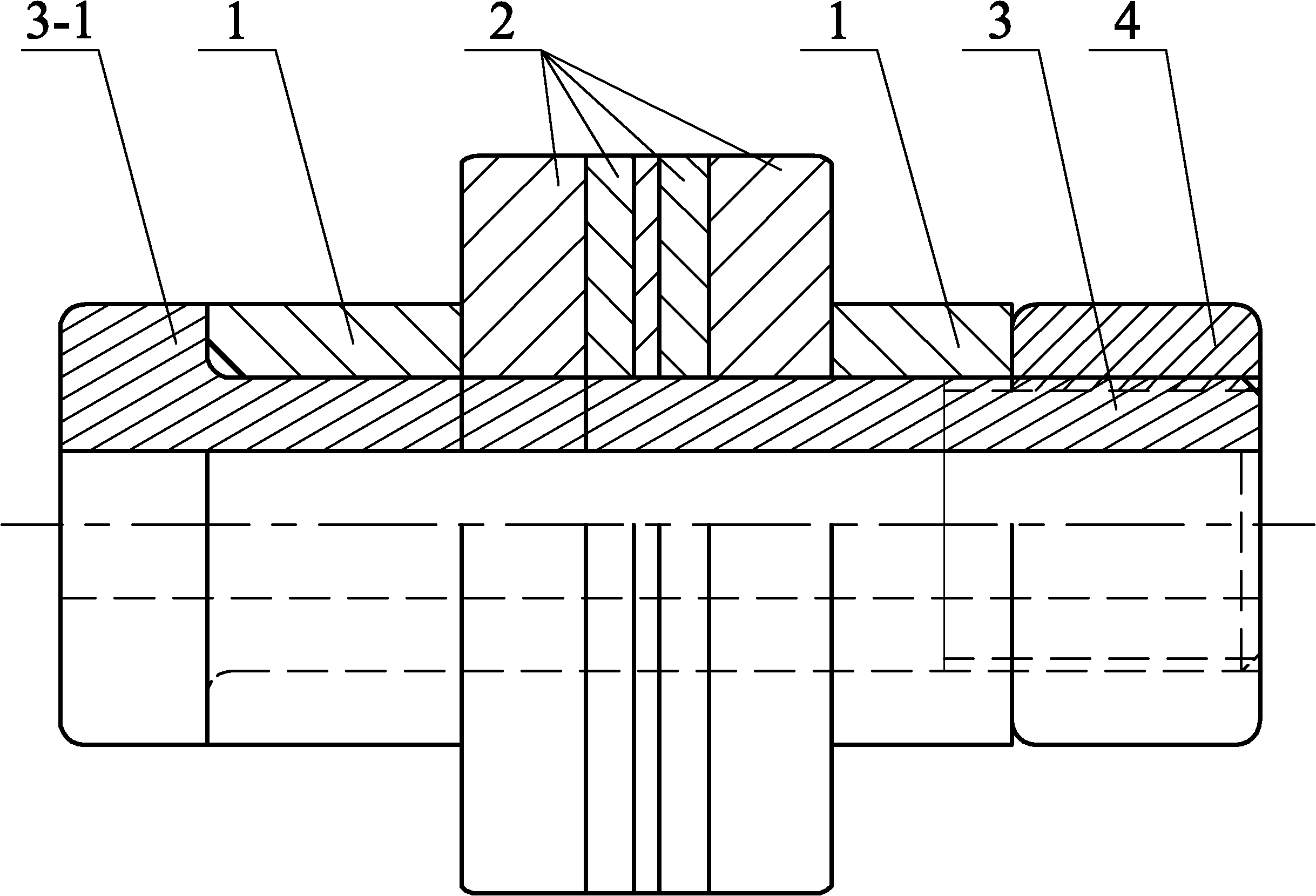

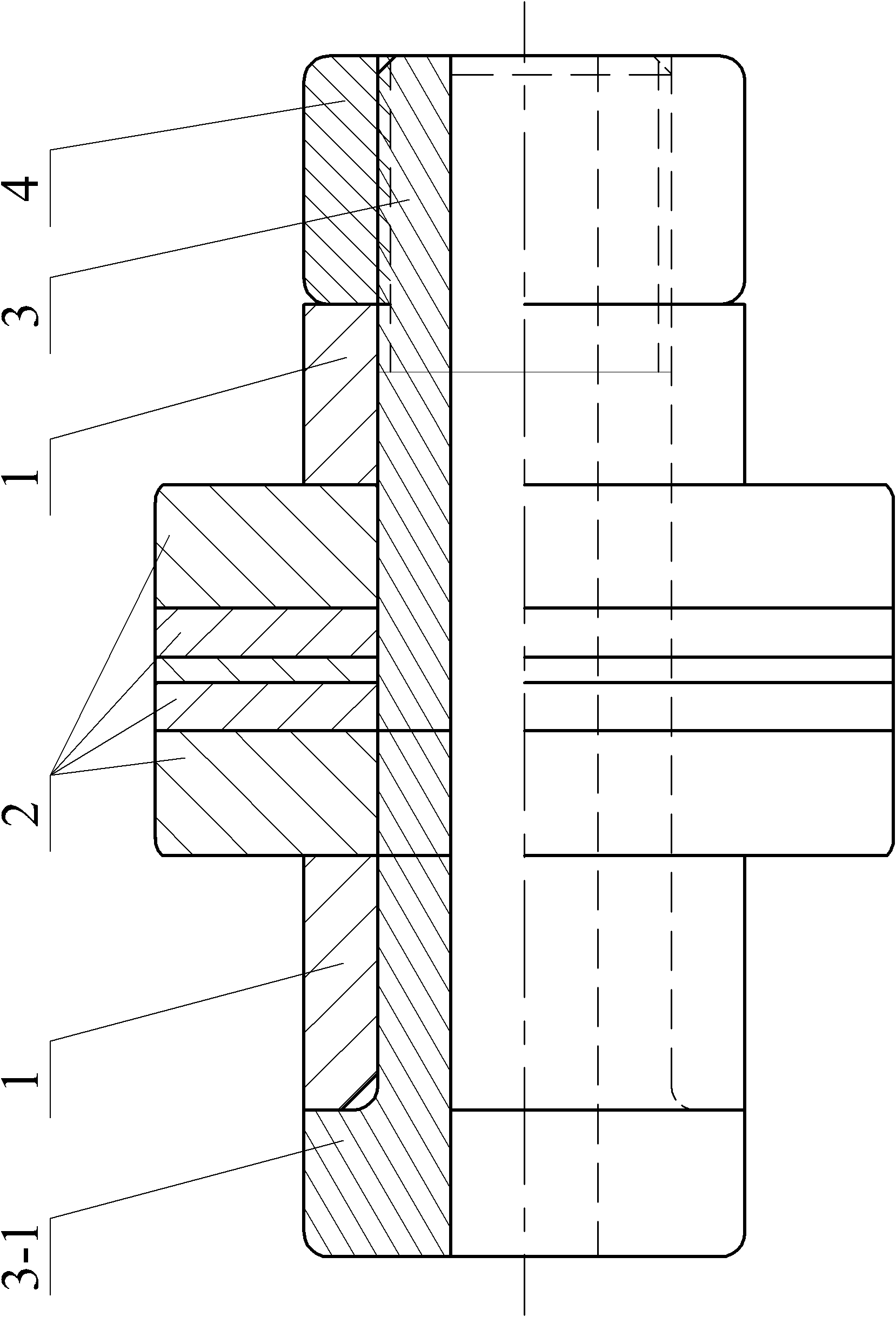

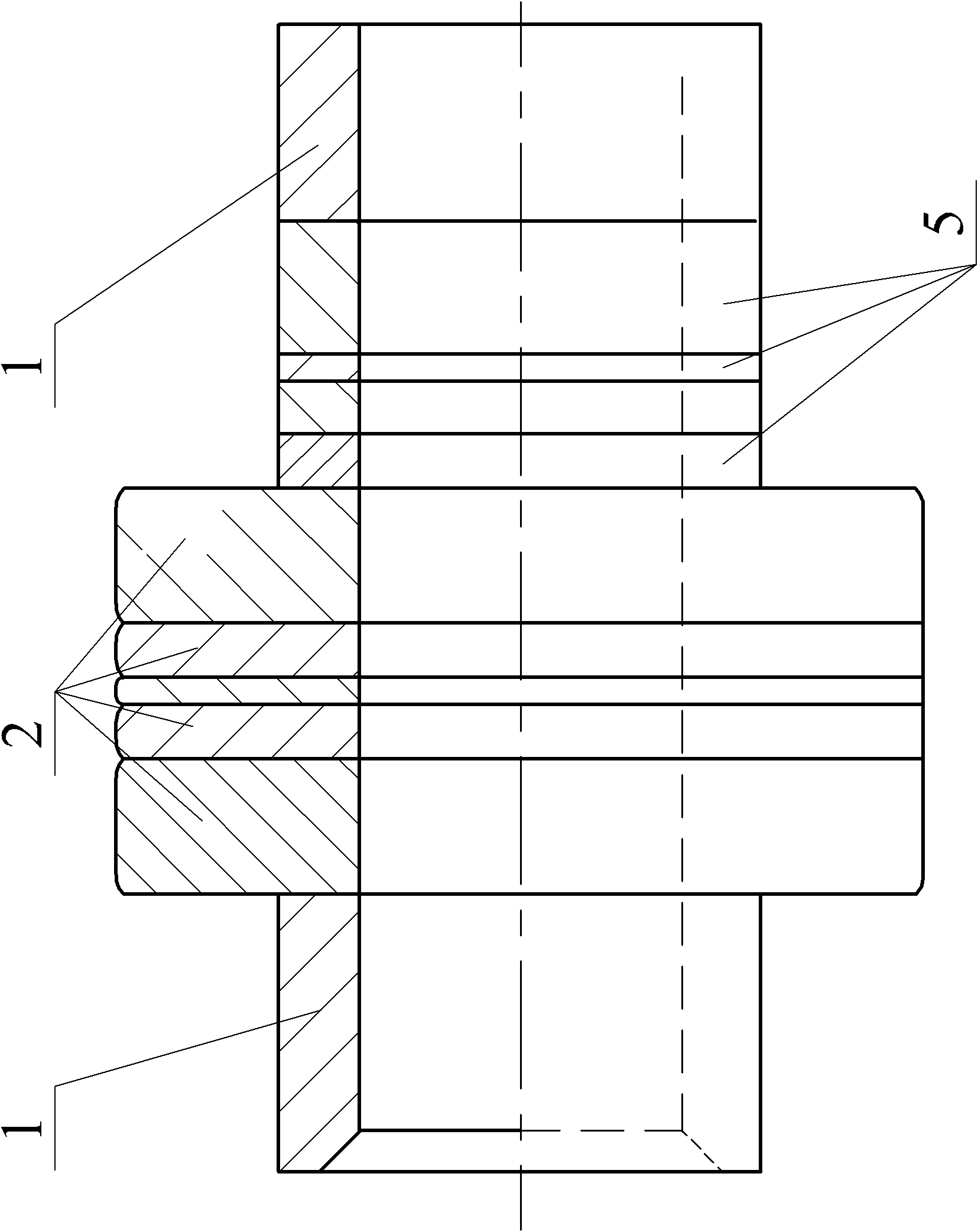

Narrow-gap adjustable device and cosmetic welding adjustable device for improving bearing capacity of butt joints

InactiveCN102091892AImprove carrying capacityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesButt jointWelding residual stress

The invention improves a narrow-gap adjustable device and a cosmetic welding adjustable device for improving the bearing capacity of butt joints, which belong to the field of a welding technique and can acquire high-quality butt joints with good bearing capacity. A fastener is used for axially pressing and fixedly mounting a group of annular sheets with different thicknesses and two wheel rim bodies on a shaft sleeve; and the two wheel rim bodies and the group of annular sheets with different thicknesses between the two wheel rim bodies are arranged coaxially, and the surface profile of the integration of the wheel rim bodies and the annular sheets is matched with the surface shape of the weld reinforcement of the butt joints. The narrow-gap adjustable device is convenient in operation, and has the advantages of high efficiency, high adaptability and the like; and the device with the adjustability can shape the butt joints which have different thicknesses and are made of different materials during welding. Under the sequential action of the narrow-gap adjustable device and the cosmetic welding adjustable device, butt joints with less weld defects, fine grains, low welding residual stress, desired shape and size, and high bearing capacity can be manufactured.

Owner:HARBIN INST OF TECH

A Bourdon tube welding method for pressure gauge

ActiveCN103737215BAvoid cloggingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention discloses a device and a method for welding a bourdon tube for a pressure gauge, and belongs to the field of pressure gauge production. The device comprises a base, a gas feeding tube, a water ejection tube, a first groove and a second groove, wherein the first groove and the second groove are formed in the base; one end of the second groove is vertically connected with the first groove; the gas feeding tube is fixed on the base; one end of the gas feeding tube is arranged in the second groove; the water ejection tube is arranged on the base. By the adoption of the device, a gas can be supplied in welding, so that through holes are prevented from being blocked, and meanwhile due to arrangement of the water ejection tube, weld seams can be conveniently cooled down, and meanwhile due to addition of special substances in water in the welding method, the anticorrosion effect can be achieved, and the welding defects can be greatly reduced.

Owner:MAANSHAN NAITE INSTR TECH

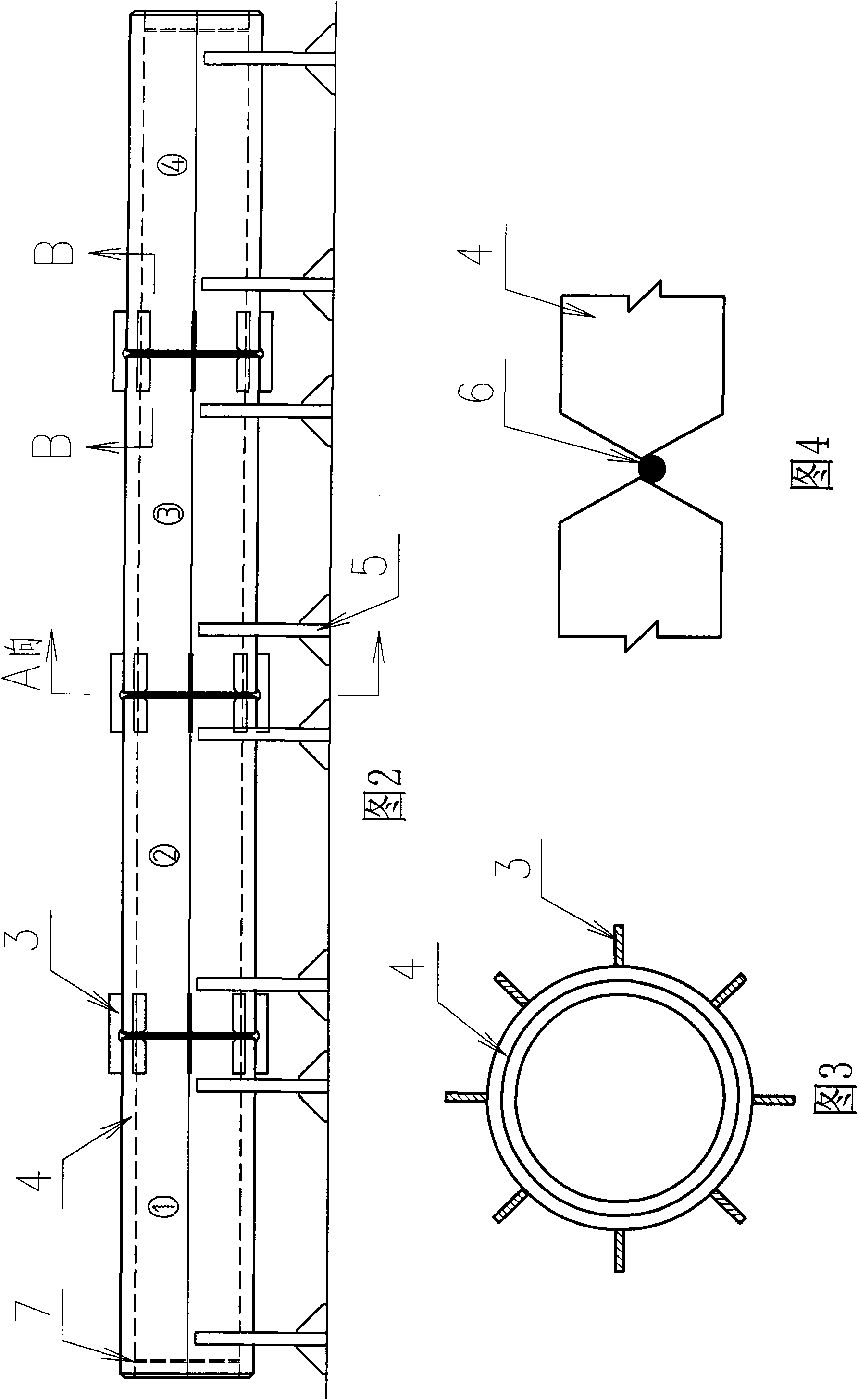

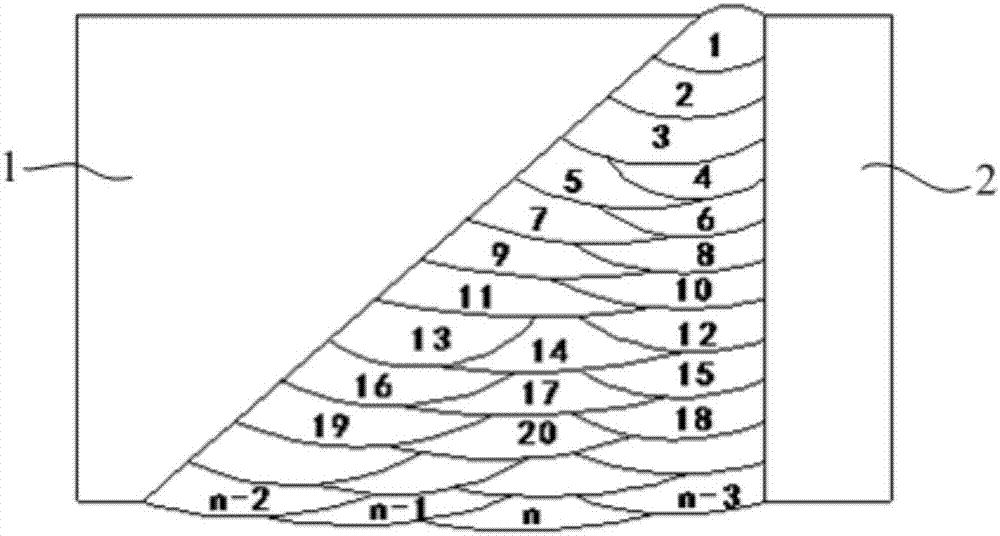

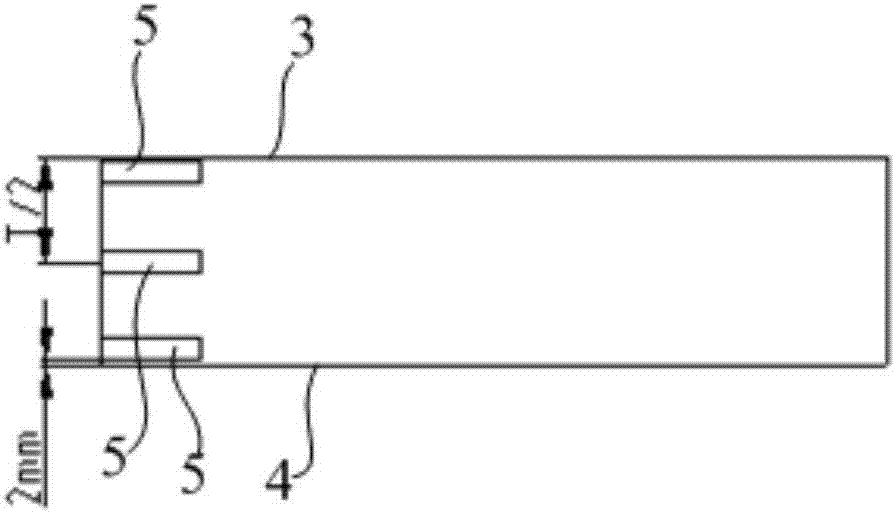

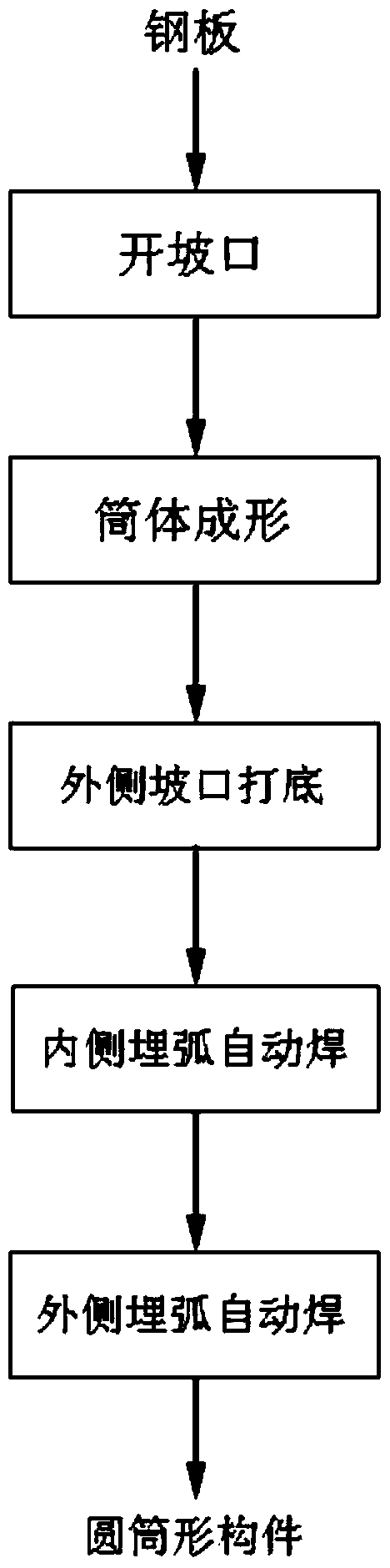

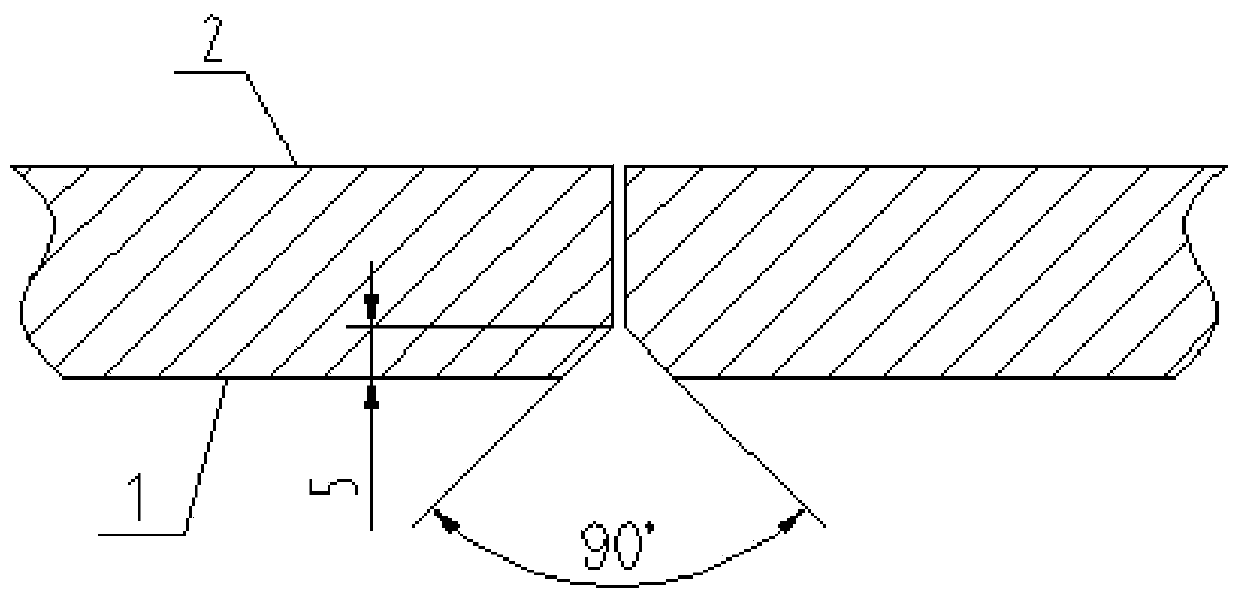

A cylindrical full penetration submerged arc automatic welding method without root cleaning

ActiveCN105345235BGood size controlAvoiding the problem of easy-to-penetrate weldsArc welding apparatusShielded metal arc weldingButt joint

The invention discloses a cylindrical no-root full-penetration union melt welding method. The method comprises the following steps: a beveling step: one-way grooves of 45+-2 degrees with depths of 4-12 mm are formed in four edges, near the outer side of a cylinder, of a steel plate; a cylinder molding step: the steel plate is wound according to the diameter, the alignment tolerance and the welding line gap not more than 1 mm, or is in butt joint to form a cylinder in radial direction after winding, and a V-shaped welding line is formed on the outer side surface; an outer side groove bottoming step: the groove at the outer side of the longitudinal or annular gap of the cylinder is bottomed according to a filling thickness of 3-4 mm by manual arc welding or gas shielded welding; an inner side union melt welding step: the union melt welding is performed for the welding line at the inner side of the cylinder according to a welding layer filling thickness of 2-4 mm and cover surface weld reinforcement of not more than 2.5 mm; and an outer side union melt welding step: the union melt welding is performed for the welding line at the outer side of the cylinder according to the cover surface weld reinforcement of 1-3 mm. The method has the characteristics of smooth welding lines, high welding efficiency, stable quality and no open arc irritation and noise pollution.

Owner:SINOHYDRO ENG BUREAU 4 XIANGYUN MACHINERY ENERGY EQUIP CO LTD

Energy-efficient plasma electric welding machine device with magnetically stabilized arc

The invention discloses an energy-efficient plasma electric welding machine device with the magnetically stabilized arc, including a body box, a spray head main body and a gas mixing chamber. The gasmixing chamber is arranged at the bottom of the body box, a gas pressurizing pump is installed on one side of the gas mixing chamber through a mounting piece, an argon storage chamber is arranged at one end of the inner bottom of the body box, an air pump is installed at one side of the argon storage chamber through a mounting bracket, a hydrogen generator is connected with the inner top of the body box through a connecting frame and an output end of the hydrogen generator is connected with the air mixing chamber through a pipe, a feeding chamber is arranged on one side of the hydrogen generator, a motor is installed at the bottom of the feeding chamber through bolts, and an infrared heating pipe is installed at the top part of the feeding chamber through a connecting seat. As the arc reaches a magnetically stable state, a welding column is thin and long, the penetration force is strong, the weld speed is fast, the welding seam defects are few, and the welding quality is high.

Owner:叶露穗

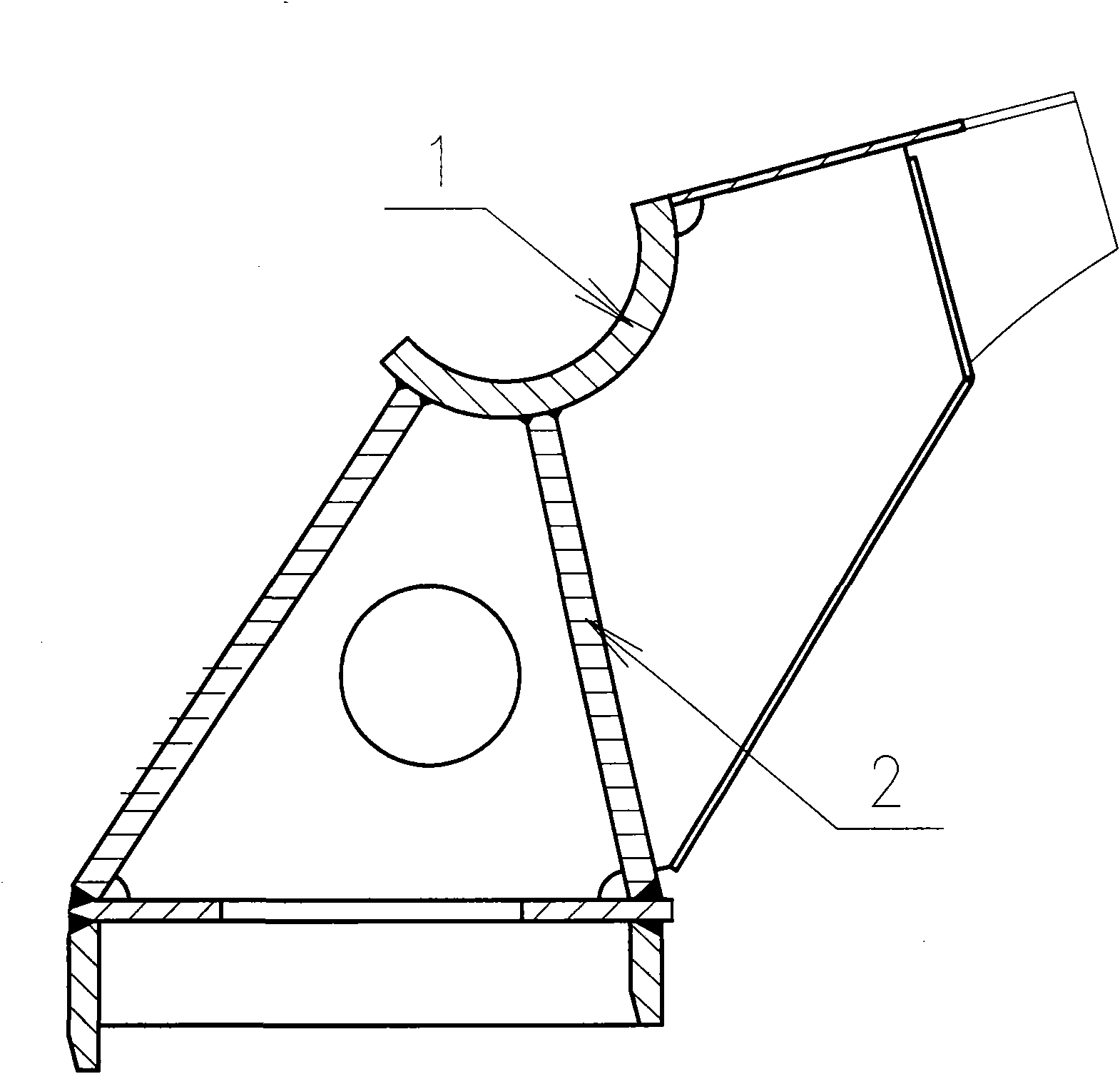

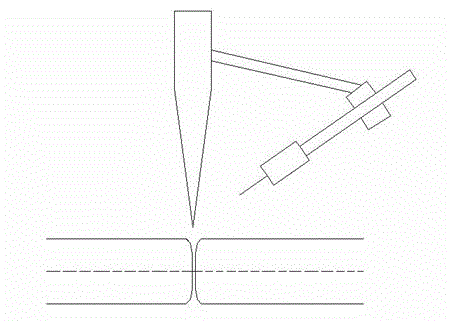

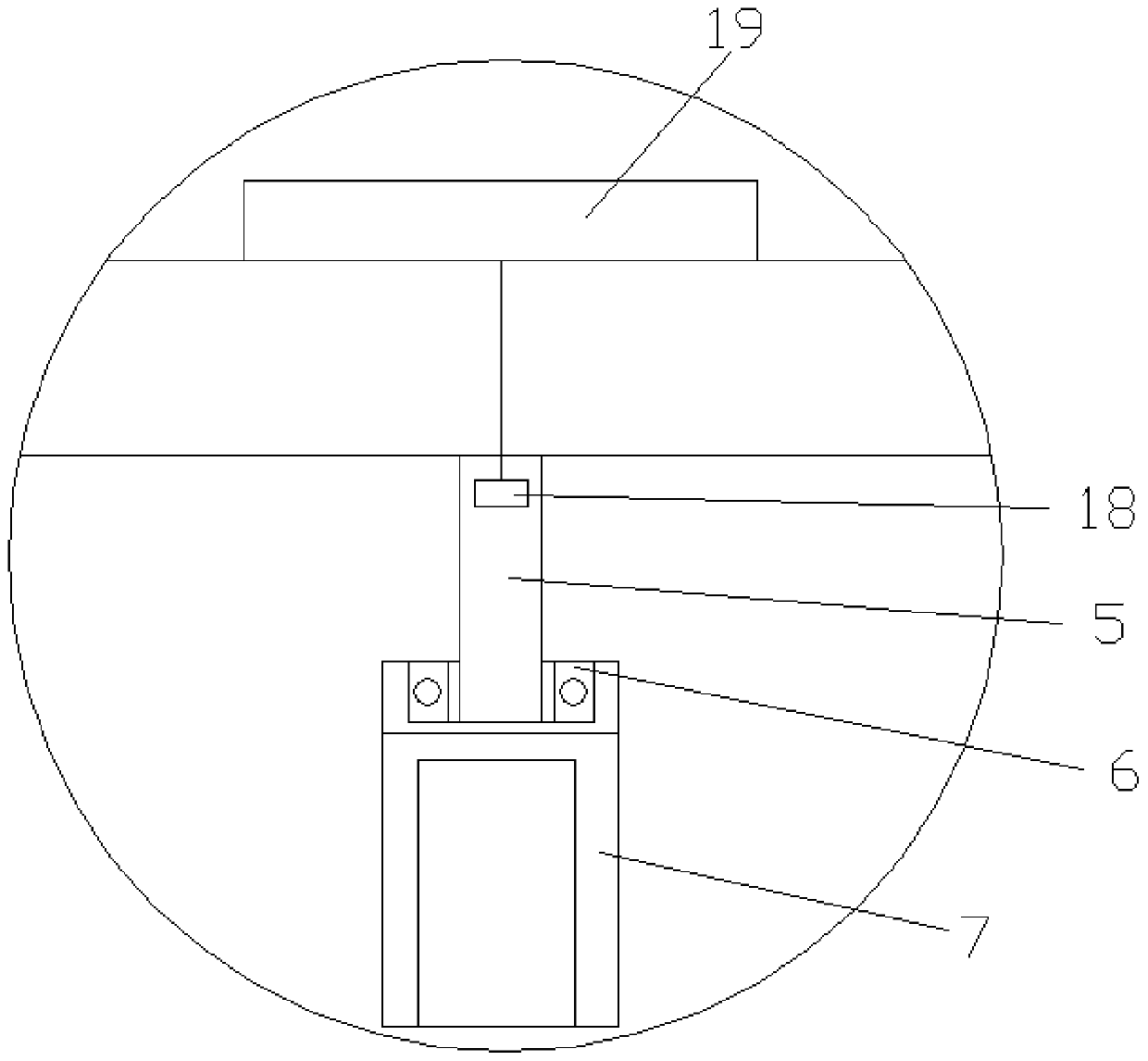

A laser arc hybrid welding method and fixture for thick plate high-strength steel

ActiveCN103406675BReduce utilizationProlong clotting timeWelding/cutting auxillary devicesAuxillary welding devicesThick plateErbium lasers

The invention relates to a laser and electric arc combined welding method for thick high-strength steel plates and a clamp for the method. A 45-mm thick high-strength steel is welded with a 6-KW fiber laser and through a double-sided welding forming method, small double-sided grooves are opened, and a 1mm-1.5mm gap is reserved, accordingly, the 45-mm thick high-strength steel can be completely welded. Compared with traditional multi-layer multi-pass welding which requires at least 20 passes of welding, the combined welding method has the advantages that the progress is apparent, preheating processes are simplified, preheating time is shortened, and welded joint performances reach client required indexes; the production efficiency is improved apparently, consumption of base metal and welding wires is reduced, energy consumption is decreased, the mechanical property of welded joints is improved, the residual stress and the deformation are reduced, automation of production can be easily achieved, and the like. The special clamp is a combined clamp with four pressing plates arranged on the upper portion and a base plate used on the lower portion during welding so as to improve the efficiency and quality of the welding method. By means of the clamp, a workpiece can be positioned and fixed, the welding quality is guaranteed, and the workpiece cannot be abraded.

Owner:NANJING ZHONGKE RAYCHAM TECH

A kind of laser welding fixture and laser welding method

ActiveCN108941907BDoes not block the spin welding processGuaranteed face to faceWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

The invention discloses a laser welding fixture and method. The laser welding fixture comprises a supporting rod, a positioning plate, U-shaped rotation arms and pressure covers; the supporting rod isarranged in the vertical direction, and the top end of the supporting rod is provided with the positioning plate in the horizontal direction; the upper surface of the positioning plate is provided with a storage groove, and the two sides of the positioning plate are provided with the U-shaped rotation arms; the pressure covers are installed on the U-shaped rotation arms; and driving devices are installed on the lower portions of the U-shaped rotation arms and used for driving the U-shaped rotation arms to rotate and do vertical reciprocating motion. The laser welding method comprises the following steps that a laser welding head is started, the U-shaped rotation arms on the fixture are started to rotate at the same time, and thus, the U-shaped rotation arms of the fixture rotate while thewelding head does rotary welding so that welding of an annular welding zone can be achieved at a time through the welding head; and a pressure sensor on the fixture can measure the pressure value applied to the pressure covers. According to the laser welding device and method, the welding sealing performance is good, and the welding efficiency is high.

Owner:SHENZHEN DADE LASER TECH CO LTD

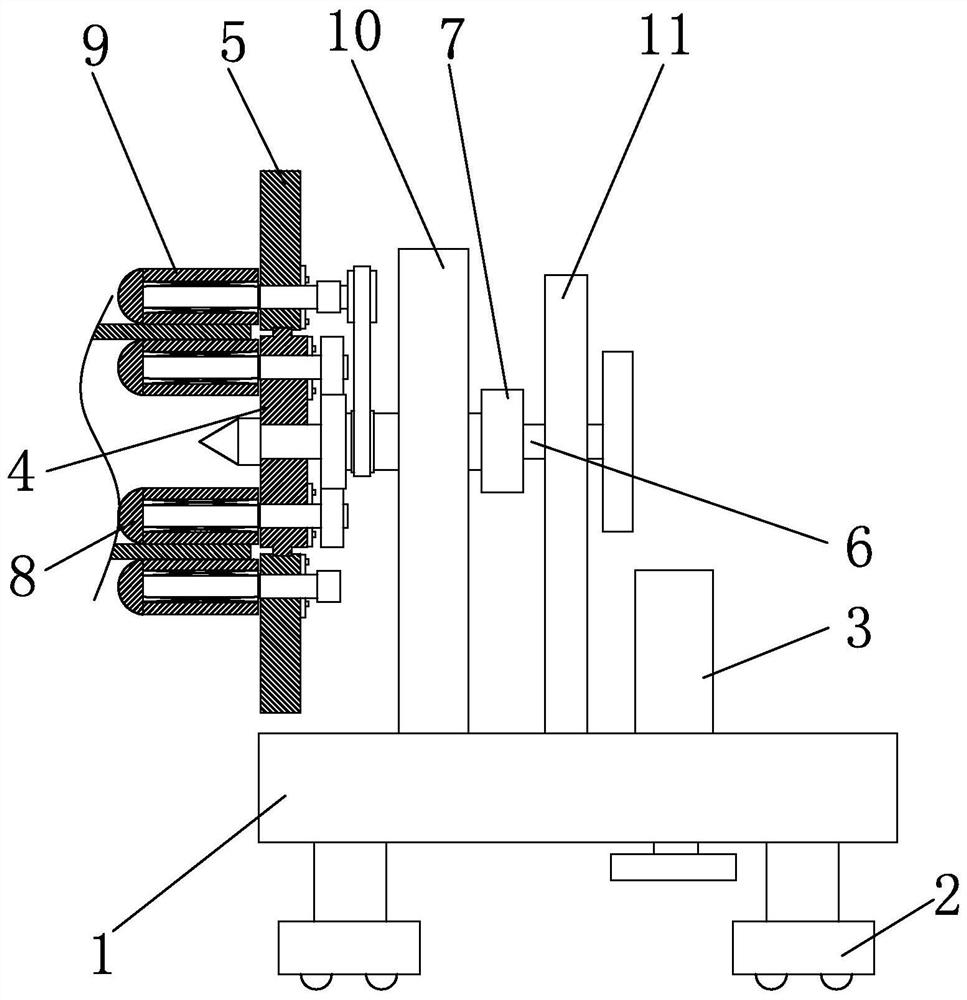

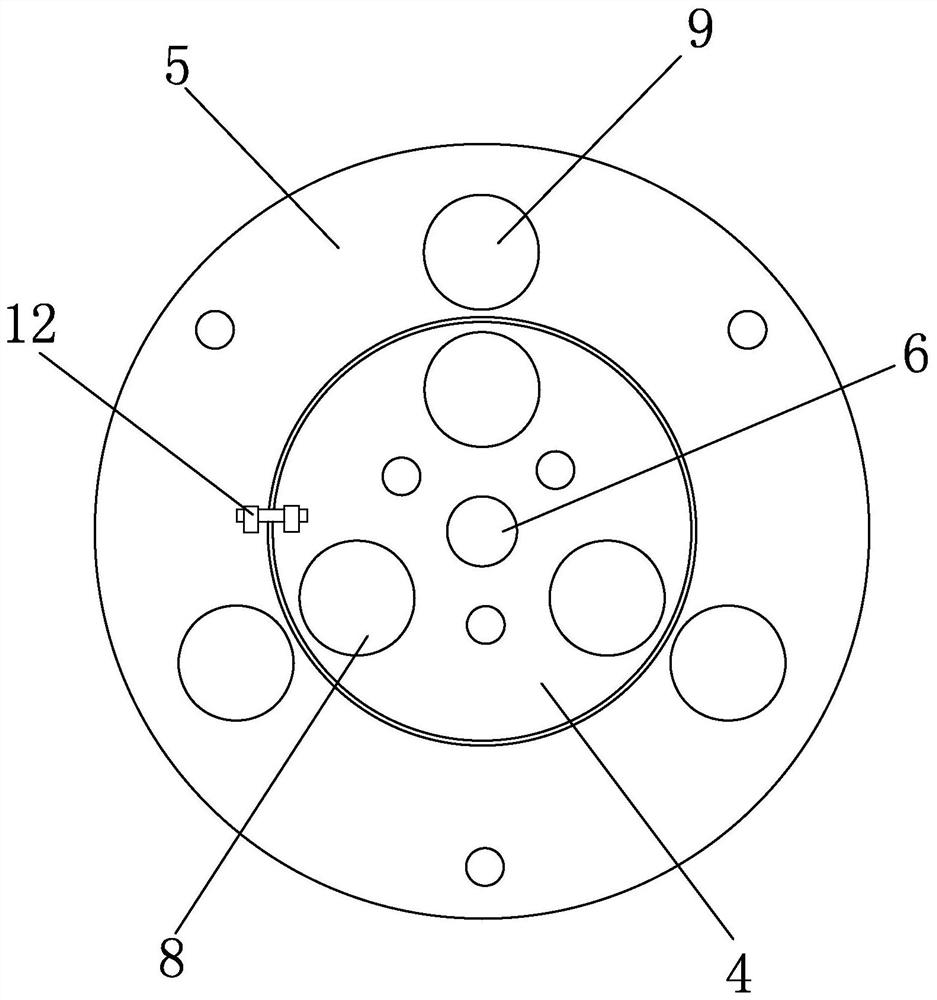

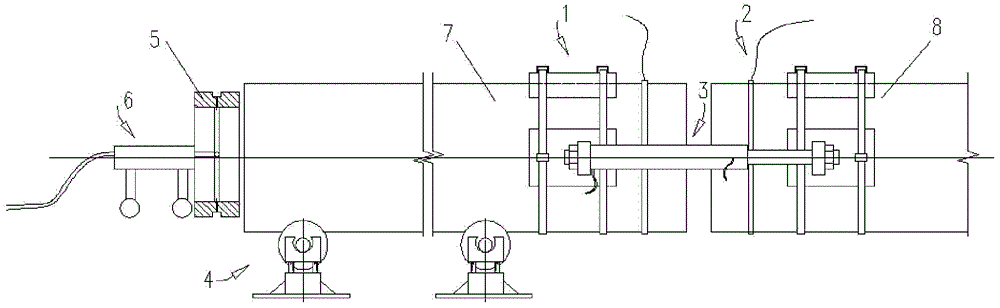

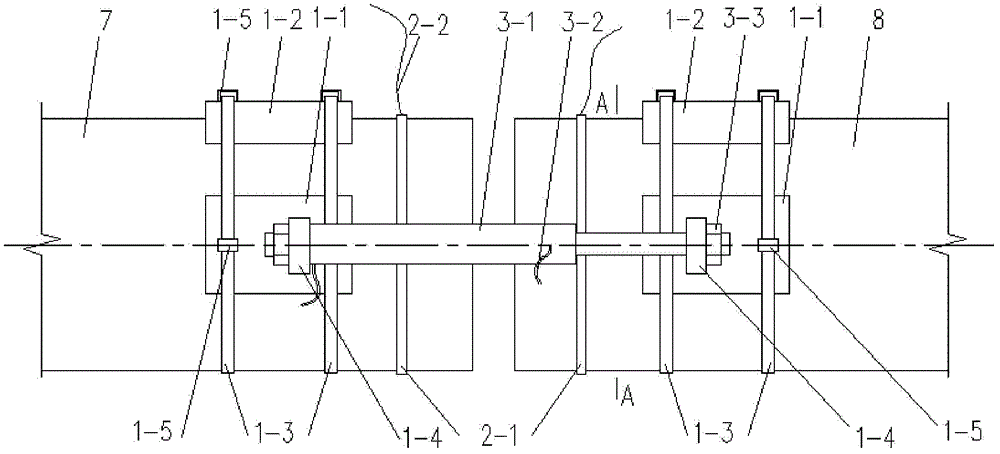

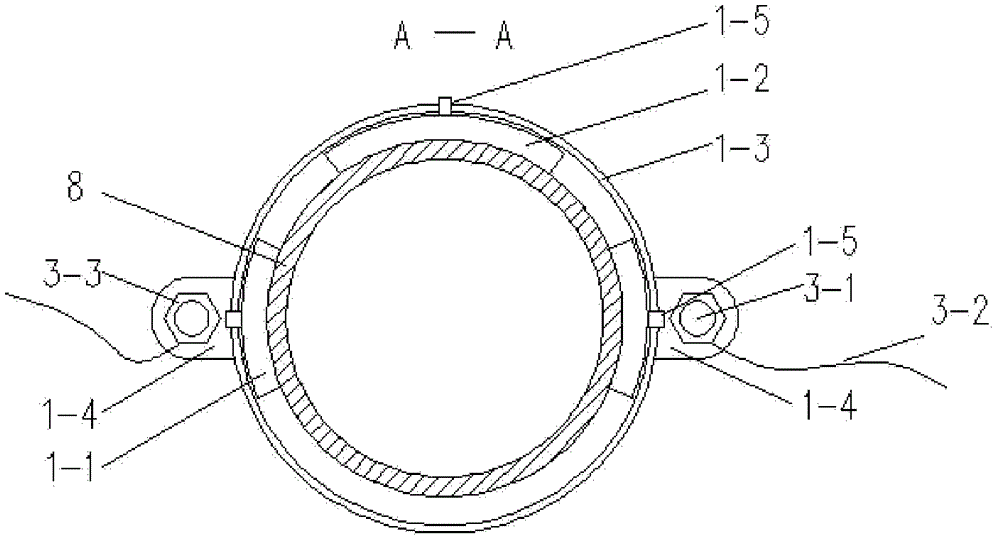

Bimetal composite pipe automatic butt welding equipment

ActiveCN103372707BQuick and easy butt welding operationReduce weld defectsWelding/cutting auxillary devicesArc welding apparatusButt weldingEngineering

The invention discloses automatic butt welding equipment for bimetal composite pipes and belongs to the field of oil and gas pipelines. The equipment mainly comprises clamping devices, conducting devices, a hydraulic source connecting device, support adjusting devices, a ceramic ring, and an electric propulsion unit. A movable bimetal composite pipe to be welded is disposed on the support adjusting devices. The end, to be welded, of the movable bimetal composite pipe to be welded corresponds to the end, to be welded, of a fixed bimetal composite pipe to be welded. Horizontal center lines of the two pipes are coaxial. A set of clamping devices is disposed on the outer periphery of each of the butt-welded end of the movable bimetal composite pipe to be welded and the butt-welded end of the fixed bimetal composite pipe to be welded. The automatic butt welding equipment for bimetal composite pipes has the advantages that the bimetal composite pipe can be butt-welded on the site quickly and conveniently, weld defects are less, weld failure accidents are less, and the equipment is simple in structure, convenient to operate and faster for construction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Welding process of a fully enclosed aluminum alloy anti-rolling multifunctional cabinet

ActiveCN108296609BImprove corrosion resistanceReduce weightArc welding apparatusWelding/soldering/cutting articlesIn vehicleStructural engineering

The invention belongs to the technical field of an aluminum alloy welding and relates to a welding technology of a fully-enclosed aluminum alloy anti-roll multifunctional cabinet externally arranged at a heavy truck. The fully-enclosed aluminum alloy anti-roll multifunctional cabinet comprises a bottom plate, a top plate, a rear plate and side plates; the top plate is fixedly arranged on the frontside of the bottom plate; the rear plate is fixedly arranged on the rear side of the bottom plate;, the side plates are fixedly arranged on the left side and right side of the bottom plate correspondingly; a cuboid is defined by the bottom plate, the top plate, the rear plate and the side plates; lifting lug plates are fixedly arranged at the four corners of the cuboid; a door plate is buckled onthe four corners of the cuboid; reinforcing ribs are arranged at the four corners of the door plate in a crossed manner; and a bottom section is fixedly arranged under the bottom plate. In the welding process, the top plate, the rear plate and the bottom plate are welded with the side plates correspondingly, the bottom section is welded with the bottom plate, the lifting lug plates are welded with side plates and the bottom section, and door plate is welded with the reinforcing ribs at four welding stages correspondingly, so that the problems that energy conservation and emission reduction are not facilitated and the corrosion resistance can not meet the requirement since an existing vehicle-mounted multifunctional cabinet and anti-roll beams, which are made of carbon steel and steel plate materials, are heavy are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

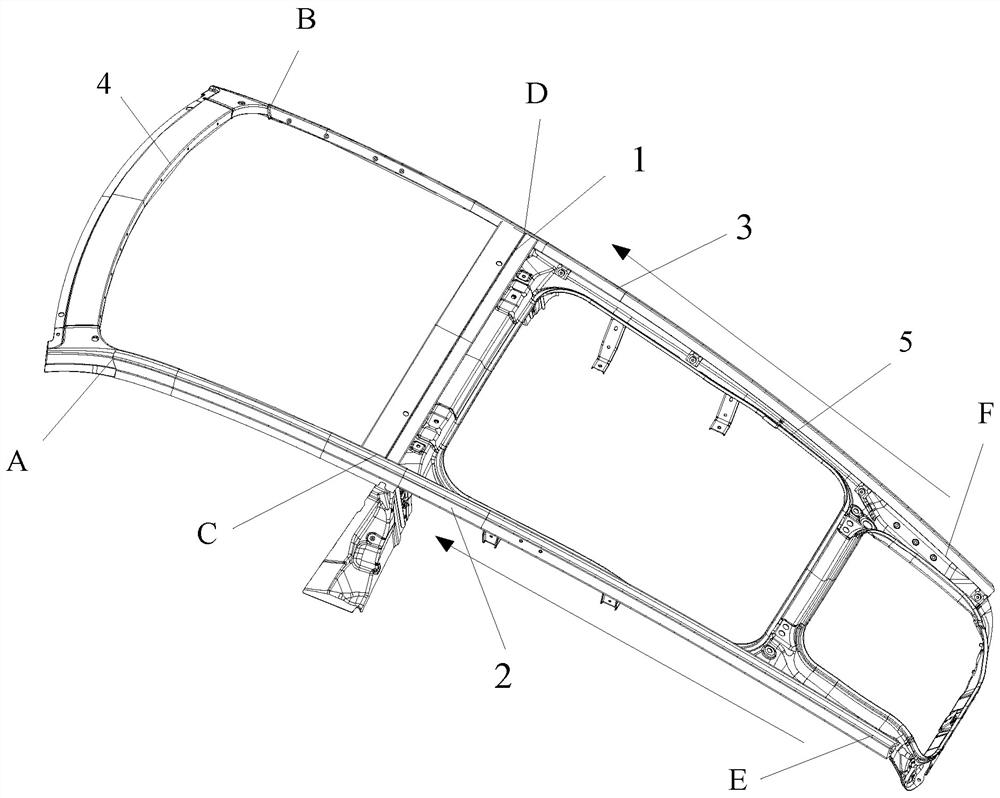

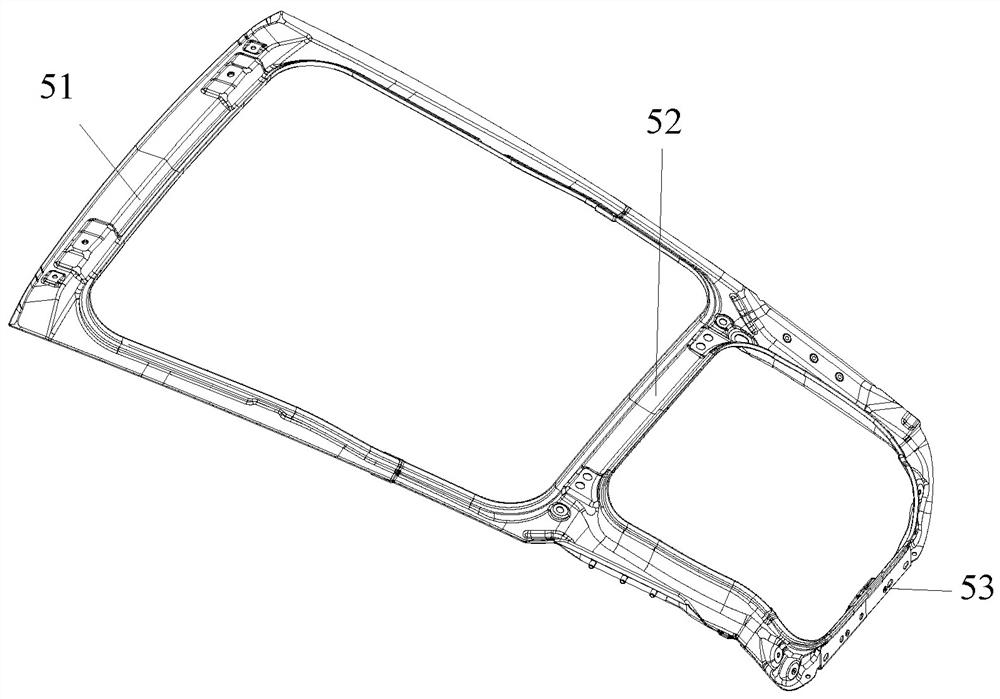

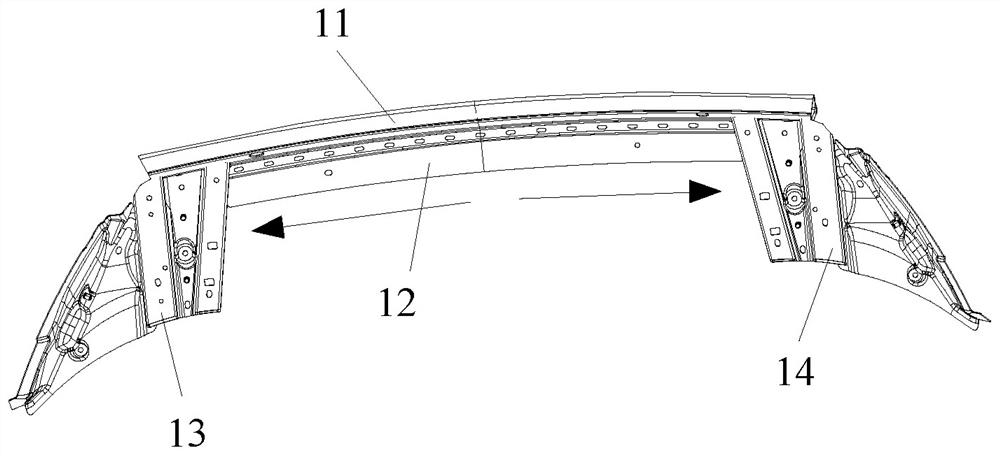

Welding method of frame type aluminum alloy body roof

ActiveCN108857127BGuaranteed dimensional accuracyReduce welding distortionWelding apparatusStructural engineeringWeld seam

Owner:CH AUTO TECH CORP CO LTD

Aqueous cleaning low-temperature welding paste and preparation method thereof

ActiveCN102398122BLow melting pointFast welding speedWelding/cutting media/materialsSoldering mediaActive agentAlloy

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com