Device and method for welding bourdon tube for pressure gauge

A welding device and welding method technology are applied in the field of Bourdon tube welding devices for pressure gauges, which can solve the problems of pits at the welding position, low service life, and easy corrosion of the welding seam, and achieve slow local flow rate, long service life, The effect of less weld defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

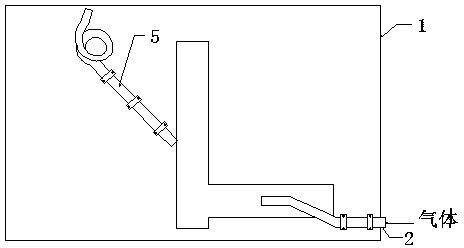

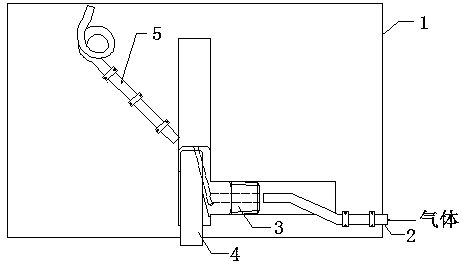

[0035]A Bourdon tube welding device for a pressure gauge, comprising a base 1, a vent pipe 2, a water spray pipe 5, a first groove and a second groove; the first groove and the second groove are arranged on the base 1; the One end of the second groove is vertically connected to the first groove; the air pipe 2 is fixed on the base 1, and one end of the air pipe 2 is arranged in the second groove; the water spray pipe 5 is arranged on the base 1. The cross section of the second groove is semicircular, the inner diameter of the second groove is equal to 2 cm, and the diameter d (inner diameter) of the air pipe 2 is equal to 1 cm. The axial centerline of the water spray pipe 5 and the axial centerline of the second groove (the cross section of the second groove is a semicircle, and the centers of all semicircles are connected into a line, which is the second groove The included angle of the axial centerline of ) is 135°. The port of the air pipe 2 is provided with a protrusion w...

Embodiment 2

[0043] Same as Example 1, the difference is that the inner diameter of the second groove is equal to 2.4 cm, the diameter d (inner diameter) of the air pipe 2 is equal to 0.8 cm, and the angle between the central axis of the air pipe 2 and the central axis of the second groove is 15°, and the gas introduced in step (2) is carbon dioxide. The welded Bourdon tubes had no clogging, and out of 1000 welded products, only 3 were unqualified. And the welding defects are significantly reduced by 70% compared with the welding defects when there is no ventilation. In particular, there is no depression or incomplete penetration of the welds inside the through holes, and the welded Bourdon tubes have not been corroded after one year of use.

Embodiment 3

[0045] Same as Example 1, the difference is that the inner diameter of the second groove is equal to 2.4 cm, the diameter d (inner diameter) of the air pipe 2 is equal to 1.2 cm, and the angle between the central axis of the air pipe 2 and the central axis of the second groove is 15°. The welded Bourdon tubes had no clogging, and out of 1000 welded products, only 3 were unqualified. And the welding defects are significantly reduced by 70% compared with the welding defects when there is no ventilation. In particular, there is no depression or incomplete penetration of the welds inside the through holes, and the welded Bourdon tubes have not been corroded after one year of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com