Vertical down surfacing welding method capable of realizing aesthetic welding joint and low dilution rate

A dilution rate, vertical down technology, applied in welding equipment, arc welding equipment, applications, etc., can solve the problems of discounted metallurgical properties of the surfacing layer, unattractive appearance, large overlap ratio of welds, etc., to achieve stable and continuous quality , the appearance is smooth and continuous, and the effect of dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

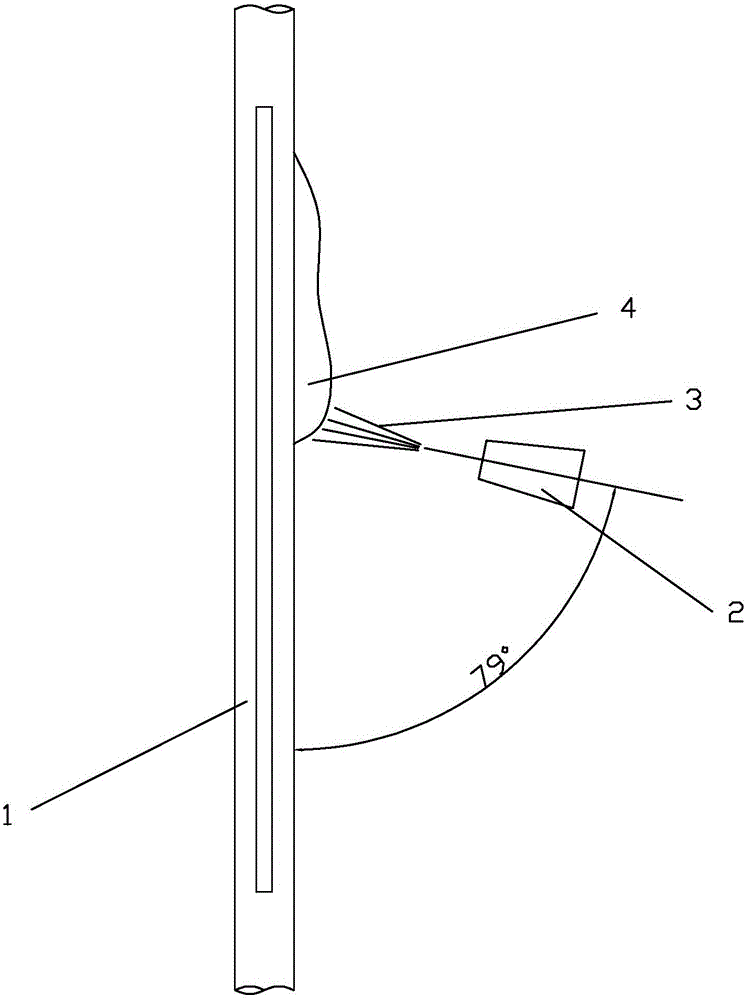

[0015] refer to figure 1 , a vertical downward surfacing welding method with beautiful weld seam and low dilution rate, using pulsed MIIG welding welding power supply; pipe 1 is placed vertically, welding torch 2 points obliquely upward and the included angle with the vertical direction is 75° ~ 80 degrees, the arc 3 ejected by the welding torch 2 blows to the molten pool 4; the welding torch 2 swings reciprocatingly laterally, the swing frequency is 500-900 times / min, and the swing width is 5-9mm; the welding current is 120-180A, and the welding voltage is 22-25V, the wire feeding speed is 6-8 m / min, the dry elongation of the welding wire is controlled at 10-15mm; the speed of the welding torch 2 moving downward is 600-1200 mm / min. The welding gas is mixed with inert gases such as helium, argon and non-inert gases such as oxygen and carbon dioxide according to the appropriate ratio. The mixing ratio will be different for different welding forms, welding metals and welding mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com