Method for preparing super-clean and high-purity isopropanol and apparatus thereof

A preparation device and isopropanol technology, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of hydroxyl compounds, can solve the problem of inability to meet the processing requirements of VLSI, unstable quality of high-purity isopropanol products, Low impurity content and other issues, to achieve the effects of small footprint, easy processing, and large complexation constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

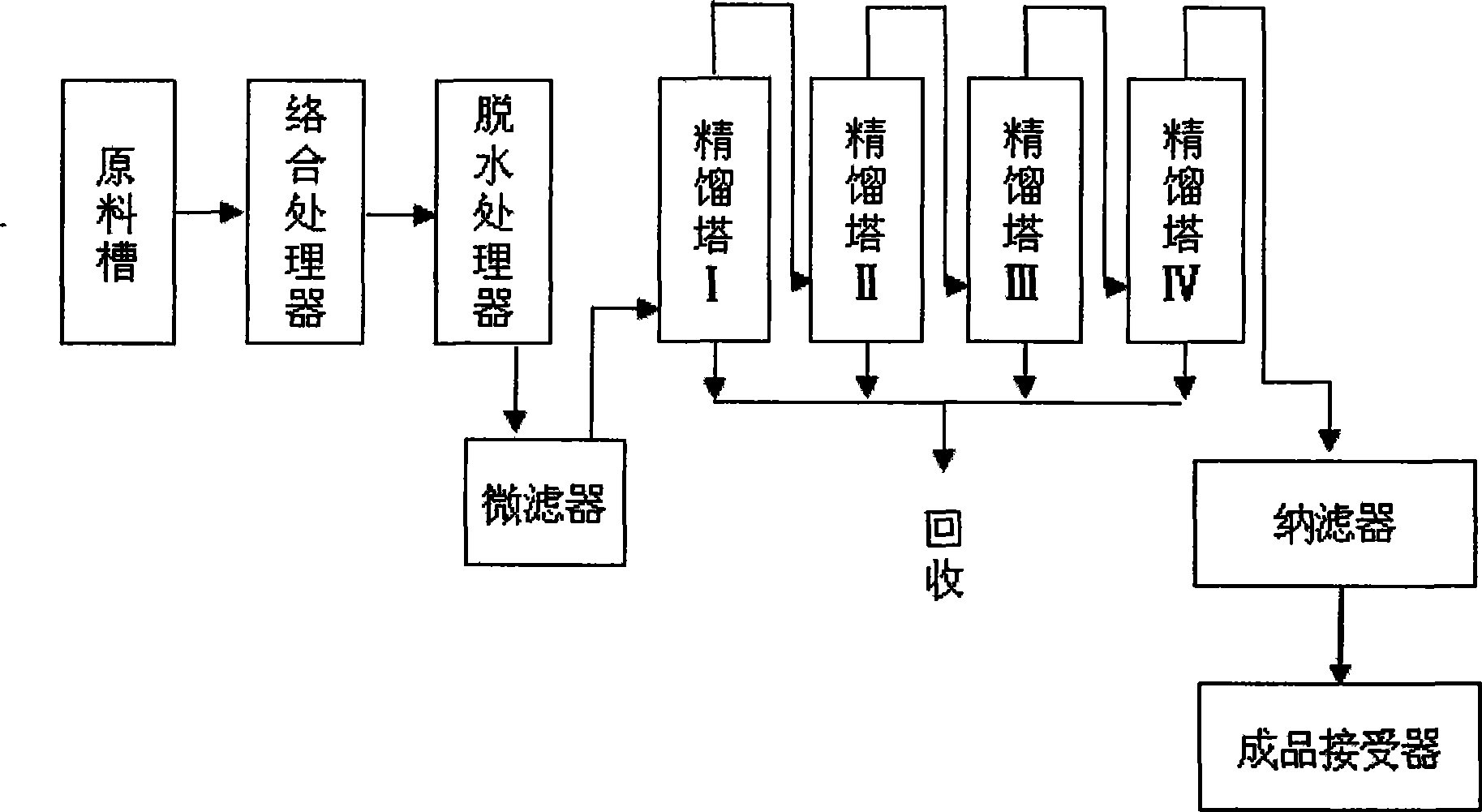

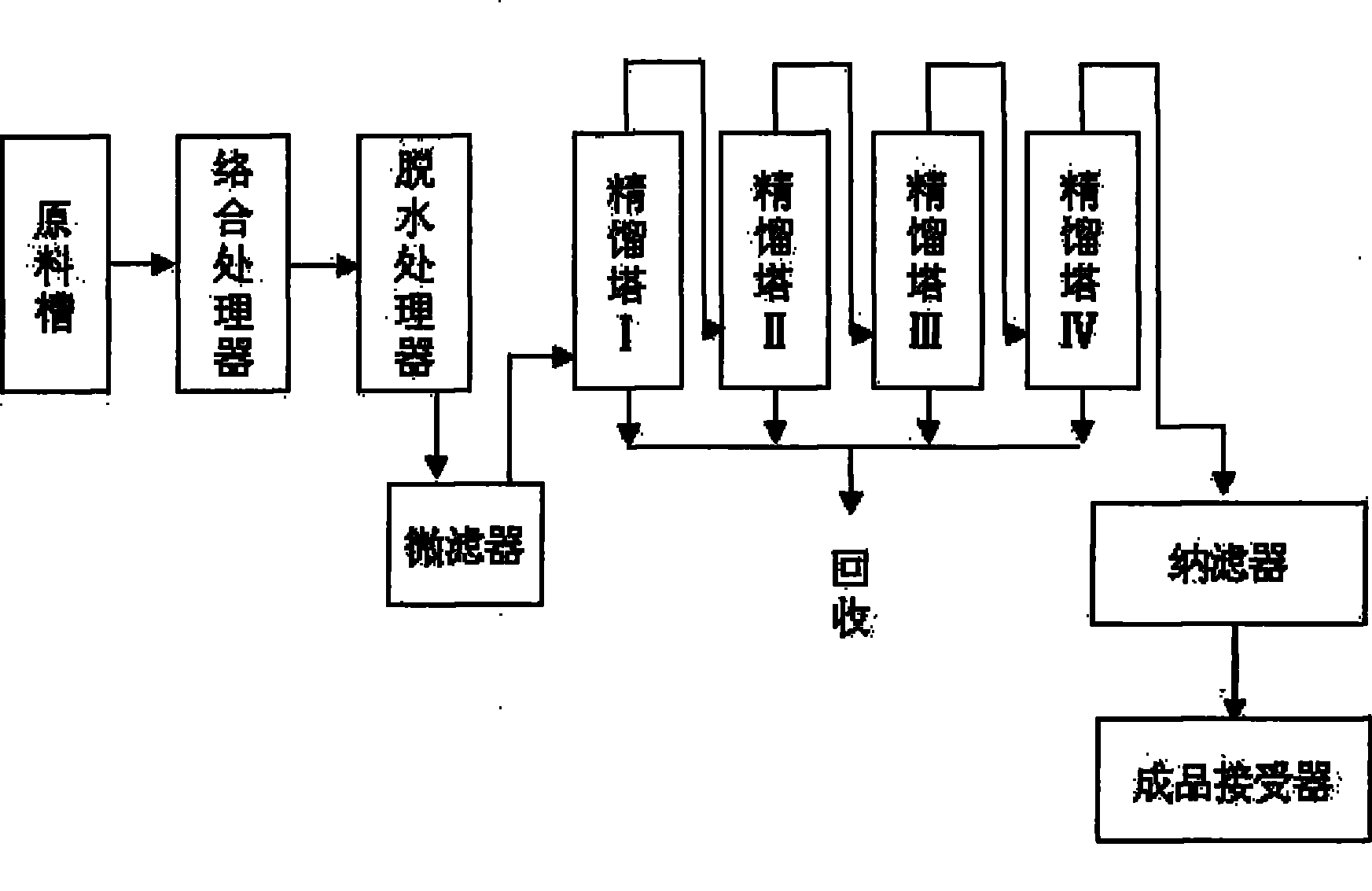

[0012] Embodiment 1: the preparation method of ultra-clean high-purity isopropanol

[0013] A kind of preparation technology of ultra-clean high-purity isopropanol, first with industrial grade isopropanol (98%) raw material and the metal ion complexing agent that is 0.5%~5% of isopropanol raw material weight in complexing processor Mix, enter the dehydration processor at normal temperature and pressure for 30-120 minutes, mix with a dehydrating agent that is 0.1%-15% of the weight of isopropanol raw material at 60°C-100°C for 60-150 minutes, and then mix at 0.1-0.2 Under the operating pressure of MPa, it is filtered through the microfiltration membrane of the microfilter, and the filtrate enters the multi-stage rectification tower. Enter the finished receiver. In this embodiment, the metal ion complexing agent is an organosilicon polymer complexing agent prepared by addition of bisallyl crown ether and hydrogen-containing silicone oil; the bisallyl crown ether is bisallyl Ba...

Embodiment 2

[0018] Embodiment 2: the difference between this embodiment and embodiment 1 is: the described dehydrating agent is magnesium sulfate, calcium chloride, calcium hydride, acid anhydride or silica gel. The pressure selection for microfiltration membrane filtration is: 0.15 or 0.2MPa; the pressure selection for nanofiltration membrane filtration is: 0.6 or 0.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com