Fast frequency-variable polarity TIG welding power source and system based on SiC module

A welding power supply and polarity-changing technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of long tailing off time, no more than 20kHz, and irregular output current waveform, etc., and achieve dynamic response speed Ideal, guaranteed cathode cleaning effect, stable and undistorted waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

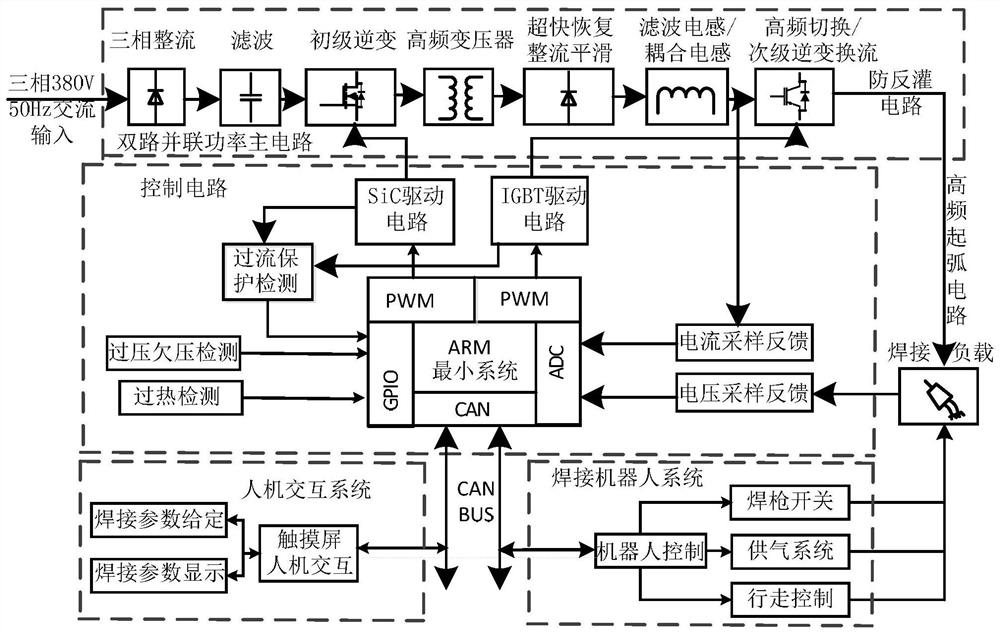

[0034] like figure 1 As shown, in this embodiment, a fast-frequency variable-polarity TIG welding power source based on a SiC module includes a dual parallel power main circuit, a control circuit and a human-computer interaction system.

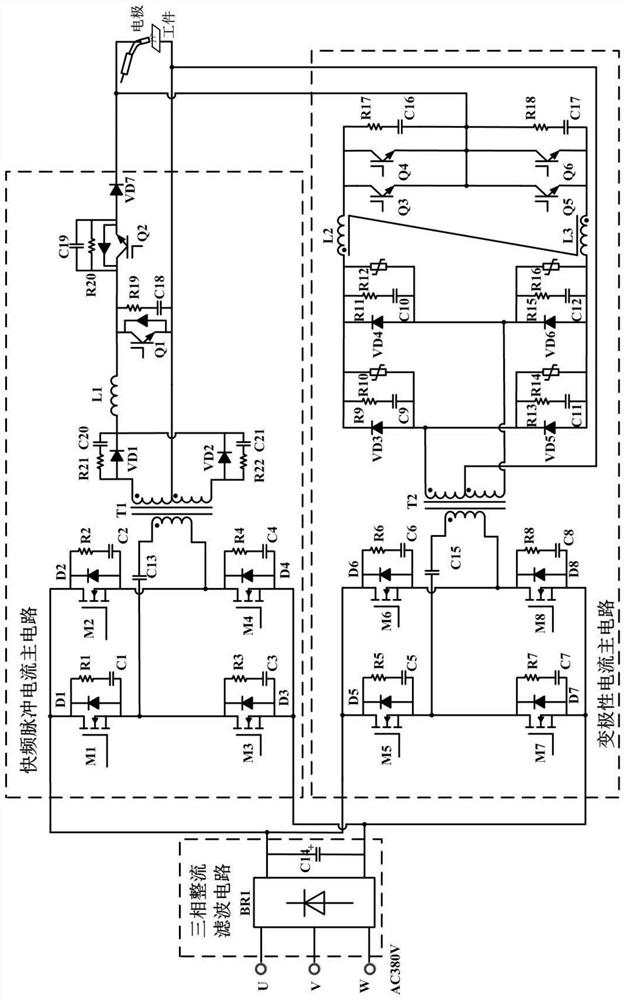

[0035]The two-way parallel power main circuit includes a three-phase rectification and filter circuit, a fast-frequency pulse current main circuit and a variable-polarity current main circuit; both the fast-frequency pulse current main circuit and the variable-polarity current main circuit include a primary inverter circuit, A high-frequency transformer and an ultra-fast recovery rectification and smoothing circuit; the fast-frequency pulse current main circuit also includes a filter inductor and a high-frequency switching circuit sequentially connected to the ultra-fast recovery rectification and smoothing circuit; The coupled inductor and the secondary inverter conversion circuit after the fast recovery rectification and smoothing circuit; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com