Aluminum alloy guide rail and welding method thereof

A technology of aluminum alloy and guide rail, applied in the field of aluminum alloy, can solve the problems of large welding deformation, low production efficiency, welding seam defects, etc., and achieve the effect of reducing welding deformation, improving production efficiency, and reducing welding seam defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

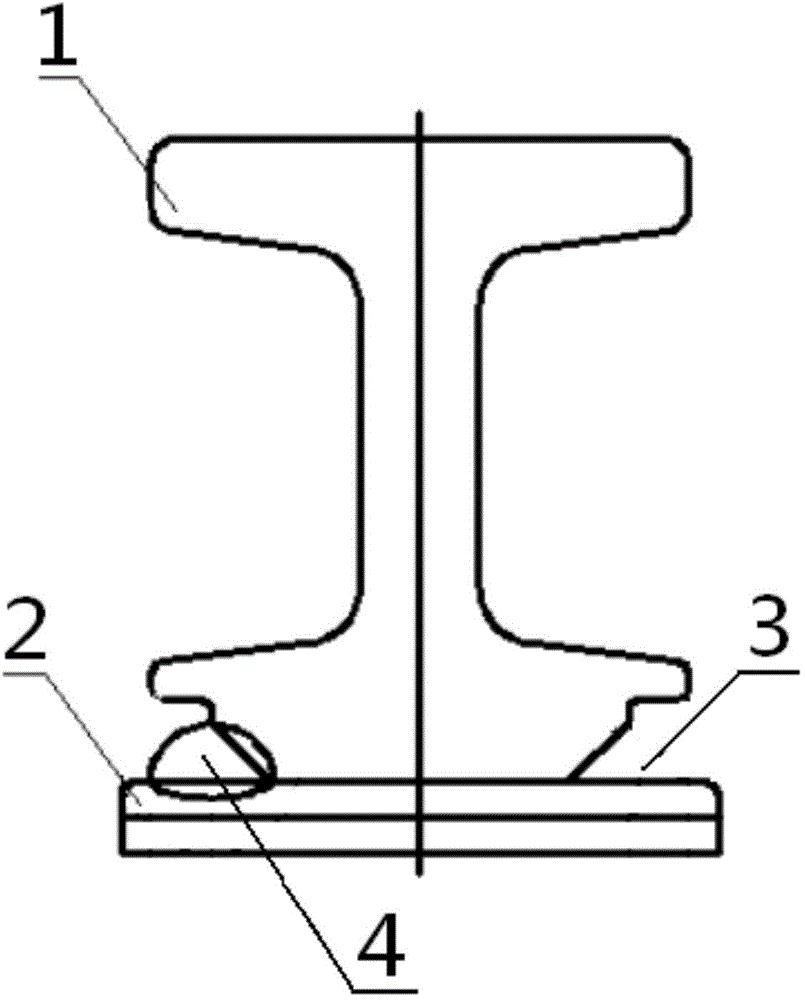

[0025] like Figure 1-3 As shown, the aluminum alloy guide rail of this embodiment includes an I-beam 1 and an aluminum-copper composite plate 2 welded and fixed on one end surface of the I-beam 1, and the aluminum-copper composite plate is welded by explosive welding.

[0026] in:

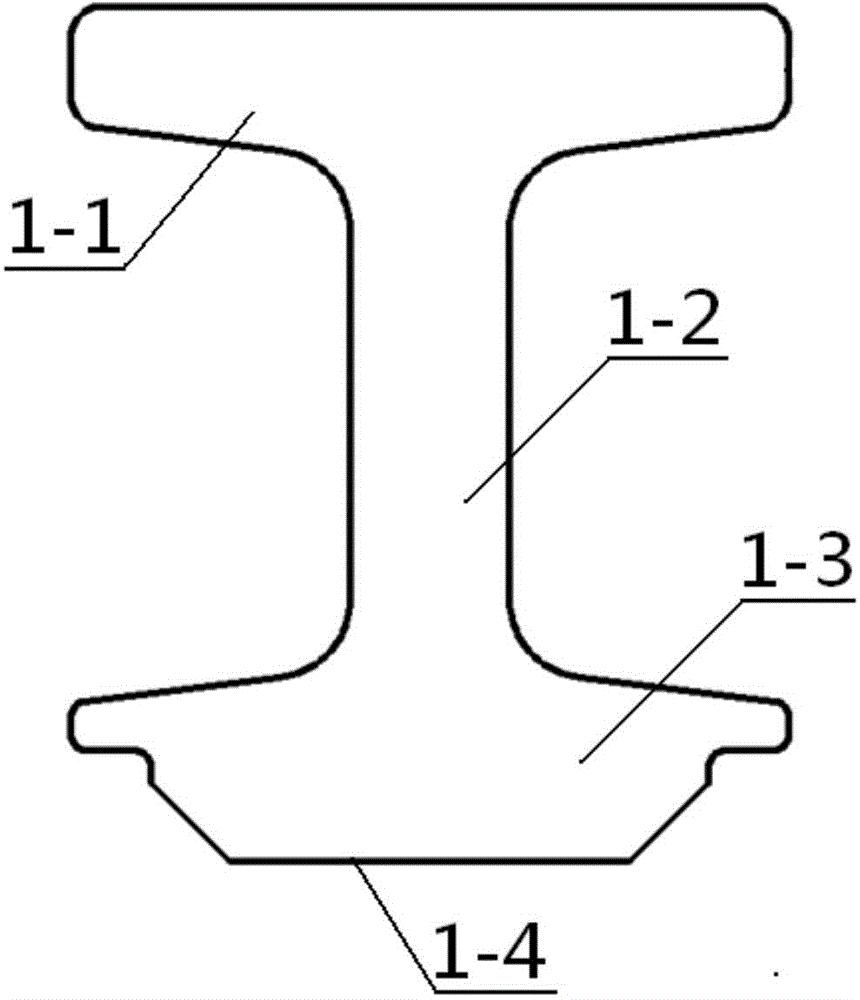

[0027] The I-beam 1 is an integrally extruded aluminum alloy profile, including a top plate 1-1, a web 1-2 and a bottom plate 1-3. The bottom plate 1-3 is in an inverted conical shape, and a platform 1-4 is provided on its lower bottom surface. On both sides of the platform 1-4, between the I-beam 1 and the aluminum-copper composite plate 2, there is a triangular welding groove 3, the height of which is 3-7mm;

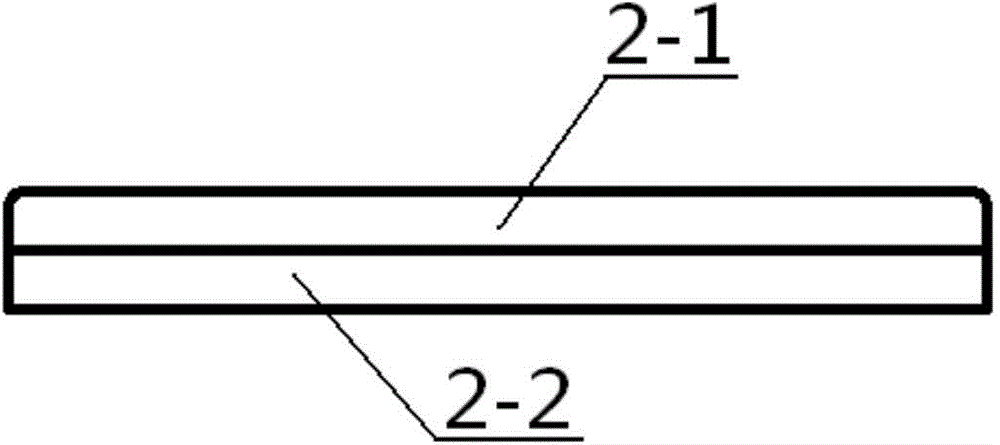

[0028] The length of the I-beam 1 and the aluminum-copper composite board 2 is 2.8-3.3m, the width of the I-beam 1 is 40-50mm, and the height is 50-60mm, the thickness of the aluminum-copper composite board 2 is 5-7mm, and the width 40-50 mm, and the thickness difference between the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com