Numerical Calculation Method for Laser Ablation with Beam Subdivision and Diffuse Reflection of Phase Interface

A numerical calculation and phase interface technology, which is applied in the field of numerical calculation of laser energy absorption and laser diffuse reflection in the process of analyzing laser ablation, can solve problems that cannot be used to study the formation process of keyholes, and cannot reflect laser incident and diffuse reflection behaviors. Can not use laser heating process flow mechanism and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with specific examples.

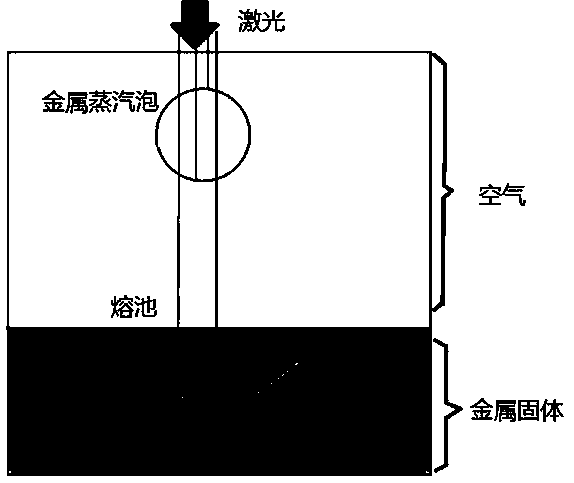

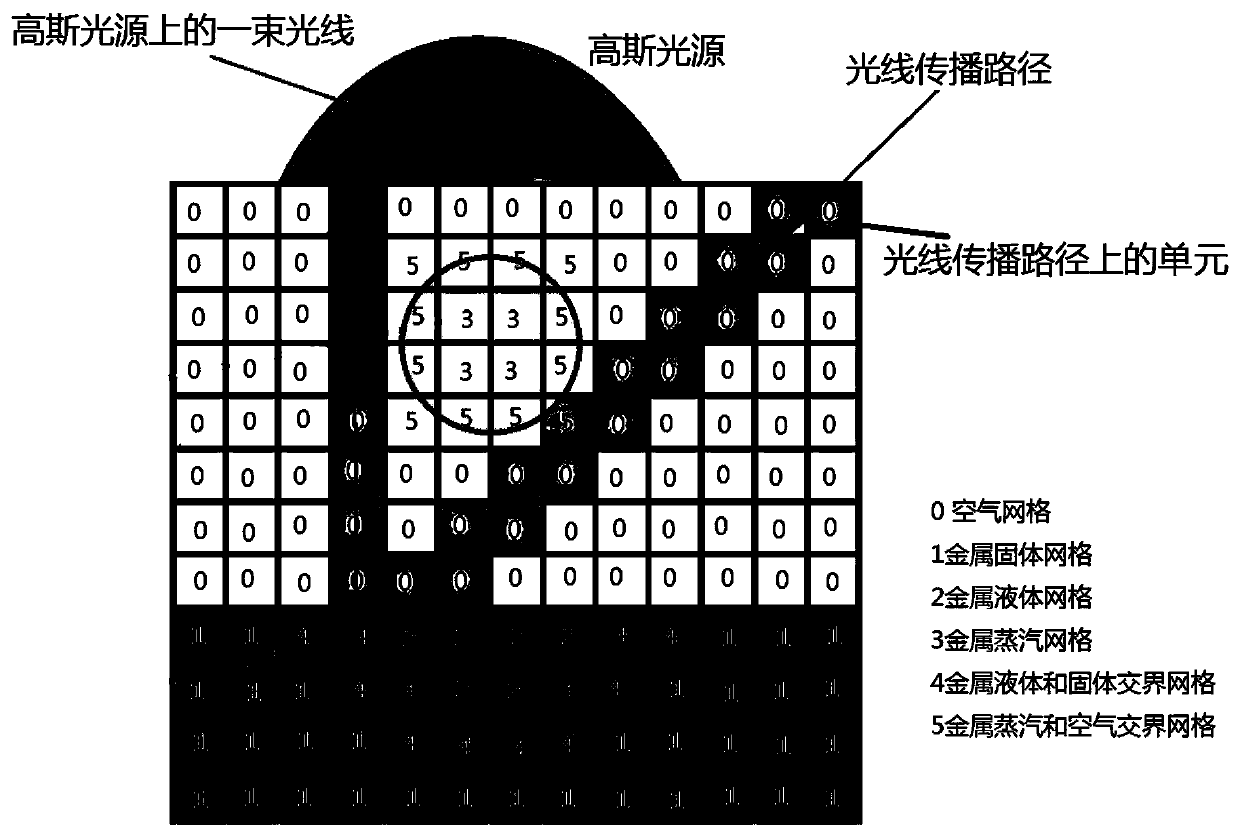

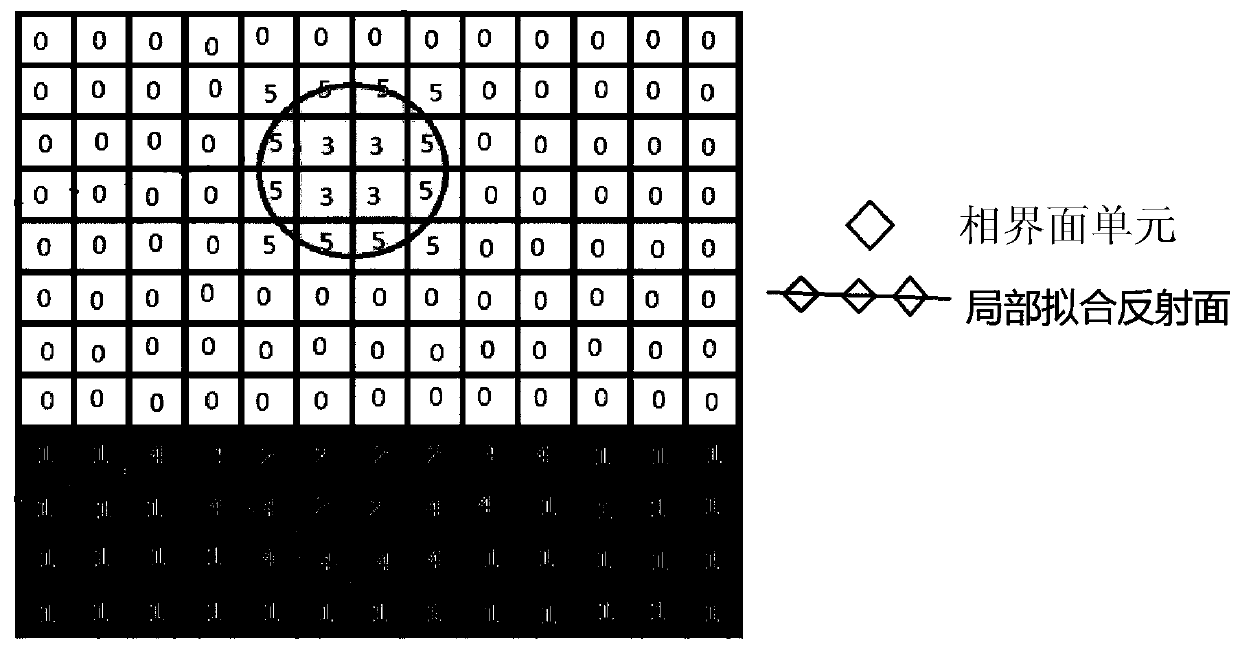

[0034] The present invention takes the laser ablation and cladding process as the object, and establishes a computational fluid dynamics model of laser ablation and cladding based on the secondary development of the fluent software by the user subroutine UDF to describe laser, metal vapor, metal Interaction between molten pool, metal substrate and assist gas. Change the simple Gaussian heat source model in the existing method, subdivide the laser beam into several independent rays, and develop the user subroutine UDF to calculate the propagation, refraction, reflection and each unit pair in the computational fluid dynamics model of each ray respectively. The absorption of laser energy to consider the heating effect of the laser on the workpiece and the environment of the workpiece. The physical model involved in the specific application is laser weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com