An integrated friction plug repair welding spindle head device

A spindle head, integrated technology, applied in the field of welding manufacturing, can solve problems such as imperfect development, and achieve the effects of a wide range of welding process parameters, a simple working principle and a fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

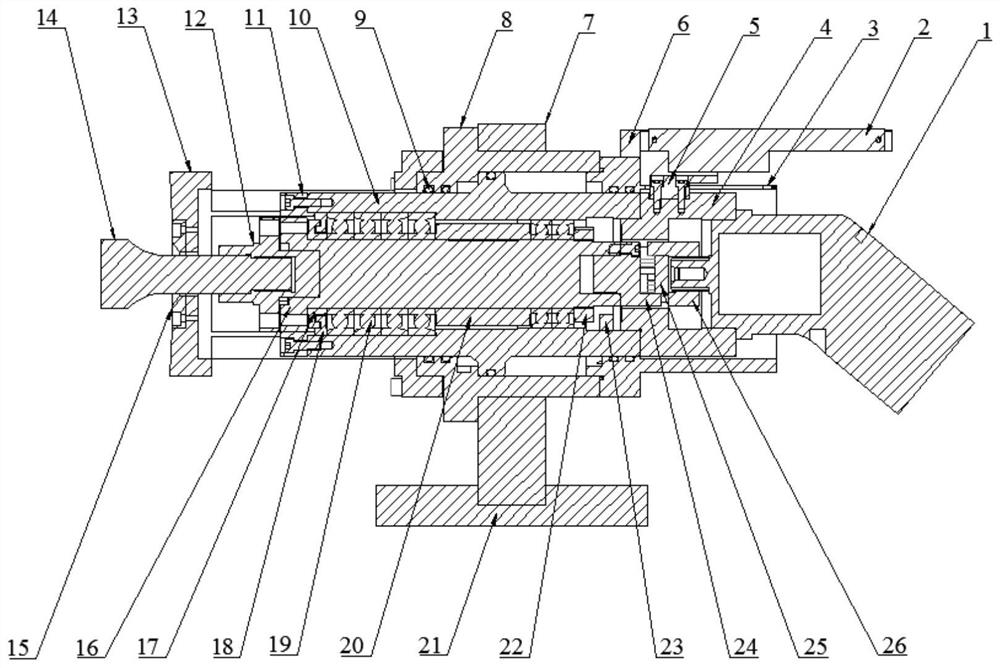

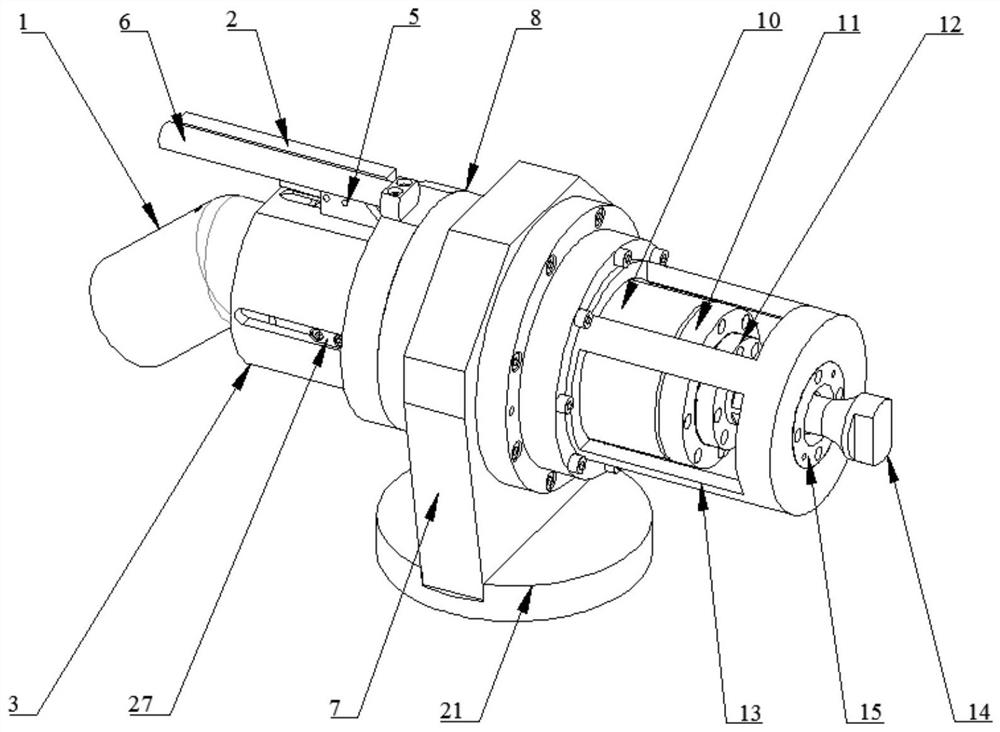

[0029] as attached Figure 1 to Figure 4 As shown, an integrated friction plug repair welding spindle head device includes a spindle head, an auxiliary support mechanism and a control system.

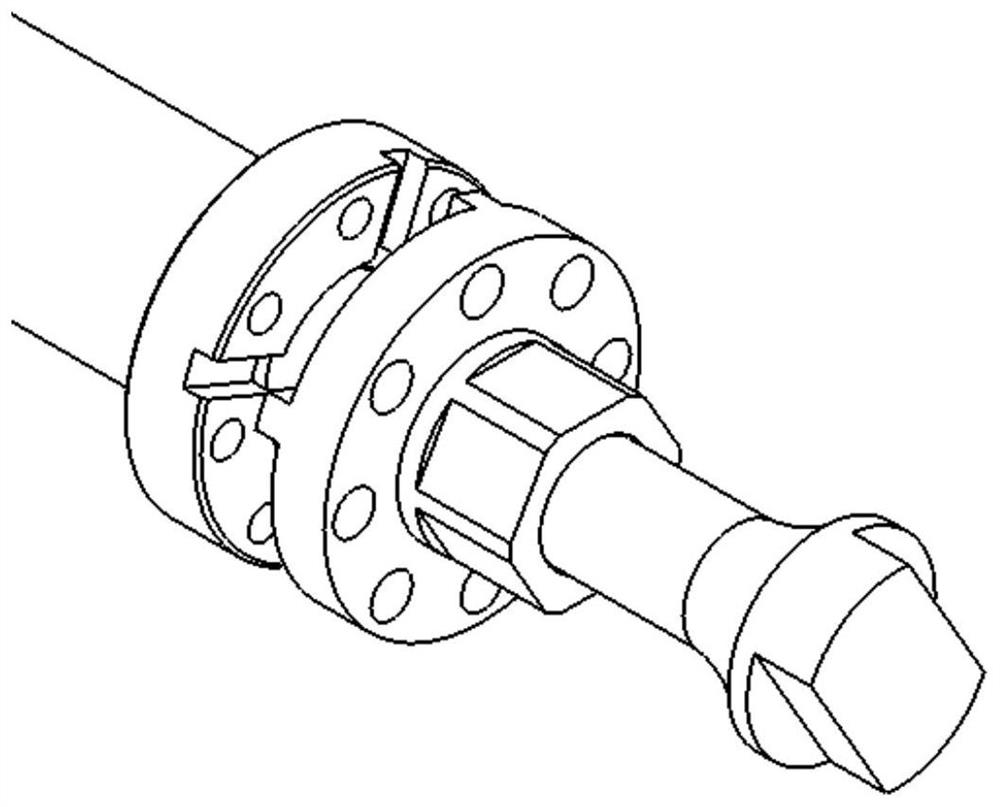

[0030] The spindle head includes a rotating shaft 16 responsible for rotation and an oil cylinder responsible for axial movement. The oil cylinder includes an outer casing 8 and a large rear cover 3 coaxially connected, and an inner casing 10 arranged in the outer casing 8 . O-rings 9 are respectively provided between the inner housing 10 and the outer housing 8 , and between the inner housing 10 and the rear large cover 3 to prevent leakage of hydraulic oil. The inner cavity of the outer shell 8 is the front cavity of the oil cylinder, and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com