Welding seam positioning device and welding method using welding seam positioning device

A positioning device and welding method technology, applied in auxiliary devices, welding accessories, welding equipment, etc., can solve problems such as weld defects, weld discontinuity, and steel plate base material damage, so as to improve the degree of automation and reduce weld defects , The effect of continuous weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

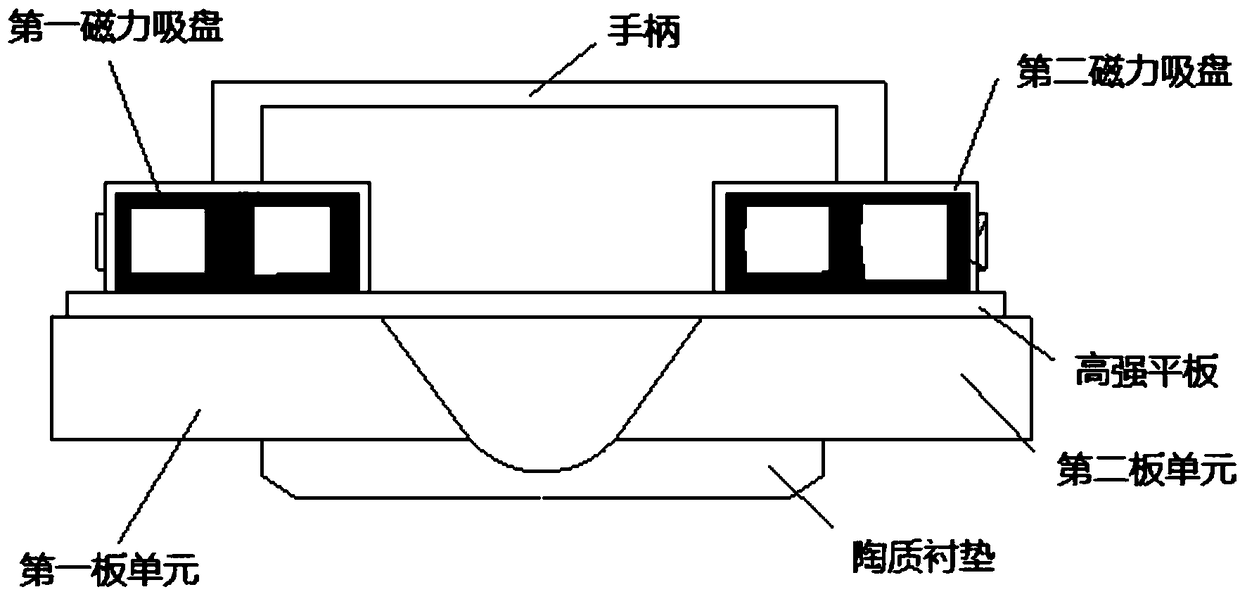

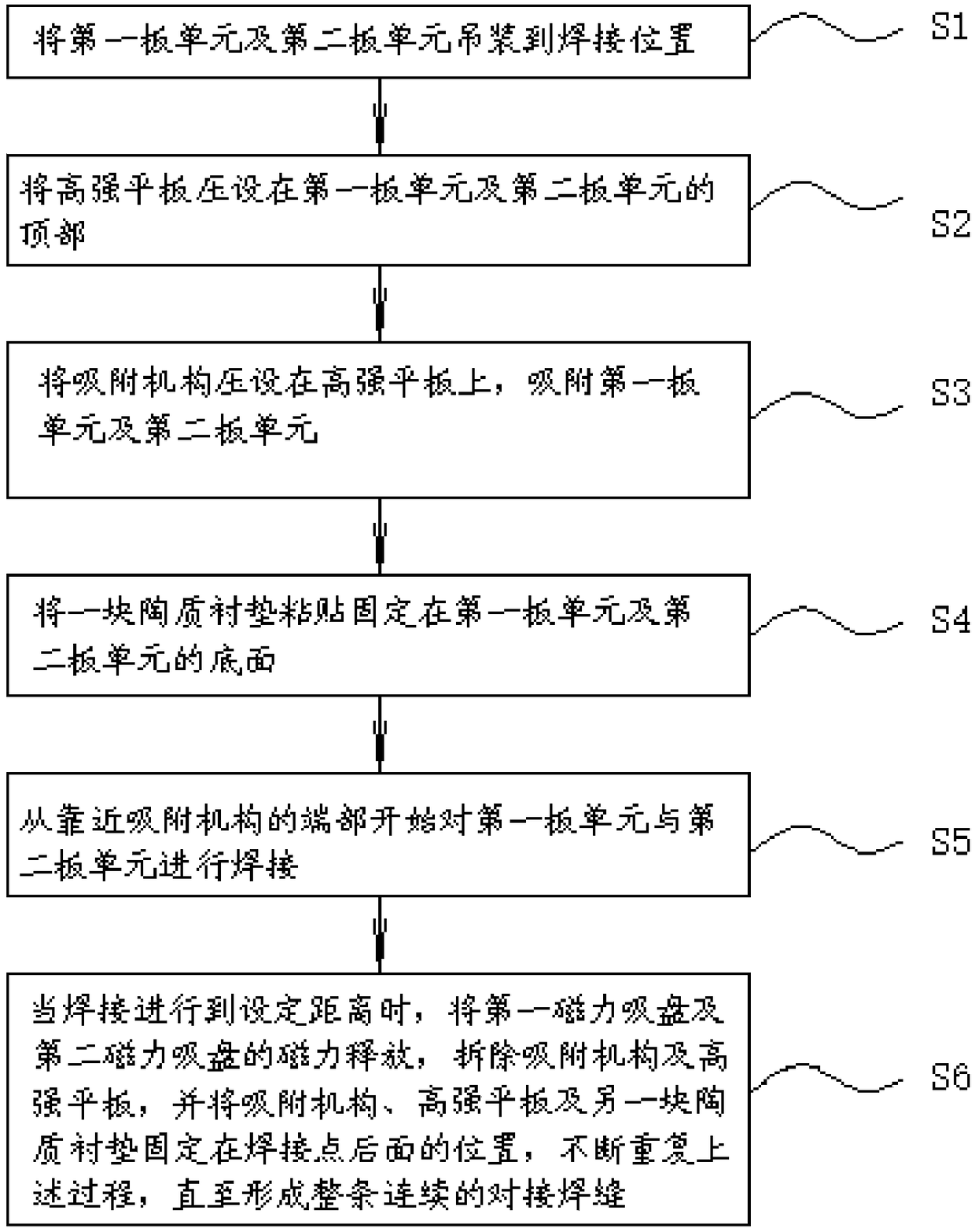

[0039] The embodiment of the present application provides a welding seam positioning device and a welding method using the welding seam positioning device, which solves or partially solves the problem of discontinuity of the weld seam caused by the assembly and positioning of the bottom plate in the prior art when the bottom plates are butt-jointed, which is easy to cause welding. Seam defects, there is a technical problem of the risk of damage to the base metal of the steel plate. By installing a weld positioning device composed of a ceramic liner, a high-strength flat plate and an adsorption mechanism to replace the horse plate for welding positioning, the use of the horse plate is avoided and the weld seam is guaranteed. , effectively reducing weld defects, avoiding the risk of damage to the base metal of the steel plate, and significantly improving the technical effect of automation.

[0040] See attached figure 1 , The present application provides a welding seam positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com