Processing technology for longitudinal-seam narrow-gap welding groove of thick-walled barrels

A technology for welding grooves and processing techniques, which is applied to metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of large demand for welding materials, large groove angles, and large labor loads, and achieve good welding effects and reduce Groove angle, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

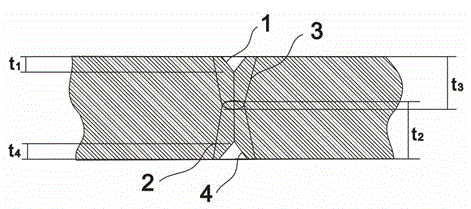

[0038] Take the longitudinal seam processing of the regulator cylinder as an example:

[0039] The wall thickness of a single barrel section of the voltage stabilizer is 119mm, the length of each barrel section is 3396±2mm, and the inner diameter is φ2134mm. The processing steps of the longitudinal seam joint groove of the barrel are as follows:

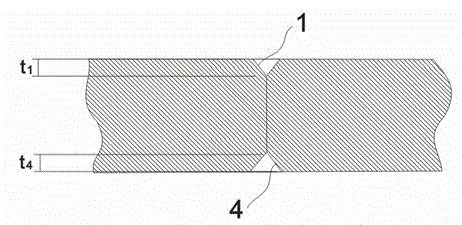

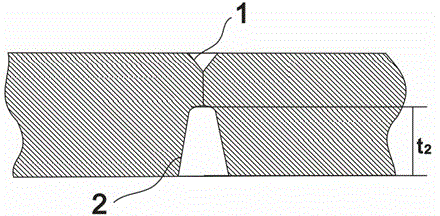

[0040] 1. If figure 2 As shown, hang the barrel joint on the plate rolling machine, do not grind the bevel for product welding before the barrel is rolled and closed, only polish the No. The No. 4 V-shaped shallow groove 4 on the inner side acts as a guide for the grinding wheel; other areas are not ground.

[0041] The V-shaped angle of No. 1 V-shaped shallow groove 1 is 40-45 degrees, and the grinding depth is t 1 18-20mm.

[0042] The V-shaped angle of No. 4 V-shaped shallow groove 4 is 40-45 degrees, and the grinding depth is t 4 9-11mm.

[0043] 2. The barrel section is rolled and closed; and on the plate rolling machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com