Double sides double arc welding method

A double-sided, double-arc, welding method technology, applied in welding equipment, arc welding equipment, edge parts of workpieces, etc., to reduce welding deformation, shorten engineering construction period, and ensure welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

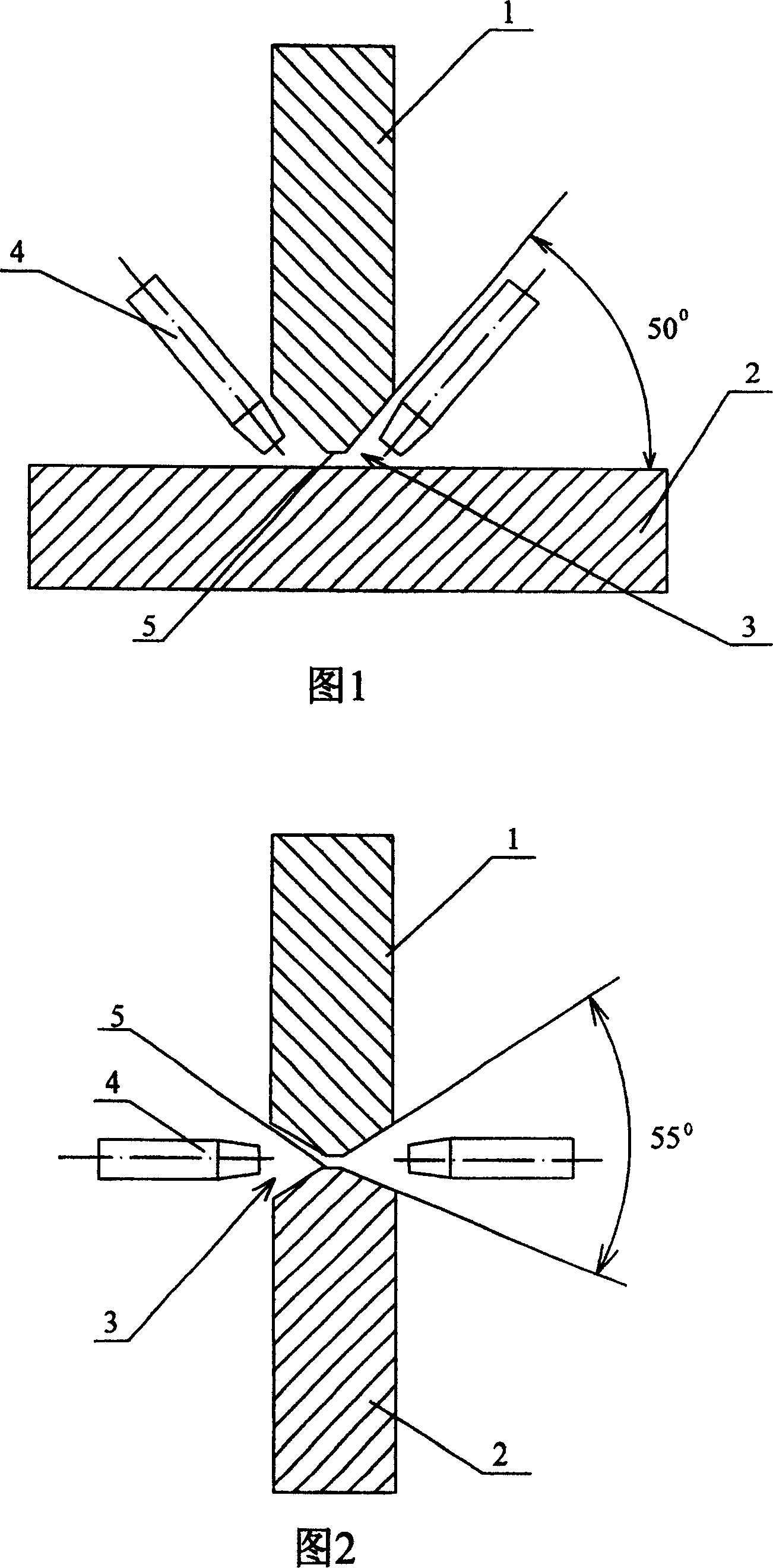

[0042] For the double-sided double-arc welding method, the fillet seam welding process is as follows: both workpiece 1 and workpiece 2 to be welded use steel plates with a thickness of 35 mm. The double-sided symmetrical welding groove 3 is processed on the workpiece 1, and the blunt edge 5 of the tip is 1mm. The type of the double-sided symmetrical welding groove is shown in Figure 1. 50°, and then use the special tooling fixture to position, the gap between the positioned workpiece 1 and workpiece 2 is not greater than 2mm. Before welding, grind the double-sided symmetrical welding groove 3 and the surfaces on both sides within 30 mm, and clean the groove and the surfaces on both sides of the groove with acetone. Two welders use two welding torches 4 on two welding machines to start arcs on both sides of the workpiece 1 for flat fillet welding. First, double-sided double-arc bottom welding is used. Connect to direct current, positive polarity, welding current 180A. Gas tun...

Embodiment 2

[0044] Double-sided double-arc welding method, the implementation of the butt seam welding process is as follows: the workpiece 1 and the workpiece 2 to be welded are both steel plates with a thickness of 40mm, and the double-sided symmetrical welding groove 3 is processed on the workpiece 1 and workpiece 2. The blunt edge 5 of the upper part is 0.8mm, and the type of double-sided symmetrical welding groove is shown in Figure 2. After the assembly of the workpiece 1 and the workpiece 2, the angle between both sides is 55°, and then the special tooling fixture is used for positioning. The gap between it and workpiece 2 is 1 mm. Before welding, grind the double-sided symmetrical welding groove 3 and the surfaces on both sides within 30 mm, and clean the groove and the surfaces on both sides of the groove with acetone. Two welders use two torches 4 on two welding machines to start arcs on both sides of the workpiece for vertical welding respectively. First, double-sided double-ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com