Narrow-gap adjustable device and cosmetic welding adjustable device for improving bearing capacity of butt joints

A technology for bearing capacity and butt joints, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as surface cracks, low machining efficiency, and no special equipment for butt joint bearing capacity, etc., to achieve grain refinement , Improve welding quality, wide production adaptability effect

Inactive Publication Date: 2011-06-15

HARBIN INST OF TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Generally, the required joint size is obtained by machining. Considering that the machining efficiency is low and it is easy to cause some potential surface cracks and other deficiencies, therefore, during the welding seam forming process, welding impact rolling should be carried out to improve the butt joint. Joint bearing capacity, during the welding process, a specially designed and adjustable device is used to act on the weld metal of the butt joint, but there is no provision in the prior art for improving the bearing capacity of the butt joint (joint with reinforcement) special equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

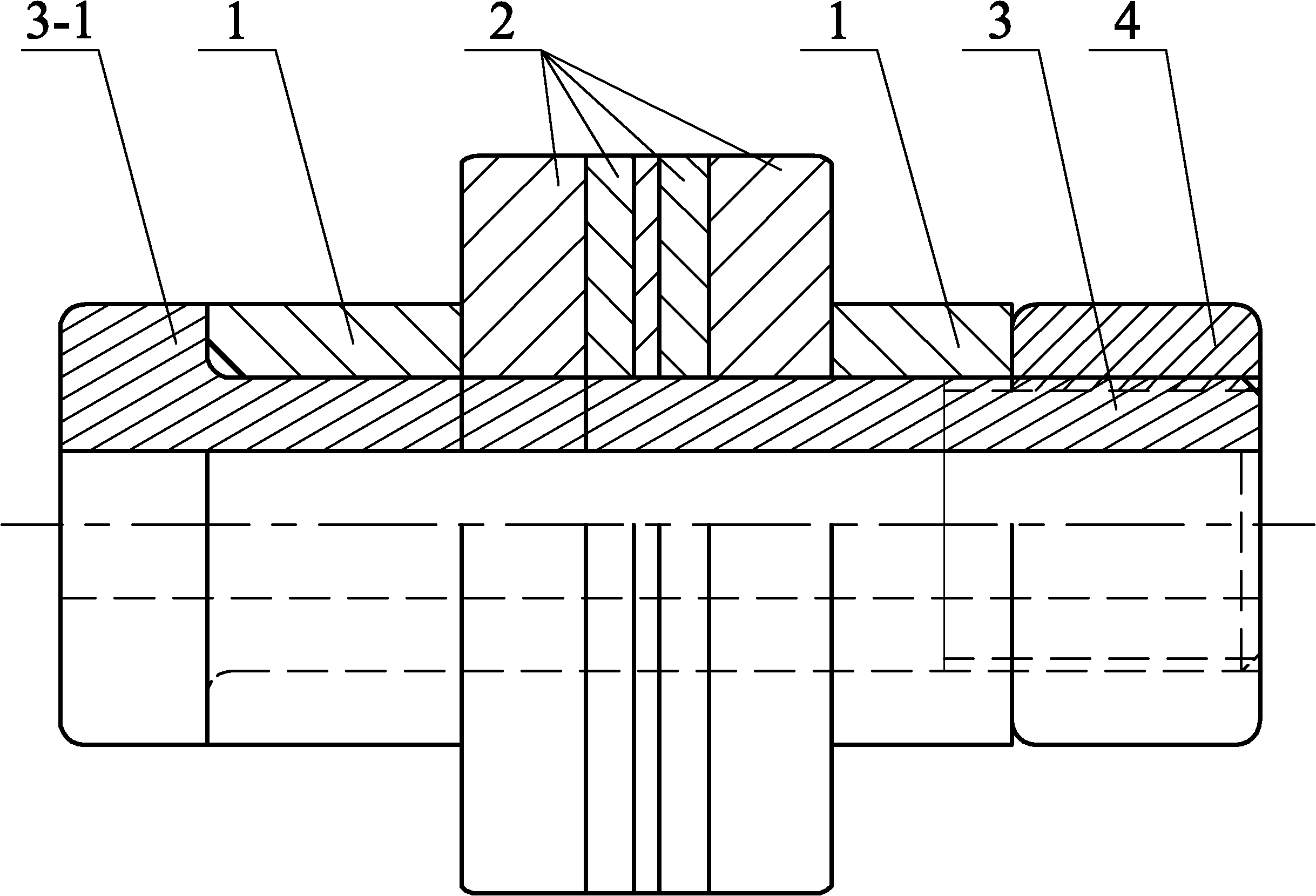

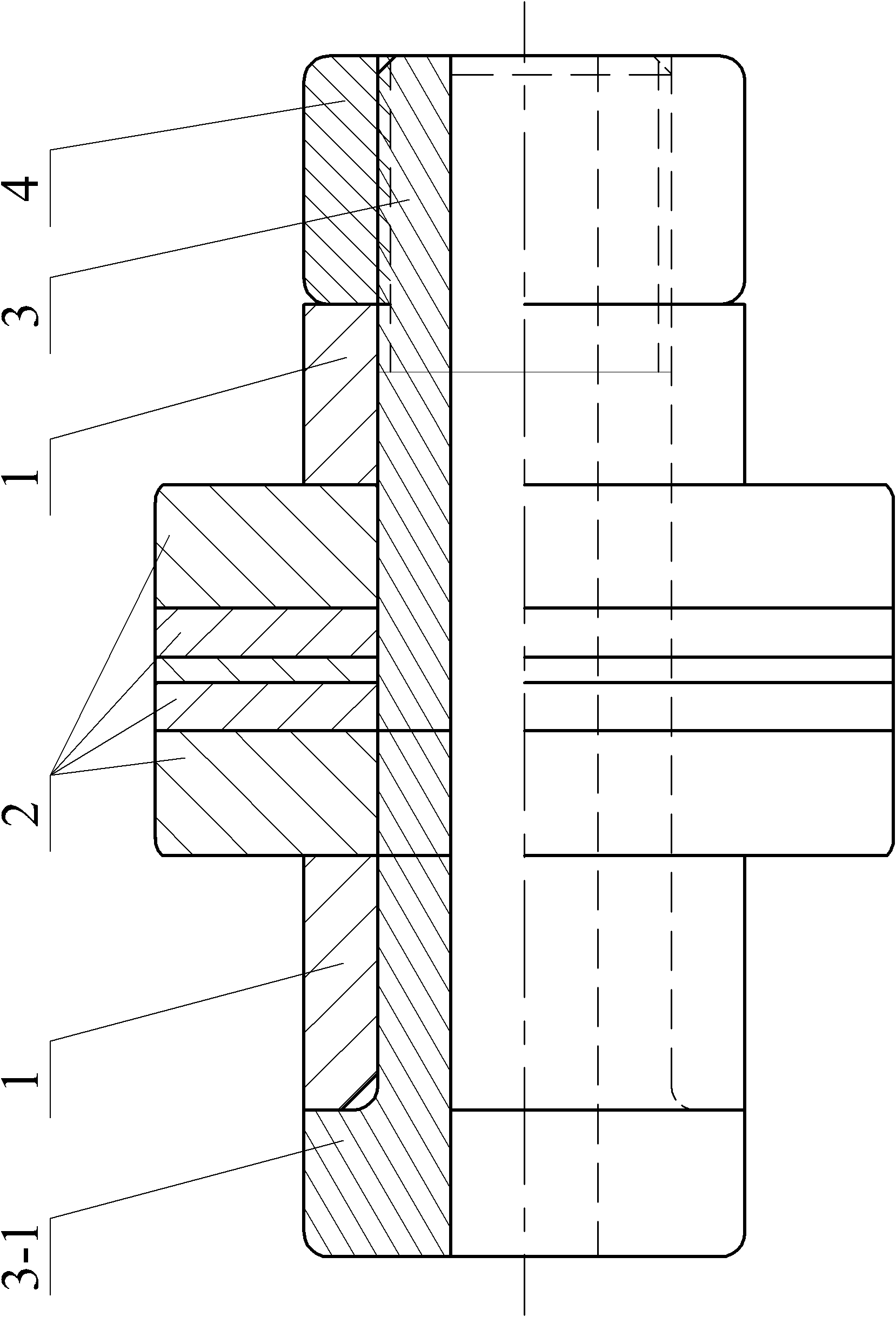

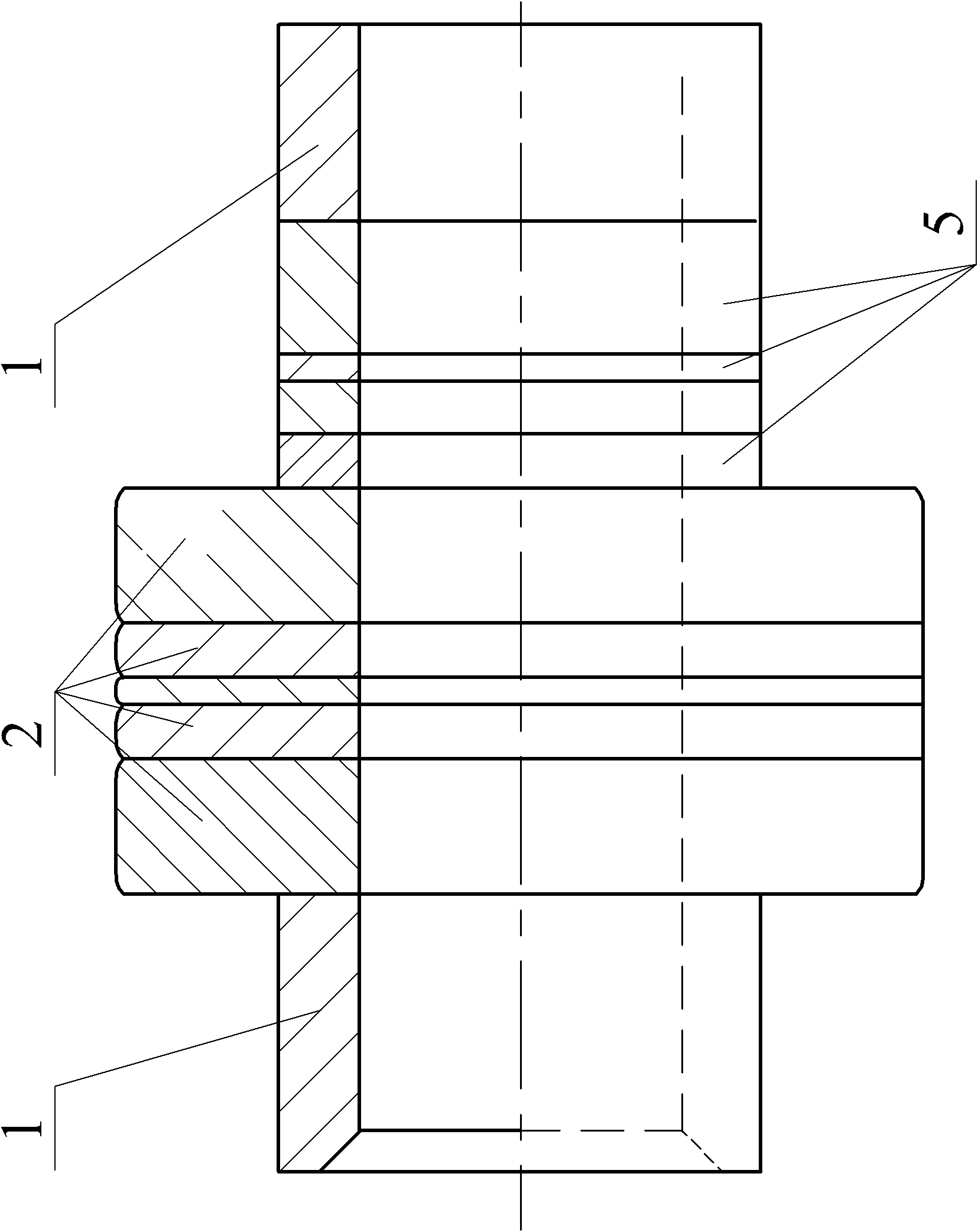

Login to View More Abstract

The invention improves a narrow-gap adjustable device and a cosmetic welding adjustable device for improving the bearing capacity of butt joints, which belong to the field of a welding technique and can acquire high-quality butt joints with good bearing capacity. A fastener is used for axially pressing and fixedly mounting a group of annular sheets with different thicknesses and two wheel rim bodies on a shaft sleeve; and the two wheel rim bodies and the group of annular sheets with different thicknesses between the two wheel rim bodies are arranged coaxially, and the surface profile of the integration of the wheel rim bodies and the annular sheets is matched with the surface shape of the weld reinforcement of the butt joints. The narrow-gap adjustable device is convenient in operation, and has the advantages of high efficiency, high adaptability and the like; and the device with the adjustability can shape the butt joints which have different thicknesses and are made of different materials during welding. Under the sequential action of the narrow-gap adjustable device and the cosmetic welding adjustable device, butt joints with less weld defects, fine grains, low welding residual stress, desired shape and size, and high bearing capacity can be manufactured.

Description

Narrow gap adjustable device and cover welding adjustable device to improve the bearing capacity of butt joints technical field The invention relates to an adjustable device for improving the bearing capacity of a butt joint, which belongs to the technical field of welding. Background technique During the welding process, due to the local metal melting and rapid cooling during the formation of the weld, the material of the weld area changes, and at the same time, the weld area often produces large residual tensile stress and is prone to defects such as pores and microcracks, which make the weld area Often become the weak link of the joint. Therefore, the purpose of improving the bearing capacity of the joint can be achieved by increasing the bearing capacity of the weak zone of the weld. For thick plate welding, narrow gap, multi-layer and multi-pass welding are generally used. The surface of the weld is prone to defects such as pores, and the defects close to the surfa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K37/00

Inventor 杨建国王涛方洪渊刘雪松董志波黎明张敬强王佳杰周立鹏

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com