Steel pipe end rounding device

A pipe end and steel pipe technology, which is applied in the field of steel pipe end rounding devices, can solve the problems of steel pipe surface indentation, heavy workload, and low efficiency, and achieve the effects of high work efficiency, round and beautiful appearance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

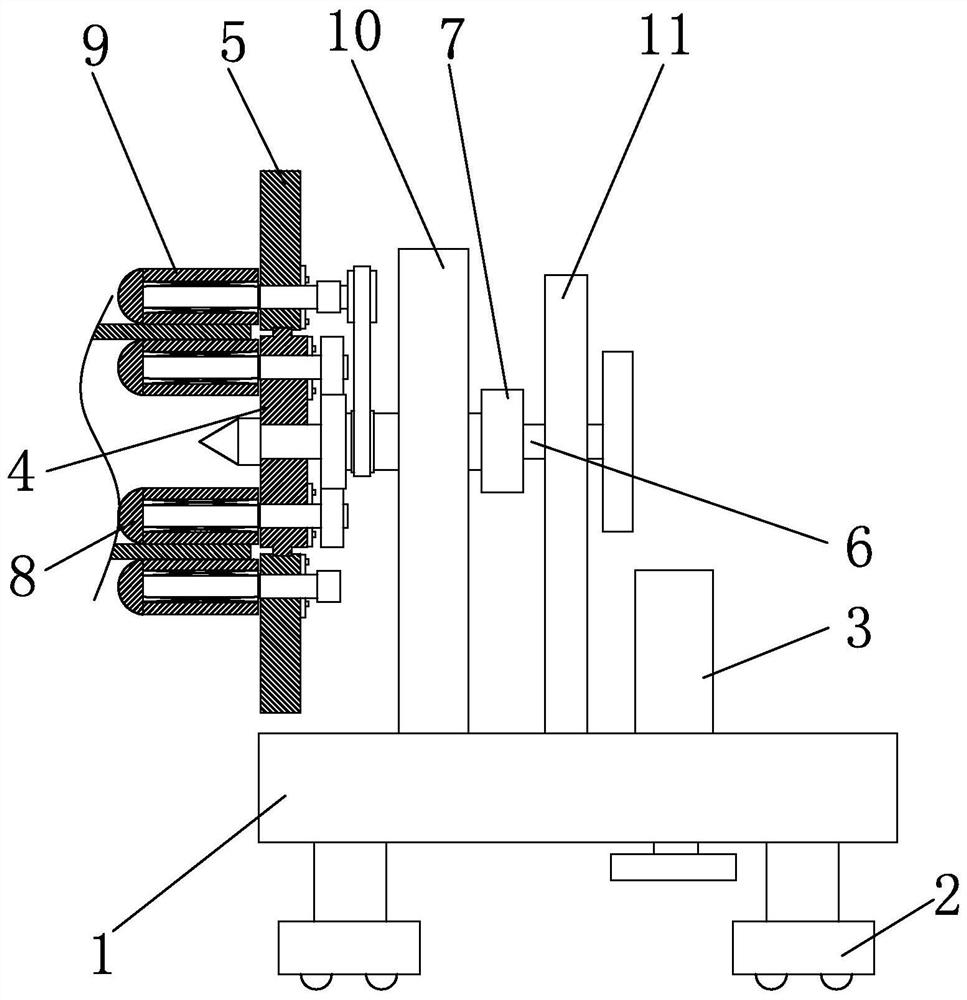

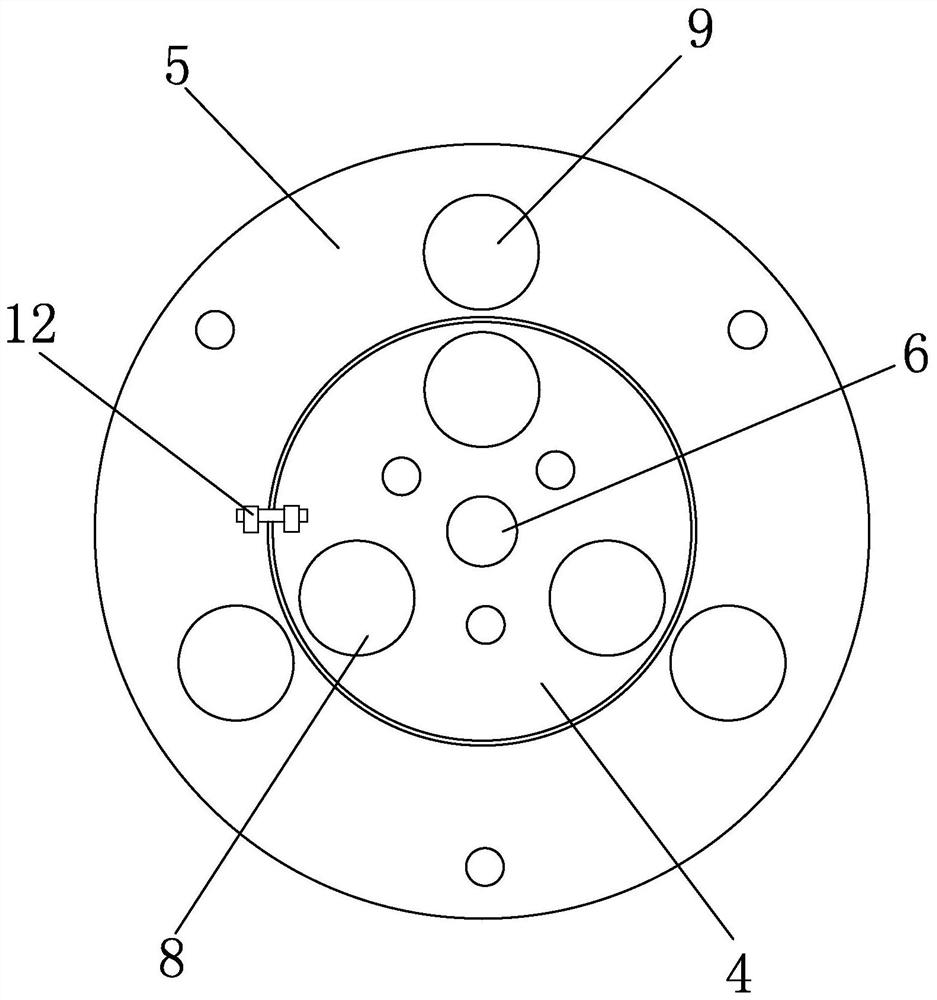

[0029]Combinefigure 1 withfigure 2, The present invention is a rounding device for the end of a steel pipe, which is used for the rounding operation of the end of the steel pipe. The rolling rounding method is adopted, and the steel pipe does not need to be clamped and fixed multiple times, and the rounding operation can be completed at one time. The present invention includes a movable seat 1, a supporting component installed on the movable seat 1, and a round mechanism fixed and movably arranged on the movable seat 1 through the supporting component. Generally, in order to facilitate the movement of the movable seat 1, a T-shaped slider 2 is installed under the movable seat 1, and a ball is provided at the bottom of the T-shaped slider 2. In the present invention, the T-shaped sliding block 2 is installed in the T-shaped chute and moves along the T-shaped chute. The support assembly is mainly used to install and fix the full circle mechanism.

[0030]The full circle mechanism is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com