Automatic ultrasonic impact device for girth weld

An ultrasonic impact, girth weld technology, applied in the field of metal welding, can solve the problems of high labor intensity, low production efficiency, high difficulty, etc., achieve simple installation and disassembly steps, improve post-weld processing efficiency, and reduce weld defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

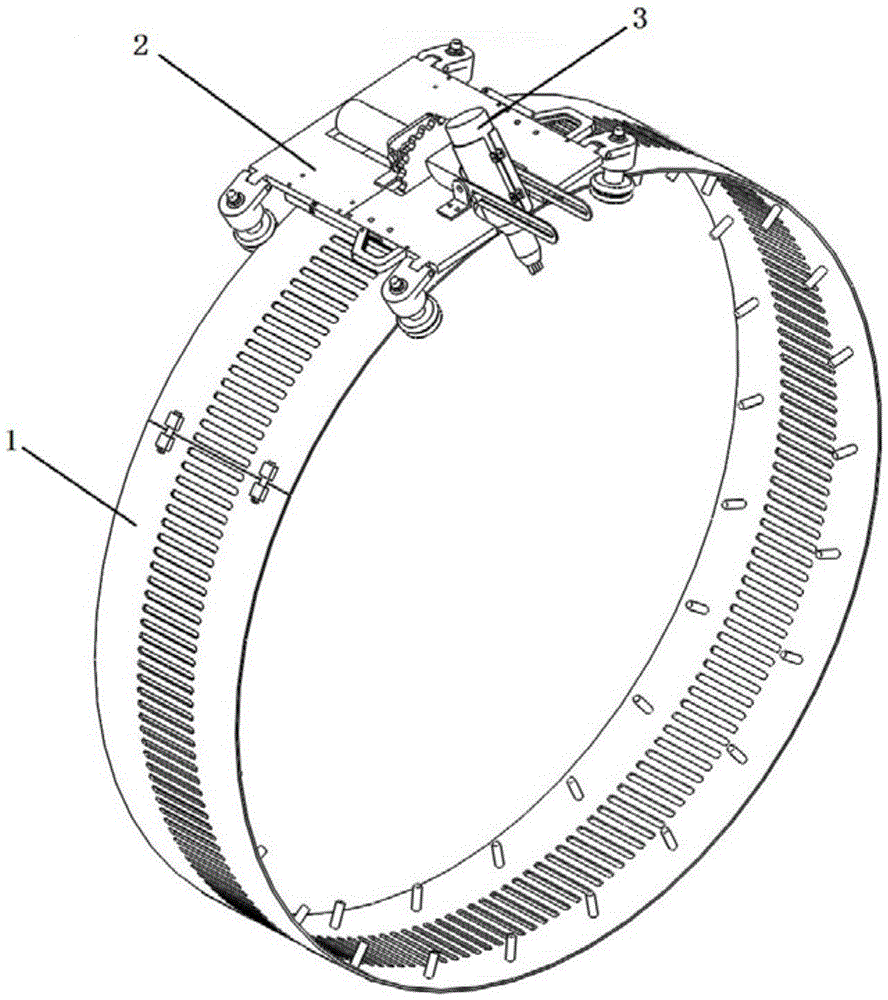

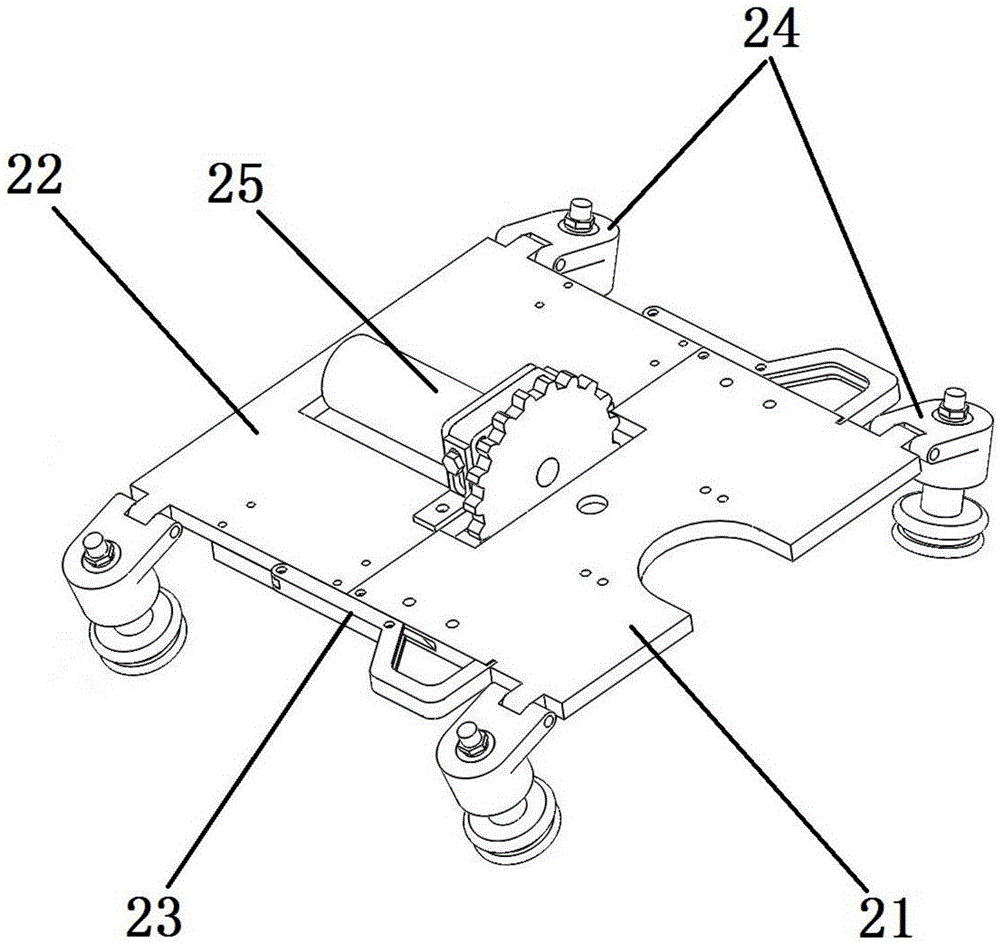

[0021] like figure 1 As shown, the automatic ultrasonic impact device for girth weld includes: ring guide rail 1, running mechanism 2, and stress relief mechanism 3; ring guide rail 1 surrounds and is fixed on the outside of the pipeline or pressure vessel, and is used to support the running mechanism 2; the running mechanism 2 is installed On the circular guide rail 1, circular motion can be made along the circular guide rail 1; the stress relief mechanism 3 is fixed on one side of the traveling mechanism 2, driven by the traveling mechanism 2, ultrasonic shock stress relief treatment can be performed on the welding toes on both sides of the girth weld respectively .

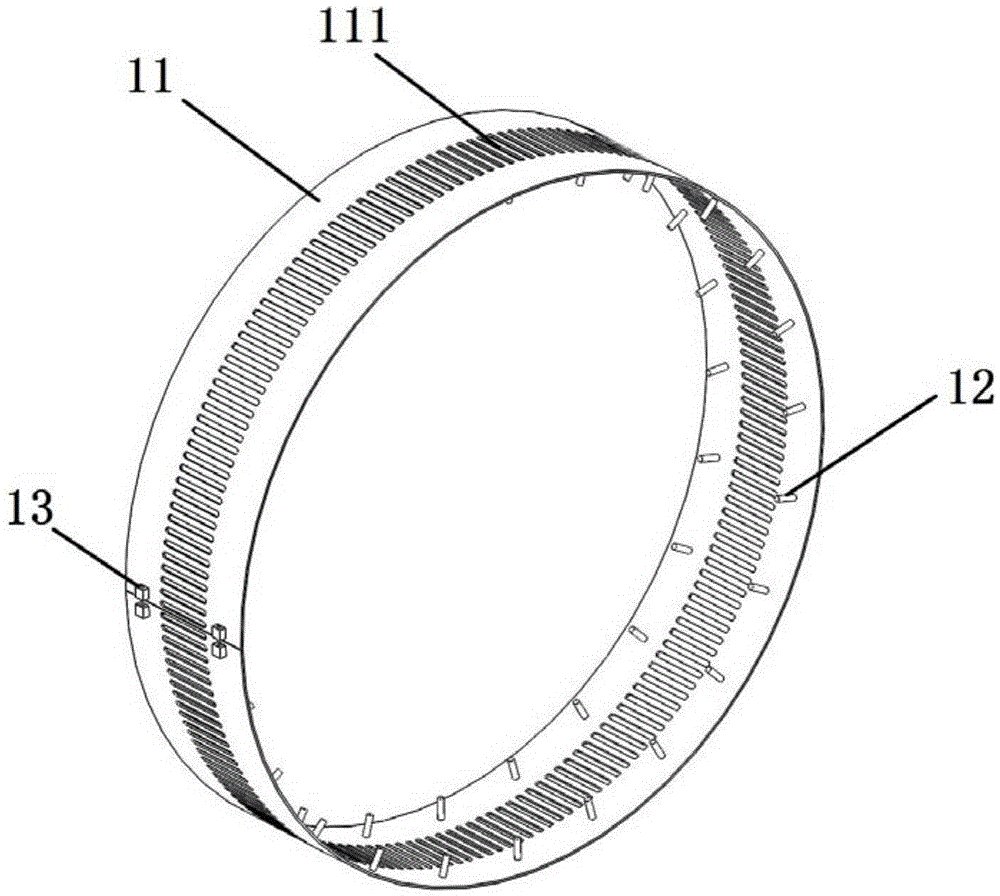

[0022] like figure 2 As shown, the annular guide rail 1 includes: a guide rail ring 11, a support stud 12, and a tension block 13; the guide rail ring 11 is a ring structure rolled from an elastic thin plate, and the middle part of the thin plate is provided with guide rail ring slots 111 at equal intervals. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com