Welding technology of fully-enclosed aluminum alloy anti-roll multifunctional cabinet

A multi-functional cabinet and welding process technology, applied in the field of aluminum alloy welding, can solve the problems of unfavorable energy saving and emission reduction, the corrosion resistance cannot meet the requirements, and the weight of the anti-rolling beam is large, so as to improve the incomplete sealing and improve the rain resistance. Snow ability, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below.

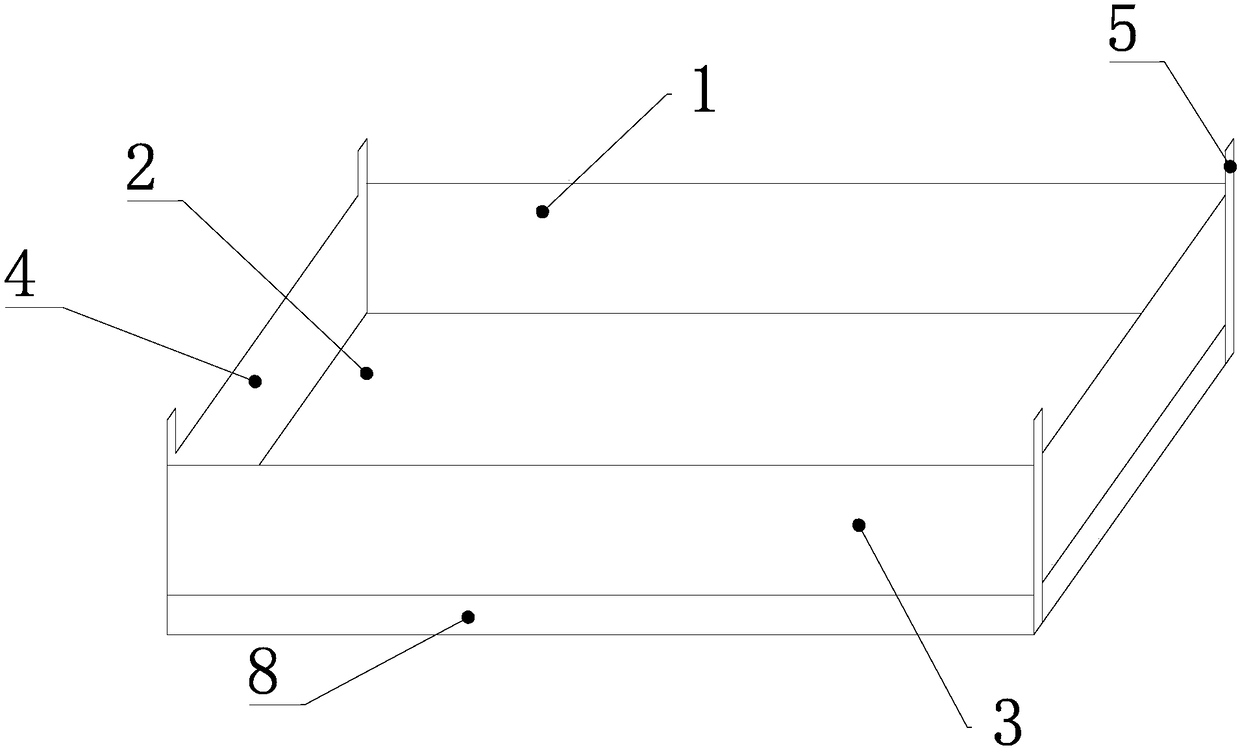

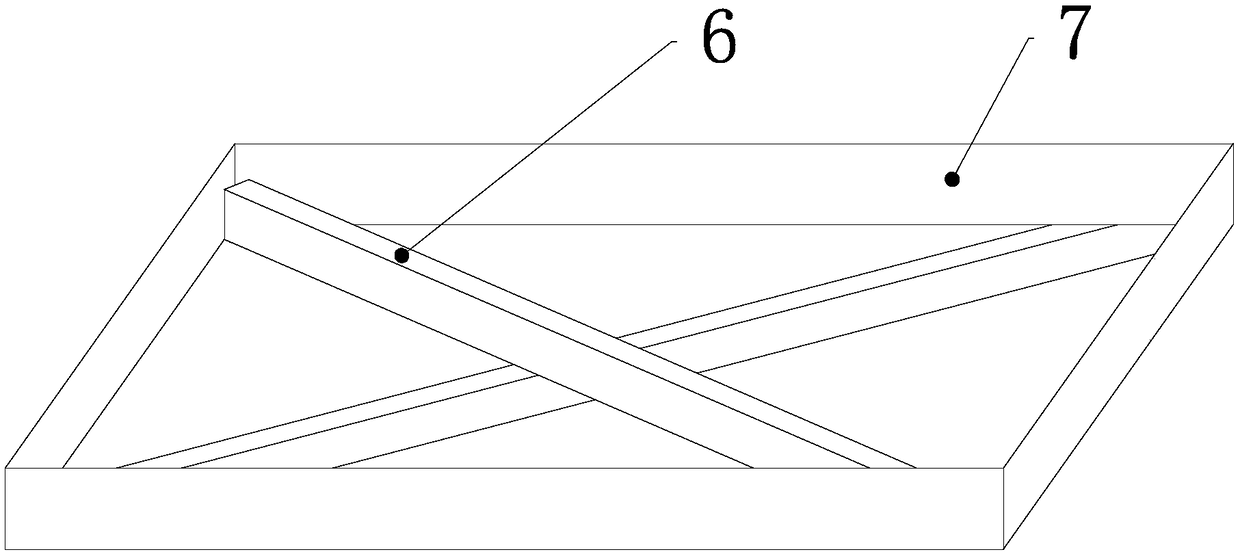

[0023] The reference signs in the drawings of the description include:

[0024] Top plate 1, bottom plate 2, rear plate 3, side plate 4, lug plate 5, rib plate 6, door plate 7, bottom profile 8.

[0025] Such as Figure 1~2 The welding process of the fully enclosed aluminum alloy anti-roll multifunctional cabinet is shown. The anti-roll multifunctional cabinet is made of 5052-H32 anti-rust aluminum plate, and the thickness of the anti-rust aluminum plate is 2mm. The welding equipment is Rpanasonic YC-300BP Panasonic electric welding machine, the shielding gas is Ar gas, the welding material used is aluminum welding wire Er 5356, and the diameter of the aluminum welding wire is 2.4mm. The anti-roll multifunctional cabinet includes a bottom plate 2, a top plate 1 and a rear plate 3 fixedly installed on the front and rear sides of the bottom plate 2 respectively, and side plates 4 fixedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com