A cylindrical full penetration submerged arc automatic welding method without root cleaning

A submerged arc automatic welding and automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as low welding efficiency, achieve stable welding quality, solve the effect of large welding material consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

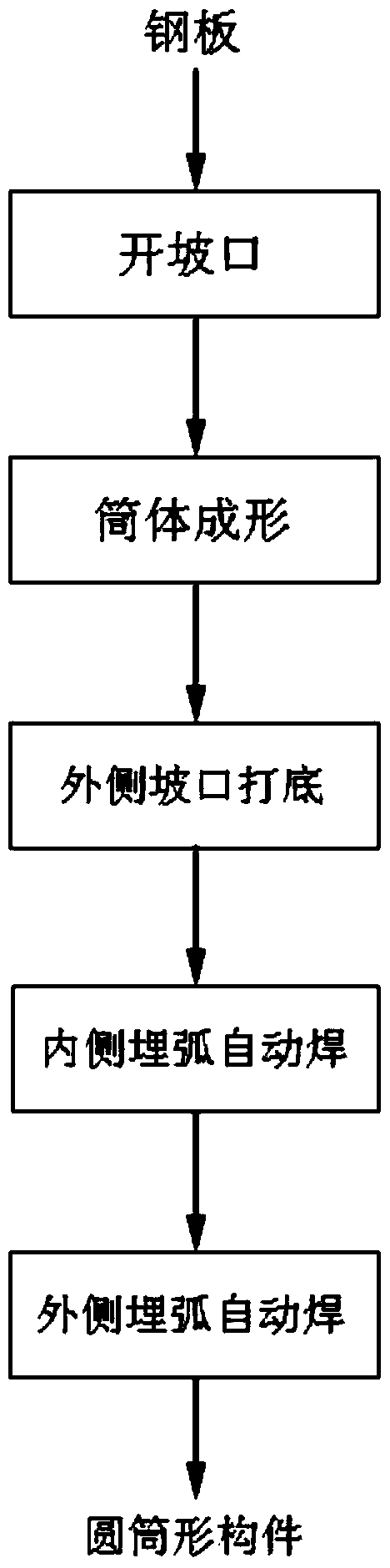

[0046] like figure 1 , 2 As shown in and 6, the welding process parameters and steps are as follows:

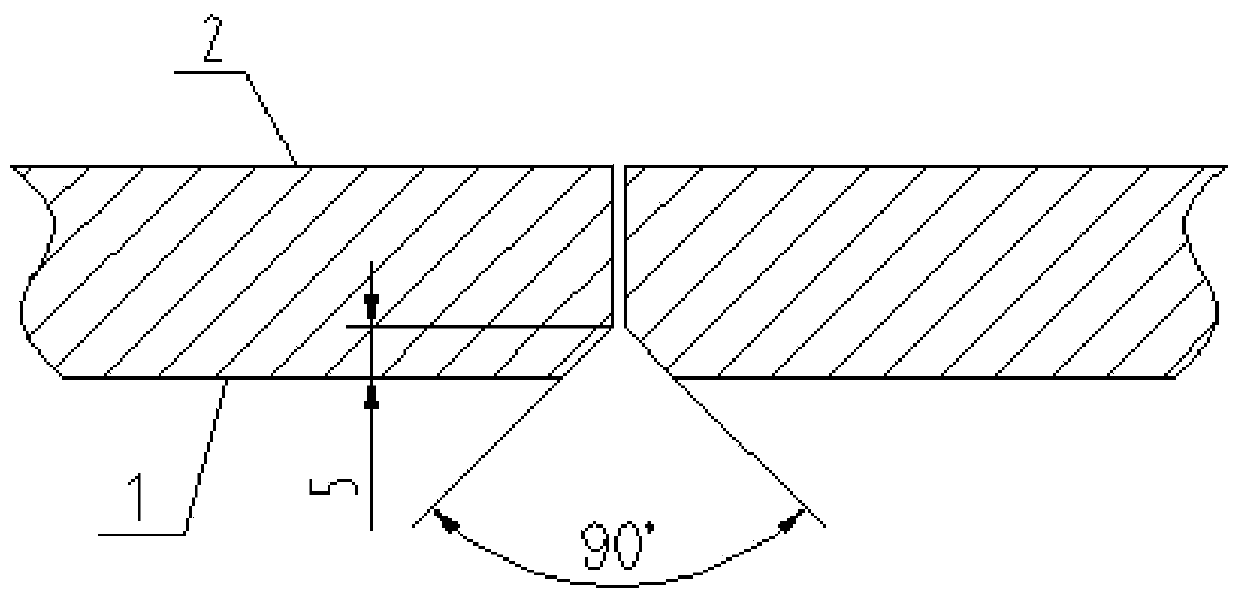

[0047] S100: Cut the material according to the requirements, and then make a one-way groove with an angle of 45±2° and a depth of 4mm on the long side of the steel plate against the outside of the cylinder (that is, the thickness of the blunt side is 10mm);

[0048] S200: Roll the above-mentioned beveled steel plate according to the requirements of φ4300 and the misalignment amount is not greater than 1mm and the weld gap is not greater than 0.5mm to form a cylinder and form a V-shaped weld on the outer side;

[0049] S250: Position the gaps on the outer side of the forming cylinder for manual arc spot welding at intervals of 500mm, and then clean up the height of the welding points to be lower than the height of the submerged arc welding wire, as well as weld corrosion, scale, and sundries.

[0050] S300: For the outer groove of the longitudinal gap of the formed cylinder,...

Embodiment 2

[0055] like figure 1 , 2 As shown in and 6, the welding process parameters and steps are as follows:

[0056]

[0057] S100: Cut the material according to the requirements, and then make a one-way groove with an angle of 45±2° and a depth of 6mm on the long side of the steel plate against the outside of the cylinder (that is, the thickness of the blunt side is 14mm);

[0058] S200: Roll the above-mentioned beveled steel plate according to the requirements of φ4300 and the misalignment amount is not greater than 1mm and the weld gap is not greater than 0.5mm to form a cylinder and form a V-shaped weld on the outer side;

[0059] S250: Position the gaps on the outer side of the forming cylinder for manual arc spot welding at intervals of 500mm, and then clean up the height of the welding points to be lower than the height of the submerged arc welding wire, as well as weld corrosion, scale, and sundries.

[0060] S300: For the outer groove of the longitudinal gap of the form...

Embodiment 3

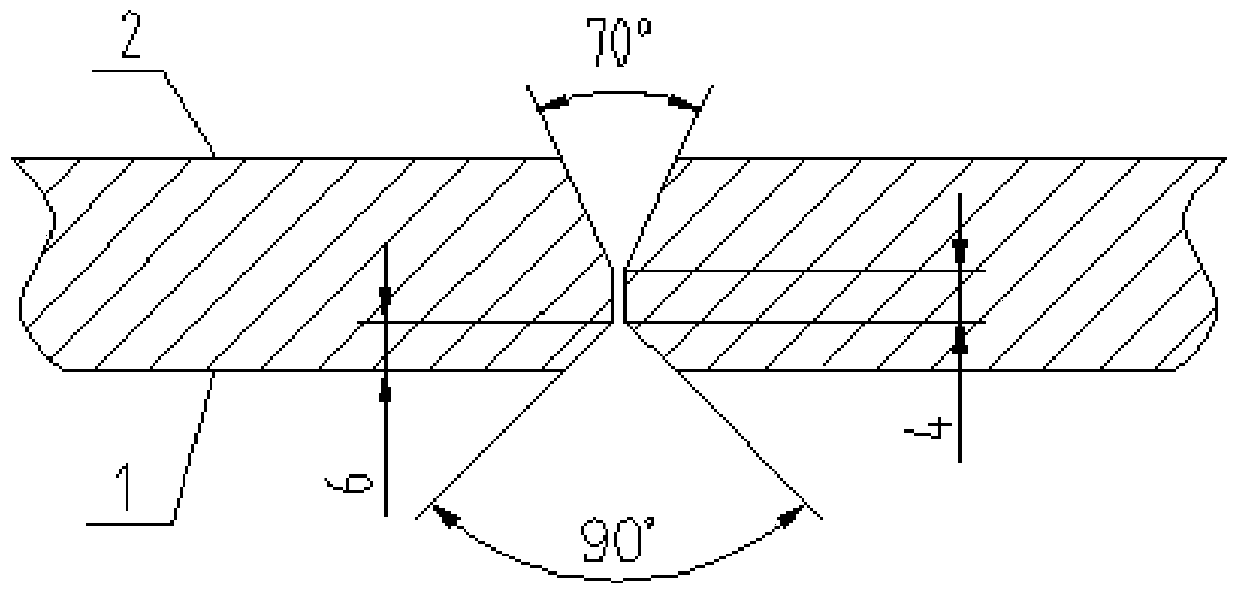

[0065] like figure 1 , 3 As shown in and 7, the welding process parameters and steps are as follows:

[0066] S100: Cut the material according to the requirements, and then open the short side of the steel plate against the outside of the cylinder to an angle of 45±2° and depth

[0067]

[0068] A one-way bevel of 6mm, and a one-way bevel with an angle of 35±2° and a depth of 12mm on the short side of the steel plate near the inner side of the cylinder (that is, leave the blunt edge 4mm);

[0069] S200: Roll the above-mentioned beveled steel plate according to the requirements of φ4300, misalignment not greater than 1mm and weld gap not greater than 1mm to form a cylinder and form double V-shaped welds;

[0070] S250: Position the gaps on the outer side of the forming cylinder for manual arc spot welding at intervals of 500mm, and then clean up the height of the welding points to be lower than the height of the submerged arc welding wire, as well as weld corrosion, scale,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com