Energy-efficient plasma electric welding machine device with magnetically stabilized arc

A plasma and magnetic stabilization technology, applied in the field of material processing, can solve the problems of insufficient arc column penetration, uneven weld thickness, unstable arc, etc., and achieve fast welding speed, less weld defects, and thin welding columns long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

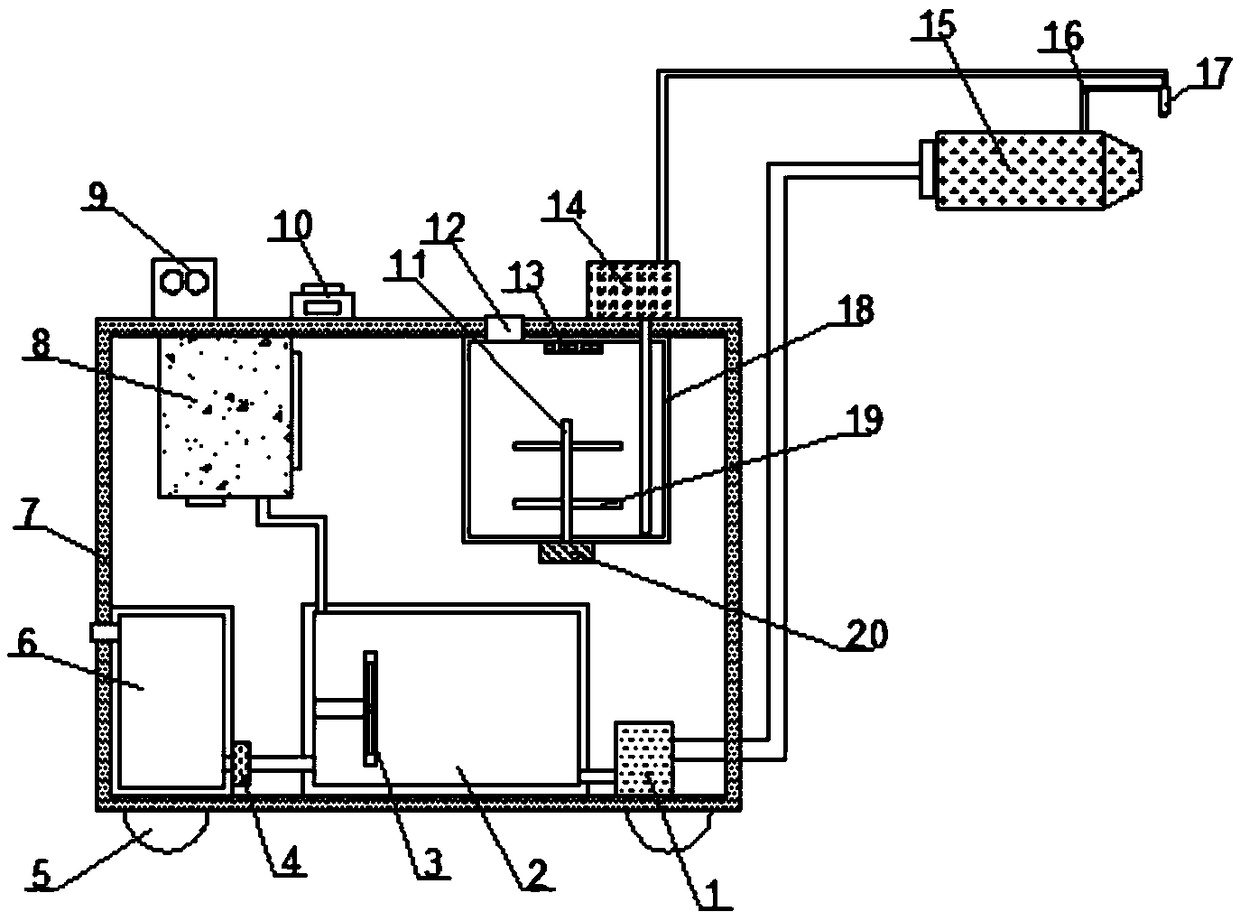

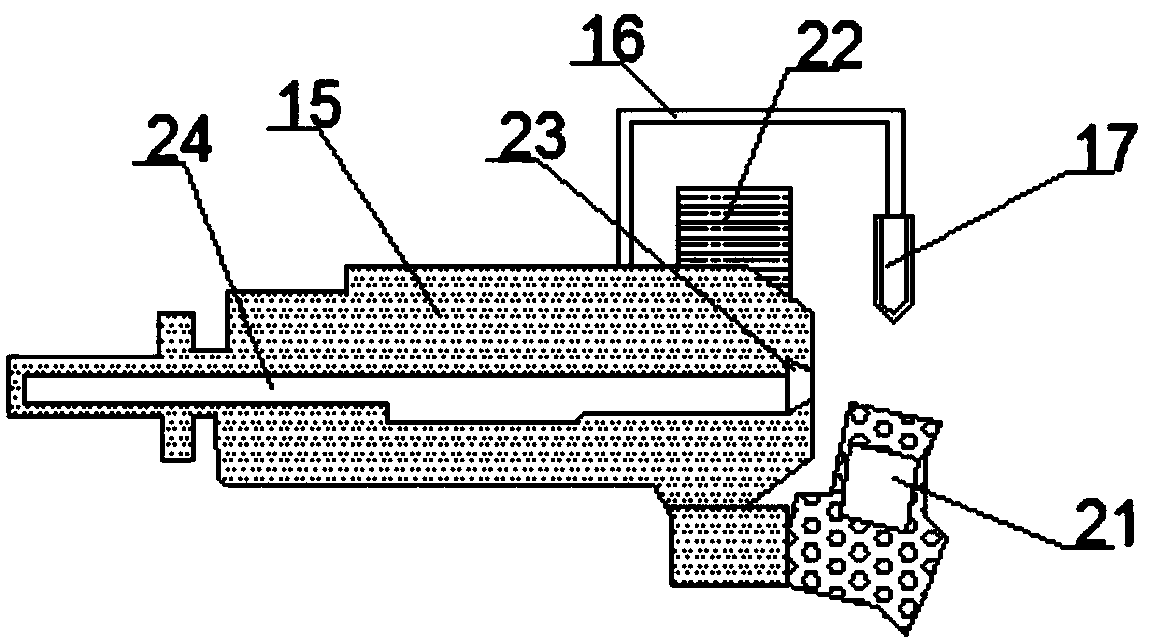

[0022] Such as Figure 1-2 As shown, an energy-efficient plasma welding machine with a magnetically stable arc includes a main body box 7, a nozzle body 15, and a gas mixing chamber 2. The inner bottom of the main body box 7 is provided with a gas mixing chamber 2, and the gas mixing chamber 2 A gas booster pump 1 is installed on one side through a mounting piece, and an argon gas storage chamber 6 is arranged at one end of the inner bottom of the main body box 7, and an air pump 4 is installed on one side of the argon gas storage room 6 through a mounting bracket. 7. The inner top is connected with a hydrogen generator 8 through a connecting frame and the output end of the hydrogen generator 8 is connected to the gas mixing chamber 2 through a pipeline. One side of the hydrogen generator 8 is provided with a feed chamber 18, and the bottom of the feed chamber 18 is A motor 20 is installed by bolts, an infrared heating tube 13 is installed on the top of the feed chamber 18 thr...

Embodiment 2

[0036] Such as Figure 1-2As shown, an energy-efficient plasma welding machine with a magnetically stable arc includes a main body box 7, a nozzle body 15, and a gas mixing chamber 2. The inner bottom of the main body box 7 is provided with a gas mixing chamber 2, and the gas mixing chamber 2 A gas booster pump 1 is installed on one side through a mounting piece, and an argon gas storage chamber 6 is arranged at one end of the inner bottom of the main body box 7, and an air pump 4 is installed on one side of the argon gas storage room 6 through a mounting bracket. 7. The inner top is connected with a hydrogen generator 8 through a connecting frame and the output end of the hydrogen generator 8 is connected to the gas mixing chamber 2 through a pipeline. One side of the hydrogen generator 8 is provided with a feed chamber 18, and the bottom of the feed chamber 18 is A motor 20 is installed by bolts, an infrared heating tube 13 is installed on the top of the feed chamber 18 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com