Patents

Literature

55results about How to "To achieve the warm-up effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

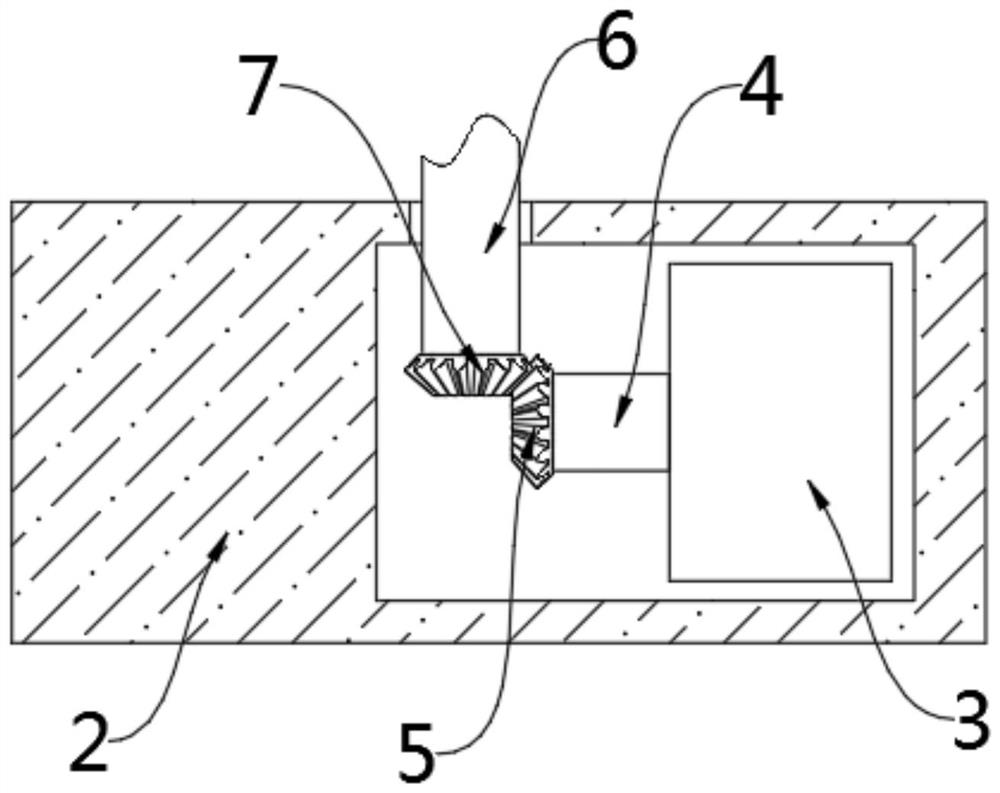

Casting defect eliminating method

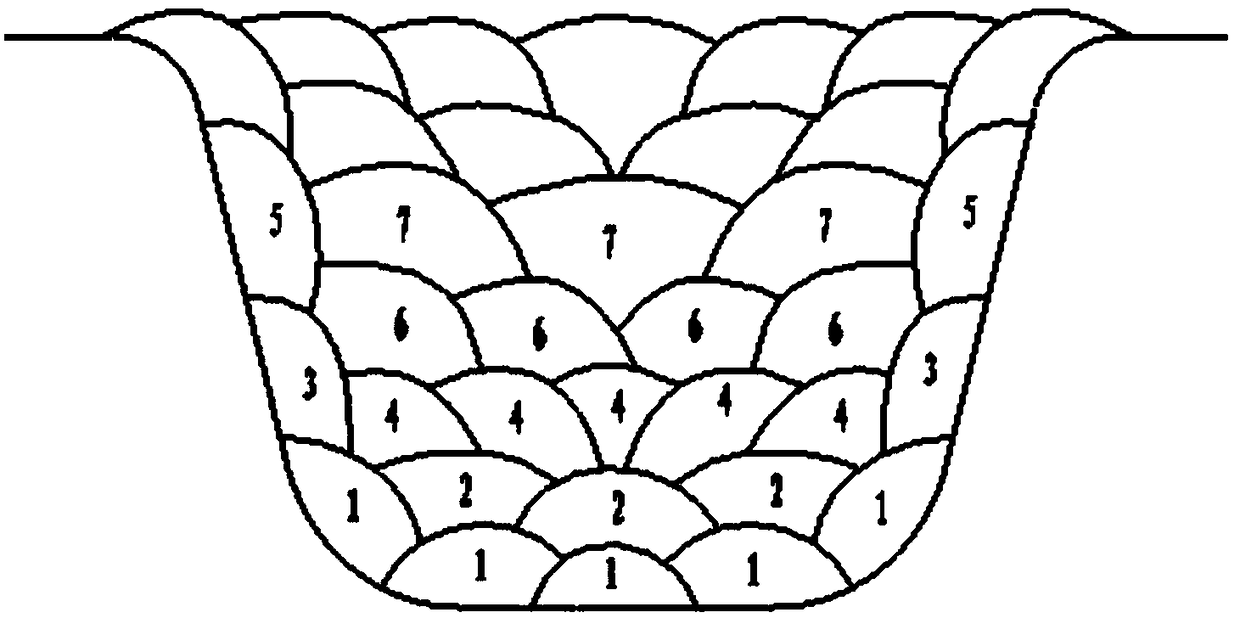

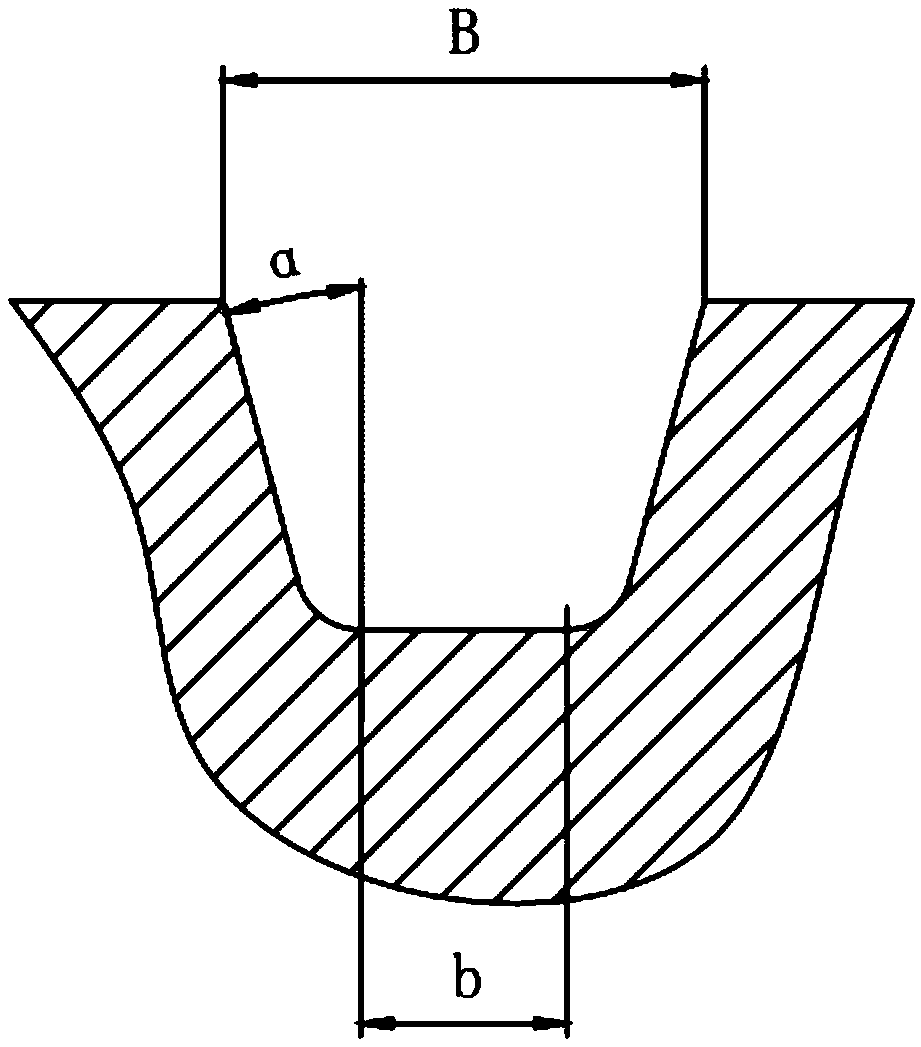

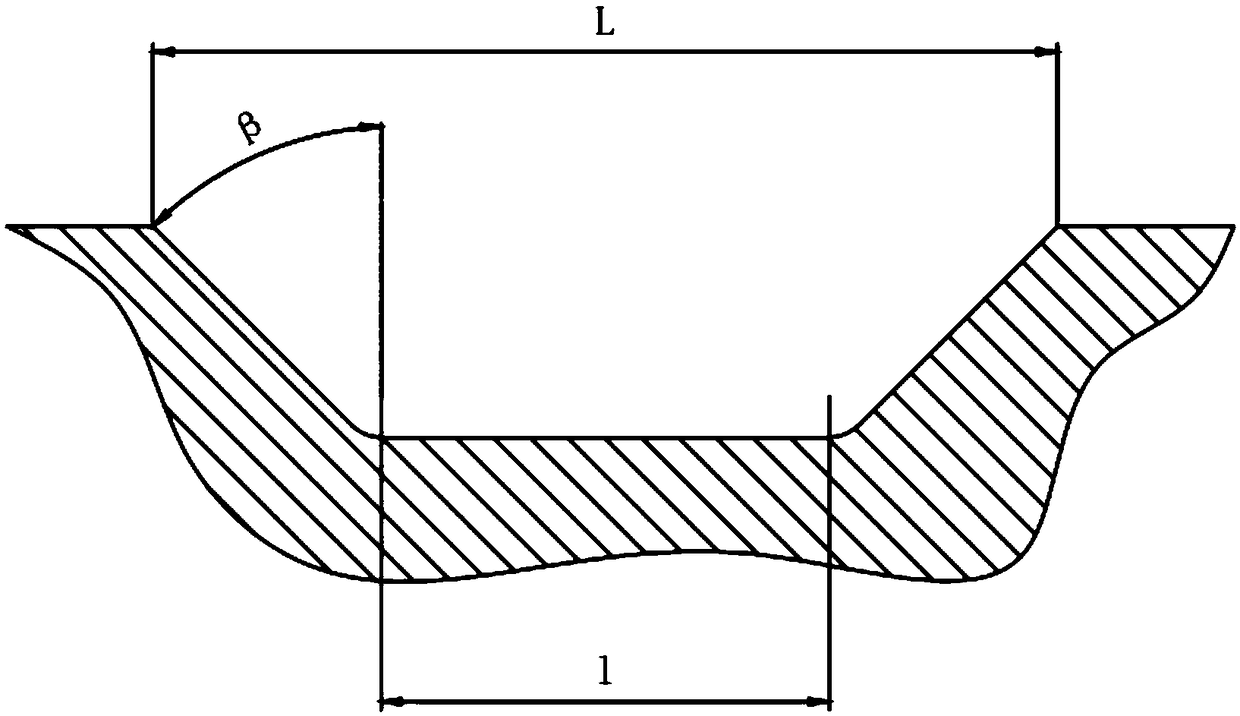

The invention discloses a casting defect eliminating method which belongs to the field of casting treatment. The casting defect eliminating method provided by the invention comprises five steps: defect cleanup, bevel preparation, weld preheating, welding repair and postweld treatment, wherein the defect cleanup refers to eliminating common surface defects by grinding, and common crack defects andgreats defects are subjected to a next step; the bevel preparation refers to forming a U-shaped bevel in the defected position and the bevel surface is a smooth curved surface; the weld preheating refers to carrying out local preheating to the common defects and integral preheating to the great defects; the welding repair refers to carrying out 1-2 layers of resurfacing welding along the side surface of a bevel, further fully welding the concave part in the resurfacing welding position and repeating the step until the whole bevel is welded to be full completely; and the postweld treatment refers to carrying out dehydrogenation treatment to the common defects after being welded and annealing treatment to the great defects after being welded. By improving the welding method and optimizing the process parameters when repairing different defects, the invention greatly reduces the probability of adverse influencing factors occurring in defect repair process, saves the time spent in defect repair and achieves the effect of cost saving while ensuring the qualified rate of casting repair.

Owner:ANHUI MAGANG HEAVY MASCH MFG CO LTD

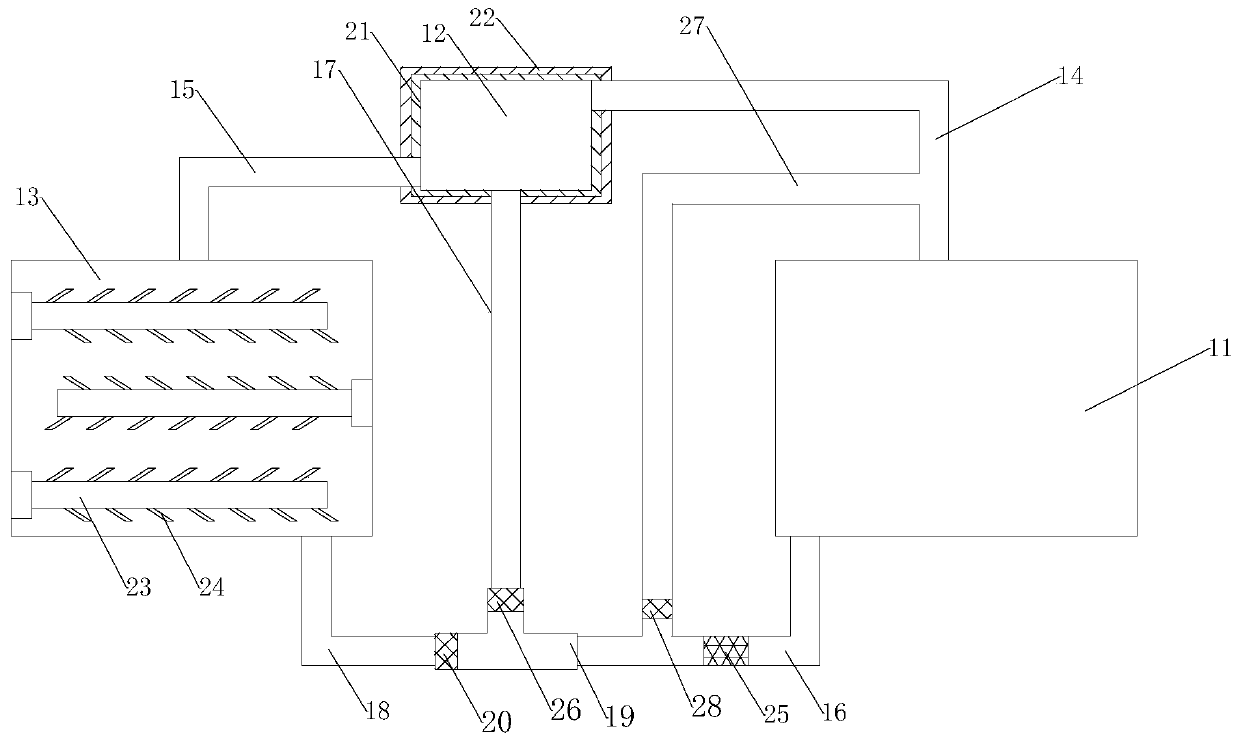

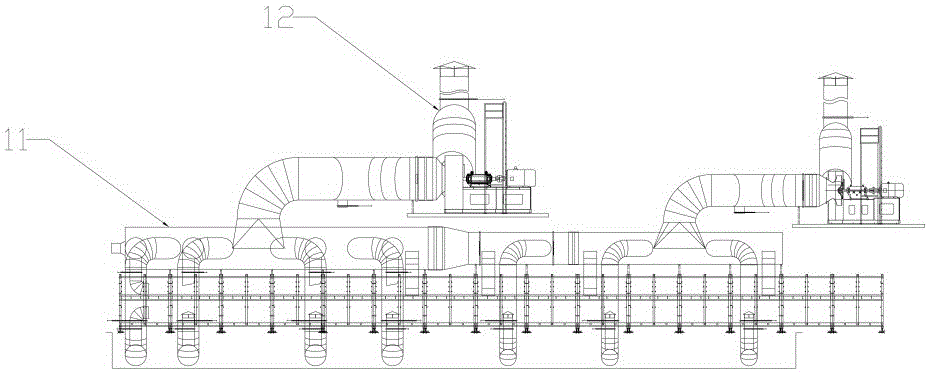

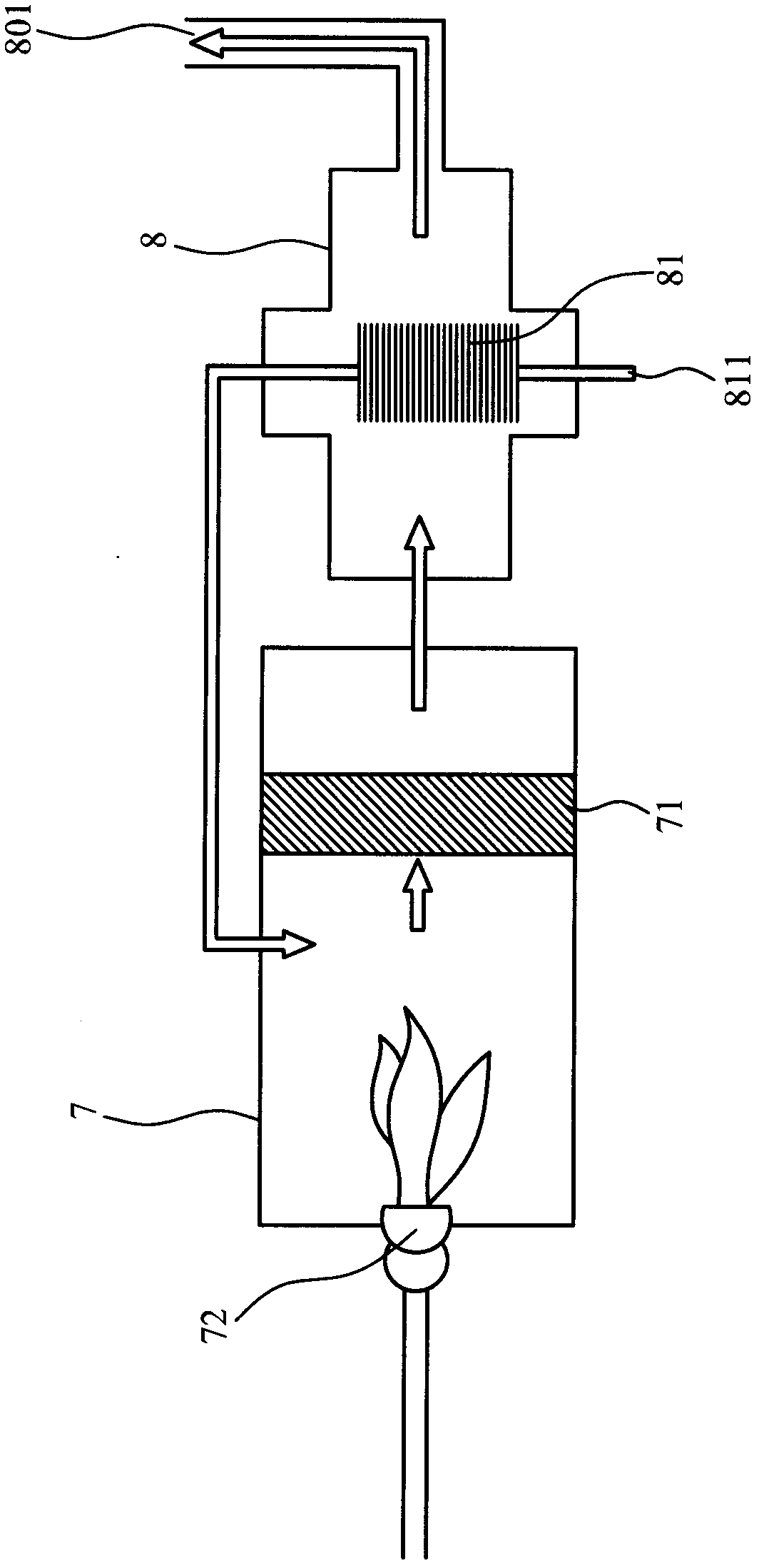

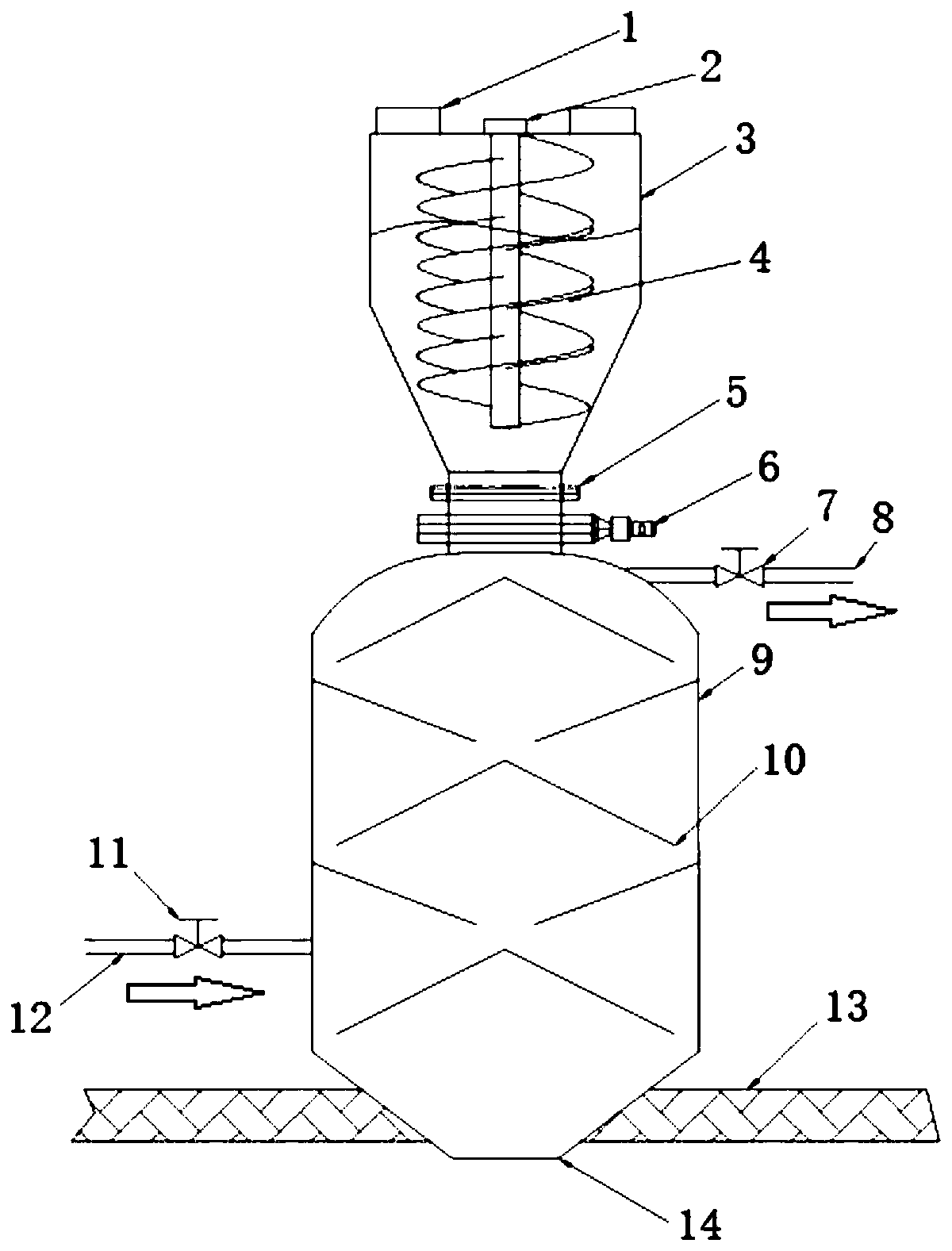

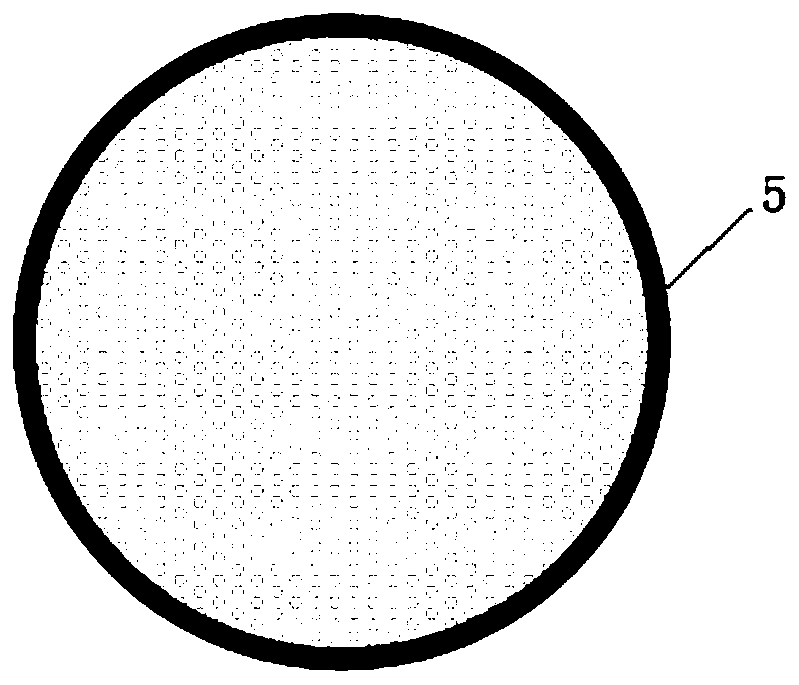

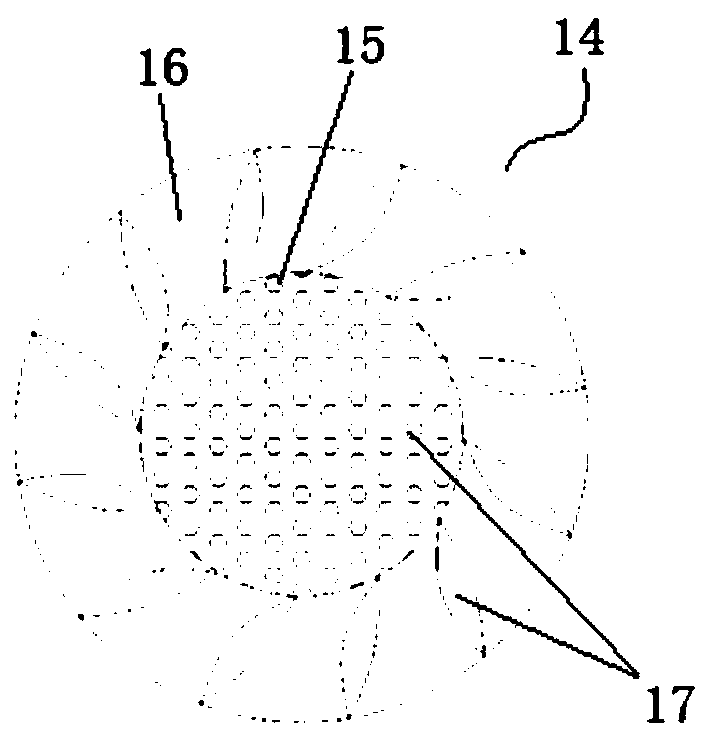

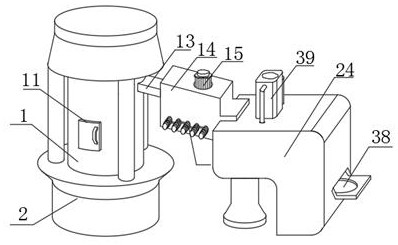

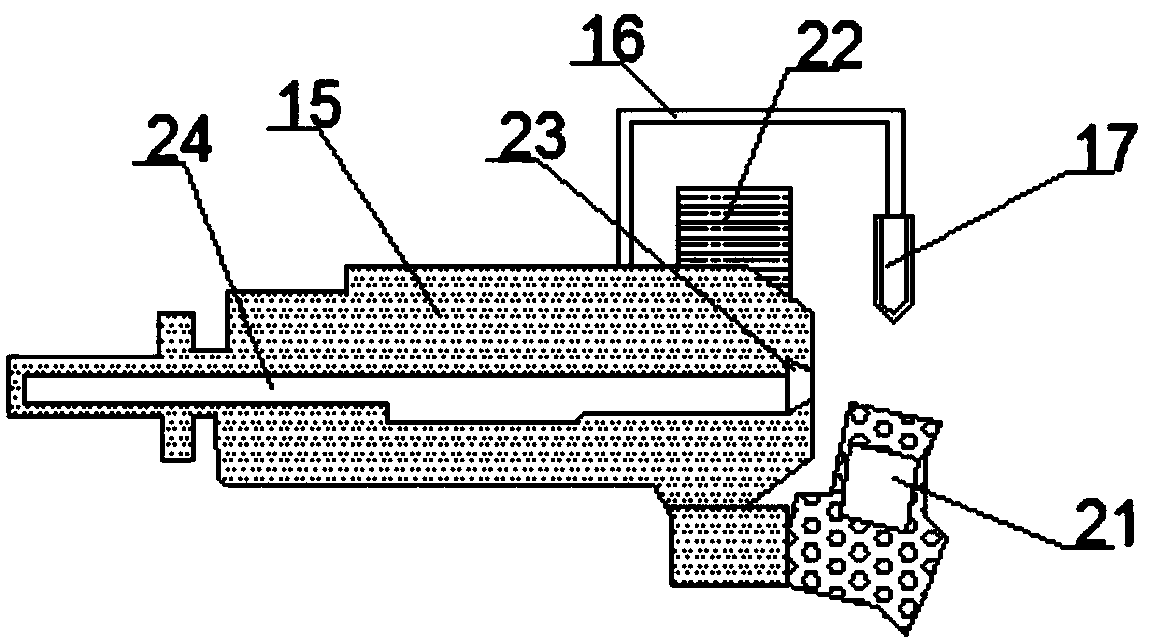

Tiny dust particle filtration and adsorption system

ActiveCN105999918AThe principle is simpleGood dust removal effectUsing liquid separation agentEngineeringDust particles

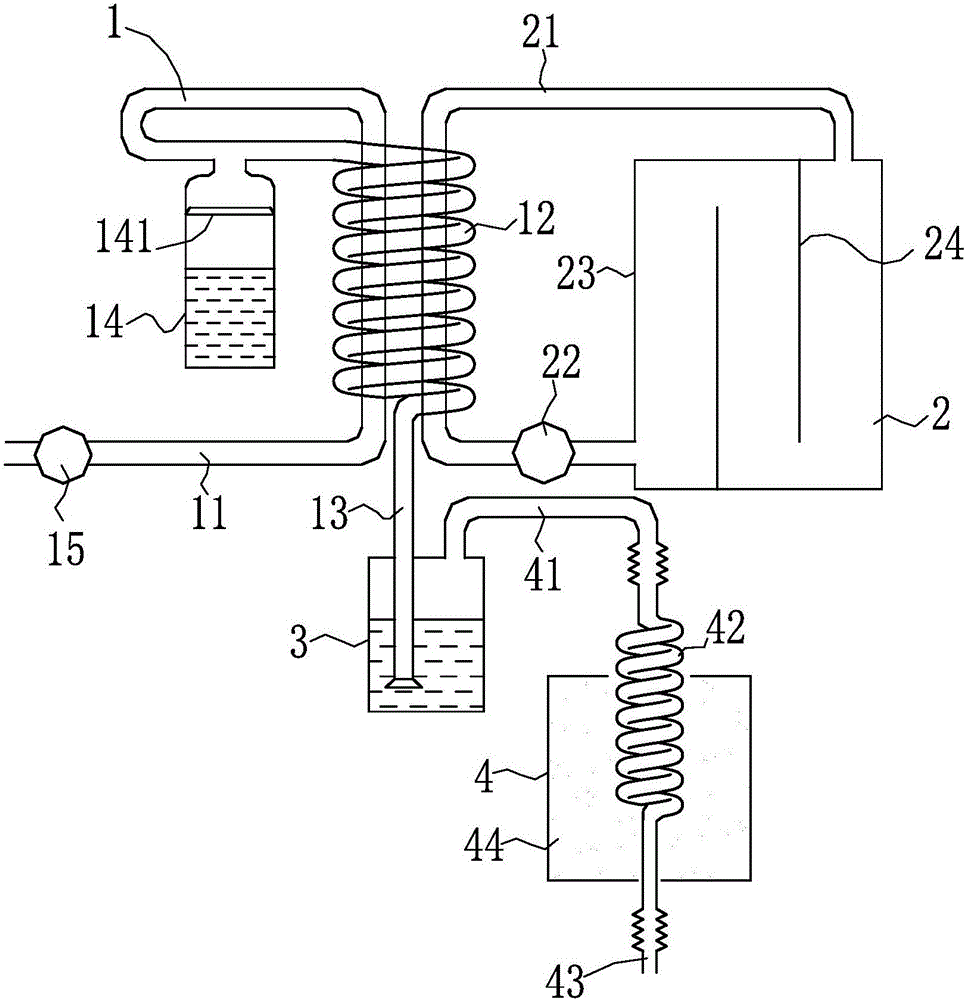

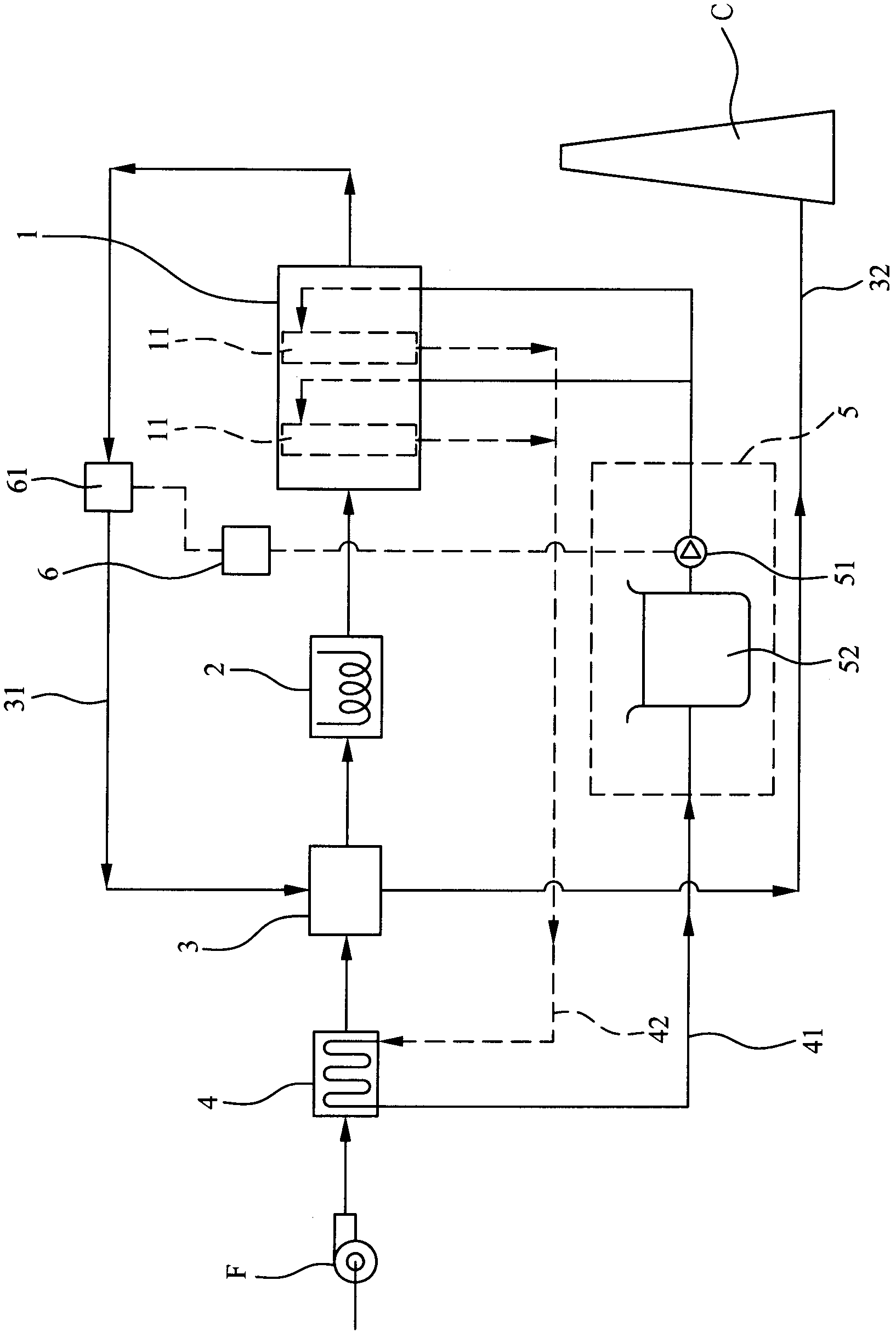

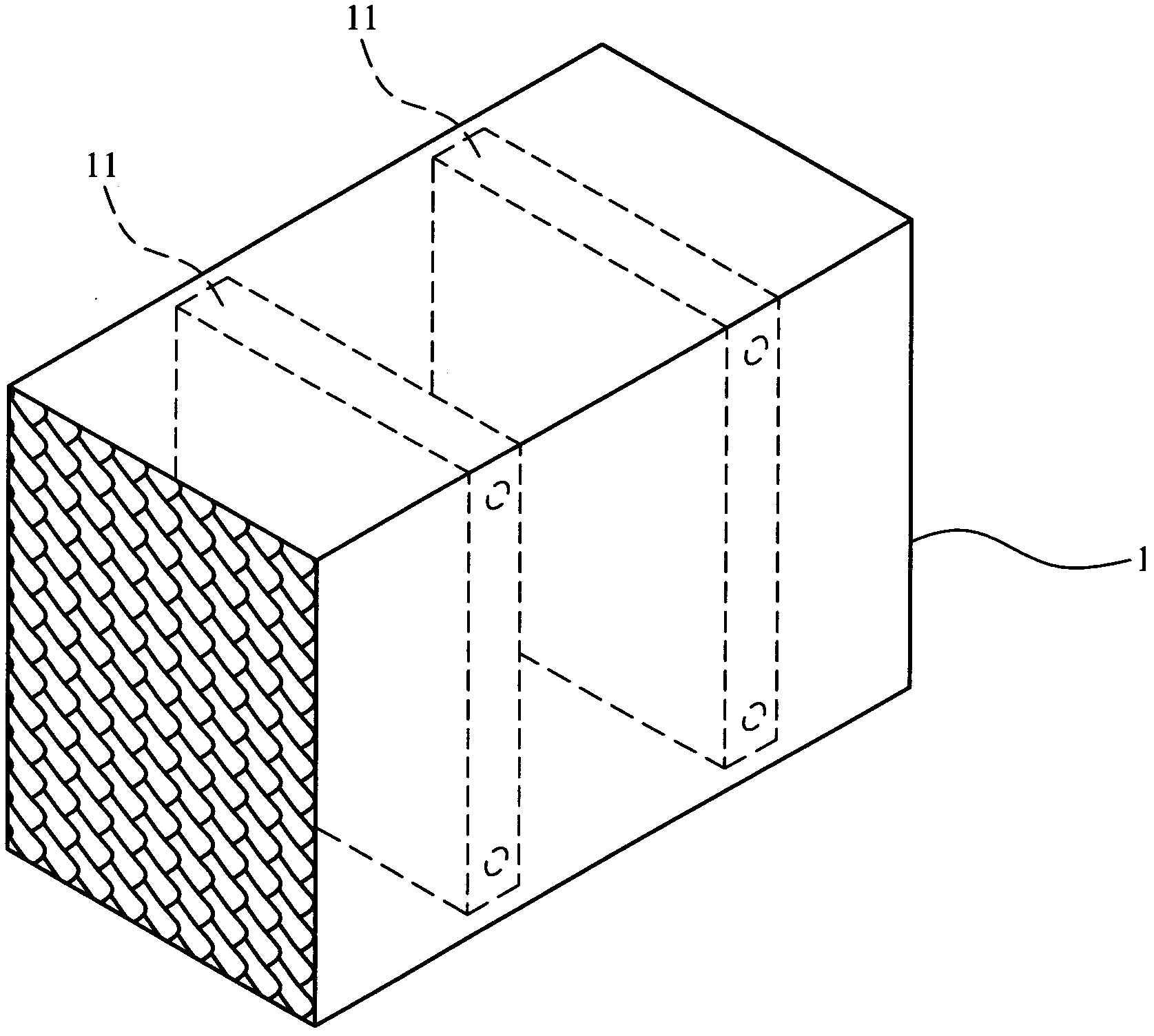

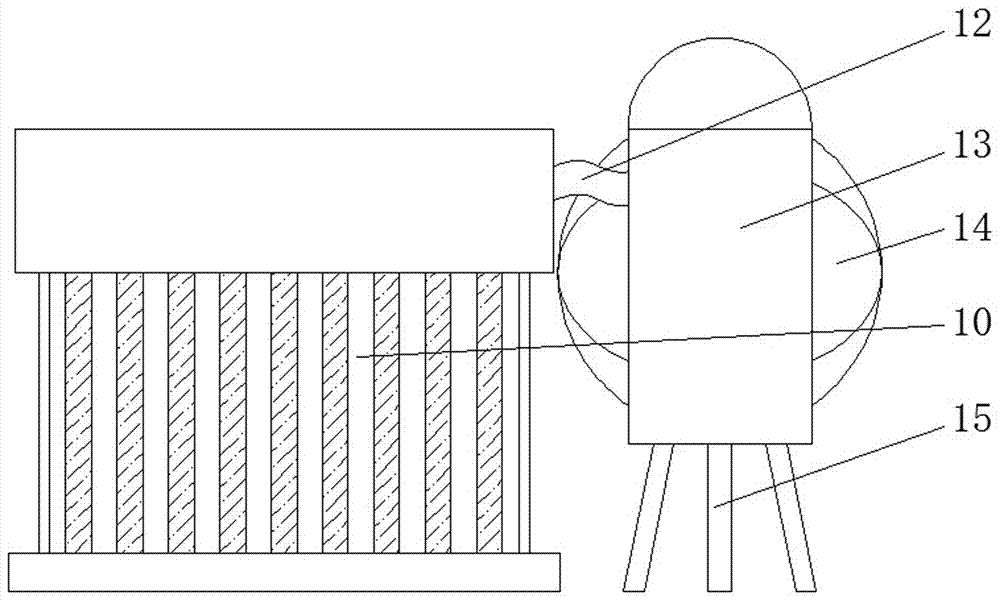

The invention relates to the field of dedusting equipment, in particular to a tiny dust particle filtration and adsorption system. The tiny dust particle filtration and adsorption system comprises an atomizing device, a circulating cooling device, an absorption device and a recooling device, wherein the atomizing device comprises an air inlet pipe, a cooling pipe, an air outlet pipe, a steam generator and an air pump, wherein the air inlet of the cooling pipe is connected with the air outlet of the air inlet pipe; the air outlet of the cooling pipe is connected with the air inlet of the air outlet pipe; the middle of the air inlet pipe penetrates through one hole of the '8'-shaped spiral cooling pipe; the output opening of the steam generator is communicated with the air inlet pipe; the steam generator is used for generating steam to be mixed with gas to be purified; the circulating cooling device is connected with the cooling pipe; the recooling device is connected with the absorption device. The tiny dust particle filtration and adsorption system imitates mist formation in meteorology, tiny dust particles serve as condensation nucleuses to form water mist first, and then the water mist is condensed into water, so that the dust particles and the water are combined and discharged. The system is simple in principle, obvious in dust removal effect, recyclable, lower in cost, and convenient to popularize.

Owner:HEBEI NAT LIGHTING PHOTOELECTRIC TECH CO LTD

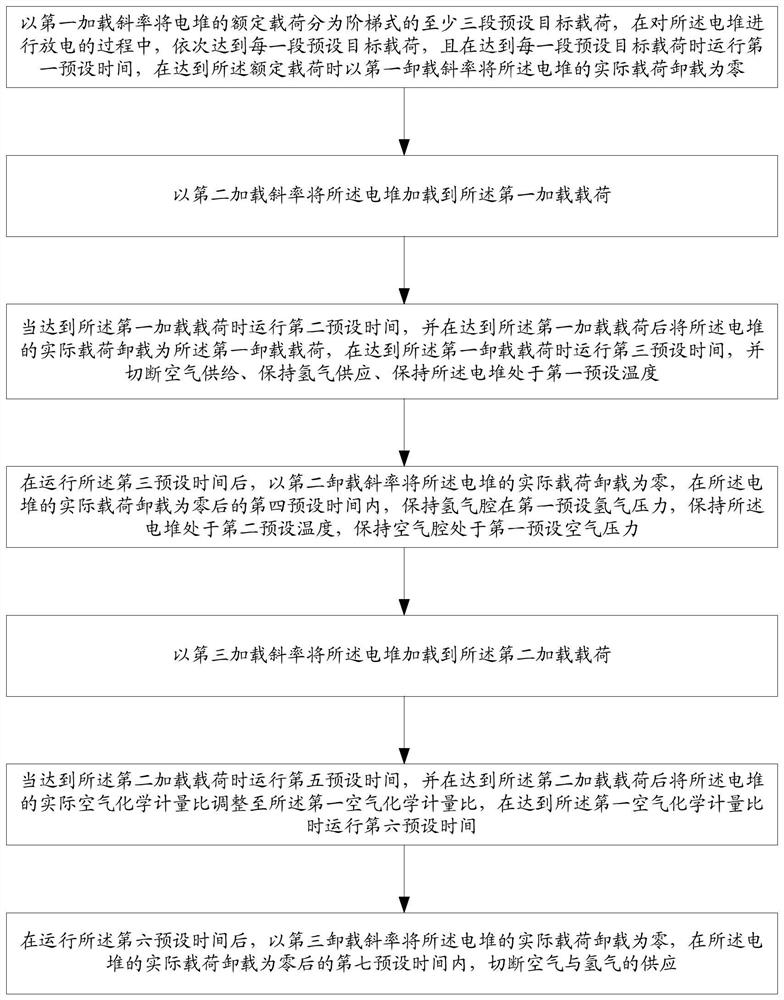

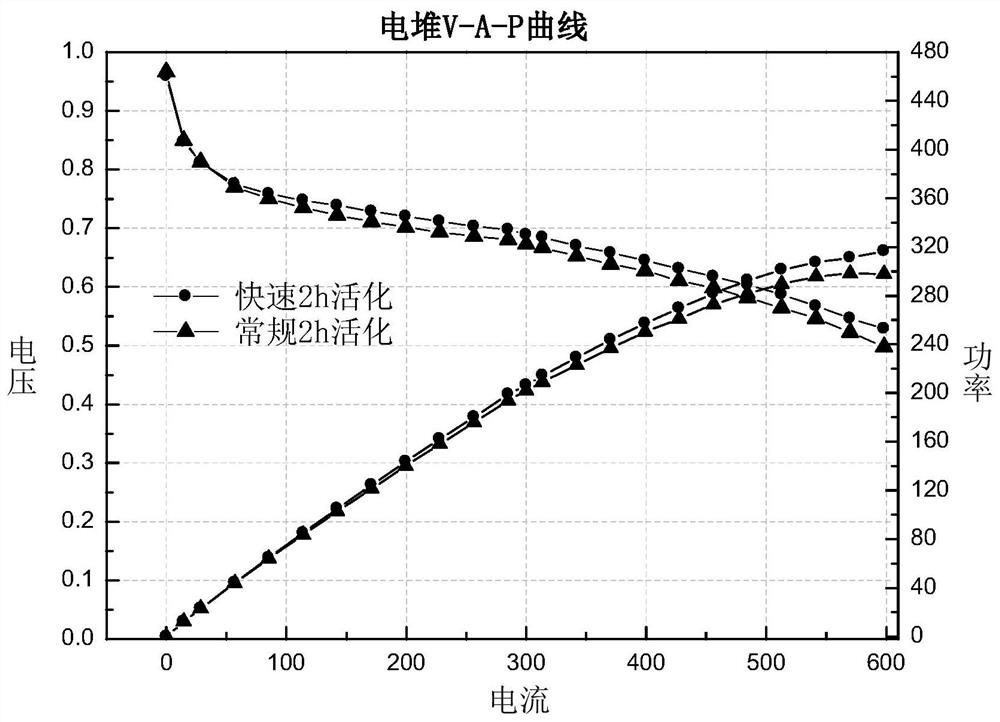

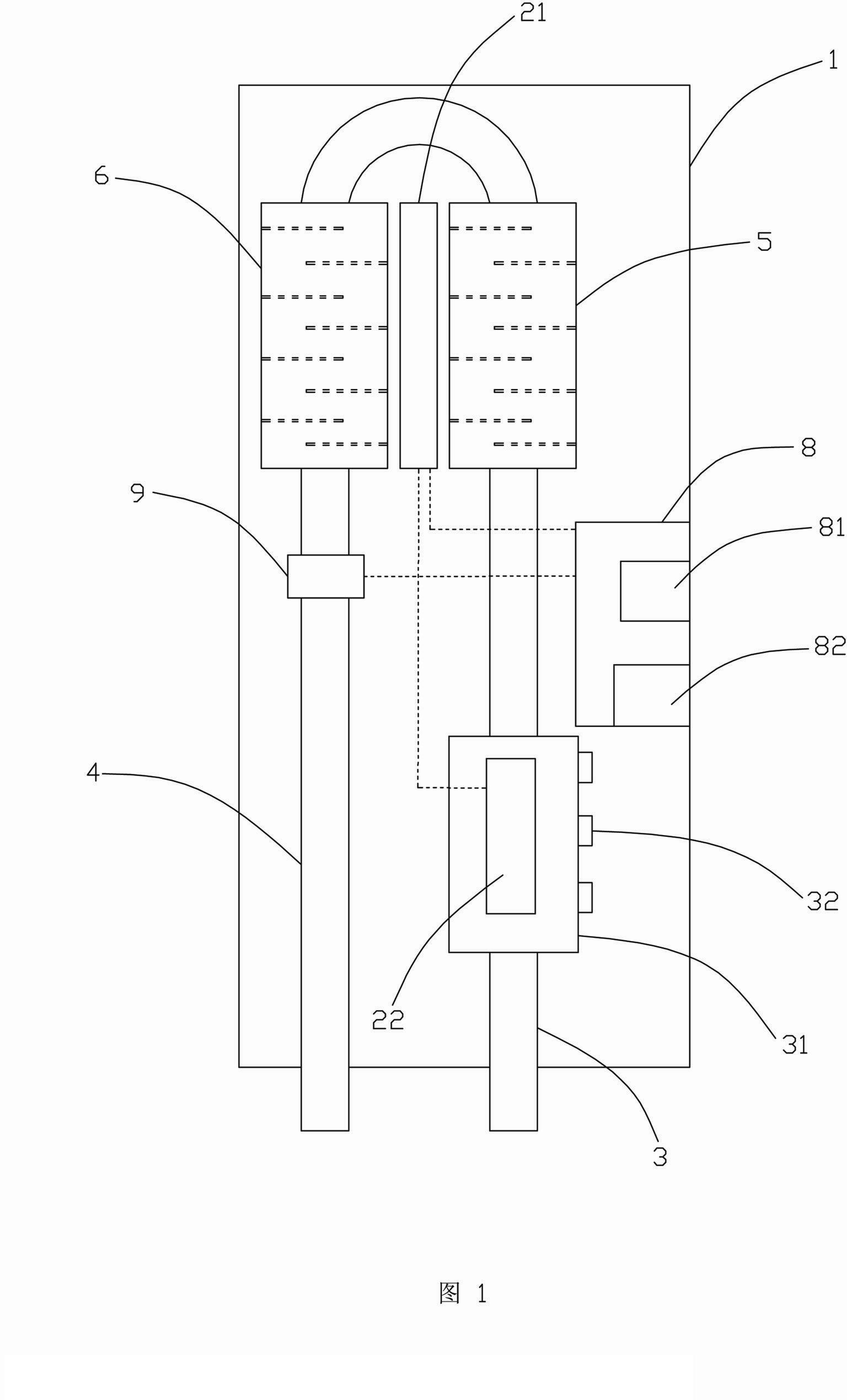

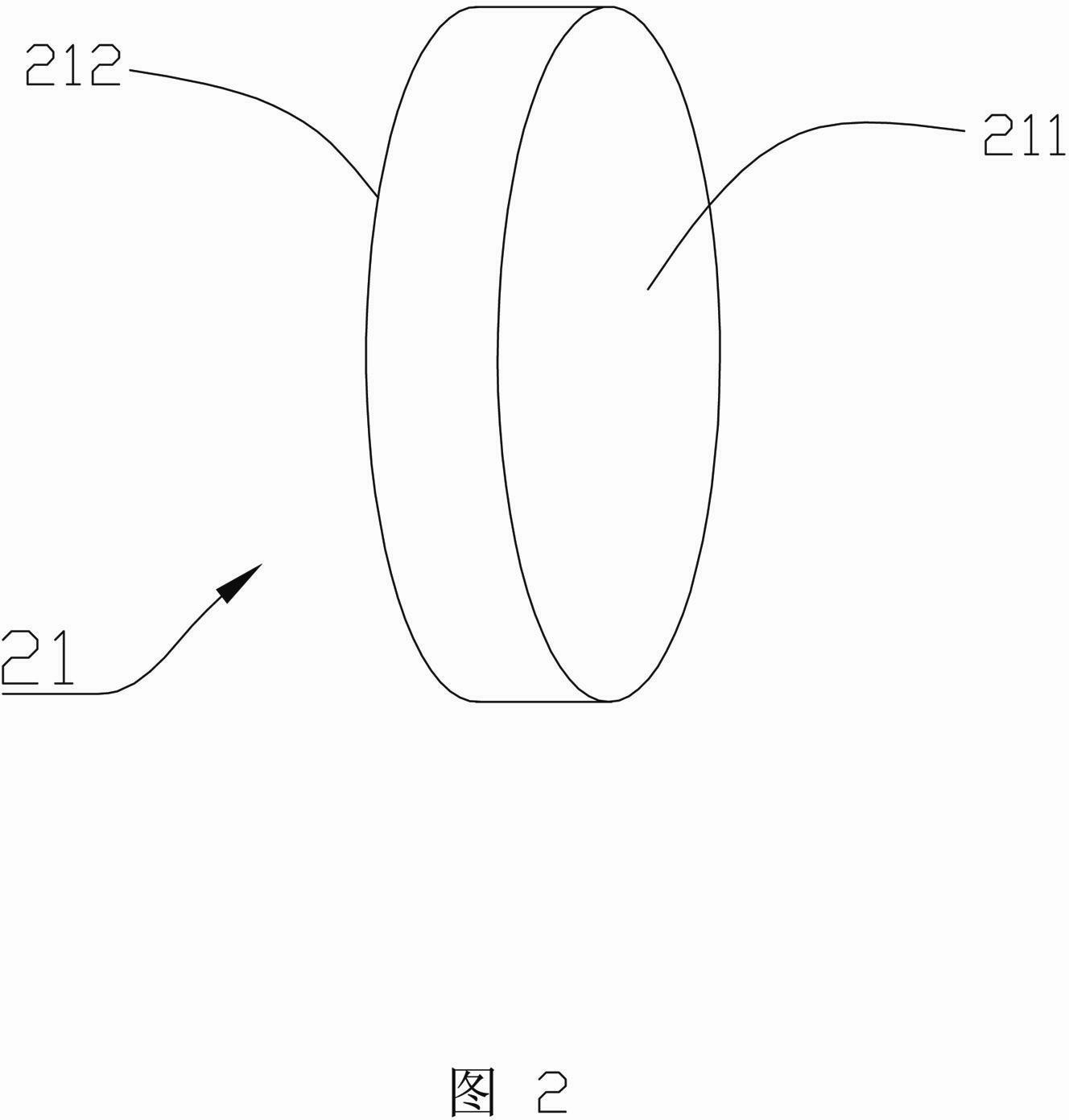

Stack activation method of fuel cell

ActiveCN111740134AIncrease surface areaTo achieve the warm-up effectFuel cell heat exchangeFinal product manufacturePtru catalystStructural engineering

The invention discloses a stack activation method of a fuel cell. The stack activation method comprises the following specific steps of carrying out sectional loading on a stack; respectively presetting a first loading load and a first unloading load, and loading the stack to the first loading load; unloading the actual load of the stack into the first unloading load; unloading the actual load ofthe stack to zero; presetting a second loading load and a first air stoichiometric ratio respectively; loading the stack to the second loading load; adjusting the actual air stoichiometric ratio of the stack to the first air stoichiometric ratio; and unloading the actual load of the stack to zero. According to the stack activation method of the fuel cell provided by the embodiment of the invention, different and targeted regulation and control are carried out on the discharge current, and the catalyst is activated through the reduction of hydrogen to the active site of the catalyst and low potential, so that the activation time is greatly shortened, and the production efficiency of the proton exchange membrane fuel cell is improved.

Owner:国鸿氢能科技(嘉兴)股份有限公司

Method for preheating forged steel cold roll before induction quenching

InactiveCN102766737ATo achieve the warm-up effectEasy to operateFurnace typesIncreasing energy efficiencyEngineeringInduction hardening

The invention discloses a method for preheating a forged steel cold roll before induction quenching. A quench machining tool is used for induction preheating at the proper temperature lower than AC1. A preheated part of the cold roll is not water-cooled during moving. By matching the heating temperature with the movement speed of the cold roll, surface heat is transferred inward during movement of the cold roll, and the inside and the outside of the cold roll are uniformly heated. The cold roll moves to an initial position after preheating. The surface temperature of the cold roll is controlled to 200-400 DEG C, and the overall heating is achieved. By the induction heating high in heating speed, the whole preheating process takes about 40 minutes, and machining efficiency is high. The induction heating depends on electromagnetic induction, energy utilization rate reaches more than 90% generally, and energy consumption is far lower than that of preheating by a resistance furnace. The initial temperature of the roll is low, and accordingly the roll is convenient for an operator to lift. The method achieves the effect of overall preheating that is achieved by the resistance furnace, and induction quenching can be performed right after the preheating.

Owner:耿震宇

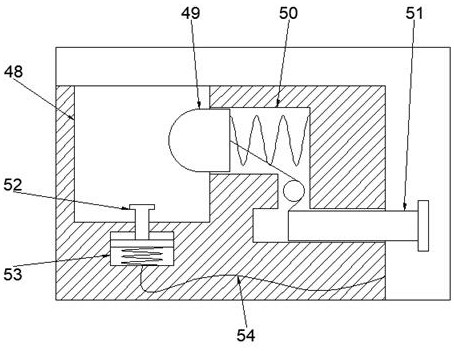

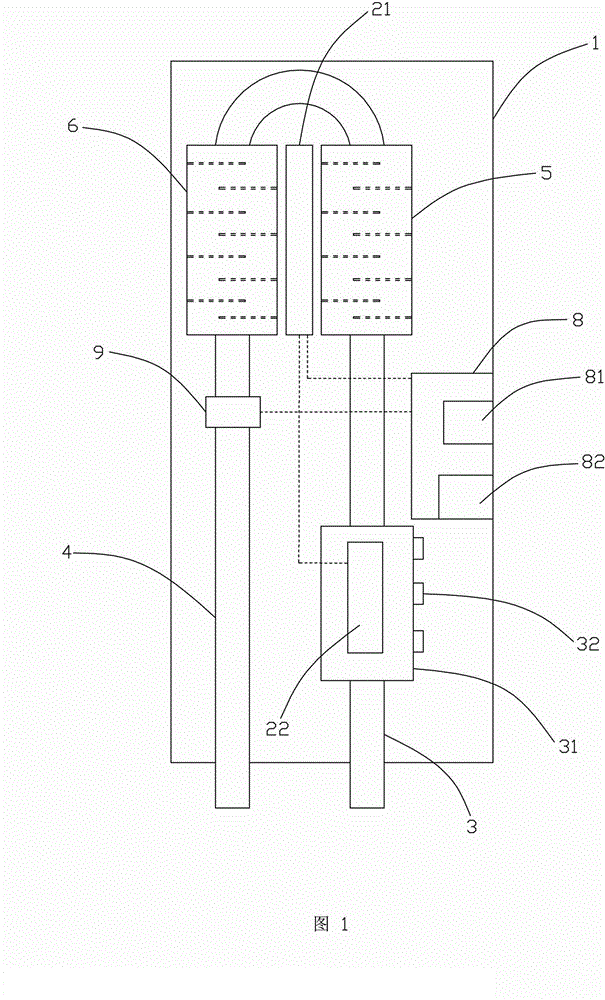

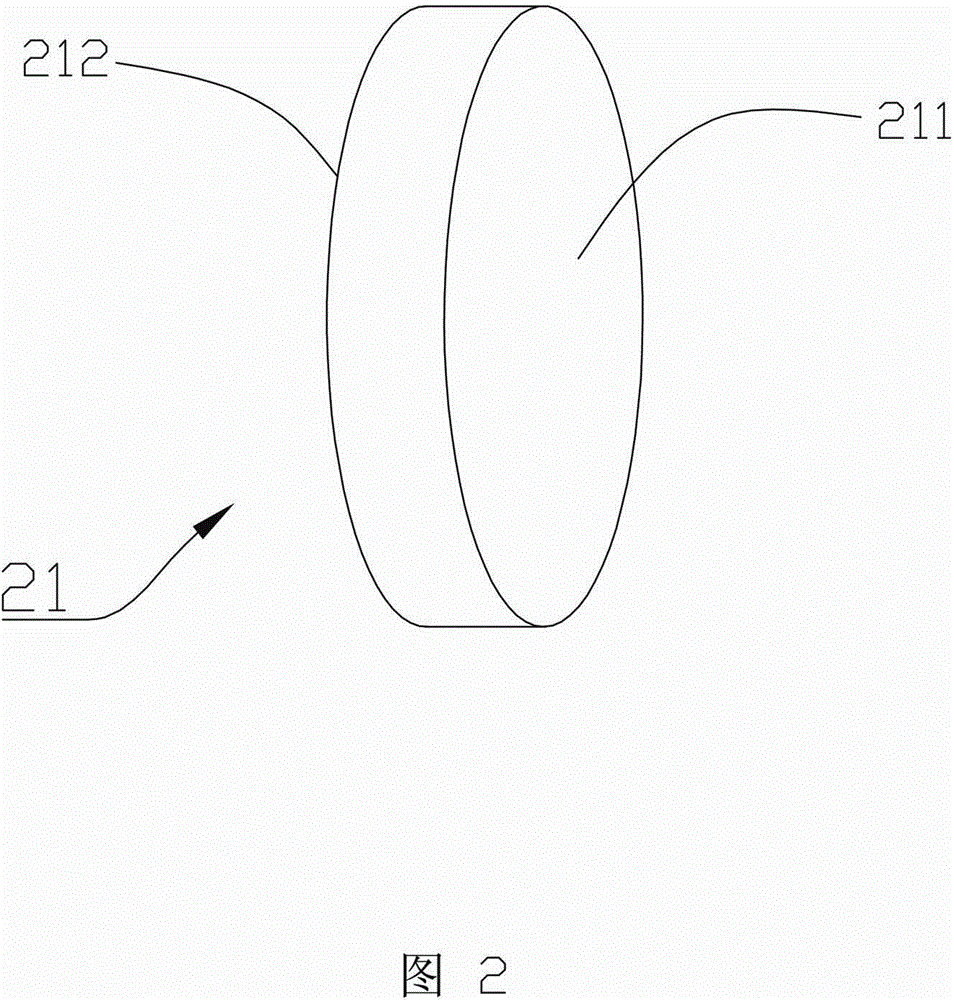

Instant-heating-type electromagnetic water heater

InactiveCN102305472AReduce the temperatureReduce lossesFluid heatersEngineeringElectromagnetic heating

The invention discloses an instant-heating-type electromagnetic water heater which comprises a shell and an electromagnetic heating device assembled in the shell, wherein a water inlet pipe and a water outlet pipe are connected to the shell; the electromagnetic heating device comprises a heating device body and a heat radiator for heat radiation of the heating device body; the electromagnetic heating device body is in the shape of a short cylinder and comprises a front heating surface and a rear heating surface; the instant-heating-type electromagnetic water heater also comprises a first heating inner container and a second heating inner container which are respectively positioned on the front side and rear side of the electromagnetic heating device body and are manufactured from a magnetic conductive metal; the first heating inner container and the second heating inner container are communicated mutually, the water inlet of the first heating inner container is connected with the water inlet pipe, and the water outlet of the second heating inner container is connected with the water outlet pipe; the first heating inner container and the second heating inner container are respectively close to the front heating surface and the rear heating surface; and the heat radiator is attached on the outer side wall of the water inlet pipe. According to the invention, the heat energy loss in the heating process of water is less, and the consumed power is less.

Owner:李善福 +1

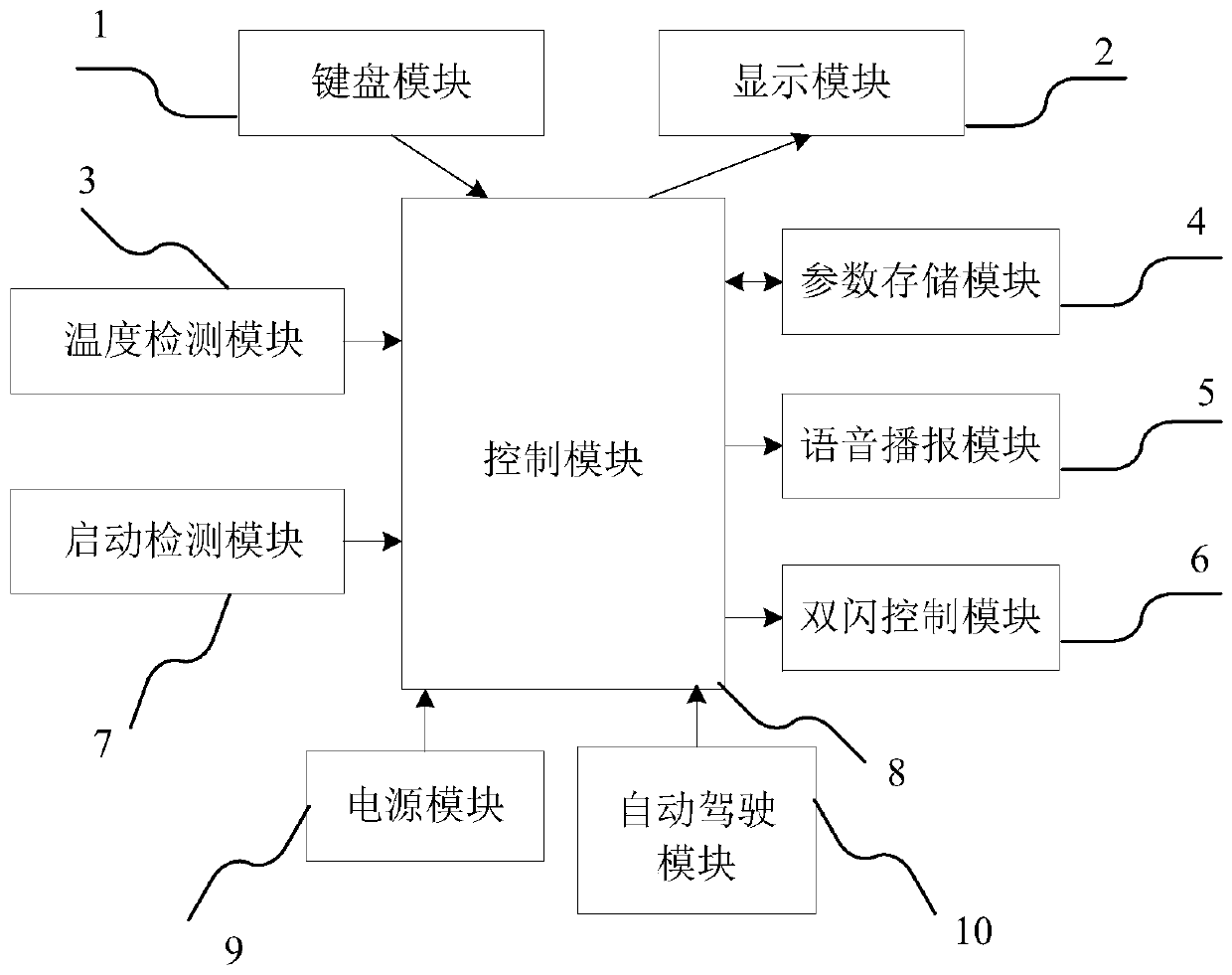

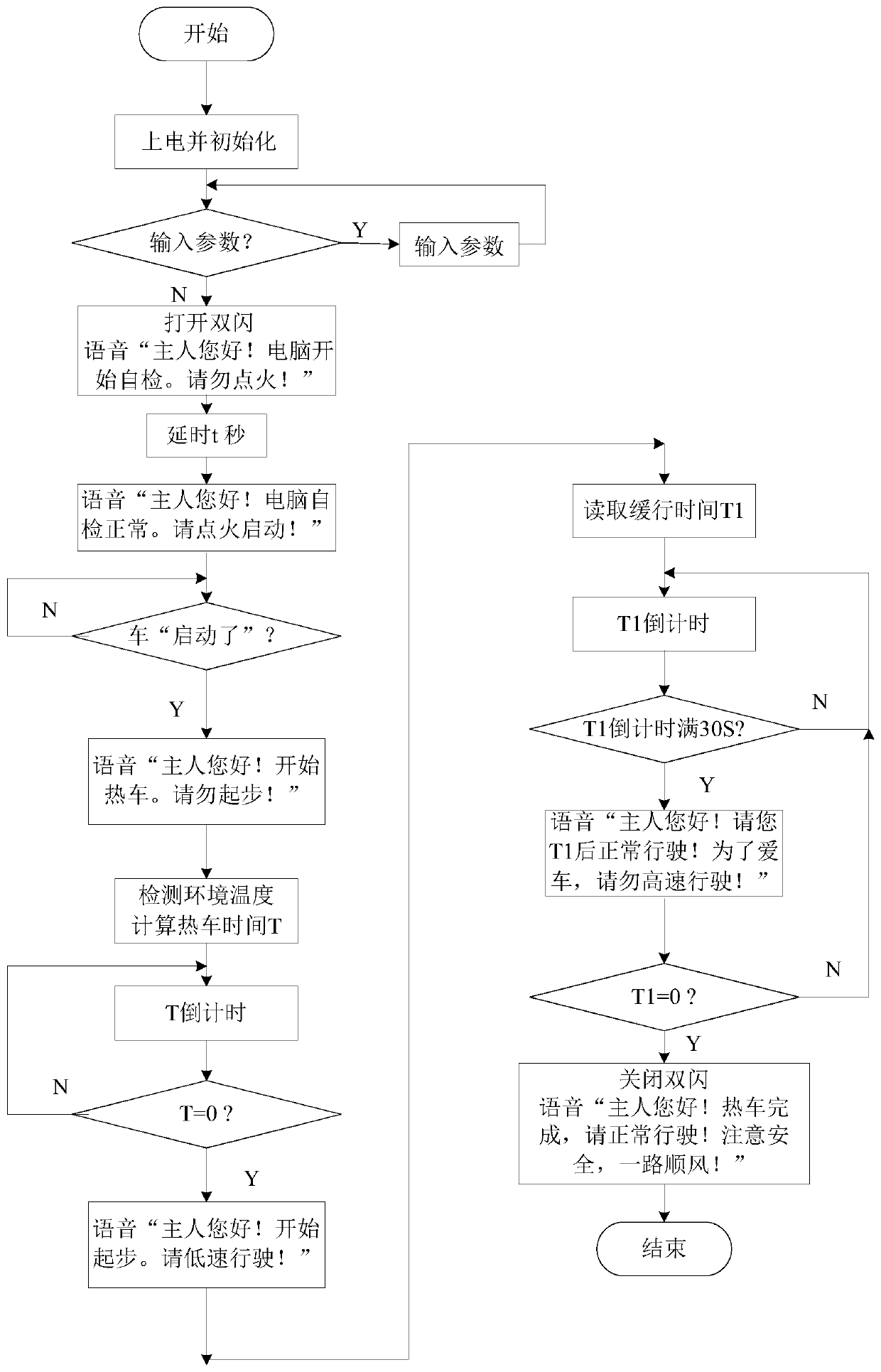

Voice prompting device and method for motor vehicle warming and starting

InactiveCN109808616AReduced chance of wearEnergy savingMachines/enginesSignalling/lighting devicesElectricityAutopilot

The invention belongs to the field of automobile driving, in particular to a voice prompting device and a voice prompting method for motor vehicle warming and starting. The voice prompting device comprises a start detection module, a temperature detection module, a parameter storage module, a voice broadcasting module, a power module and a control module, and further comprises a keyboard module, adisplay module, a double flash control module and an automatic driving module, wherein the keyboard module comprises a manual mode and an automatic mode. The voice prompting method comprises the following five steps: electrifying and initializing, turning on a double-flash lamp and performing self-inspection on a computer, judging whether the motor vehicle is started, warming the motor vehicle, and slowing down and closing the double-flash lamp after completion of slowing down. By adopting the voice prompting device and the voice prompting method, the wear probability of an automobile enginecan be reduced, and the effects of saving energy and reducing haze are achieved.

Owner:XIAN PEIHUA UNIV

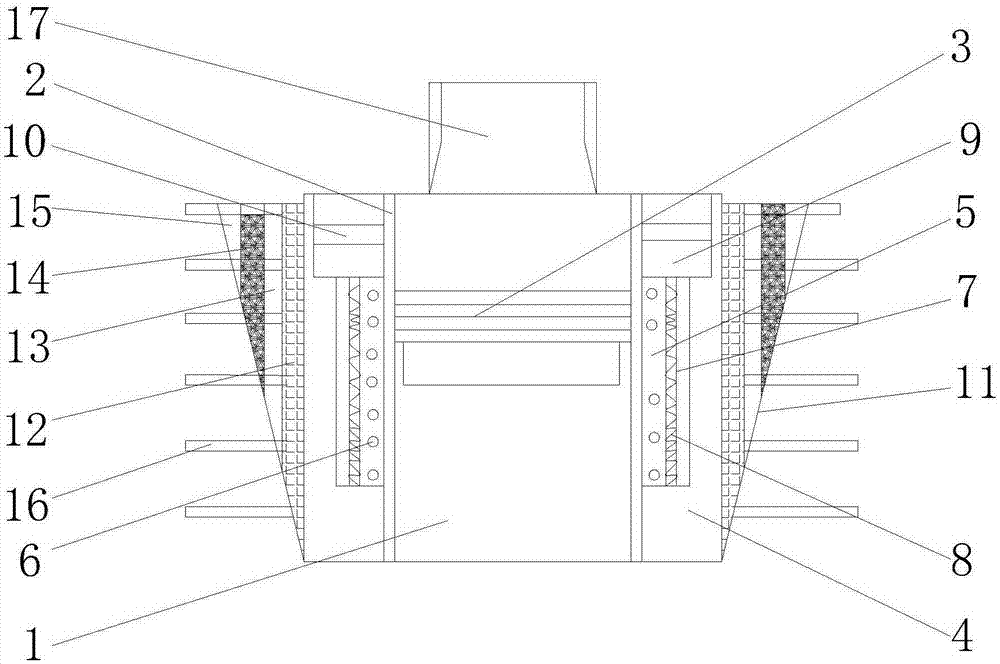

Sintering furnace

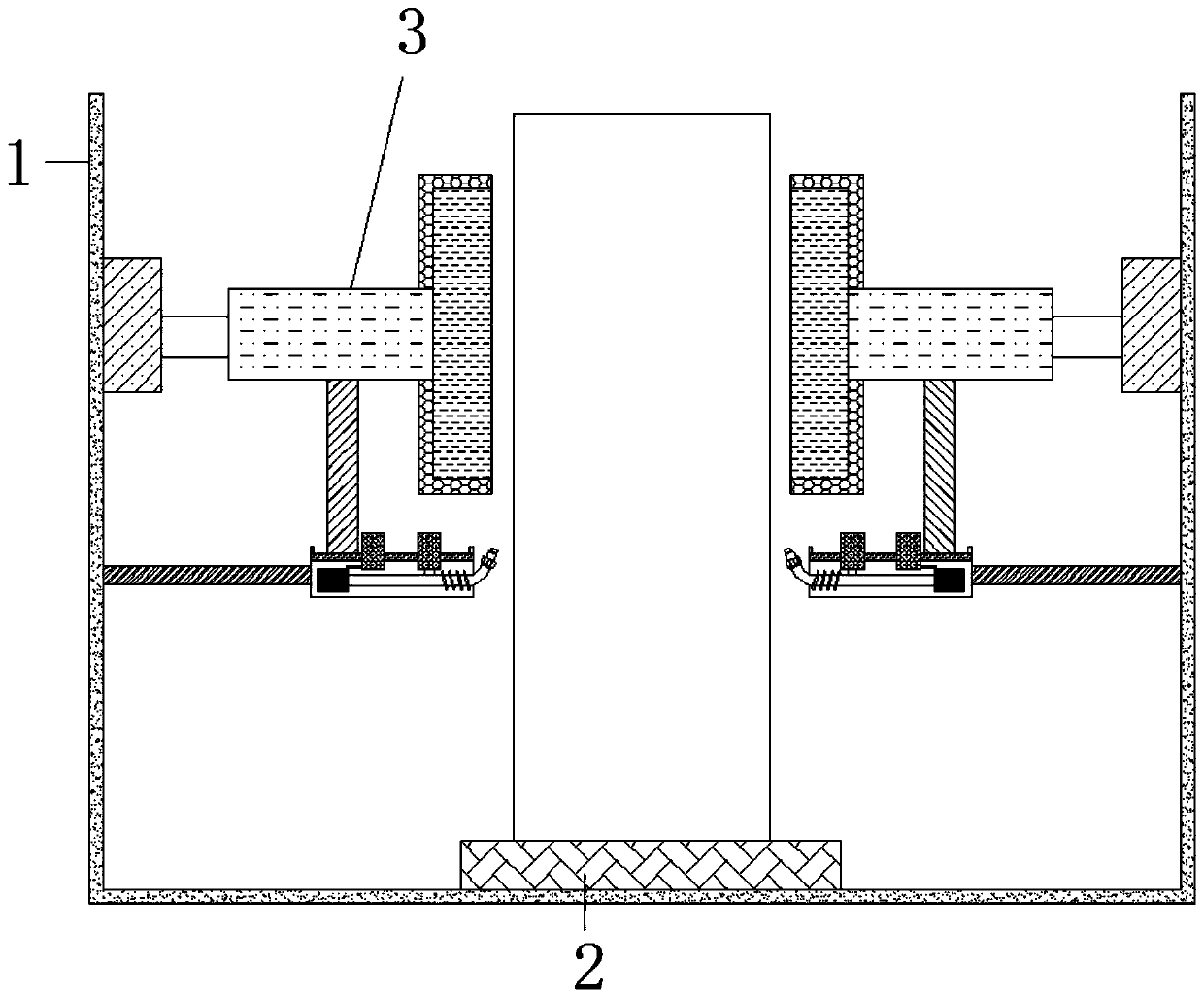

InactiveCN104374190AReduce cracksTo achieve the warm-up effectFurnace typesWaste heat treatmentFlueEngineering

The invention discloses a sintering furnace. The sintering furnace comprises a base, a first hearth and a second hearth, wherein the first hearth and the second hearth are arranged on the base, a first fuel nozzle is arranged on the left side of the first hearth, a second fuel nozzle is arranged on the right side of the second hearth, a first flue is arranged on the back side of the first hearth, a second flue is arranged on the back side of the second hearth, one end of the first flue is communicated with the first hearth, one end of the second flue is communicated with the second hearth, a first flue switch device is arranged on the first flue, a second flue switch device is arranged on the second flue, the first hearth is connected with the second hearth through a channel device, a first air inlet device is arranged on the first fuel nozzle, and a second air inlet device is arranged on the second fuel nozzle. According to the sintering furnace, waste heat is brought into the second hearth through the channel device when sintering is conducted in the first hearth, so that a shell mold of the second hearth is preheated, in this way, cracks caused by direct high-temperature sintering can be reduced, and heat energy can be fully utilized to achieve energy saving.

Owner:ZHONGSHAN CITY DONGSHENG TOWN ZHUYOU EQUIP MFG PLANT

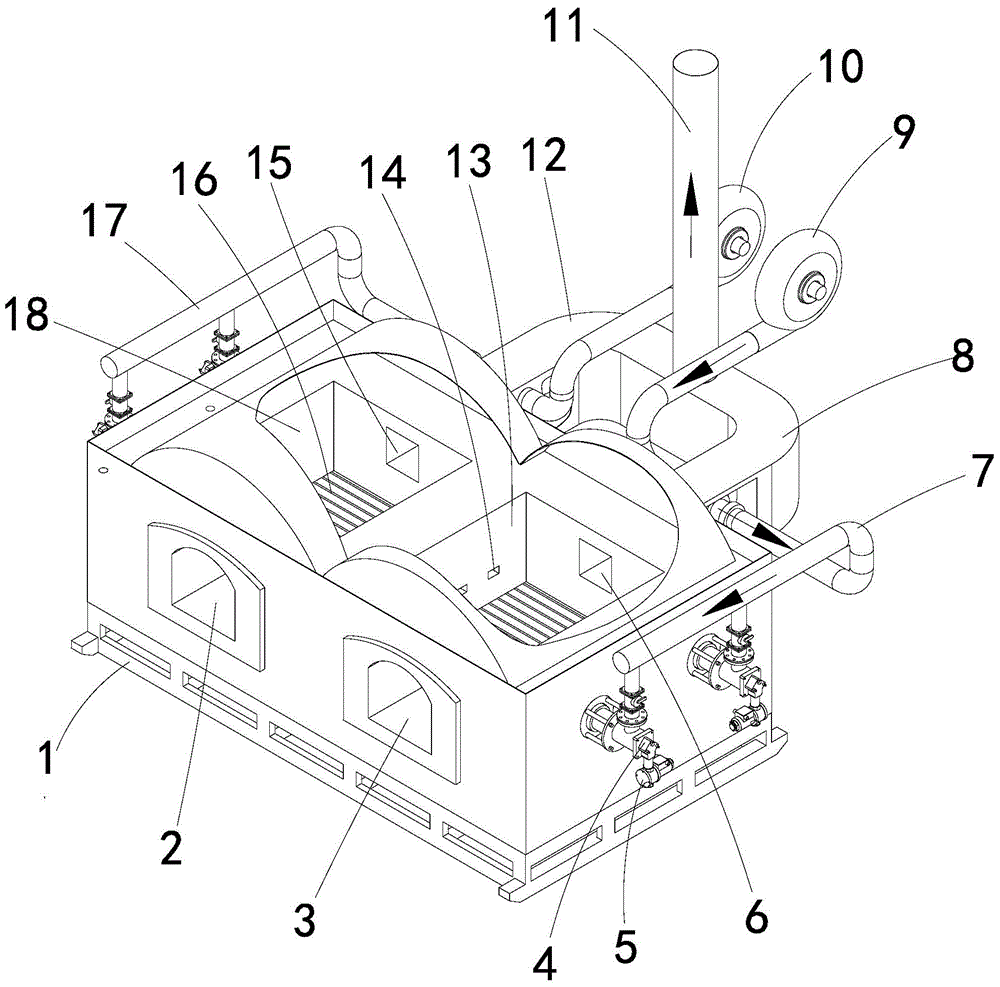

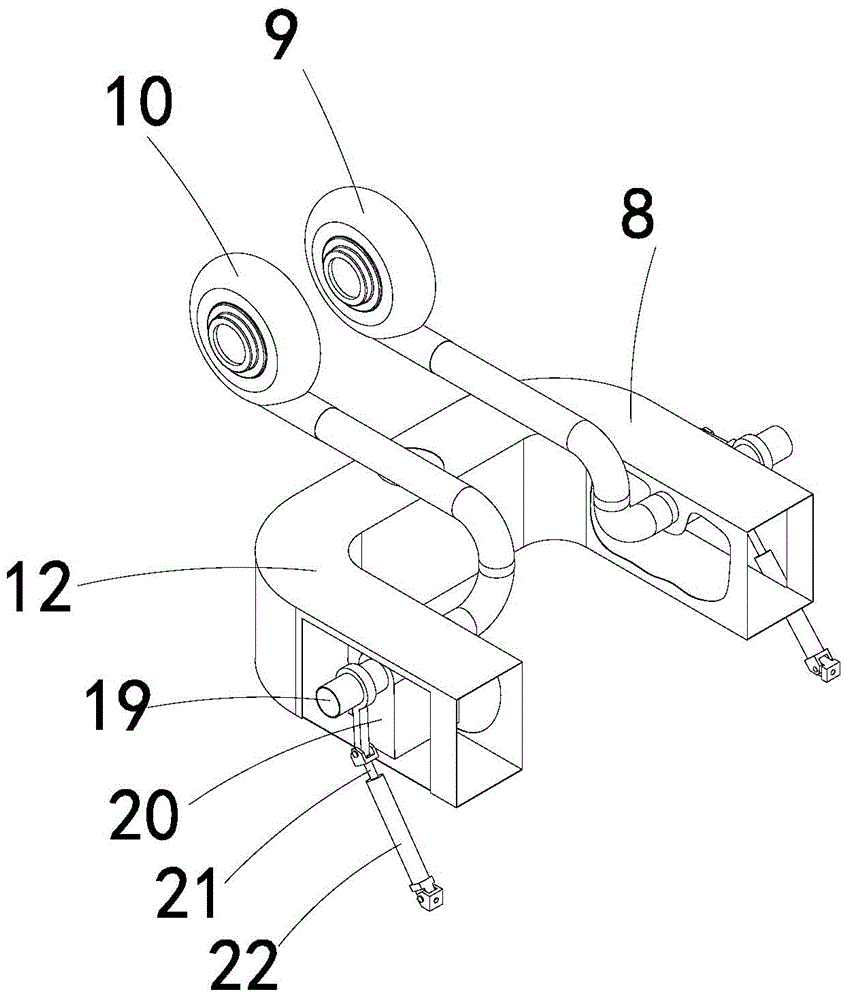

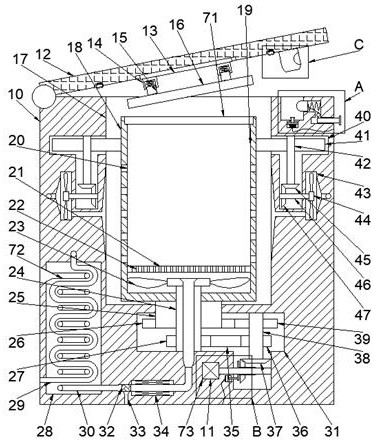

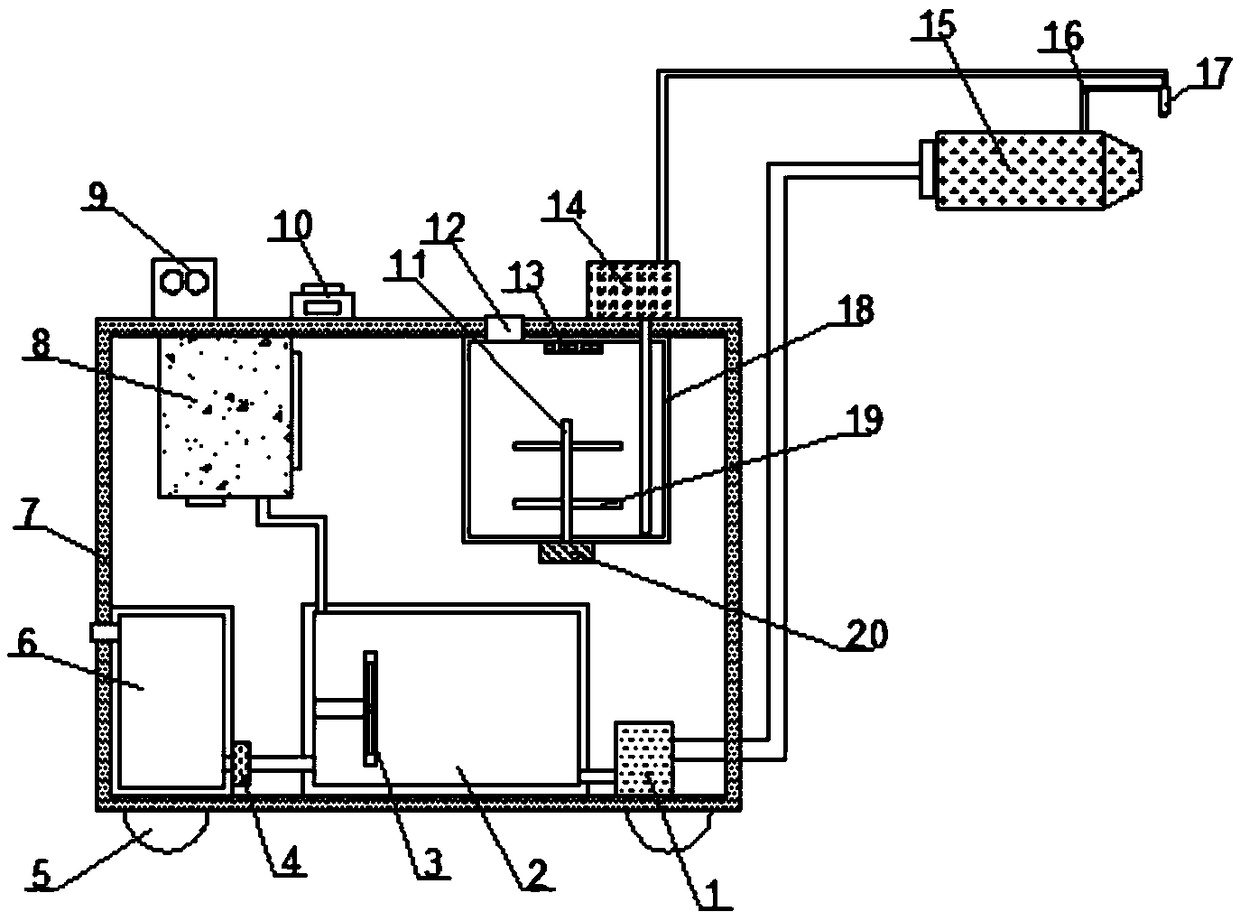

Medicine scalding fumigation therapy equipment

PendingCN111419683APromote blood circulationImprove vascular permeabilityDevices for pressing relfex pointsVibration massageBiologyScalding

The invention discloses medicine scalding fumigation therapy equipment, and belongs to the technical field of medical equipment. The equipment includes a scalding fumigation therapy cabin and a medicinal liquid and medicinal vapor preparation device; the scalding fumigation therapy cabin includes a cabin body, the cabin body is slidably connected with a cabin cover, and a medicinal liquid opening,a vapor opening and a water discharge outlet are arranged in the cabin body; the medicinal liquid and medicinal vapor preparation device includes a medicine decoction device, the medicine decoction device is provided with a medicine decoction accommodating cavity, a heating component is arranged in the medicine decoction device, the medicine decoction device is fixedly connected with a medicinalliquid cavity communicating with the medicine decoction accommodating cavity, and a water inlet chamber is arranged on the outer side of the medicinal liquid cavity along the circumferential direction; and one end, far away from the of the medicine decoction device, of the medicinal liquid cavity is fixedly connected with a medicinal vapor storage cavity, a vapor inlet pipe is fixedly connected tothe medicinal vapor storage cavity, and the vapor inlet pipe communicates with the vapor opening. The equipment can continuously and stably provide a continuous flow of medicinal vapor to the cabin body, helps to improve the fumigation and scalding effects, and is suitable for therapy courses with long duration of fumigation and scalding.

Owner:四川能节环保科技有限公司

Heat-recovery air flue system used for kiln

PendingCN106766970ATake advantage ofTo achieve the effect of recyclingCombustion processIndirect carbon-dioxide mitigationCombustionFlue

The invention provides a heat-recovery air flue system used for a kiln. In a kiln path production direction, the heat-recovery air flue system is sequentially equipped with a pre-heating region, a firing region and a cooling region, wherein the pre-heating region comprises a smoke-exhausting main tube and at least one primary smoke exhaust fan; the firing region comprises a combustion-supporting air main tube, a plurality of groups of combustion-supporting air branch tubes, at least one upper combustion-supporting air branch tube and at least one lower combustion-supporting air branch tube, which are connected with each group of combustion-supporting air branch tubes; and the cooling region comprises a heat extraction air tube, a first combustion-supporting branch tube, a second combustion-supporting branch tube, a front-cooling air inlet tube and a tail-cooling air inlet tube. In this way, air flue systems among the pre-heating region, the firing region and the cooling region of the heat-recovery air flue system are matched with one another, so that sufficient utilization of heat in the kiln path is realized.

Owner:GUANGDONG CHINA KILN TECH CO LTD

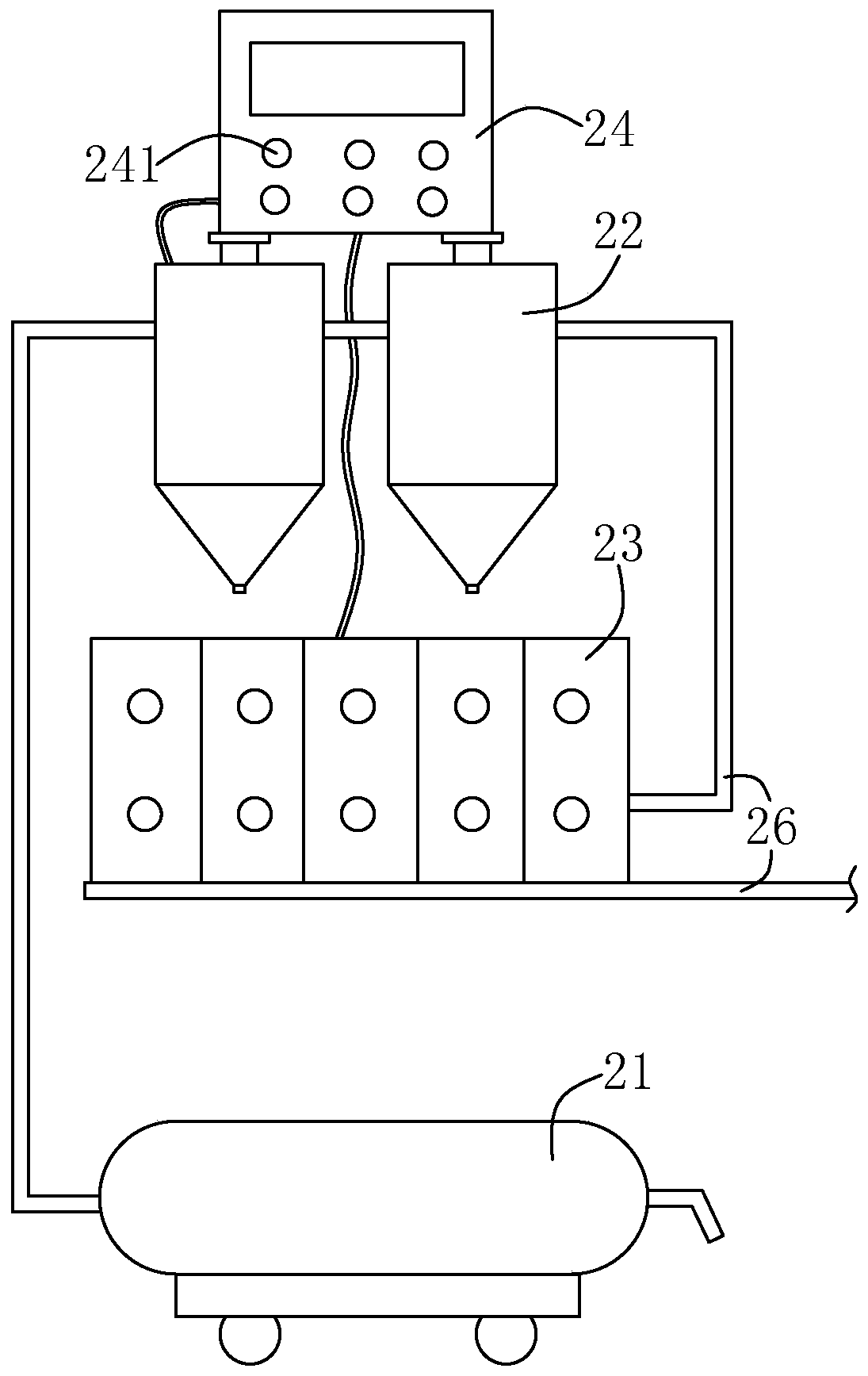

Packing machine capable of exhausting air in bags and improving working efficiency

ActiveCN110589107AImprove work efficiencyTo achieve the warm-up effectWrapper twisting/gatheringCold airCooling effect

The invention relates to the technical field of packing related equipment, and discloses a packing machine capable of exhausting air in bags and improving the working efficiency. The packing machine comprises a shell; packing devices are fixedly mounted on the left and right sides of the inner wall of the shell; the packing devices comprise driving devices and fixed rods; the driving devices are movably provided with heating devices through electric extension rods; air blowing devices are fixedly mounted on the right sides of the fixed rods; and air suppliers, air supply pipes and heating rings are fixedly mounted in the air blowing devices. In the packing machine capable of exhausting the air in the bags and improving the working efficiency, the driving devices drive the electric extension rods, the heating devices and slide rods to operate; the slide rods and slide rails are matched to drive first switches and second switches to operate and to drive the air suppliers and the heatingrings to work, so that hot air is sprayed out from nozzles; the second switches are turned off to only exhaust cold air; and the air in packing bags is extruded by air currents, so that the air in thepacking bags is exhausted, seals are preheated before machining, and the cooling effect is achieved after machining.

Owner:山东天威食品科技有限公司

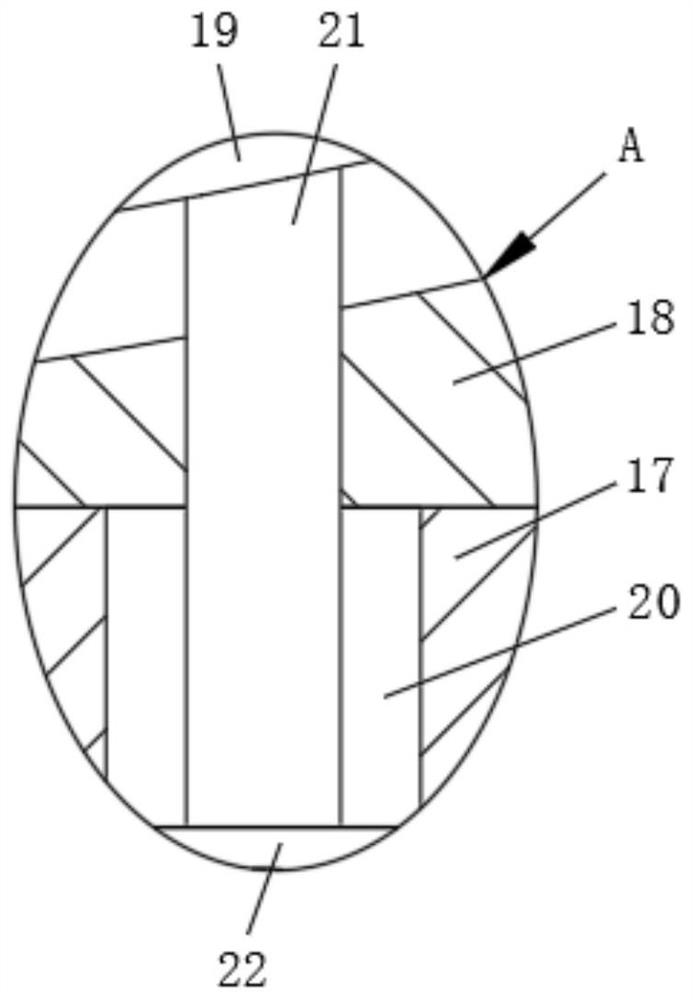

Motorcycle cylinder

InactiveCN106523174AExtend your lifeGood heating effectCylinder headsCylindersPistonElectric heating

The invention discloses a motorcycle cylinder. The motorcycle cylinder comprises a cylinder body, the surface of the inner wall of the cylinder body is covered with a cylinder sleeve, a piston is arranged in the cylinder body and is movably connected to the surface of the cylinder sleeve, gas chambers are fixedly connected to the two sides of the cylinder body, hot gas chambers are arranged in the gas chambers, vent holes are formed in the surfaces of the hot gas chambers, heating bars are fixedly mounted on the tops of the inner walls of the hot gas chambers, and the surfaces of the heating bars are wound with electric heating wires; according to the motorcycle cylinder, heating chambers and the hot gas chambers are arranged in the gas chambers, the effect of preheating the interior of the cylinder body is achieved, through the heating bars and the electric heating wires, the effect of heating gas in the hot gas chambers is achieved, the vent holes are formed in the surfaces of the hot gas chambers, the effect of gas flowing heating is achieved, the cylinder sleeve is arranged, the effect of protecting the inner wall of the cylinder body is achieved, heat conduction chambers are arranged, and the cooling effect on the cylinder body is achieved.

Owner:范广志

Catalytic thermal oxidizer with sintering prevention function and sintering prevention method thereof

ActiveCN102840590APrevent sinteringSo as not to damageIncinerator apparatusHeat flowProcess engineering

The invention relates to a catalytic thermal oxidizer with sintering prevention function and a sintering prevention method thereof. The catalytic thermal oxidizer comprises a first heat exchanger, a heater and a catalyst bed with entrance and exit, wherein a plurality of cooling devices are arranged in the catalyst bed; a second heat exchanger arranged before the first heat exchanger, wherein a heat flow pipeline is connected between the second heat exchanger and each cooling device of the catalyst bed; a cooling liquid supply and transport device, wherein a cold flow pipeline is connected among the second heat exchanger, the cooling liquid supply and transport device and each cooling device of the catalyst bed; and a controller with a temperature sensor, wherein the temperature sensor is arranged on the exit of the catalyst bed to sense wherein the temperature on the exit exceeds the preset temperature or not, furthermore the start and stop of the cooling liquid supply and transport device is controlled by the controller, so as to automatically reduce the temperature of the catalyst bed and prevent sintering.

Owner:DESICCANT TECH CORP

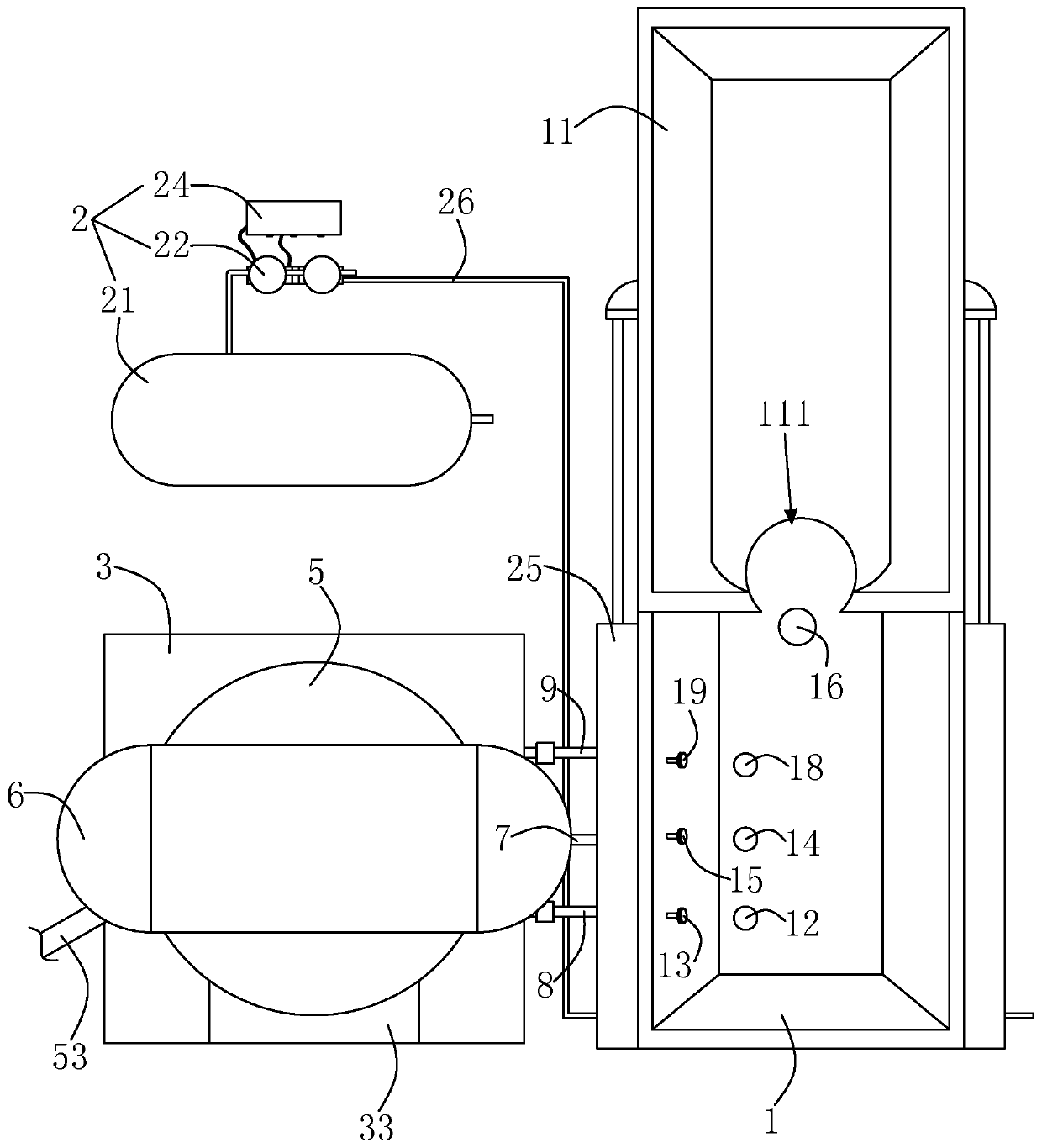

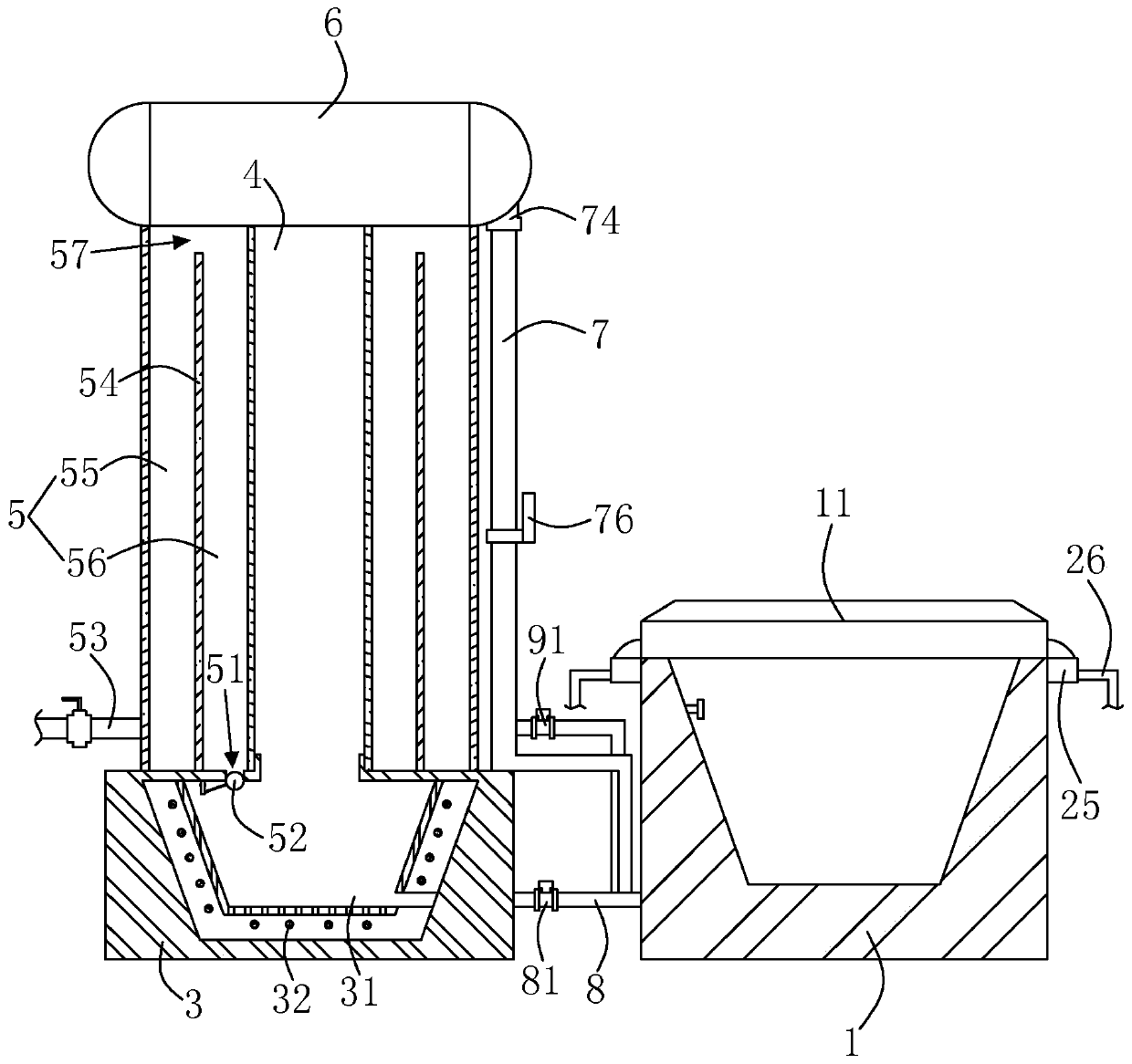

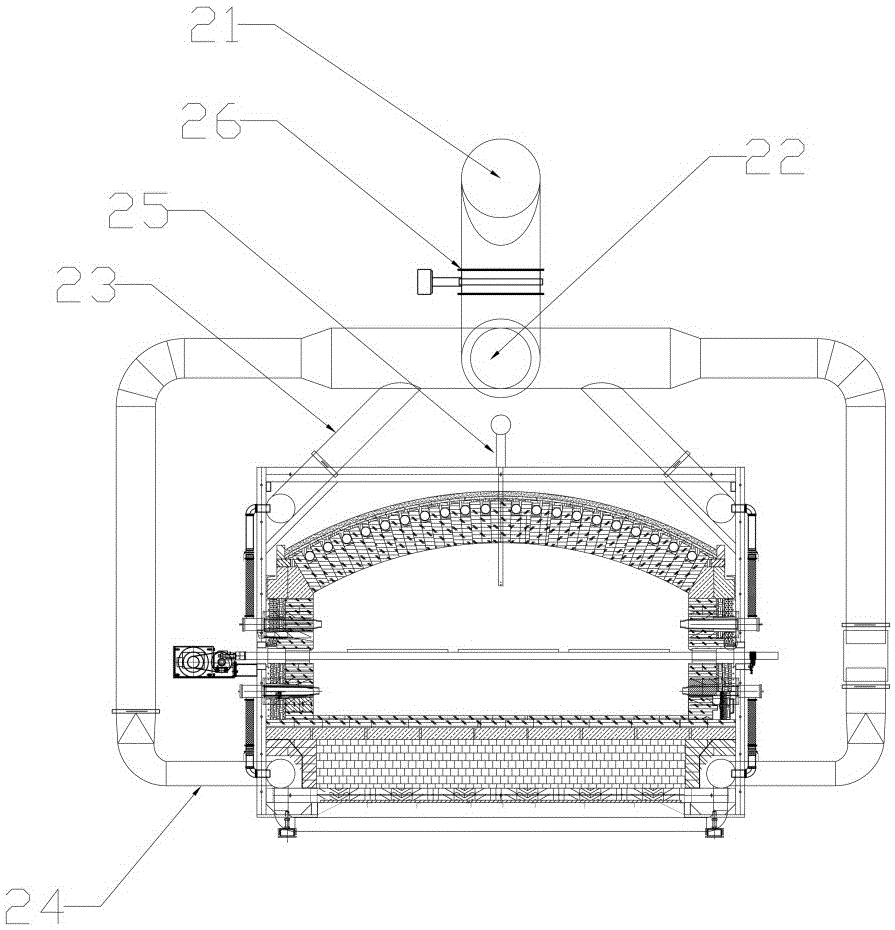

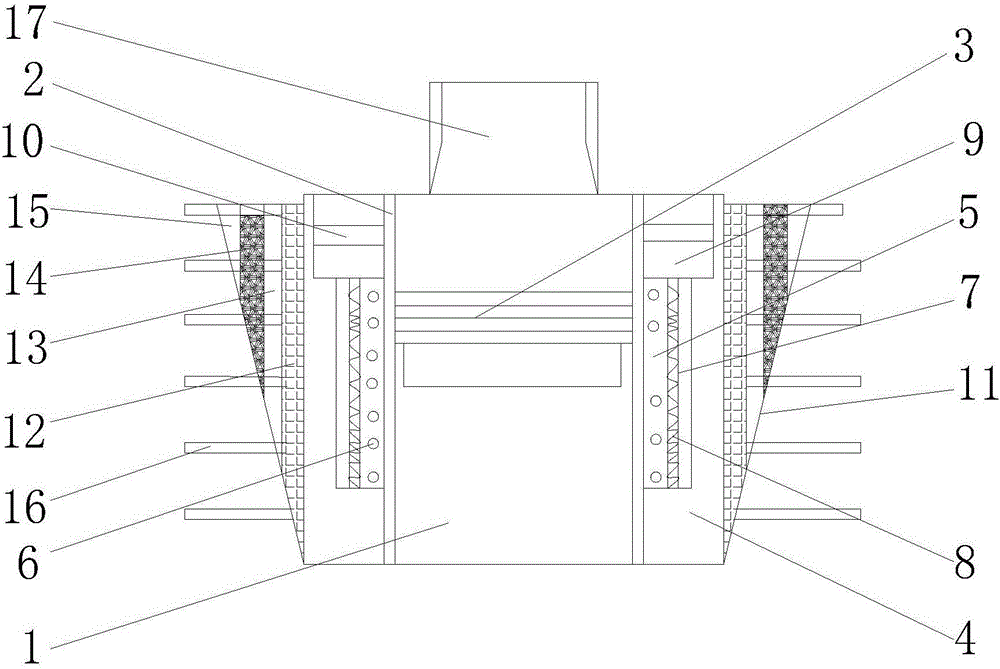

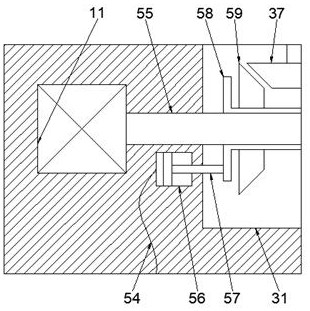

Physical simulation experiment device, system and method for SAGD technology

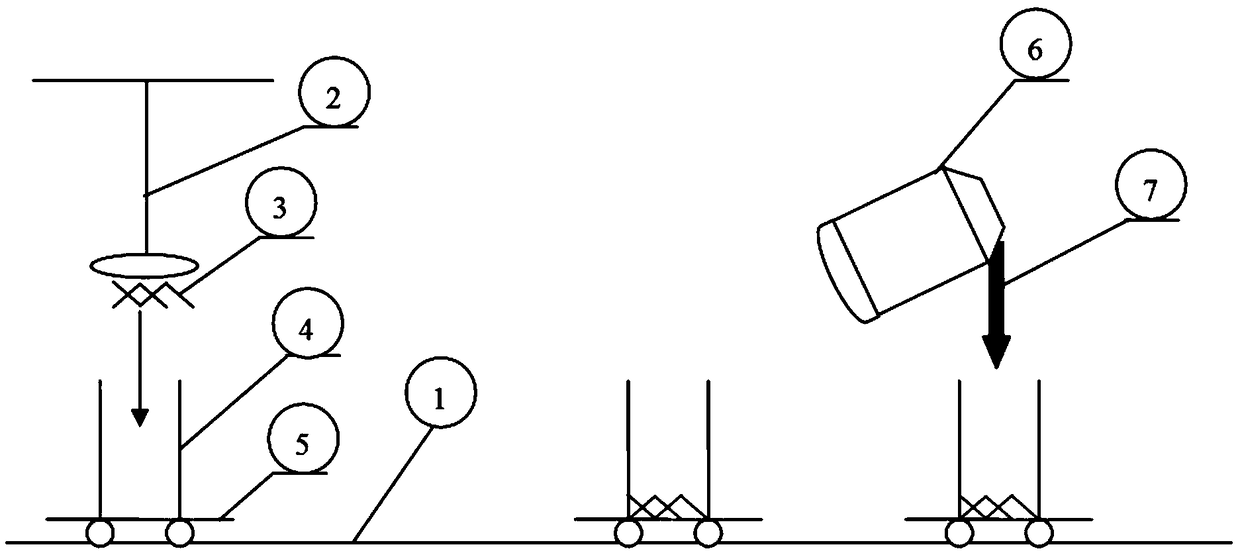

ActiveCN111155976AAvoid cloggingAccurate measurementFluid removalEducational modelsParticulatesThermodynamics

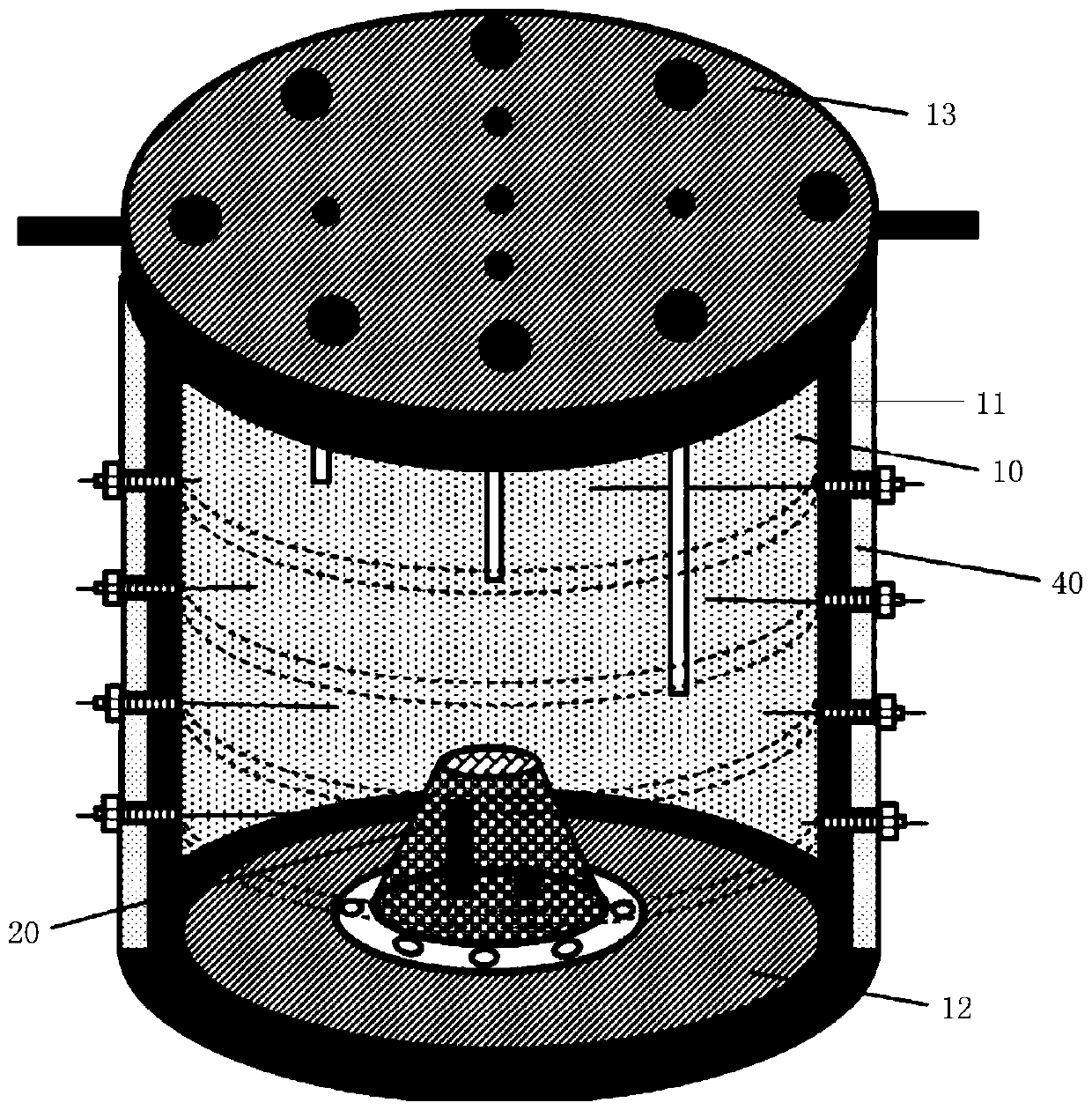

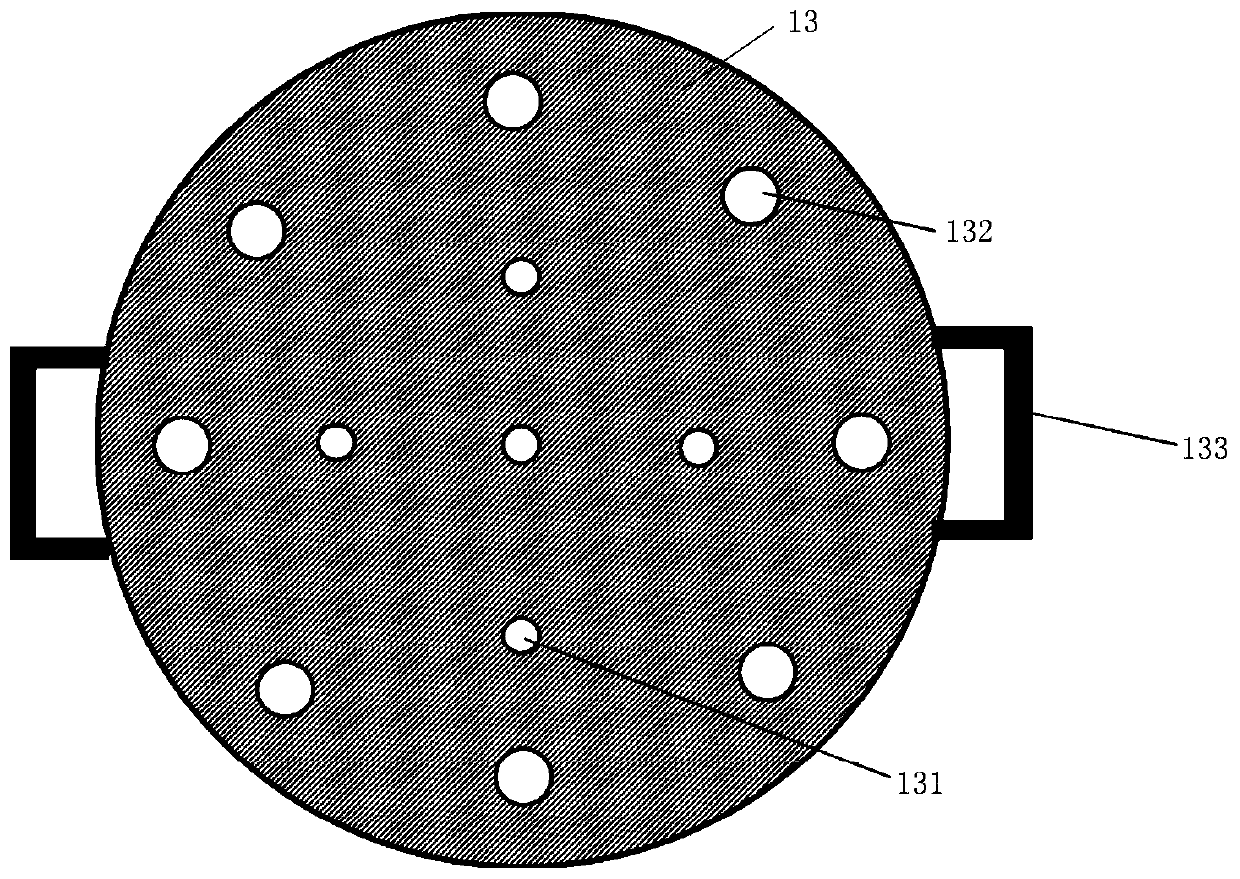

The invention provides a physical simulation experiment device, system and method for an SAGD technology. The physical simulation experiment device for the SAGD technology comprises a model cylinder,a preheating cylinder, a simulated production well and a simulated steam injection well, wherein the model cylinder is filled with a first particulate matter so as to construct a porous medium environment of an oil sand reservoir; the preheating cylinder is arranged at the bottom of the model cylinder, and the preheating cylinder is filled with the second particulate matter; a hole structure is formed in the cylinder wall of the preheating cylinder so as to communicate the preheating cylinder and the model cylinder; and the simulated production well and the simulated steam injection well communicate with the preheating cylinder. According to the physical simulation experiment device, the technical problem that in the experiment of simulating the SAGD production process, the preheating timeis long, blocking occurs easily, and a vertical relative permeability saturation curve is difficult to accurately measure is solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

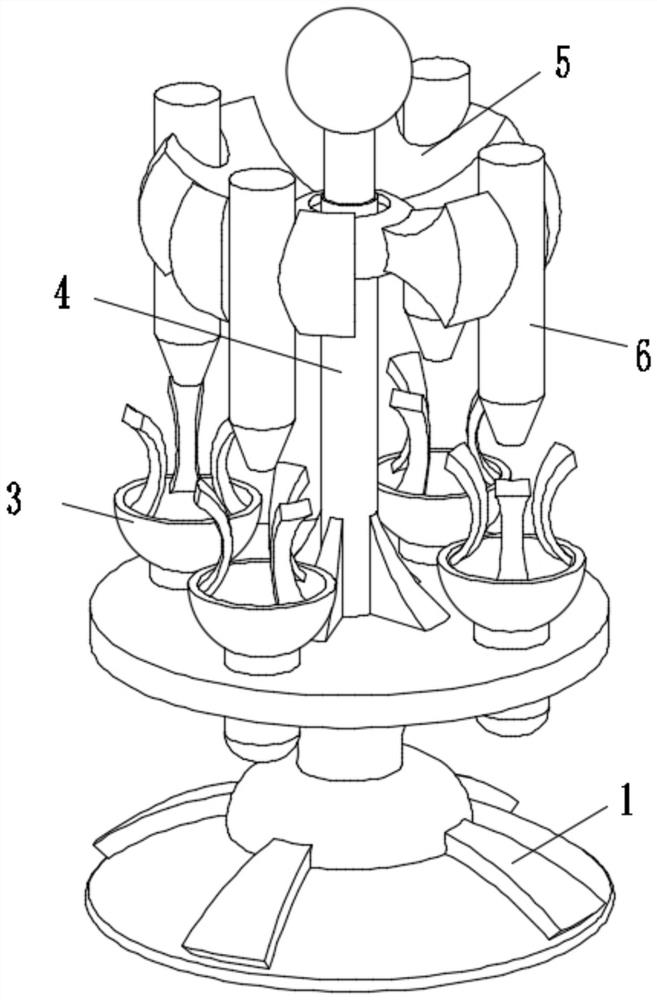

Pouring equipment for preparing fused quartz ceramic and pouring process of pouring equipment

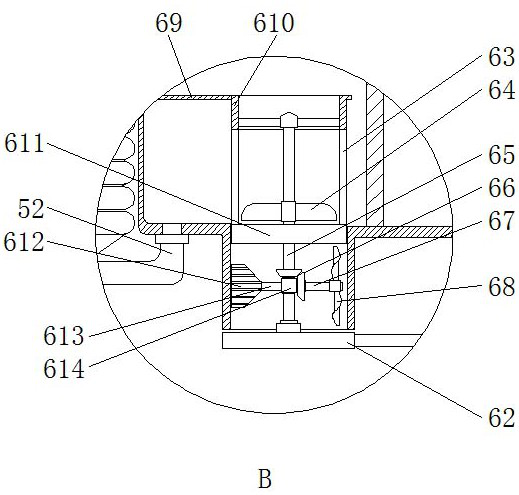

ActiveCN112622016ATo limit displacementEasy pouring workCeramic shaping plantsFeeding arrangmentsElectric machineEngineering

The invention discloses pouring equipment for preparing fused quartz ceramic and a pouring process of pouring equipment. The pouring equipment comprises a fixing base, a fixing column, a cooling mechanism and a main body part are sequentially fixed to the top end of the fixing base, a first motor is fixed to one side of the interior of the fixing column, a first rotating rod is fixed to the output end of the first motor, a first bevel gear is fixed to the end, away from the first motor, of the first rotating rod, a second rotating rod is rotatably connected to the end, away from the fixing base, of the fixing column through a bearing, and a second bevel gear is fixed to the end, close to the fixing column, of the second rotating rod. The pouring equipment for preparing the fused quartz ceramic and the pouring process of the pouring equipment have the beneficial effects that the situation that molten liquid is cooled in a conveying pipeline can be effectively avoided, a pipeline is preheated, the working efficiency of the equipment is greatly improved, the equipment can fix a mold, the pouring work of the equipment is more convenient, meanwhile, the mold can be cooled, and therefore the pouring efficiency is improved.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

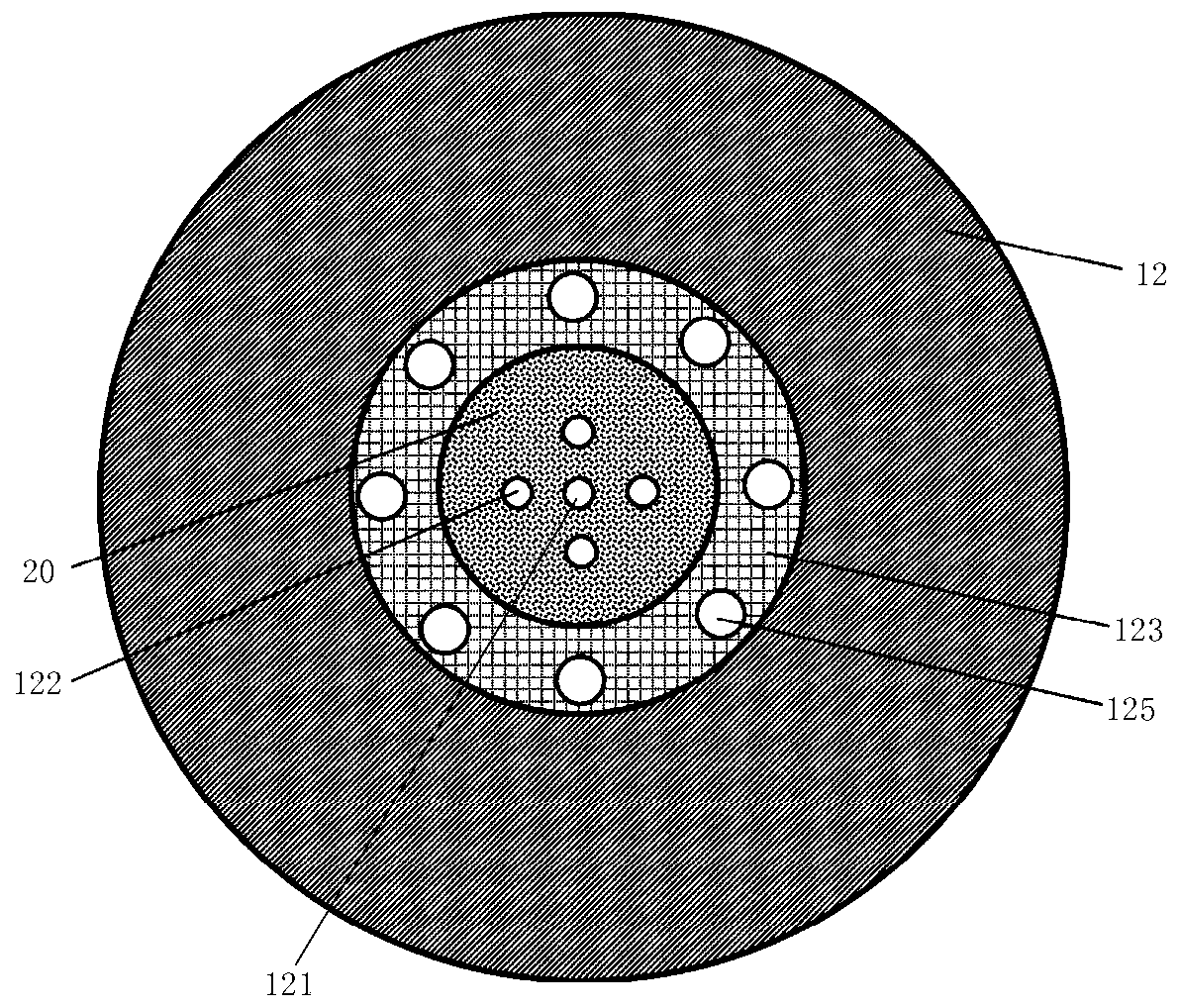

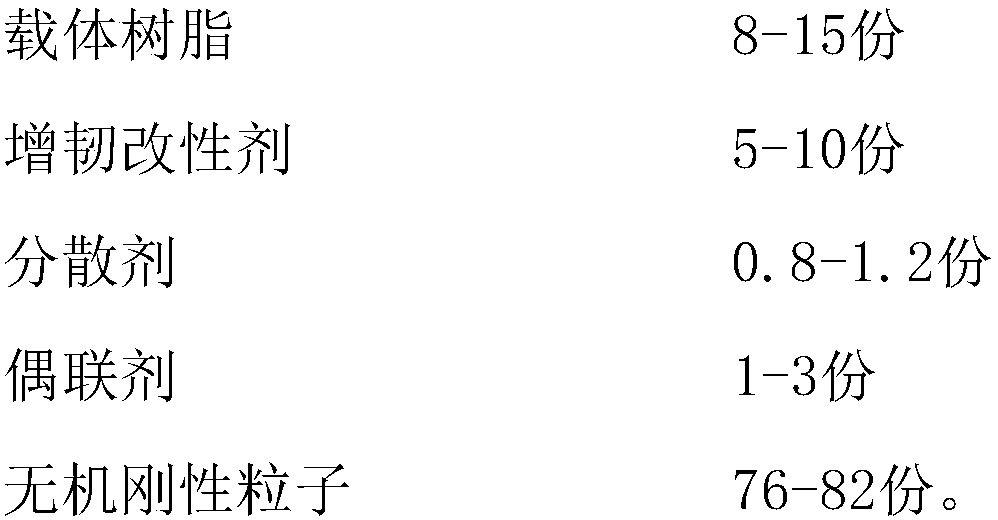

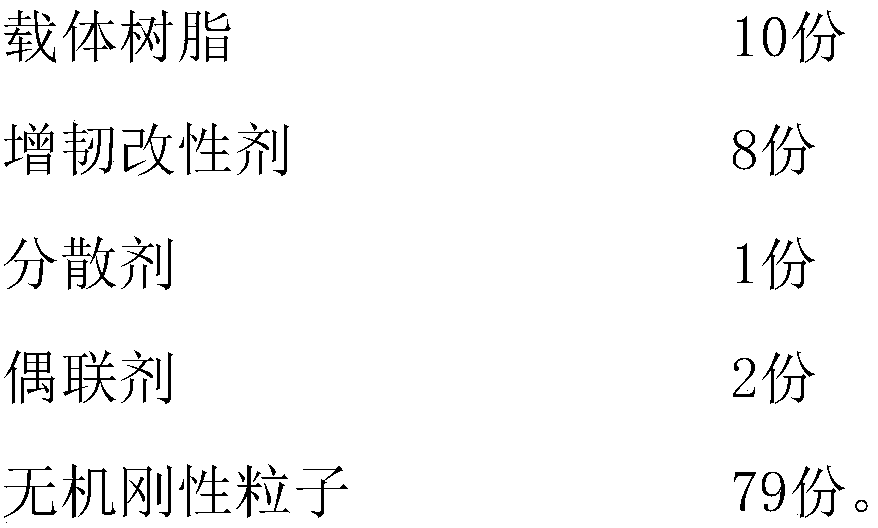

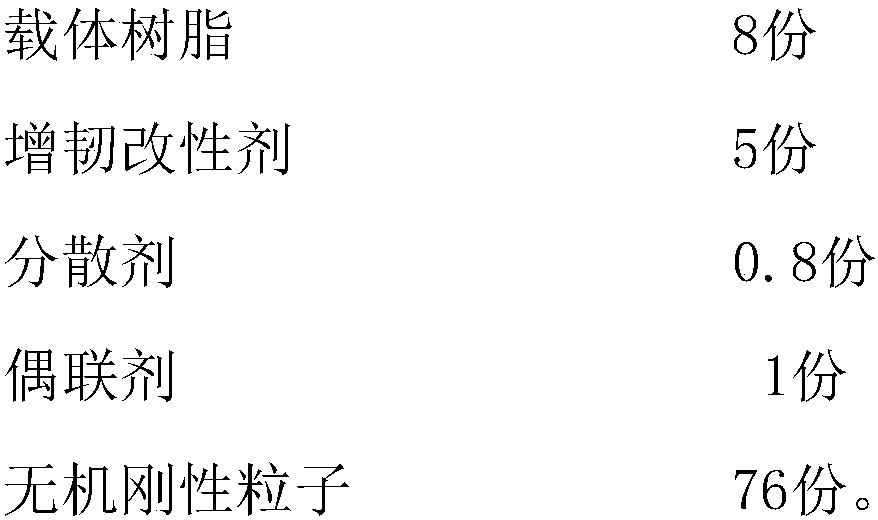

Flat filament master batch and preparation method thereof

Owner:东莞市长盈塑料编织包装有限公司

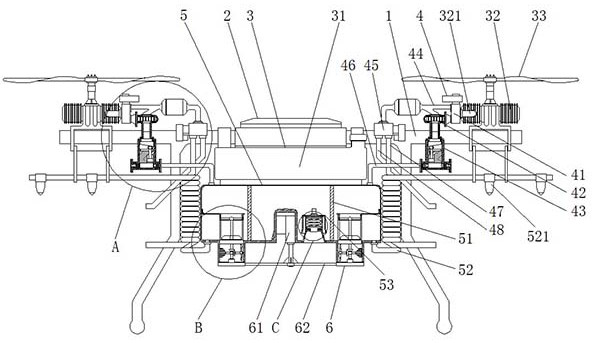

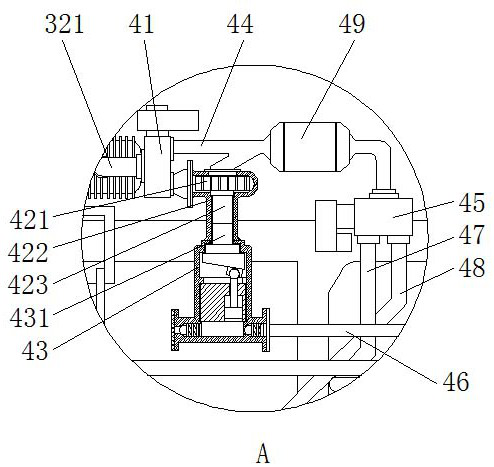

Intelligent unmanned aerial vehicle

ActiveCN113071681APrevent low temperature condensationReduce consumptionAircraft componentsCentrifugal wheel fertilisersControl systemFuel tank

The invention provides an intelligent unmanned aerial vehicle, which comprises a rack, a flight control system, a power system and a spraying box are arranged on the rack, the power system comprises an oil tank, a plurality of engines and rotor wings, a plurality of gas energy utilization assemblies are installed on the rack, and the gas energy utilization assemblies are connected with exhaust pipes of the engines. The gas energy utilization assemblies are connected with the spraying box, each gas energy utilization assembly is connected with a liquid spraying pipe on one side of the spraying box in a matched mode, a self-sealing liquid adding opening assembly is arranged at the bottom of the spraying box, and a pneumatic rotating scattering assembly is arranged at the bottom of the spraying box. According to the device, flowing kinetic energy and temperature heat energy of tail gas exhausted by the engine can be utilized at the same time through the gas energy utilization assembly, the flowing kinetic energy of the tail gas can be converted into power for pressurizing the spraying box, the temperature heat energy of the tail gas can preheat liquid medicine before spraying, and active spraying power and a heating mechanism do not need to be arranged; the energy consumption can be greatly reduced, and the unmanned aerial vehicle has longer endurance in plant protection work.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Method of reducing iron consumption for semi-steel smelting

InactiveCN109182641AIncrease the amount of participationTo achieve the warm-up effectManufacturing convertersEconomic benefitsRebar

The invention discloses a method of reducing iron consumption for semi-steel smelting. The method comprises the following steps that (1), a semi-steel ladle which has completed vanadium extracting tosemi-steel smelting for one-cycle production period is placed on a semi-steel vehicle; (2), a waste steel bar is added into the semi-steel ladle; (3), semi-steel in a vanadium extraction converter isadded into the semi-steel ladle in the step (2); and (4), the substance of the semi-steel ladle in the step (3) is poured into a semi-steel furnace for smelting. According to the method, the process of an original production technology is not changed, the original production mode is not affected, equipment does not need to be added, only at the production interval time, the waste steel bar is preheated by utilizing the surplus temperature of the semi-steel ladle, and then the waste steel bar is melted by utilizing the impact force of the semi-steel and the high temperature. Through the summaryby an inventor on production and practice, the semi-steel smelting method provided by the invention is adopted, every semi-steel furnace can use extra about 0. 7 tons of waste steel compared with before and produce about 7 kilotons of steel per year, and basing on 4300 Yuan / ton to calculate, the economic benefit can be increased by 30,000,000 Yuan / year.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Solar water heater with good heat collection effect

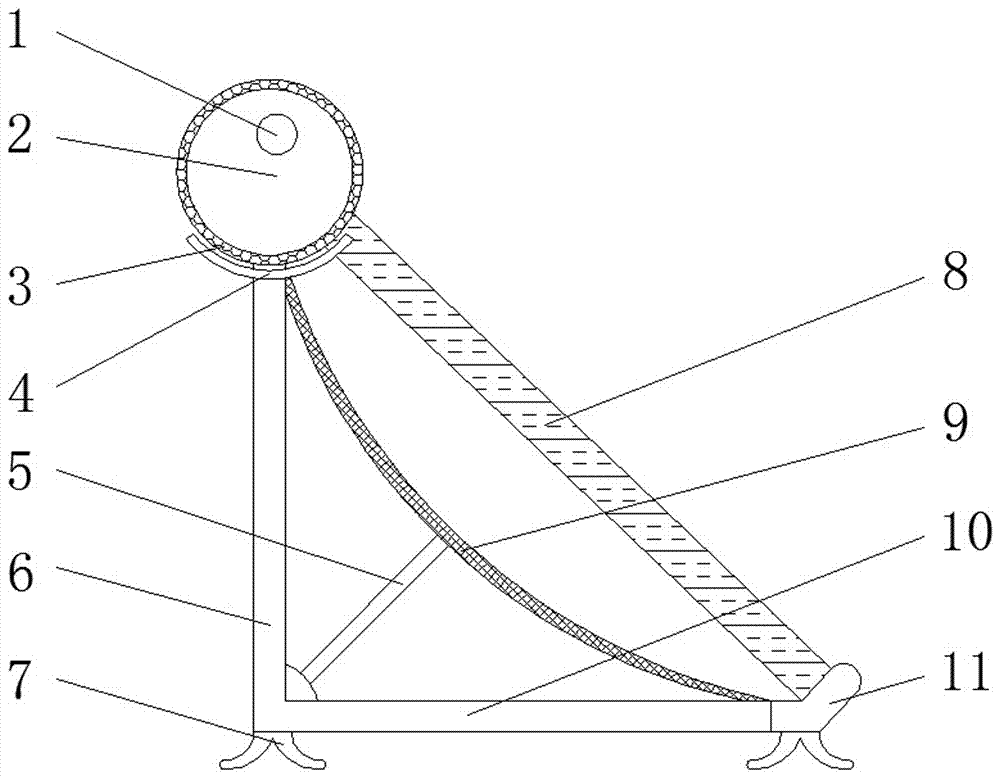

InactiveCN106885380AEasy to useHeating fastSolar heating energySolar heat devicesSolar waterEngineering

The invention provides a solar water heater with a good heat collection effect. The solar water heater comprises a solar water heater body. A triangular fixing base is arranged on the bottom of the solar water heater body, and the top of the triangular fixing base is welded to a heat preservation water tank through a semicircular tray. A heat insulation heat preservation layer is arranged in an inner wall of the heat preservation water tank. A heat absorbing pipe limiting plate is welded to the horizontal plate end opening position of the triangular fixing base, and the heat preservation water tank is welded to a storage water preheating tank through a communicating pipe. According to the solar water heater, a semispherical reflector is arranged below solar heat absorbing pipes, when the weather is bad, water in the solar water heater is difficult to rapidly heat in time, the reflector can rapidly heat the water in the solar water heater, heat is collected, the solar heat absorbing pipes rapidly absorb heat, and therefore the heating efficiency of the solar water heater is higher.

Owner:SHENZHEN SHANGYU TECH CO LTD

Motorcycle cylinder

The invention discloses a motorcycle cylinder, which comprises a cylinder, the surface of the inner wall of the cylinder is covered with a cylinder liner, the inside of the cylinder is provided with a piston, and the piston is movably connected to the surface of the cylinder liner, and the two sides of the cylinder Both are fixedly connected with a gas chamber, the interior of the gas chamber is provided with a hot gas chamber, the surface of the hot gas chamber is provided with ventilation holes, the top of the inner wall of the hot gas chamber is fixedly installed with a heating rod, and the surface of the heating rod is wound with Heating wire. The motorcycle cylinder achieves the effect of preheating the interior of the cylinder by setting a heating chamber and a hot gas chamber inside the gas chamber, and achieves the effect of heating the gas in the hot gas chamber by setting a heating rod and an electric heating wire. Ventilation holes are set on the surface of the chamber to achieve the effect of gas flow heating, the effect of protecting the inner wall of the cylinder is achieved by setting the cylinder liner, and the heat dissipation effect of the cylinder is achieved by setting the heat conduction chamber.

Owner:重庆正柱电子工程有限公司

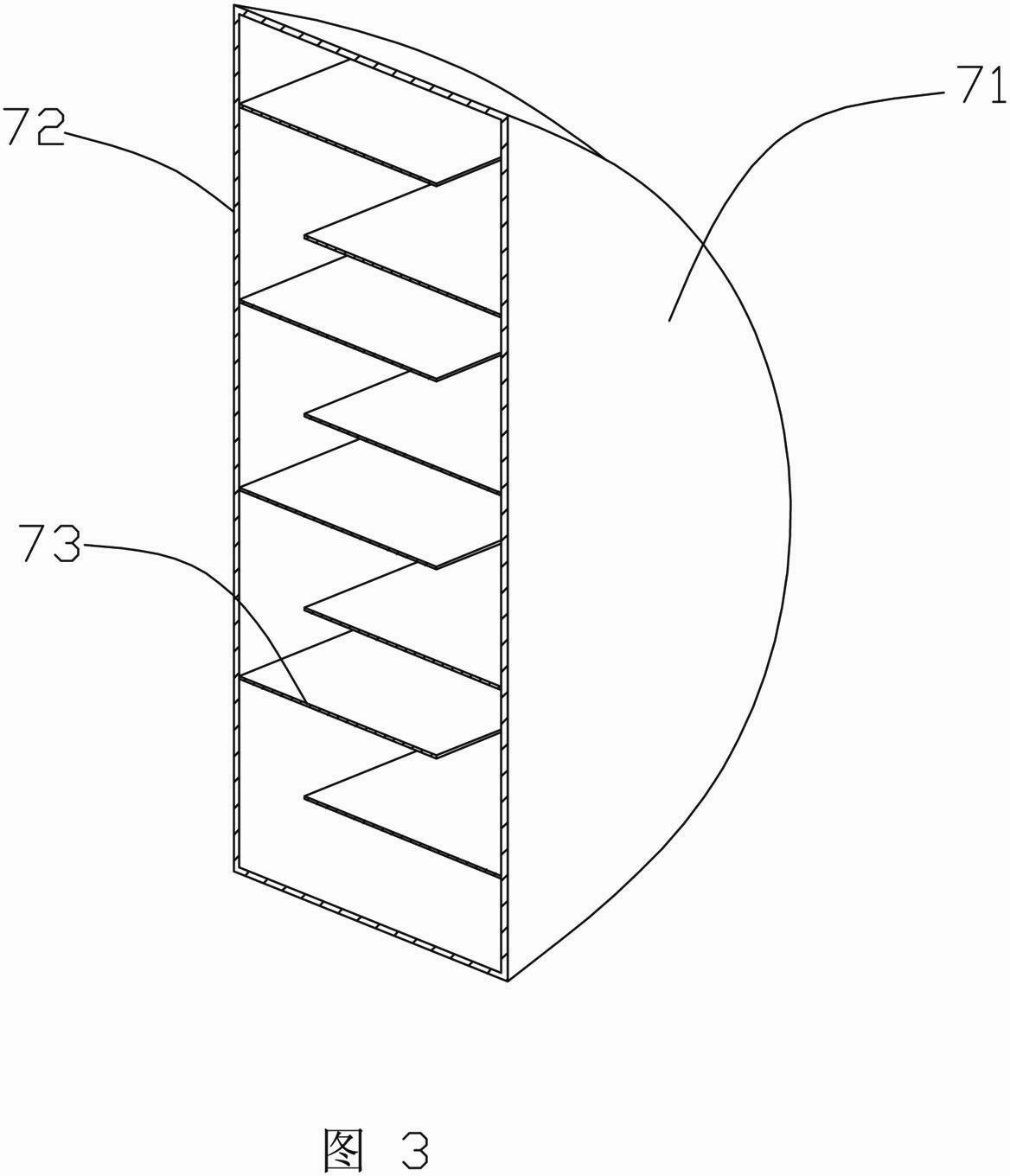

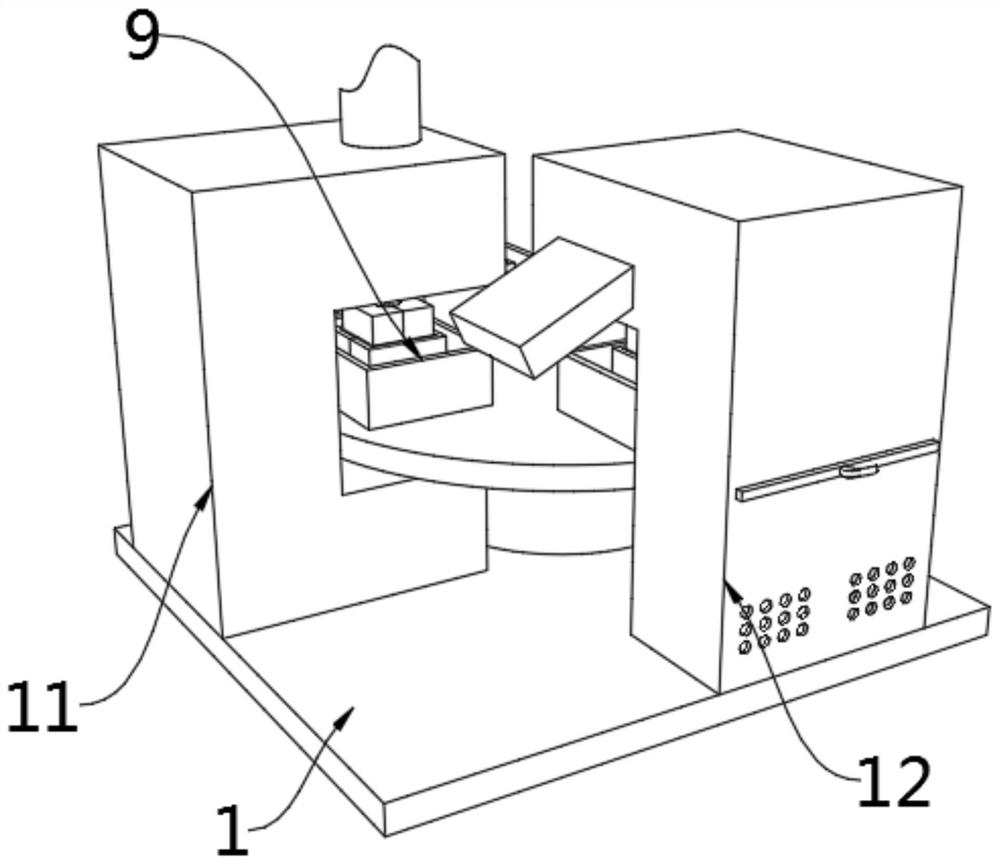

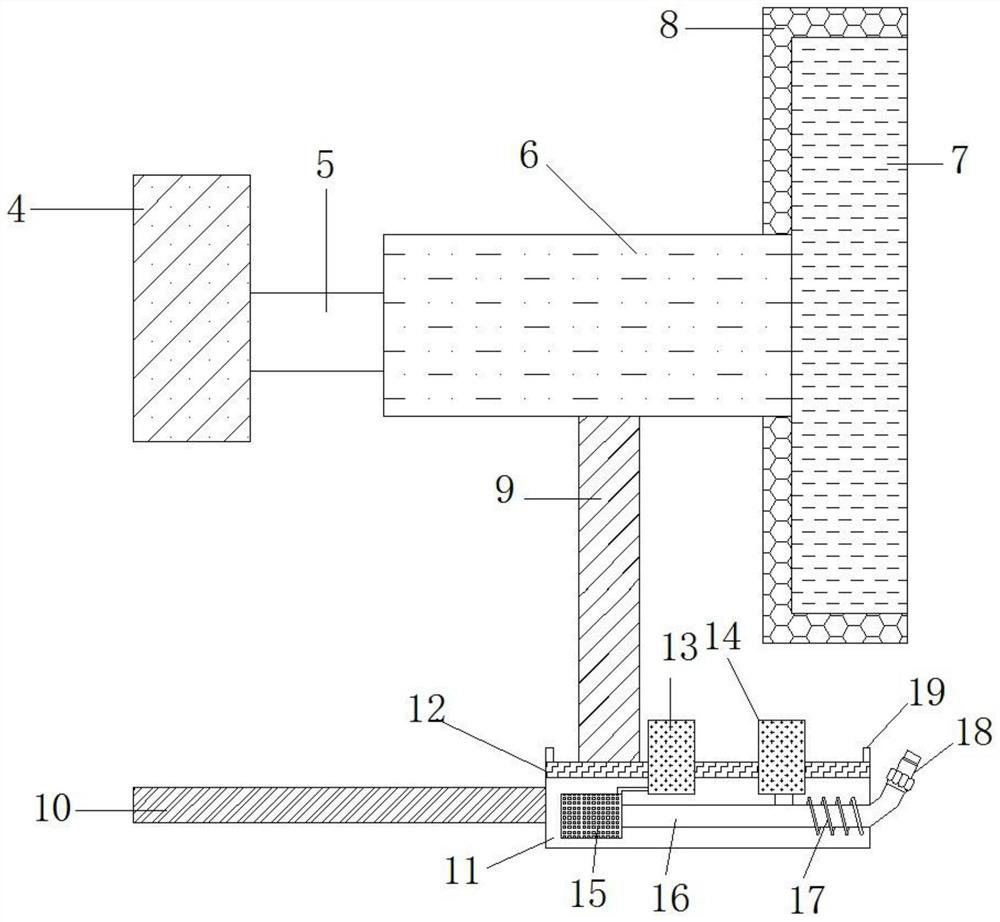

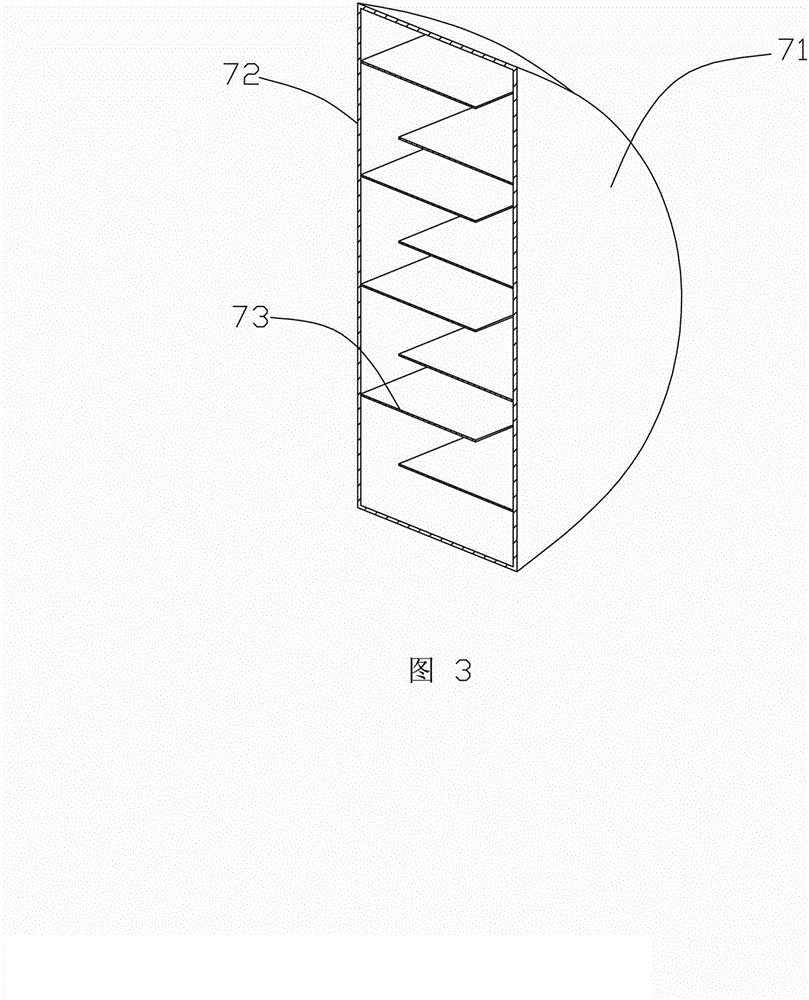

Aluminum oxide feeding system and method

The invention discloses an aluminum oxide feeding system and an aluminum oxide feeding method. The aluminum oxide feeding system comprises a pulverizing machine and a feeding machine, wherein a feed port is formed in the upper portion of the pulverizing machine, a rotary guide pole is arranged in the pulverizing machine, pulverizing blades for stirring and pulverizing aluminum oxide powder insideare arranged on the rotary guide pole, the bottom of the pulverizing machine abuts against and communicates with the feeding machine, a hierarchical diverter which extends a dropping route of the aluminum oxide powder in the feeding device is arranged in the feeding device, a feeding port which enables the aluminum oxide to enter an electrolytic bath is formed in the end point of the powder routeof the hierarchical diverter, and the interior of the feeding machine is connected in series with a gas collection tube of the electrolytic bath through an air pipe. The aluminum oxide feeding systemand method can obviously improve dispersion and dissolution speed of the aluminum oxide, achieve uniform concentration distribution of the aluminum oxide, enable concentration of the aluminum oxide inthe electrolytic bath to fluctuate stably, reduce generation of precipitates, and are high in current efficiency, low in energy consumption, and especially suitable for acid feeding of the aluminum oxide.

Owner:CENT SOUTH UNIV

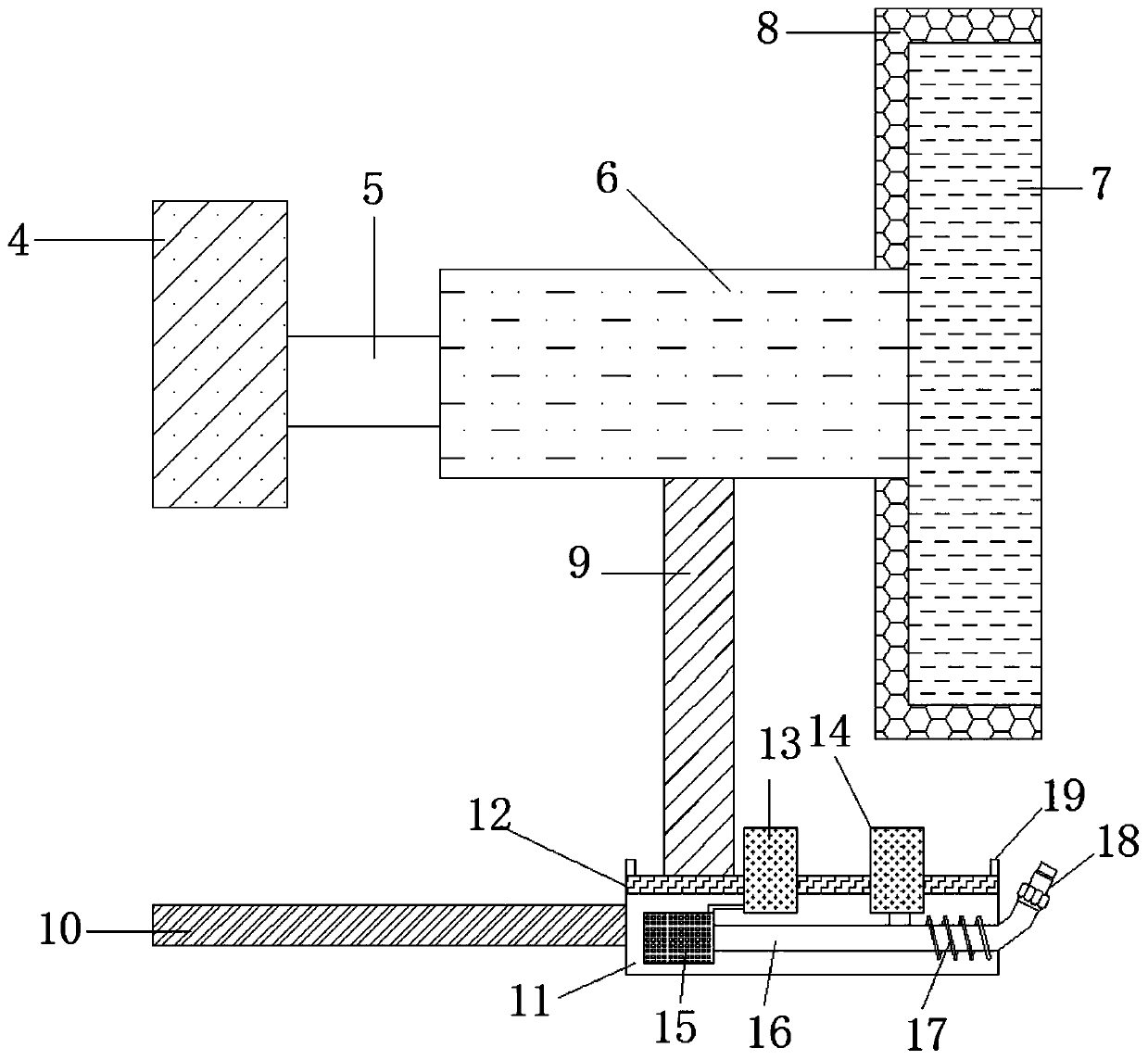

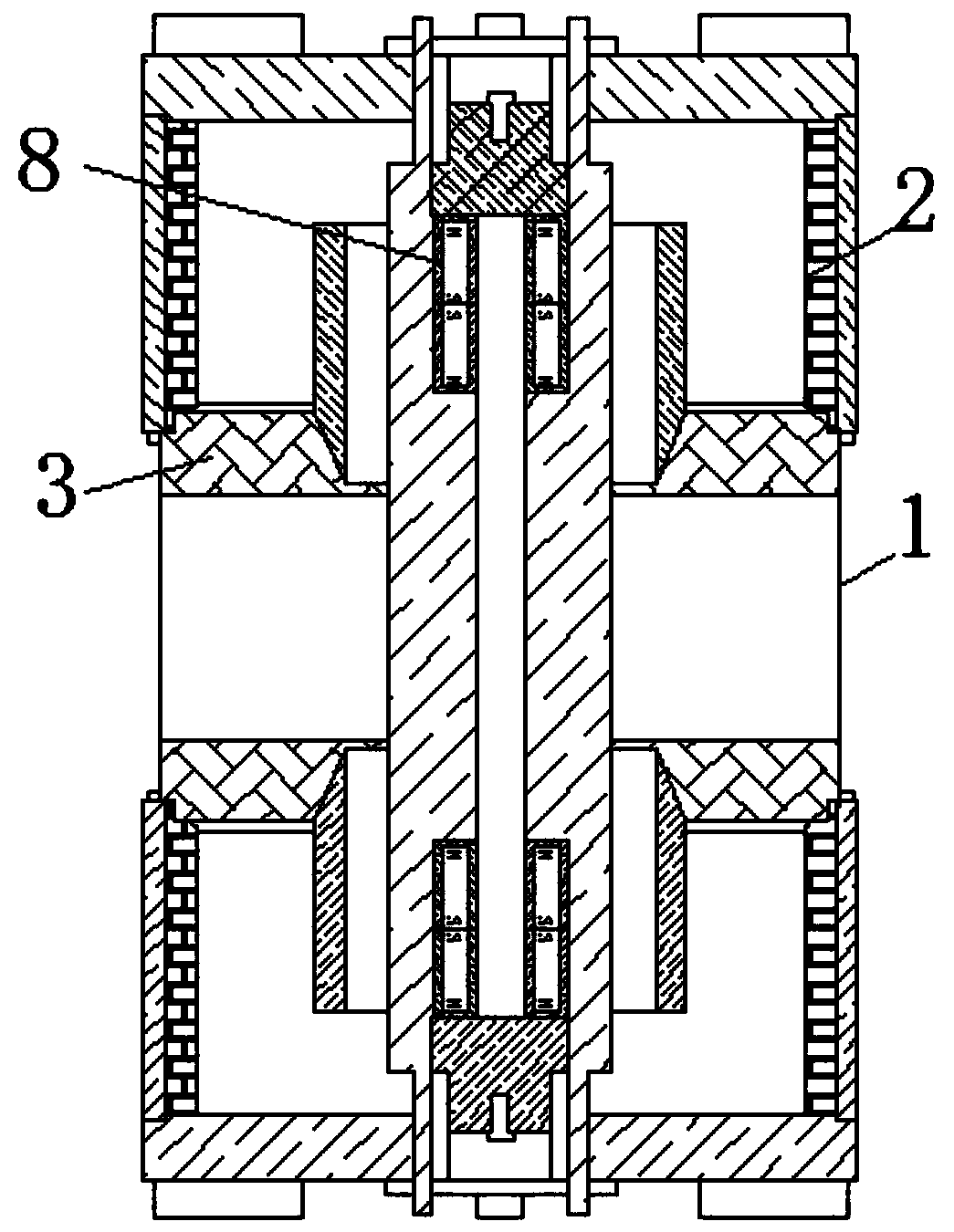

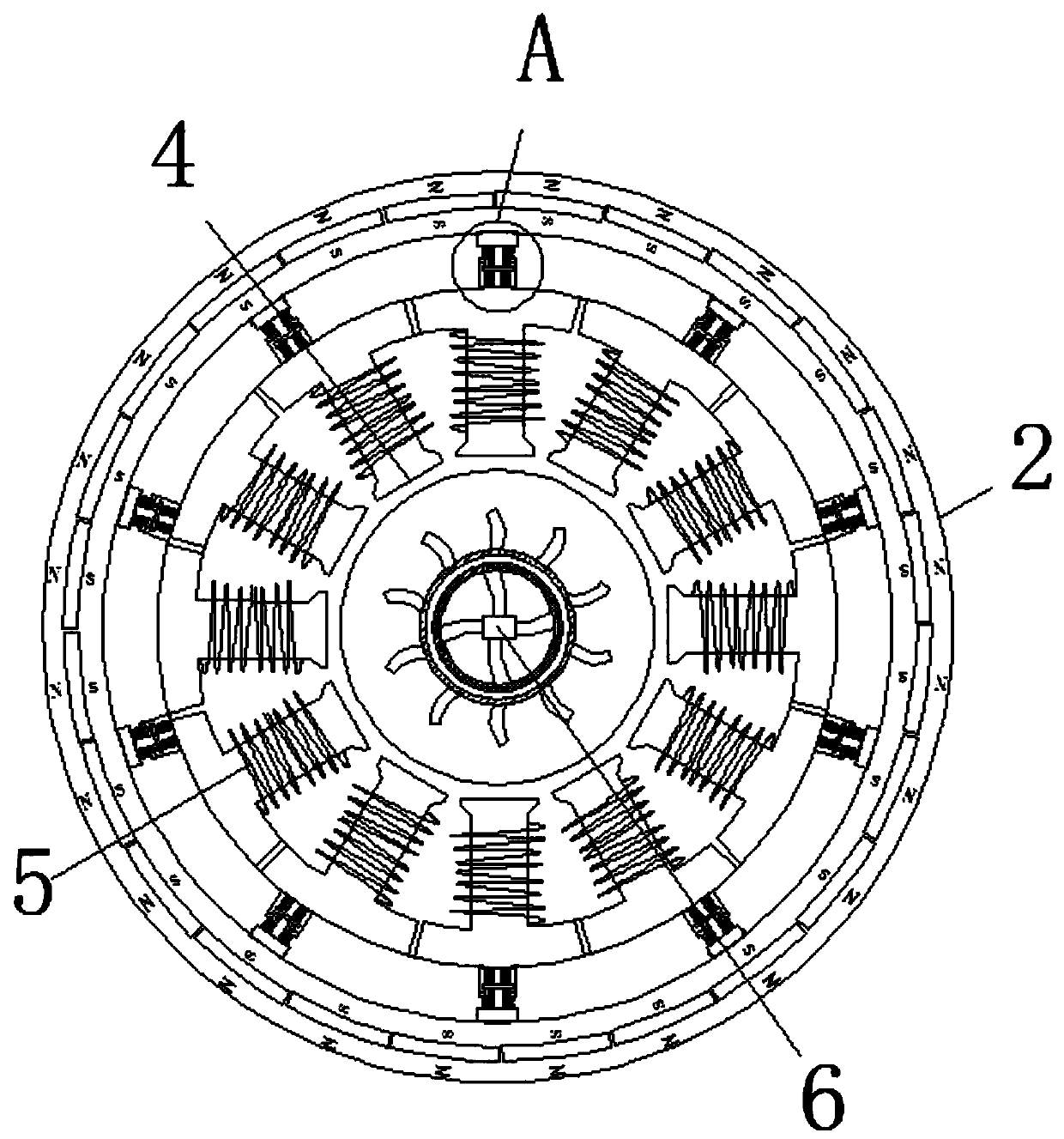

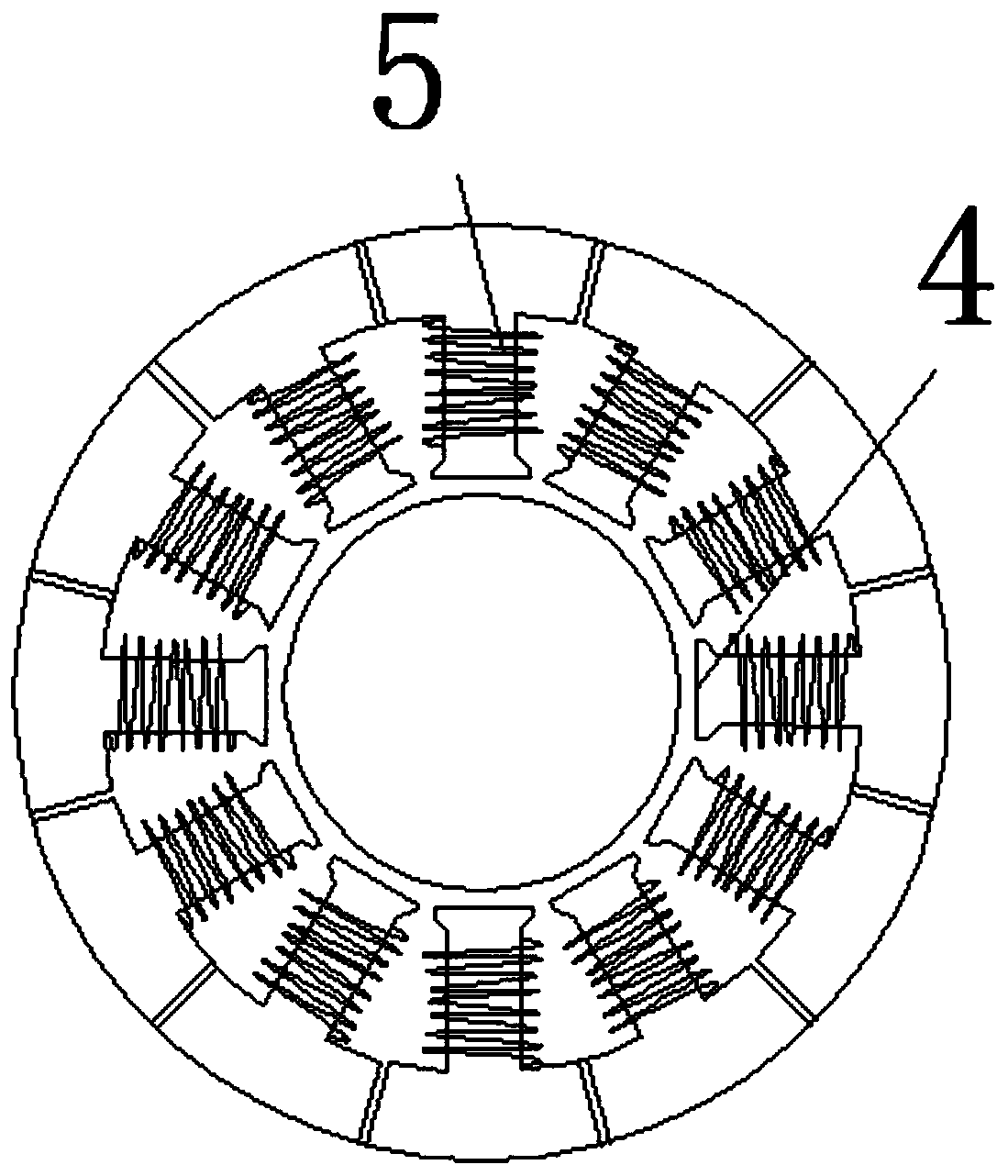

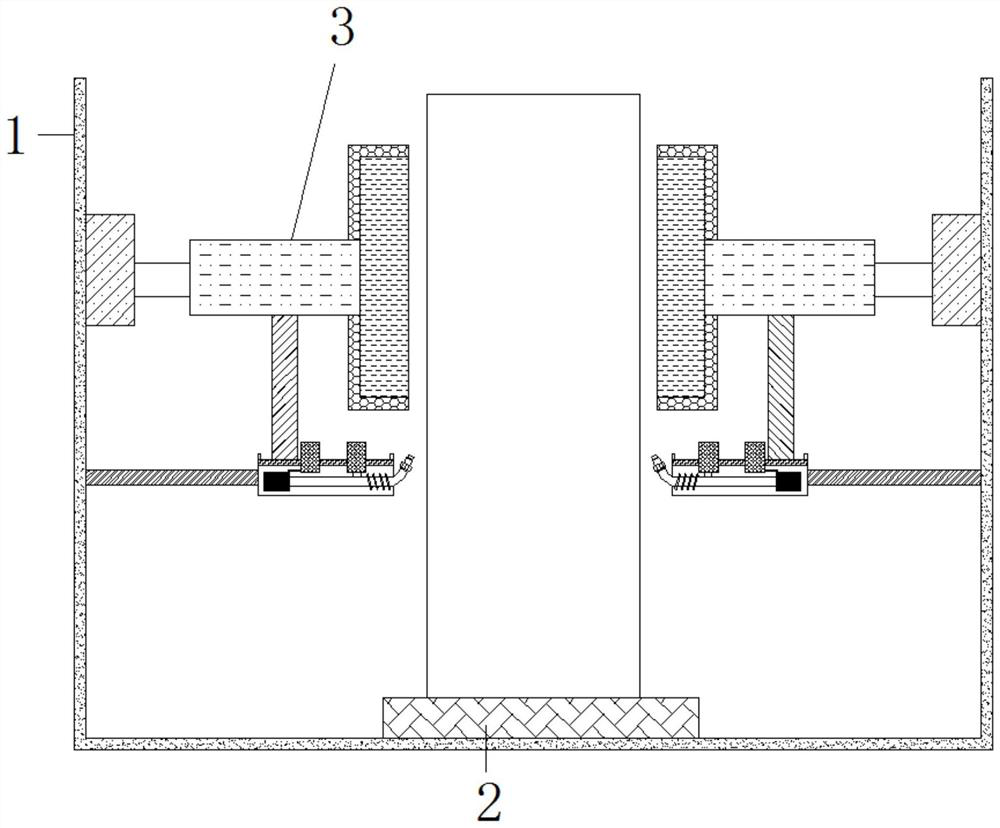

Non-contact motor stator winding dip equipment capable of eliminating liquid dropping phenomenon

InactiveCN110212717ATo achieve the warm-up effectShorten the dripping processManufacturing dynamo-electric machinesPulp and paper industryConductor Coil

The invention relates to the technical field of motor stator winding dipping. A non-contact motor stator winding dip equipment capable of eliminating a liquid dropping phenomenon comprises a shell, wherein electromagnets are movably connected with two side walls of the interior of the shell, a collection hole is fixedly connected with the interiors of the electromagnets by an adjustment mechanism,a heating wire is wound around a surface of the collection hole, a drying mechanism is arranged at one end, far away from the adjustment mechanism, of the collection hole, the drying mechanism comprises an air spraying hole, a magnet is fixedly arranged at one end, far away from the collection hole, of the air spraying hole, a drying passage is fixedly connected with one side, far away the air spraying hole, of the magnet, a dryer is fixedly arranged at one end, far away from the magnet, of the drying passage, hot air is sprayed out through the air spraying hole, a stator winding rotates under airflow influence, remaining insulation liquid on the surface of the stator winding can be dumped out during the rotation process, so that the dipping process can be reduced, the drying effect is achieved, and the dumped insulation liquid is collected by the collection hole so as to prevent waste.

Owner:丁继来

A packaging machine that can discharge the air in the bag and improve work efficiency

ActiveCN110589107BImprove work efficiencyTo achieve the warm-up effectWrapper twisting/gatheringEngineeringCold blast

The invention relates to the technical field of packaging-related equipment, and discloses a packaging machine capable of discharging air in a bag and improving work efficiency. Device and fixed rod, driving device is installed with heating device through the movable of electric telescopic rod, fixed rod right side is fixedly installed with blowing device, and blowing device inside is fixedly installed with air blower, air supply pipe and, heating ring. The packaging machine can discharge the air in the bag and improve the working efficiency. The driving device drives the electric telescopic rod, the heating device and the sliding rod to run. The sliding rod and the sliding rail cooperate to drive the No. 1 switch and the No. 2 switch to run, and drive the blower and the heating ring to work. , so that the hot air is ejected from the nozzle, and when the No. 2 switch is turned off, only the cold air is discharged, and the air flow squeezes the air inside the packaging bag, thereby achieving the effect of discharging the air inside the packaging bag, preheating the sealing part before processing, and cooling down after processing.

Owner:山东天威食品科技有限公司

Drying equipment capable of efficiently utilizing heat

InactiveCN112066674AEfficient use ofAutomatic and efficient dryingDrying gas arrangementsDrying chambers/containersThermodynamicsFresh air

The invention relates to the related field of textile drying equipment, in particular to efficient heat utilization drying equipment which comprises a machine body and a drying cavity formed in the machine body and provided with an upward opening; a drying device is arranged in the drying cavity; the drying device further comprises a transmission cavity formed in the lower side of the drying cavity; a sleeve shaft extending into the drying cavity is rotatably arranged on the top wall of the transmission cavity; and a first gear located in the transmission cavity is fixedly arranged at the bottom end of the sleeve shaft. The drying equipment capable of efficiently utilizing heat can automatically and efficiently dry a textile, can recycle heat in airflow generated after the textile is dried, and transmits the heat in the airflow to newly pumped air, so that the fresh air can achieve the preheating effect, electric power consumed when the air is reheated is saved, the effect of efficientutilization of the heat is achieved, environmental protection is achieved, and the electric power is saved.

Owner:ZHUJI PANDA TEXTILE TECH CO LTD

A badminton production, straightening and pruning integrated equipment

The invention discloses an integrated equipment for production, straightening and pruning of badminton, which comprises a discharge cylinder and a processing box. A gas supply box is provided in the middle of the interior, and a porous connector is provided at the outlet of the gas supply box. The porous connector is connected with several groups of low-speed injection pipes, and is connected with a group of high-speed injection pipes in the middle. Both the blowing pipe and the high-speed blowing pipe extend upward into the material selection chamber, the high-speed blowing pipe is equipped with an acceleration valve, and the low-speed blowing pipe is equipped with a deceleration valve. The integrated equipment for production, straightening and pruning of badminton according to the present invention is designed with a pressing structure of the airbag to replace the traditional mechanical pressing. Because the airbag is soft in texture, the damage to the feathers during the pressing process is relatively small. Thereby reducing the waste of product raw materials, applicable to different working conditions, and bringing better prospects for use.

Owner:WUWEI HONGXI SPORTS GOODS CO LTD

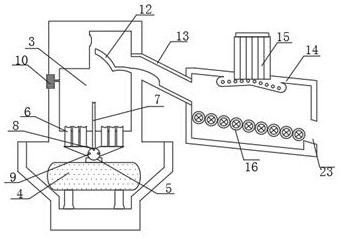

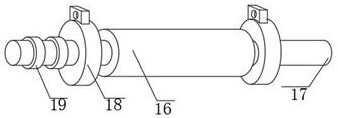

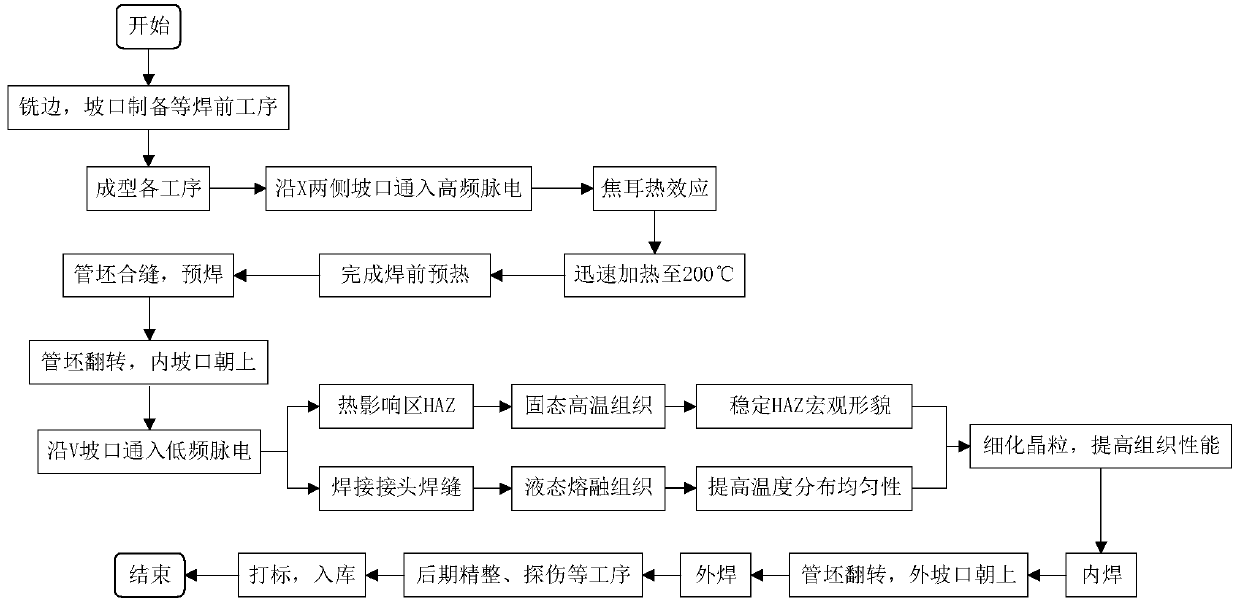

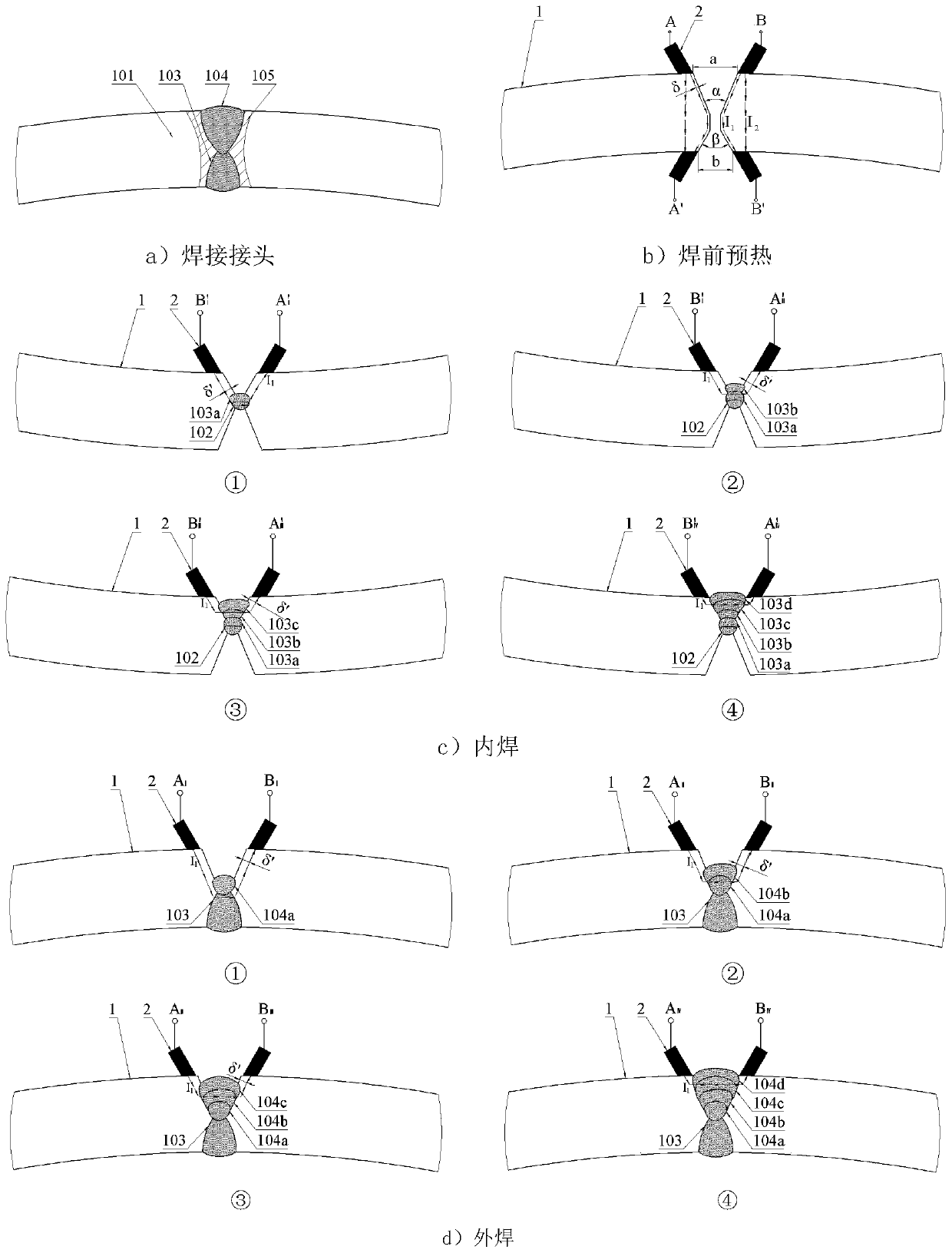

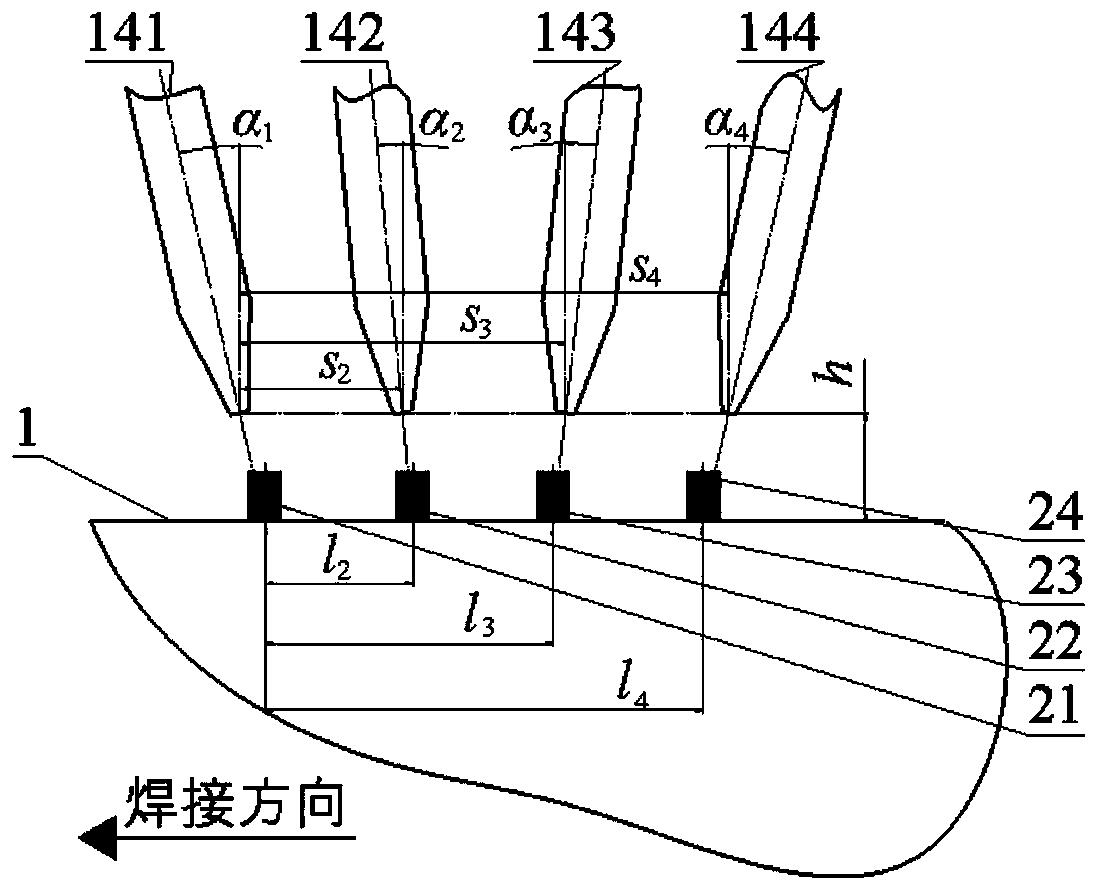

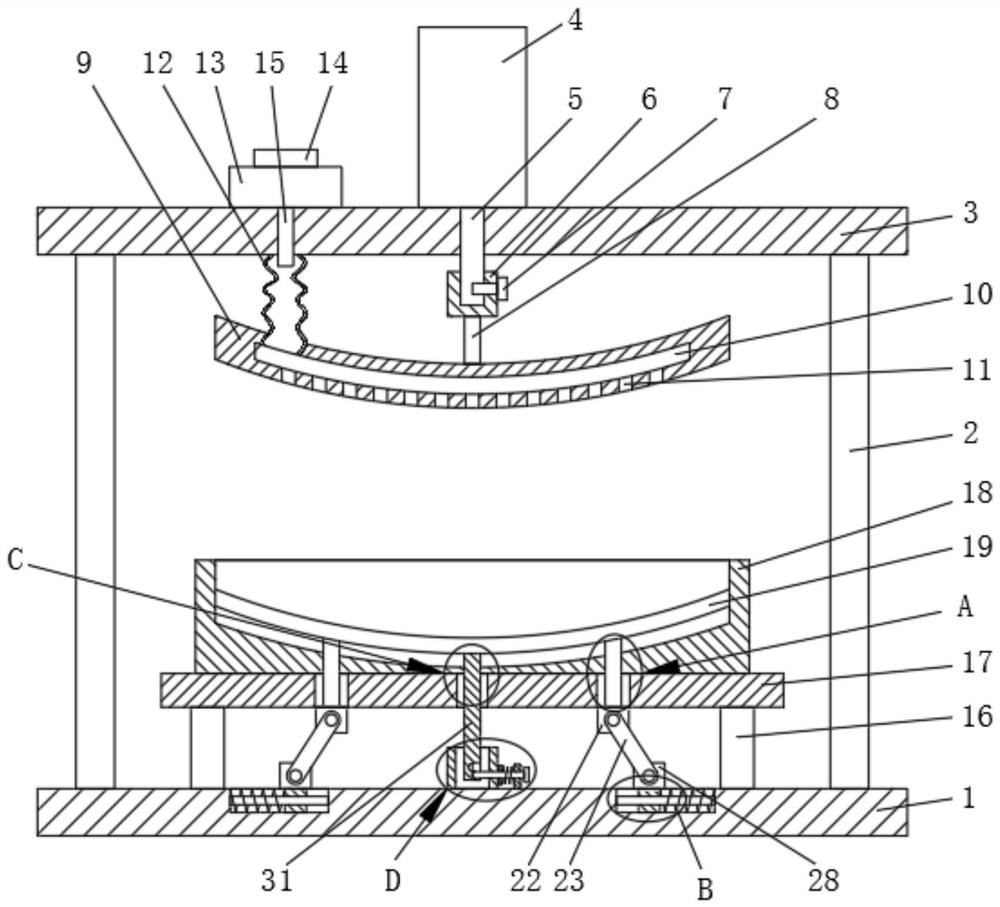

Device for assisting in welding process of LSAW pipe through pulse current and using method

ActiveCN111203614AAvoid costly and inefficient pitfallsImprove organizationArc welding apparatusMetal working apparatusGraphite electrodeHeat-affected zone

The invention relates to a device for assisting in the welding process of an LSAW pipe through pulse current and a using method. The device comprises two nuts, two graphite electrodes, two bases, beams, a first bracket, a second bracket, a servo motor, a gear, a mounting ring and a mounting arm, wherein the nuts and the graphite electrodes are coaxially mounted on the bases, a spring is mounted between each graphite electrode and the corresponding base, and the nuts, the graphite electrodes and the bases are arranged on the beams respectively through fastening bolts; and the other sides of thebeams are provided with the first bracket and the second bracket through bolts respectively, the first bracket and the second bracket are made from an insulation material, the mounting ring is mounted at the ends, away from the beams, of the first bracket and the second bracket through a bolt, and the mounting arm is coaxial to the mounting ring and is mounted in the direction away from the beams. The device can effectively refine grains in a heat-affected zone, increase the dislocation density, and reduce the residual stress after welding, the homogeneity of the structure in the heat-affected zone is improved, and thus the reliability of the LSAW pipe in the actual using process is improved.

Owner:山东尚安安全技术有限公司 +1

Automobile instrument panel and LED assembly integrated compression molding equipment and compression molding process thereof

The automobile instrument panel and LED assembly integrated compression molding equipment comprises a bottom plate and a workbench, wherein four evenly-distributed supporting rods are fixedly connected to the upper end of the bottom plate, a supporting plate is fixedly connected to the upper ends of the supporting rods, an air cylinder is arranged on the supporting plate, a driving rod of the air cylinder is slidably connected with the supporting plate, and the driving rod of the air cylinder is fixedly connected with the workbench; the outer side of the driving rod is sleeved with a connecting base, the interior of the connecting base is connected with a limiting screw through threads, the tail end of the limiting screw is connected with the driving rod in a clamped mode, a lower end of the connecting base is fixedly connected with a connecting rod, a lower end of the connecting rod is fixedly connected with an upper die, and an air channel is formed in the upper die; and an air outlet is formed in the upper die and is communicated with the upper die. The invention relates to integrated compression molding equipment for an automobile instrument panel and an LED assembly and a compression molding process of the integrated compression molding equipment. The integrated compression molding equipment has characteristics of mold preheating and convenience in demolding.

Owner:深圳市旺博科技有限公司

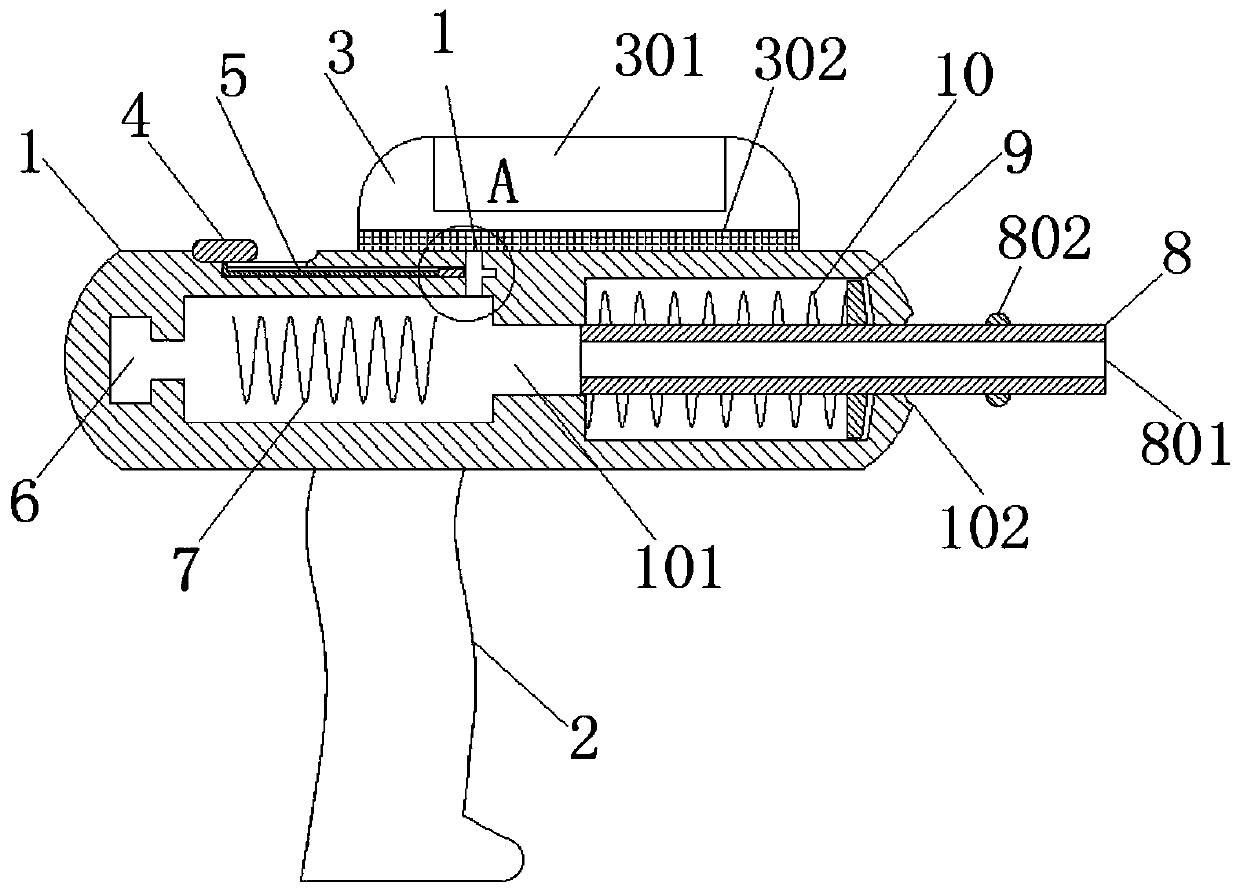

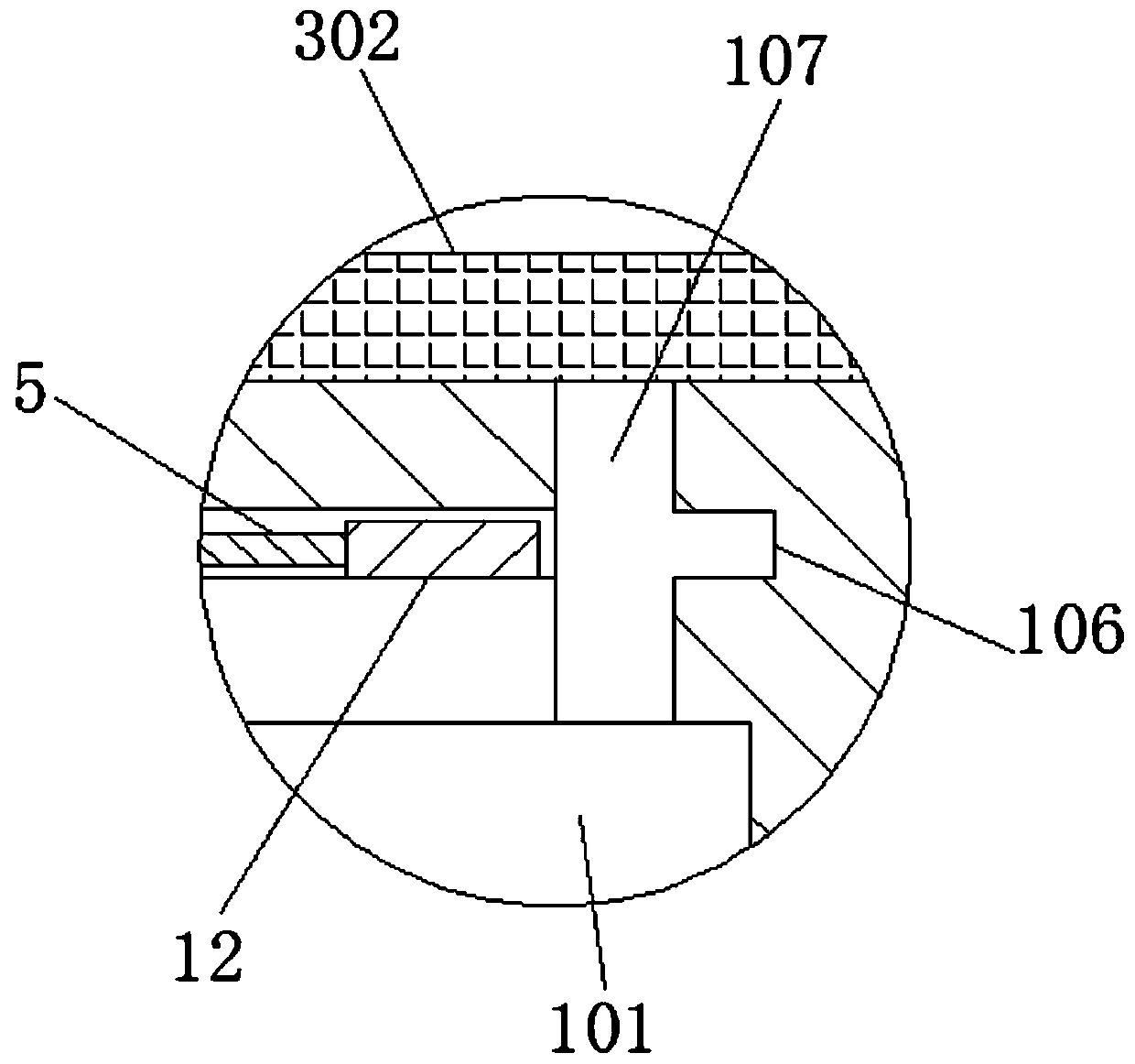

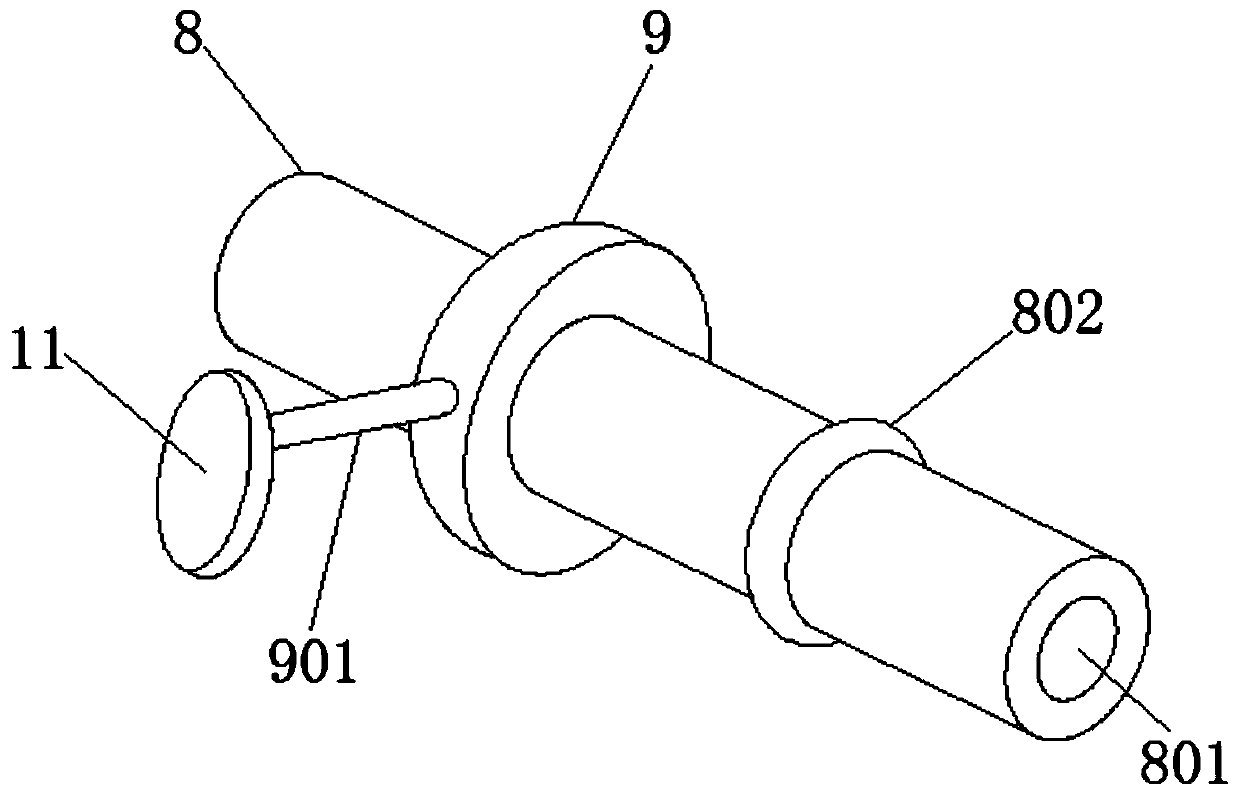

Pistol type welding gun equipment

The invention relates to the technical field of welding gun equipment, and discloses pistol type welding gun equipment. A gun body is included. The upper end of the gun body is connected with a preheating bin, the upper end of the gun body is connected with a sliding key, the lower end of the sliding key is connected with a push rod, and a fan is arranged in the gun body. The right side of the fanis provided with a heating metal wire, the right side of the heating metal wire is provided with a gun barrel, the left side of an arc circular stop block is connected with a compression spring, an indication disc is connected to one side of the arc circular stop block, and the right end of the push rod is connected with a sliding block. The heating metal wire is electrified and generates heat, the sliding key is moved to the left side of a second transverse arc groove, hot air can evenly heat plastics which are placed in a preheating bin and easily absorb moisture through a heat dissipationpad, the arc circular stop block drives the indication disc to leftwards slide in a first transverse arc groove through a connecting rod, a longitudinal line mark on the indication disc corresponds toa scale plate, and the structure solves the problems that since preheating is not conducted, the seal performance of a welding face is poor, and the pressure cannot be visually judged.

Owner:绍兴舟泽新材料股份有限公司

Energy-efficient plasma electric welding machine device with magnetically stabilized arc

The invention discloses an energy-efficient plasma electric welding machine device with the magnetically stabilized arc, including a body box, a spray head main body and a gas mixing chamber. The gasmixing chamber is arranged at the bottom of the body box, a gas pressurizing pump is installed on one side of the gas mixing chamber through a mounting piece, an argon storage chamber is arranged at one end of the inner bottom of the body box, an air pump is installed at one side of the argon storage chamber through a mounting bracket, a hydrogen generator is connected with the inner top of the body box through a connecting frame and an output end of the hydrogen generator is connected with the air mixing chamber through a pipe, a feeding chamber is arranged on one side of the hydrogen generator, a motor is installed at the bottom of the feeding chamber through bolts, and an infrared heating pipe is installed at the top part of the feeding chamber through a connecting seat. As the arc reaches a magnetically stable state, a welding column is thin and long, the penetration force is strong, the weld speed is fast, the welding seam defects are few, and the welding quality is high.

Owner:叶露穗

Instant-heating-type electromagnetic water heater

InactiveCN102305472BReduce the temperatureReduce lossesFluid heatersEngineeringElectromagnetic heating

The invention discloses an instant-heating-type electromagnetic water heater which comprises a shell and an electromagnetic heating device assembled in the shell, wherein a water inlet pipe and a water outlet pipe are connected to the shell; the electromagnetic heating device comprises a heating device body and a heat radiator for heat radiation of the heating device body; the electromagnetic heating device body is in the shape of a short cylinder and comprises a front heating surface and a rear heating surface; the instant-heating-type electromagnetic water heater also comprises a first heating inner container and a second heating inner container which are respectively positioned on the front side and rear side of the electromagnetic heating device body and are manufactured from a magnetic conductive metal; the first heating inner container and the second heating inner container are communicated mutually, the water inlet of the first heating inner container is connected with the water inlet pipe, and the water outlet of the second heating inner container is connected with the water outlet pipe; the first heating inner container and the second heating inner container are respectively close to the front heating surface and the rear heating surface; and the heat radiator is attached on the outer side wall of the water inlet pipe. According to the invention, the heat energy loss in the heating process of water is less, and the consumed power is less.

Owner:李善福 +1

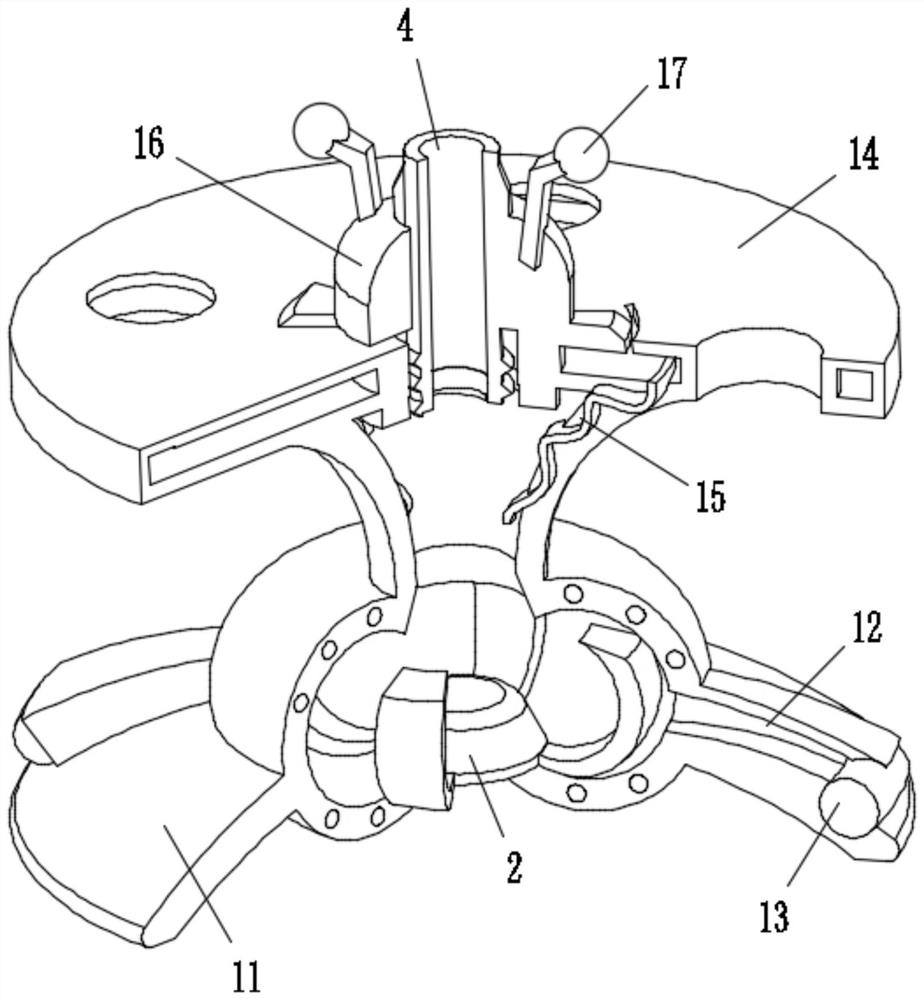

Cable-free intelligent dispensing instrument convenient to install and installation method of cable-free intelligent separate injection instrument

InactiveCN113908900AEasy to installSolve the separation problemBurettes/pipettesElectric machineryProcess engineering

The invention discloses a cable-free intelligent dispensing instrument convenient to install and an installation method thereof, and relates to the technical field of measuring equipment, the cable-free intelligent dispensing instrument comprises a feeding mechanism, the top of the feeding mechanism is fixedly connected with a protection mechanism, the feeding mechanism comprises a boss, the top of the boss is fixedly connected with a mixing mechanism, a heat insulation table is fixedly connected to the top of the mixing mechanism, a heat conductor is fixedly connected to the inner side face of the heat insulation table, one end of the heat conductor extends into the mixing mechanism, the other end of the heat conductor extends into the heat insulation table, and a motor is fixedly connected to the center of the top of the heat insulation table. According to the cable-free intelligent dispensing instrument convenient to install and the installation method thereof, through cooperative use of the feeding mechanism, the mixing mechanism, the protection mechanism, the damping mechanism and other mechanisms, the problem that how to utilize waste heat of high-temperature mixed liquid to prolong the service life of a dispensing vessel is solved, and the problem that when the mixed liquid is injected into the vessel, all mixtures are easy to separate can be solved.

Owner:XIAN LUOKE ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com