Patents

Literature

62results about How to "Not easy to sag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

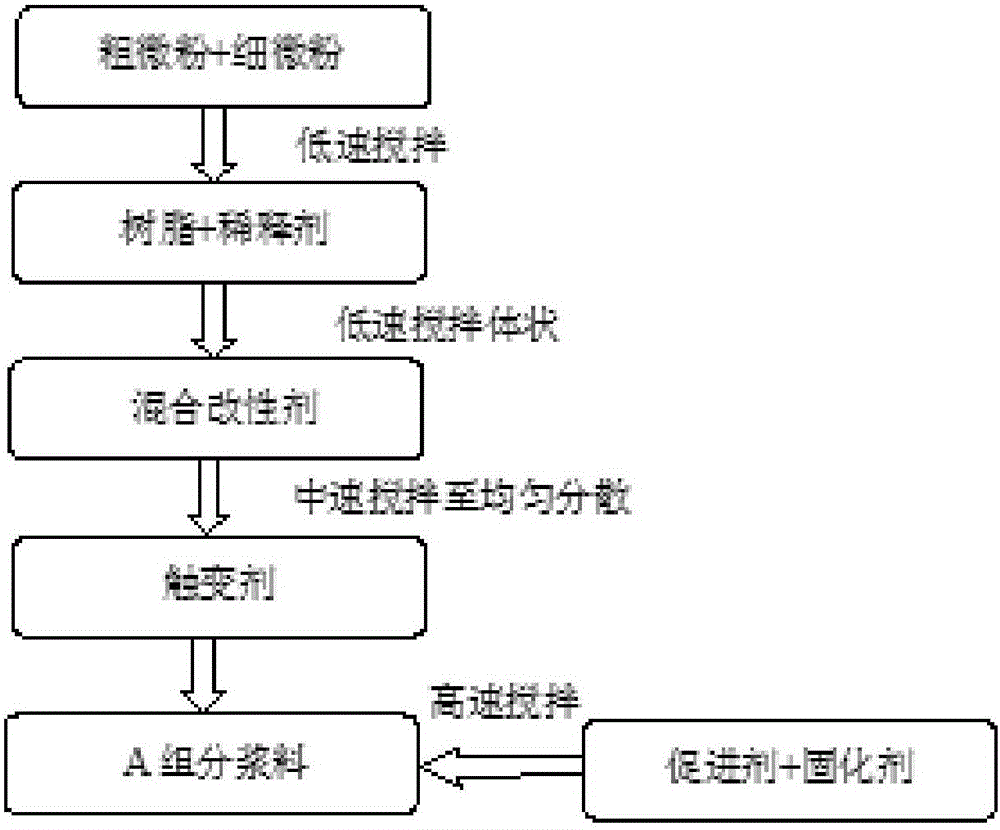

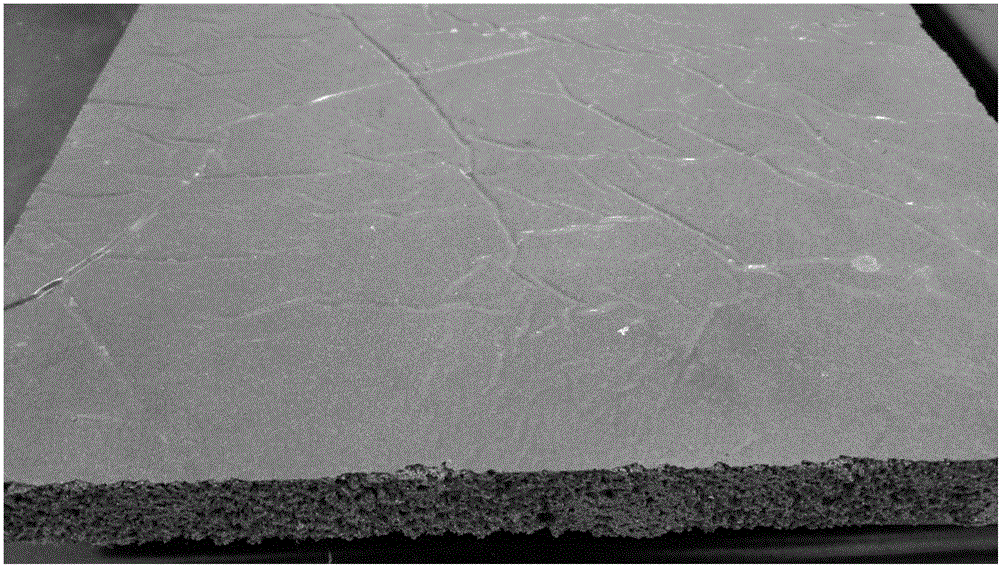

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

Casting defect eliminating method

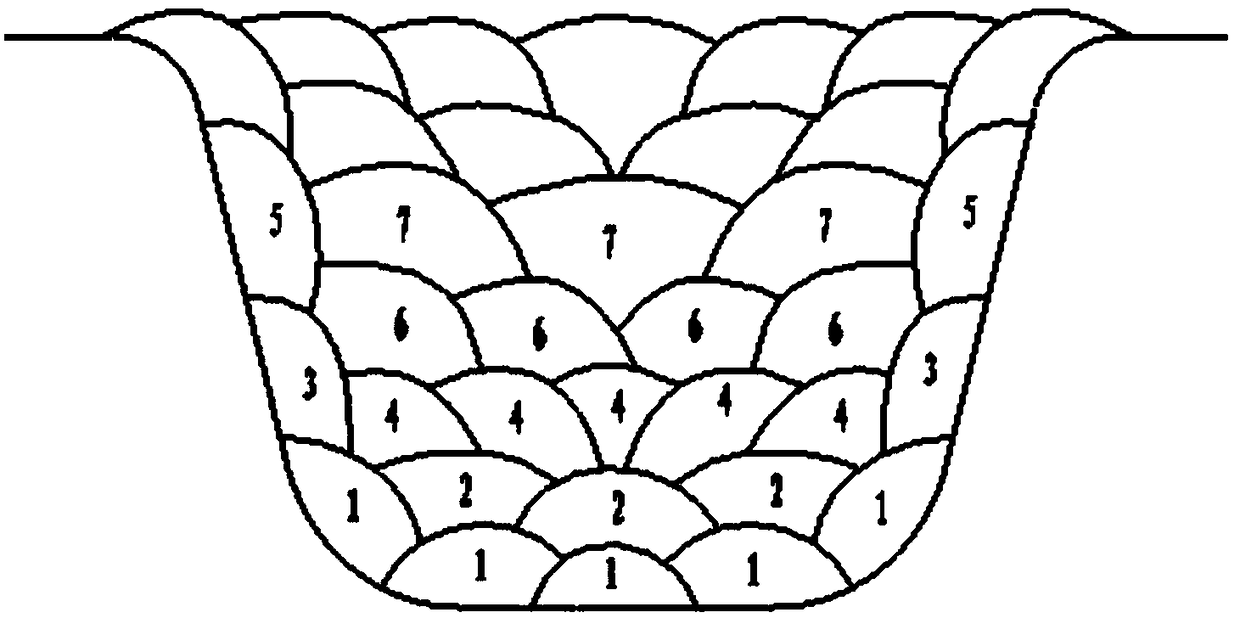

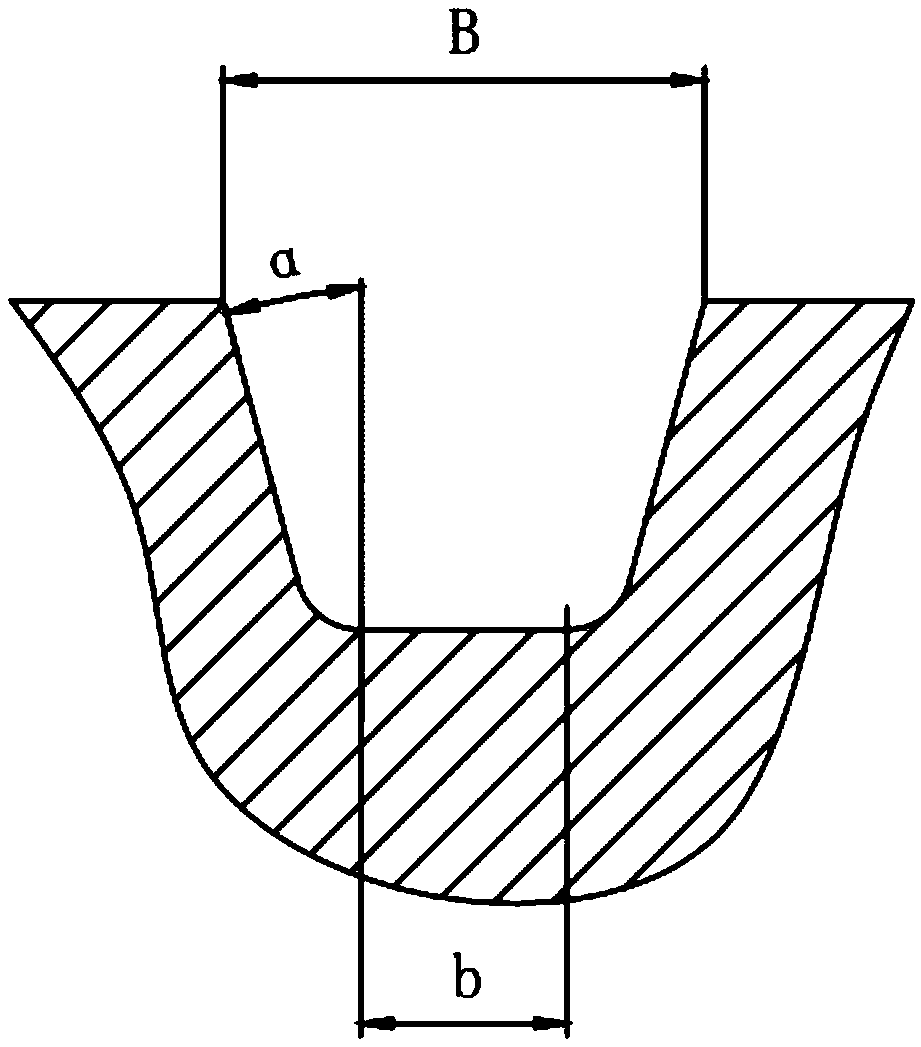

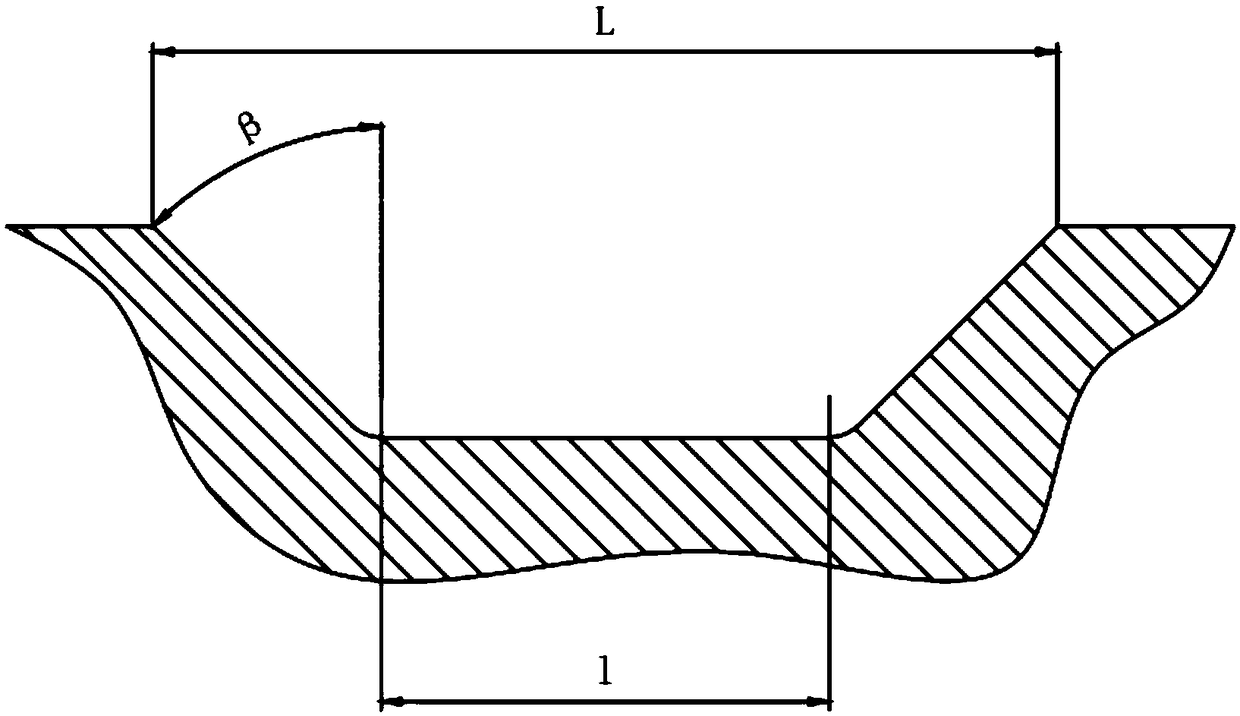

The invention discloses a casting defect eliminating method which belongs to the field of casting treatment. The casting defect eliminating method provided by the invention comprises five steps: defect cleanup, bevel preparation, weld preheating, welding repair and postweld treatment, wherein the defect cleanup refers to eliminating common surface defects by grinding, and common crack defects andgreats defects are subjected to a next step; the bevel preparation refers to forming a U-shaped bevel in the defected position and the bevel surface is a smooth curved surface; the weld preheating refers to carrying out local preheating to the common defects and integral preheating to the great defects; the welding repair refers to carrying out 1-2 layers of resurfacing welding along the side surface of a bevel, further fully welding the concave part in the resurfacing welding position and repeating the step until the whole bevel is welded to be full completely; and the postweld treatment refers to carrying out dehydrogenation treatment to the common defects after being welded and annealing treatment to the great defects after being welded. By improving the welding method and optimizing the process parameters when repairing different defects, the invention greatly reduces the probability of adverse influencing factors occurring in defect repair process, saves the time spent in defect repair and achieves the effect of cost saving while ensuring the qualified rate of casting repair.

Owner:ANHUI MAGANG HEAVY MASCH MFG CO LTD

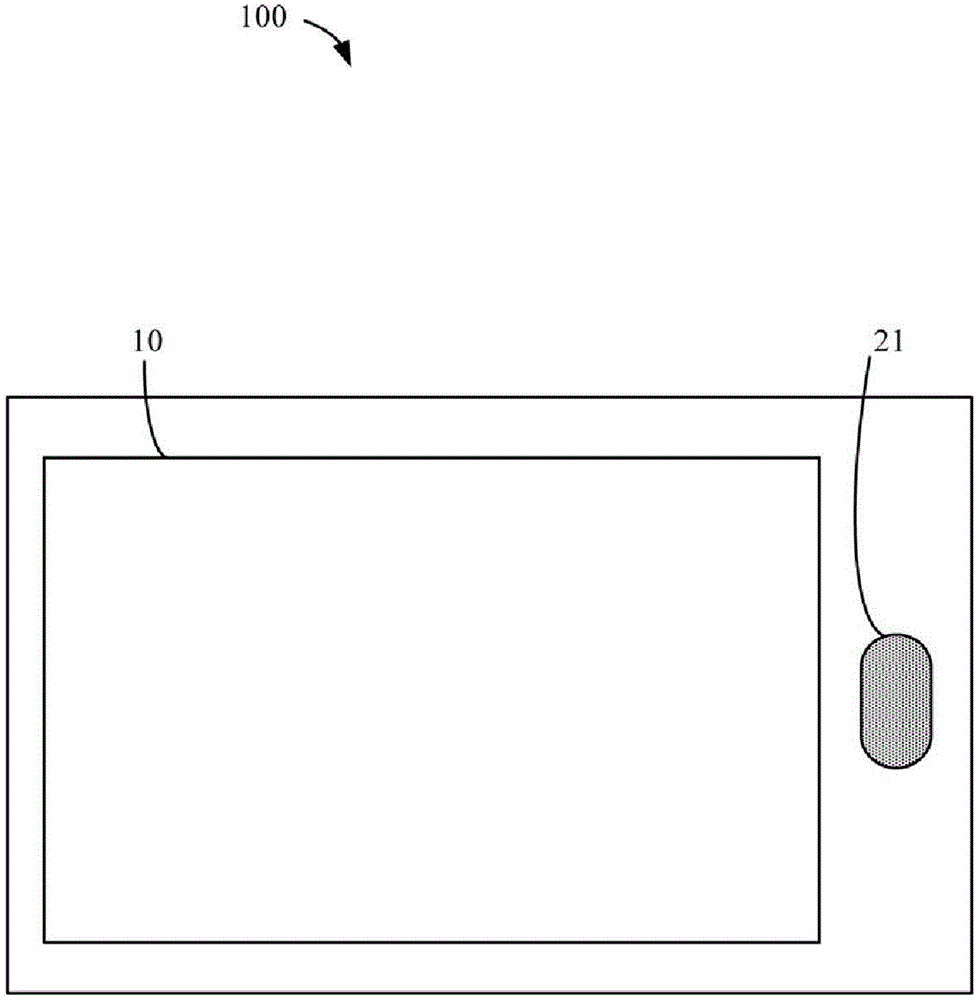

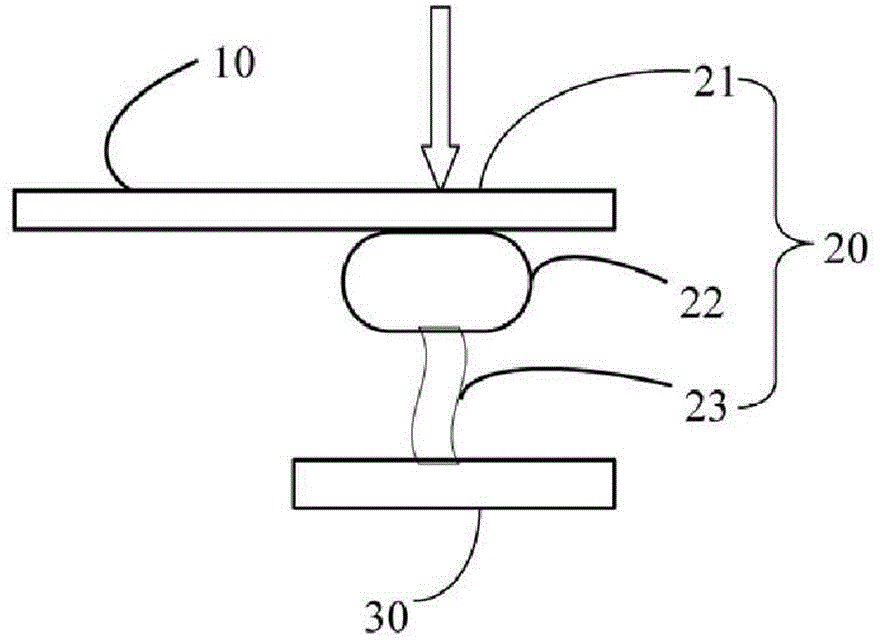

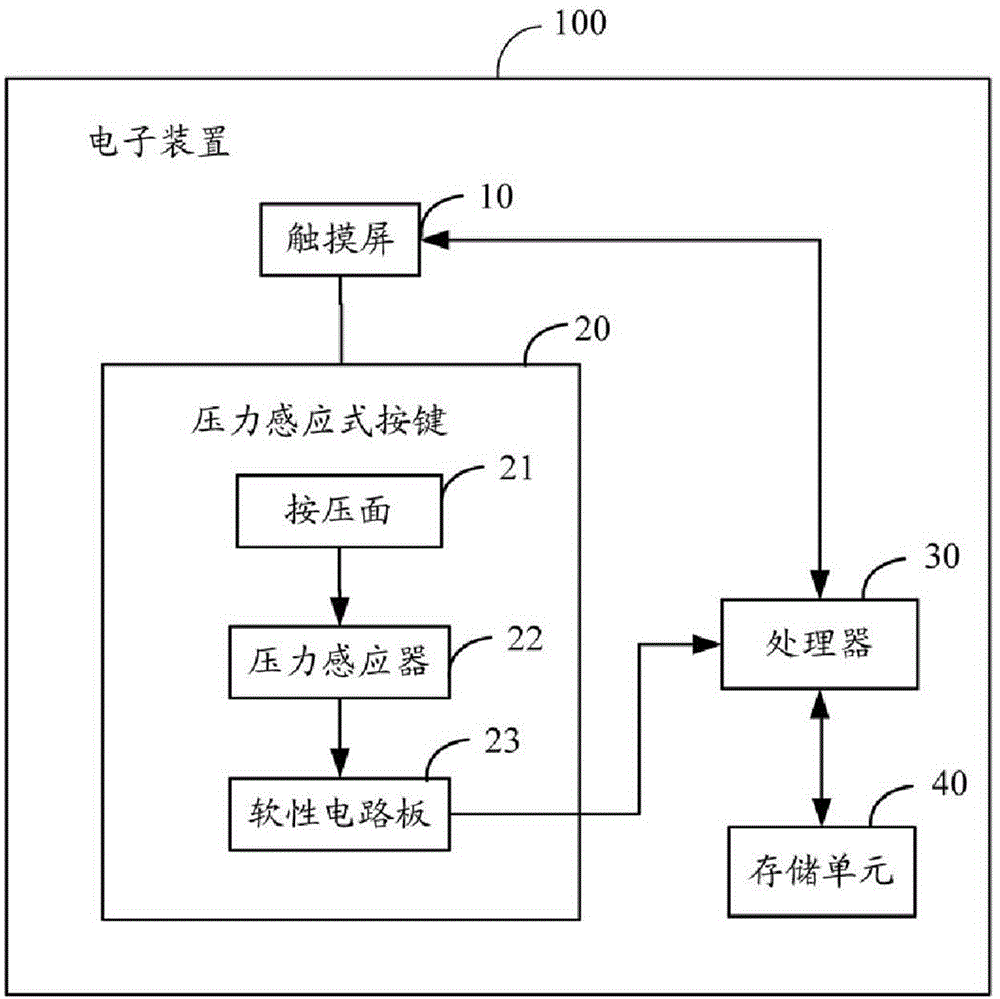

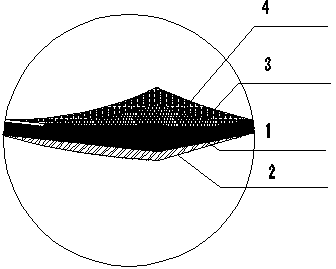

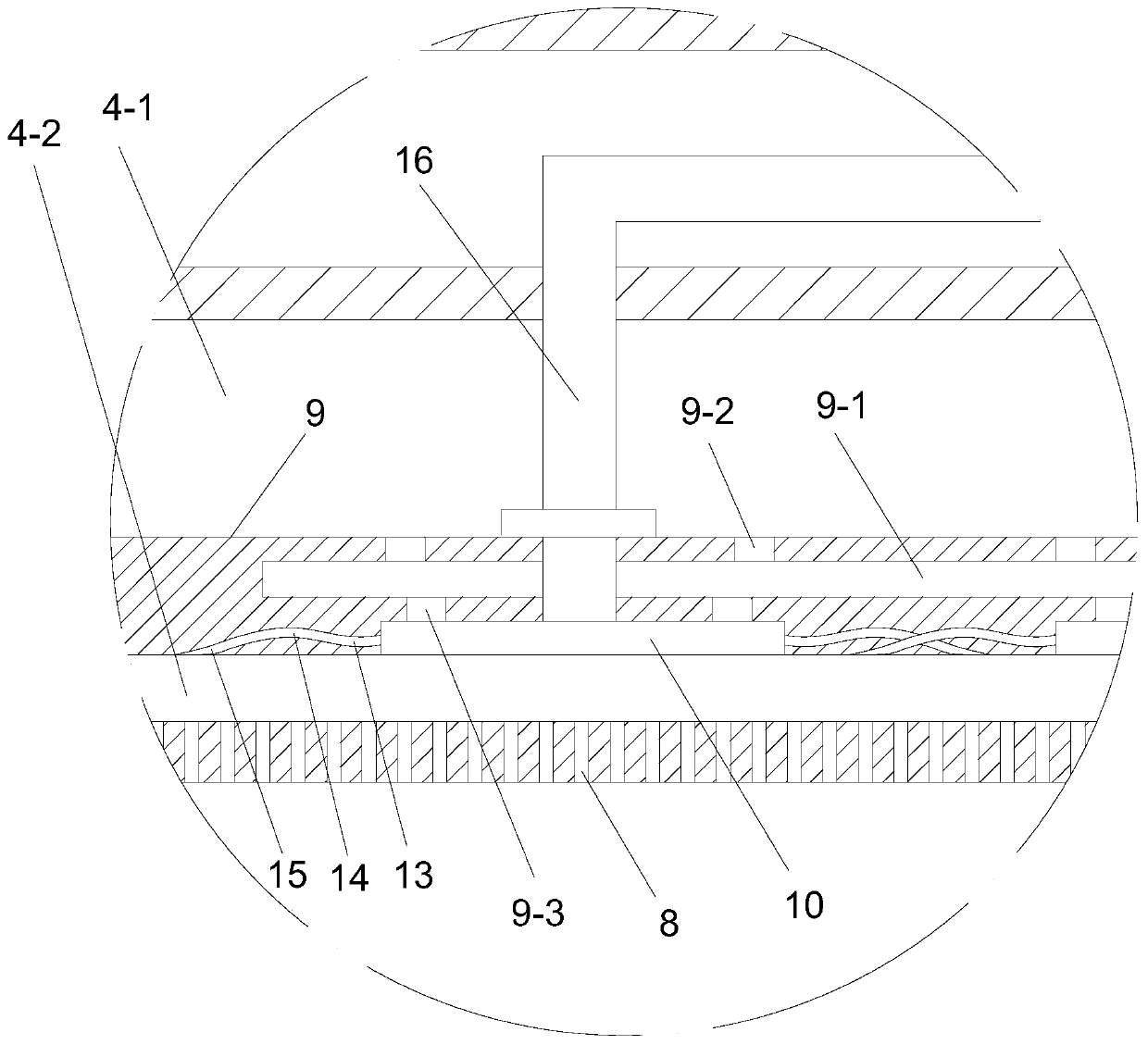

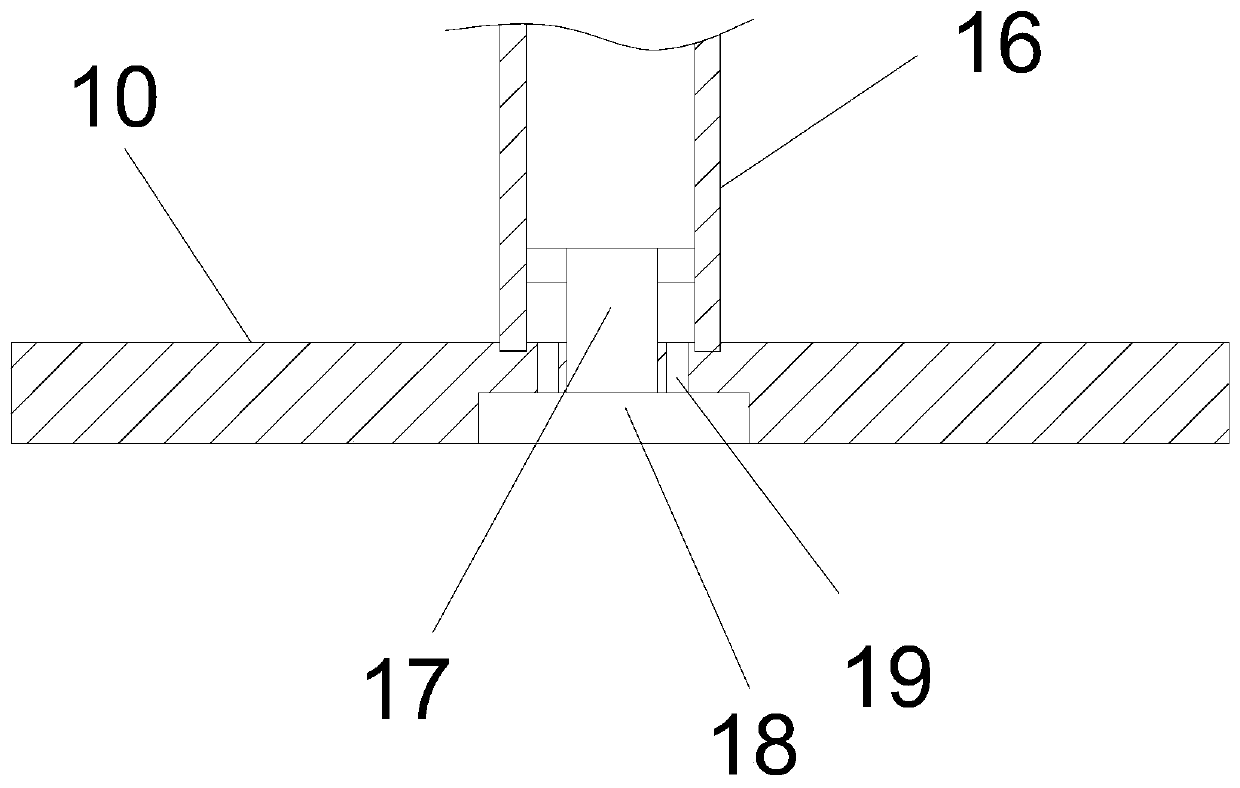

Pressure-sensitive button and electronic device with same

InactiveCN104579285AImprove reliabilityNot easy to sagElectronic switchingInput/output processes for data processingFlexible circuitsStorage cell

An electronic device comprises a storage unit, a touch screen, a processor and a pressure-sensitive button, wherein the storage unit is stored with a preset pressure value; the pressure-sensitive button comprises a pressing surface arranged on the touch screen, a pressure sensor and a flexible circuit board; the pressure sensor is mounted on the back surface of the pressing surface and is used for sensing a pressure transmitted by the pressing surface and converting the pressure into pressure information; the two ends of the flexible circuit board are connected to the pressure sensor and the processor respectively, and the flexible circuit board is used for transmitting the pressure information sensed by the pressure sensor to the processor; the processor is used for judging whether the pressure reaches the preset pressure value according to the pressure information, and if so, controlling the touch screen to display a main interface. The invention further provides the pressure-sensitive button. The pressure-sensitive button provided by the invention is unlikely to sink, deflect and / or fail, so that the reliability of the electronic device is improved.

Owner:FU TAI HUA IND SHENZHEN +1

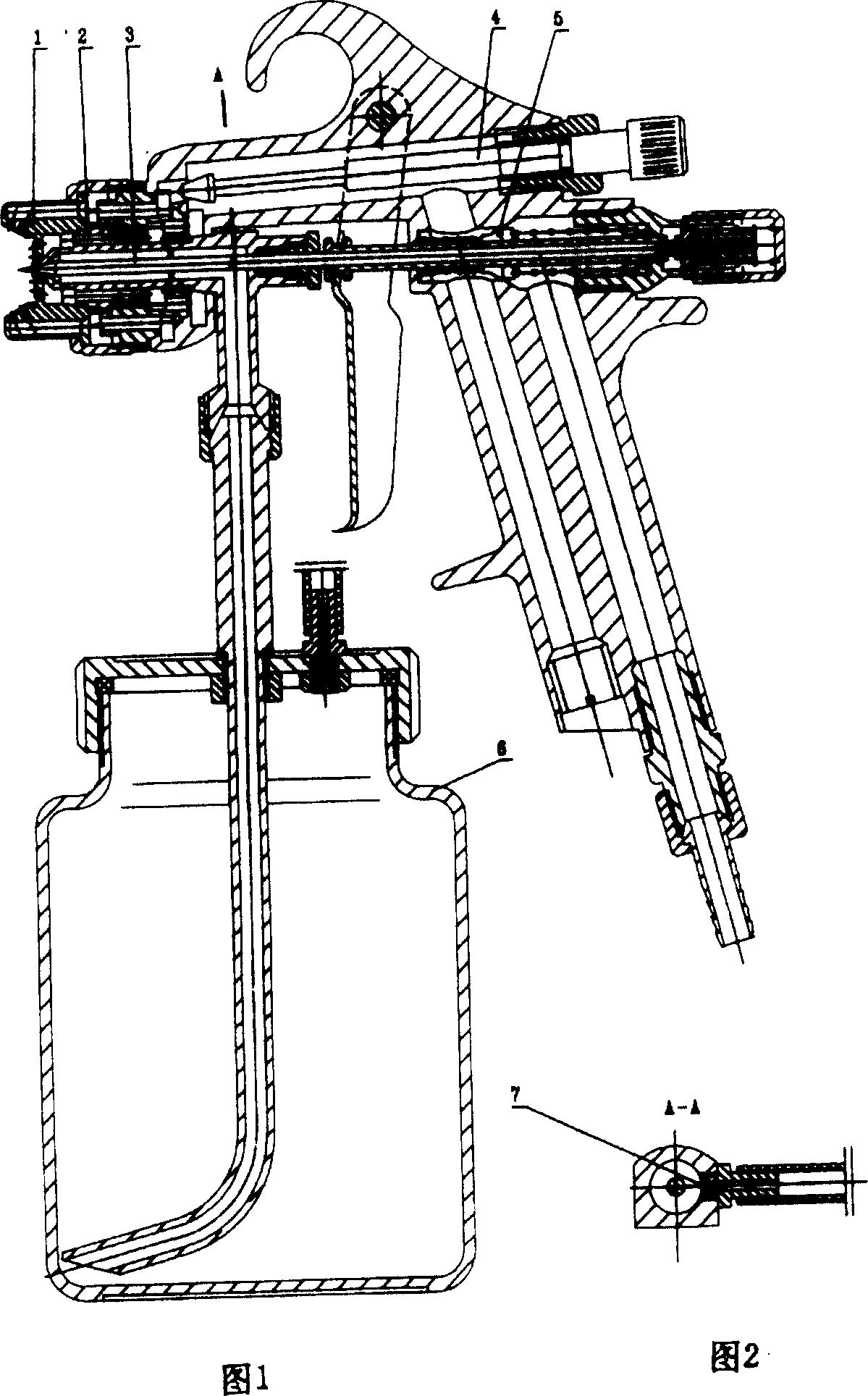

Pressing type air lance

InactiveCN1634667AIncrease profitImprove spray qualityLiquid spraying apparatusEngineeringInjection air

This invention relates to a pressure air injection gun, which is characterized by the following: setting air valve and coating valve on same axis; setting one gas path in air channel connected to the pressure tar; the pressure cover and the pressure tar are connected by screw lines means; exerting power on the pressure tar through one gas path and sending coating materials with part of air exhausted from air spray to ensure three times of atomization on the air spray. The spray mouth is set with ring hole to make first atomization and the second atomization hole is the reverse flat hole and protective hole and the third hole is edge hole.

Owner:长春泰发环保涂装设备有限责任公司

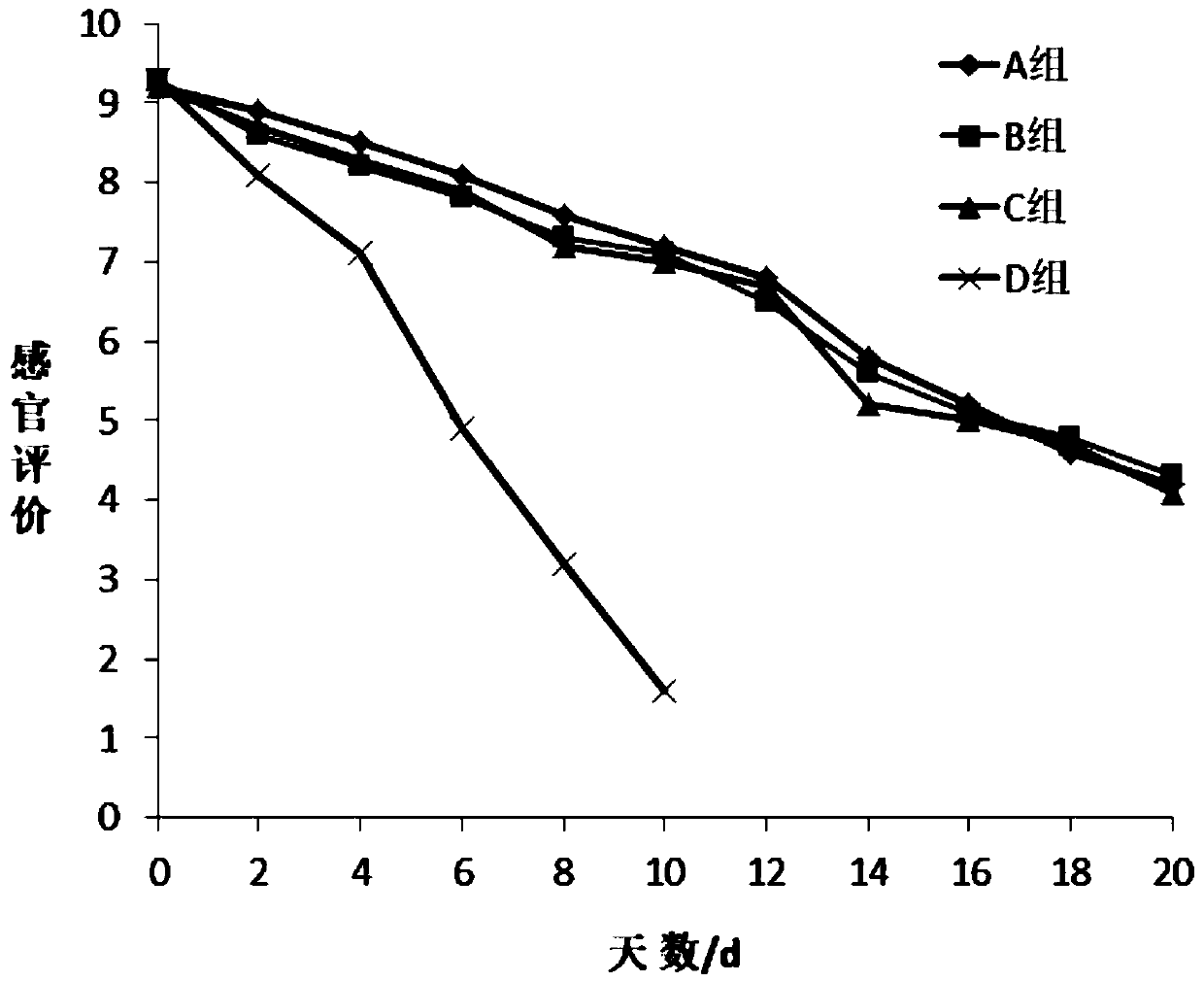

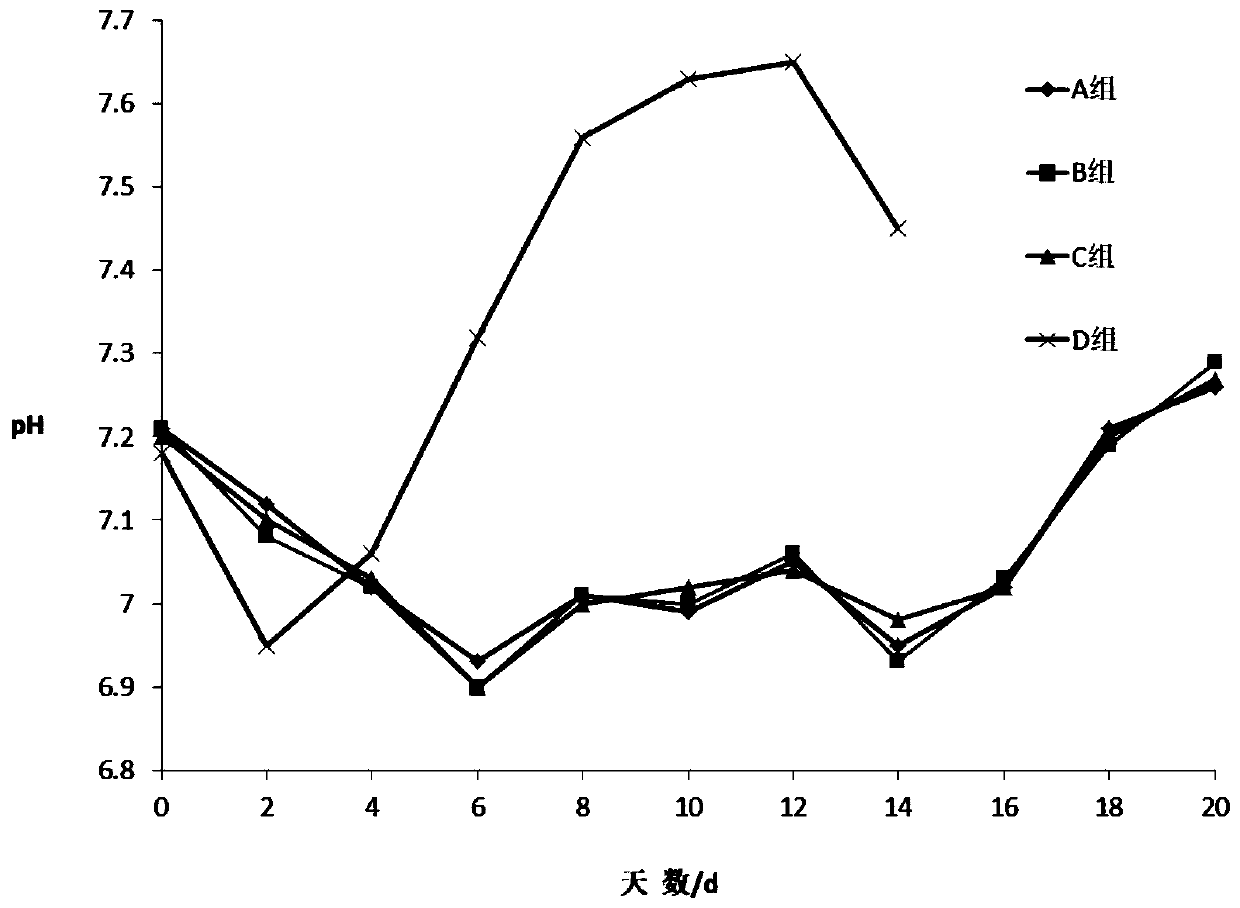

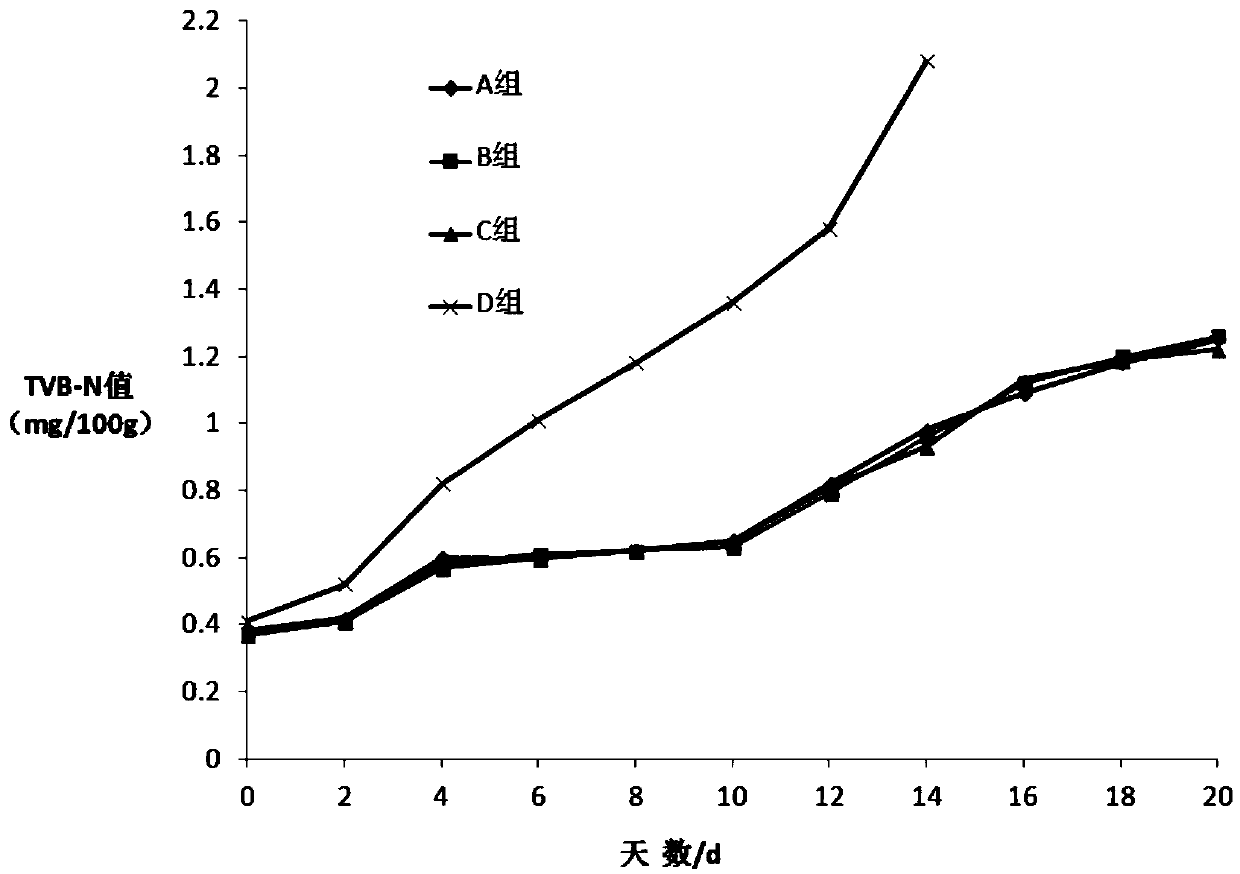

Coating and partial freezing preservation method for hairtail

ActiveCN109566718AAvoid crackingInhibition of reproductionFood freezingMeat/fish preservation by freezing/coolingOperabilityPreservation methods

The invention discloses a coating and partial freezing preservation method for hairtail. The method comprises the following steps of (1) carrying out pretreatment; (2) carrying out sterilization; (3)carrying out surface dewatering; (4) carrying out dipping and coating; (5) carrying out vacuum cooling and drying; (6) carrying out low-temperature quick-freezing; and (7) carrying out partial freezing cold storage. The coating and partial freezing preservation method for the hairtail has the advantages that the hairtail is preserved through a combined coating and partial freezing preservation technology, the steps are simple, the operability is high, the juice loss rate in the unfreezing process of the hairtail can be decreased, the physicochemical properties and the sensory quality of the hairtail can be well maintained, and the shelf life of storage and sale of the hairtail in the partial freezing state can be obviously prolonged.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

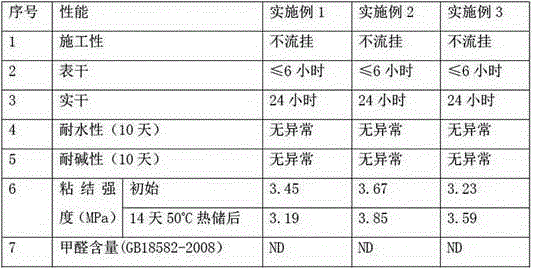

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AGood crack resistanceRapid prototypingNon-macromolecular adhesive additivesEpoxy resin adhesivesPliabilityPhysical density

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

Production technology of automobile seat decorative cover

The invention relates to a production technology of an automobile seat decorative cover. The production technology comprises the steps as follows: a seat decorative cover base material is placed in an electrical heating oven to be heated, wherein the temperature of the upper oven of the electrical heating oven is controlled within 310-330 DEG C, the temperature of the lower oven of the electrical heating oven is controlled within 340-360 DEG C, the heating time is controlled within 90-100 seconds; the heated seat decorative cover base material is laid between an upper die and a lower die of a forming machine, wherein the temperatures of the upper die and the lower die of the forming machine are both controlled within 3-7 DEG C; the forming machine is operated to obtain a semi-finished automobile seat decorative cover, wherein the forming pressure is controlled within 18-20 MPa, and the forming time is controlled within 55-65 seconds; burrs on the edge of the semi-finished automobile seat decorative cover are removed to obtain the finished automobile seat decorative cover. The production technology adopts PP / PET composite material heating and mold cold-press molding and is free from addition of any chemical composition; the production technology produces no poisonous substance in the whole production process and belongs to an environment-friendly technology.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Formaldehyde-free aqueous jointing agent and preparation method therefor

InactiveCN106590497AFast shapingEasy constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesCalcium silicateCrack resistance

The invention discloses a formaldehyde-free aqueous jointing agent and a preparation method therefor. The formaldehyde-free aqueous jointing agent is prepared through mixing a main agent and a curing agent according to the mass ratio of (0.6 to 1.8): (0.8 to 1.6). According to the formaldehyde-free aqueous jointing agent, an aqueous bi-component macromolecular gluing technology is adopted, the product forms high-density reticular glue films at joints, and the glue films can be telescoped synchronous to sheet materials in case of climatic changes, so that the product has the characteristics that the sizing speed is high, the construction is easy, the sagging is difficult, the adhesive power is high, the cracking resistance is excellent, and the like. The formaldehyde-free aqueous jointing agent is applicable to the treatment on joints and easily-cracking parts of indoor and outdoor decorative materials and can play excellent roles in carrying out bonding and preventing cracking through injecting the product into gaps of the same or different materials such as wood, bricks and stones, gypsum boards, calcium silicate and cement wall faces.

Owner:LANZHOU KETIAN ENVIRONMENTAL PROTECTION ENERGY SAVING TECH CO LTD

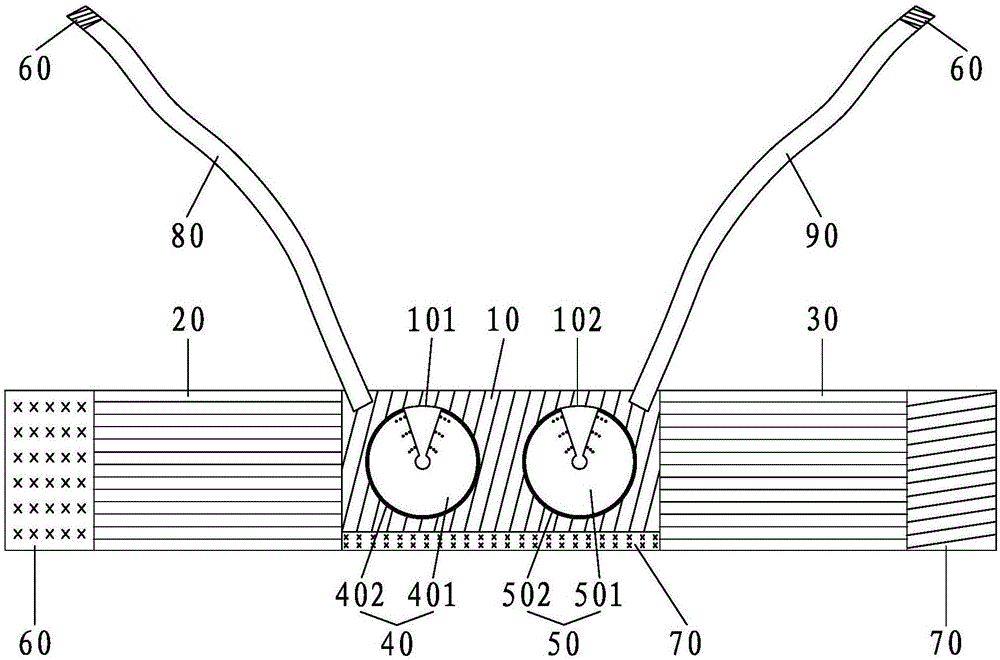

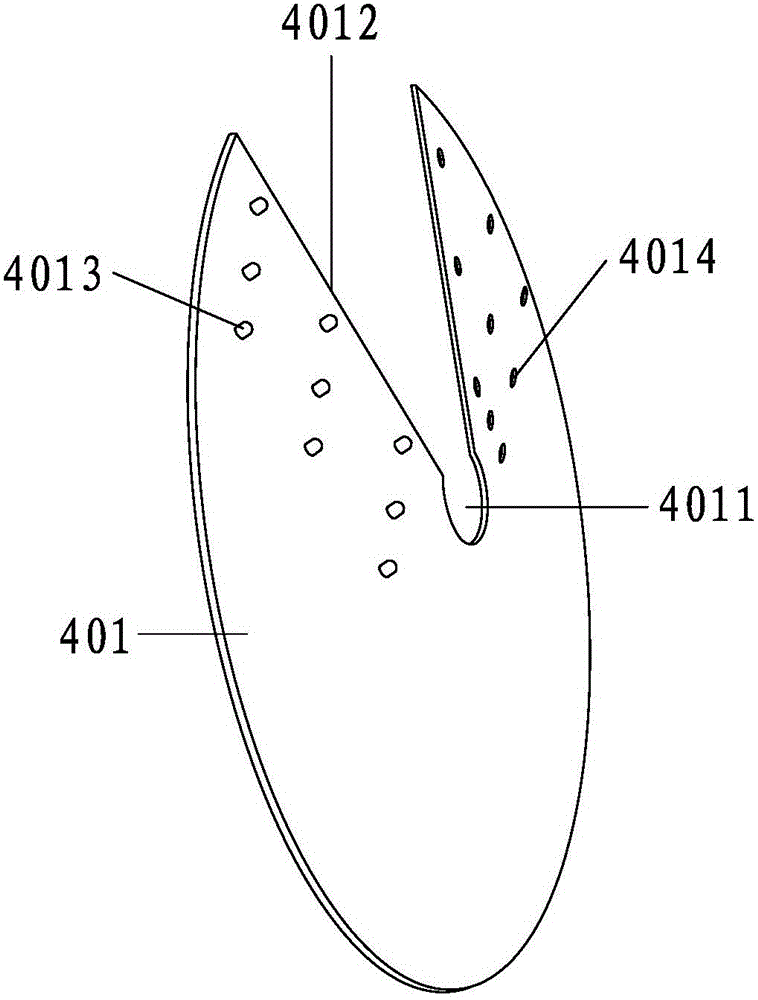

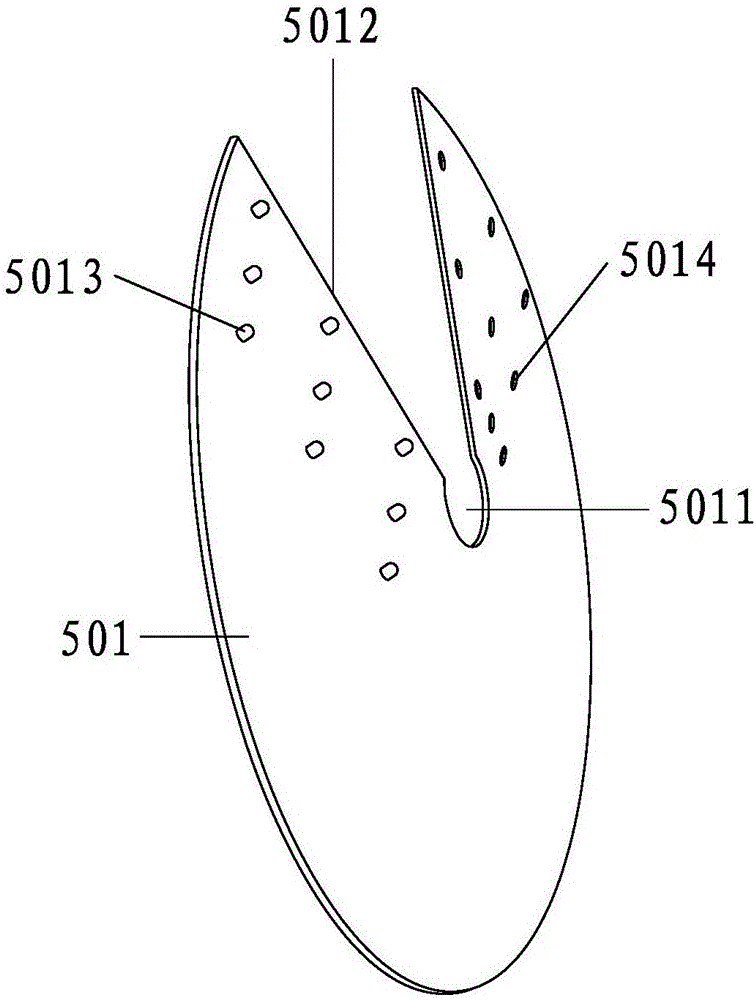

Chest enlarging postoperative shape fixing device

InactiveCN106667665ANot easy to shiftAdjustable sizeBreast bandagesThorax bandagesProsthesisShoulder girdle

The invention discloses a chest enlarging postoperative shape fixing device which comprises a chest strap, a left fixing strap, a right fixing strap, a left chest sticker and a right chest sticker. The left fixing strap is connected with the left edge of the chest strap, the right fixing strap is connected with the right edge of the chest strap, a first circular opening and a second circular opening are symmetrically formed in the front end face of the chest strap from left to right, the peripheral edge of the left chest sticker is fixed to the first circular opening, the peripheral edge of the left chest sticker is fixed to the first circular opening, the peripheral edge of the right chest sticker is fixed to the second circular opening, and the sizes of the left chest sticker and the right chest sticker can be adjusted. The chest enlarging postoperative shape fixing device has the advantages that the left chest of a female patient can be effectively covered and fixed by the left chest sticker, the right chest of the female patient can be effectively covered and fixed by the right chest sticker, so that prostheses implanted into corresponding chests are not easily shifted, the chest enlarging postoperative shape fixing device is suitable for chest enlarging postoperative female patients with different sizes of chests as the sizes of the left chest sticker and the right chest sticker can be adjusted, and the chest enlarging postoperative shape fixing device is high in practicability and adaptability and good in use effect.

Owner:PEKING UNIV SHENZHEN HOSPITAL

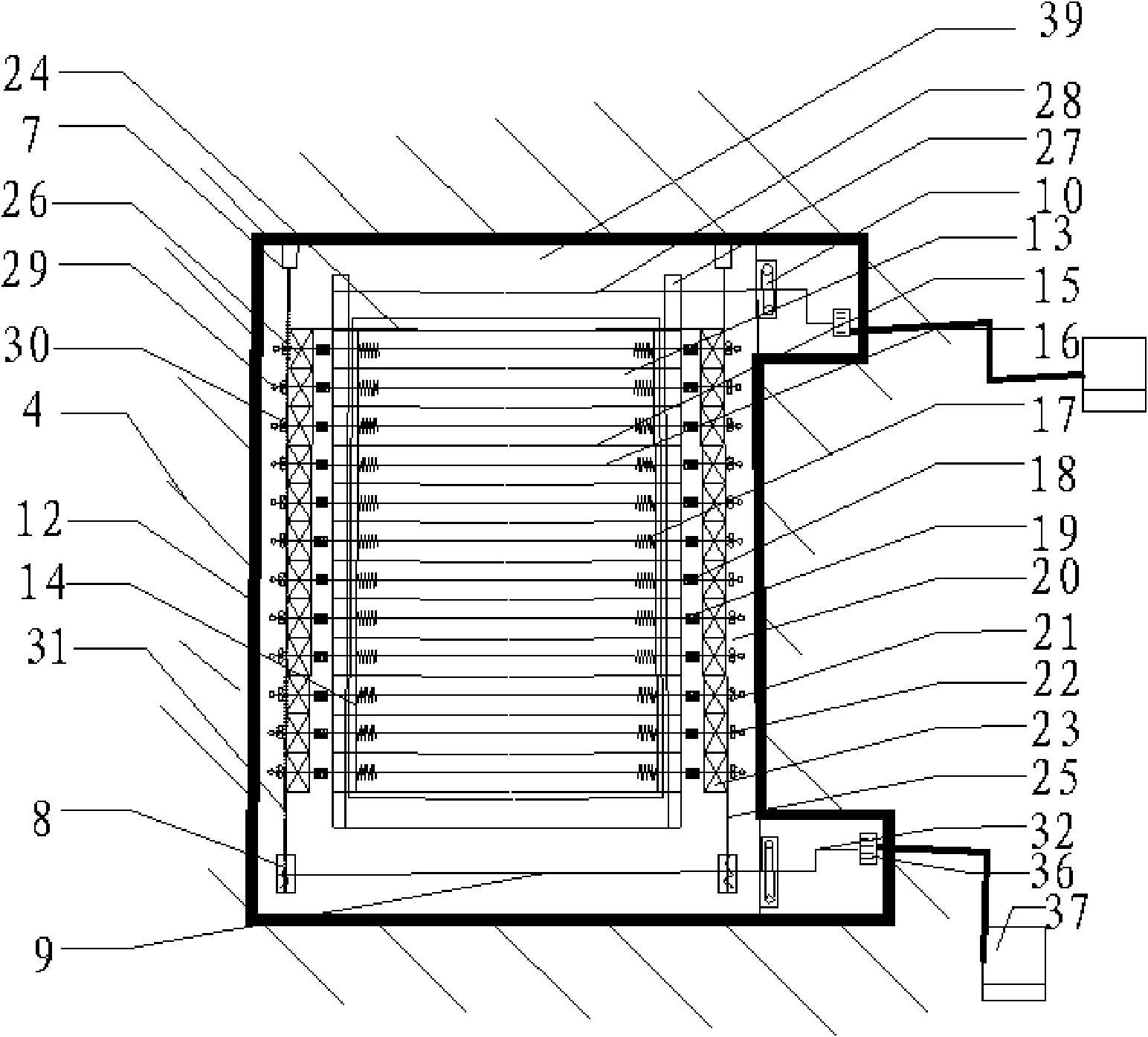

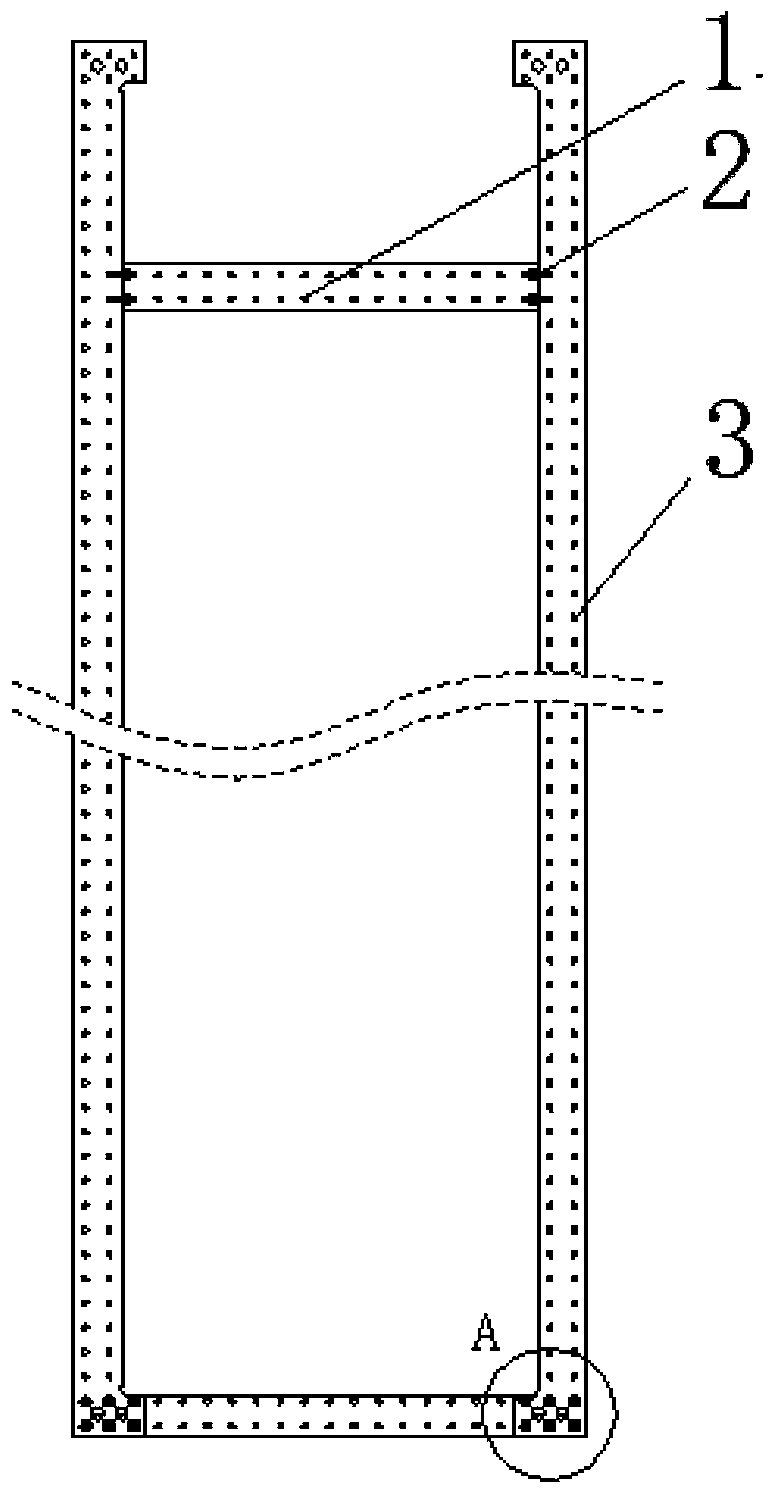

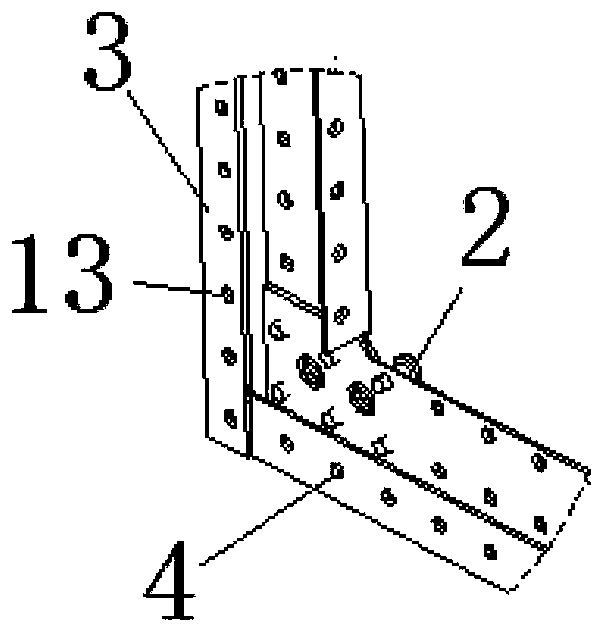

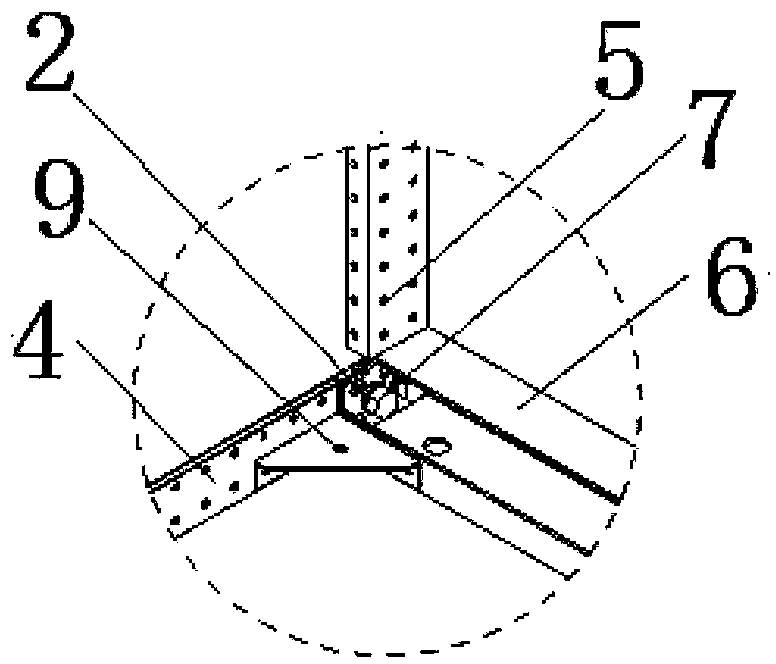

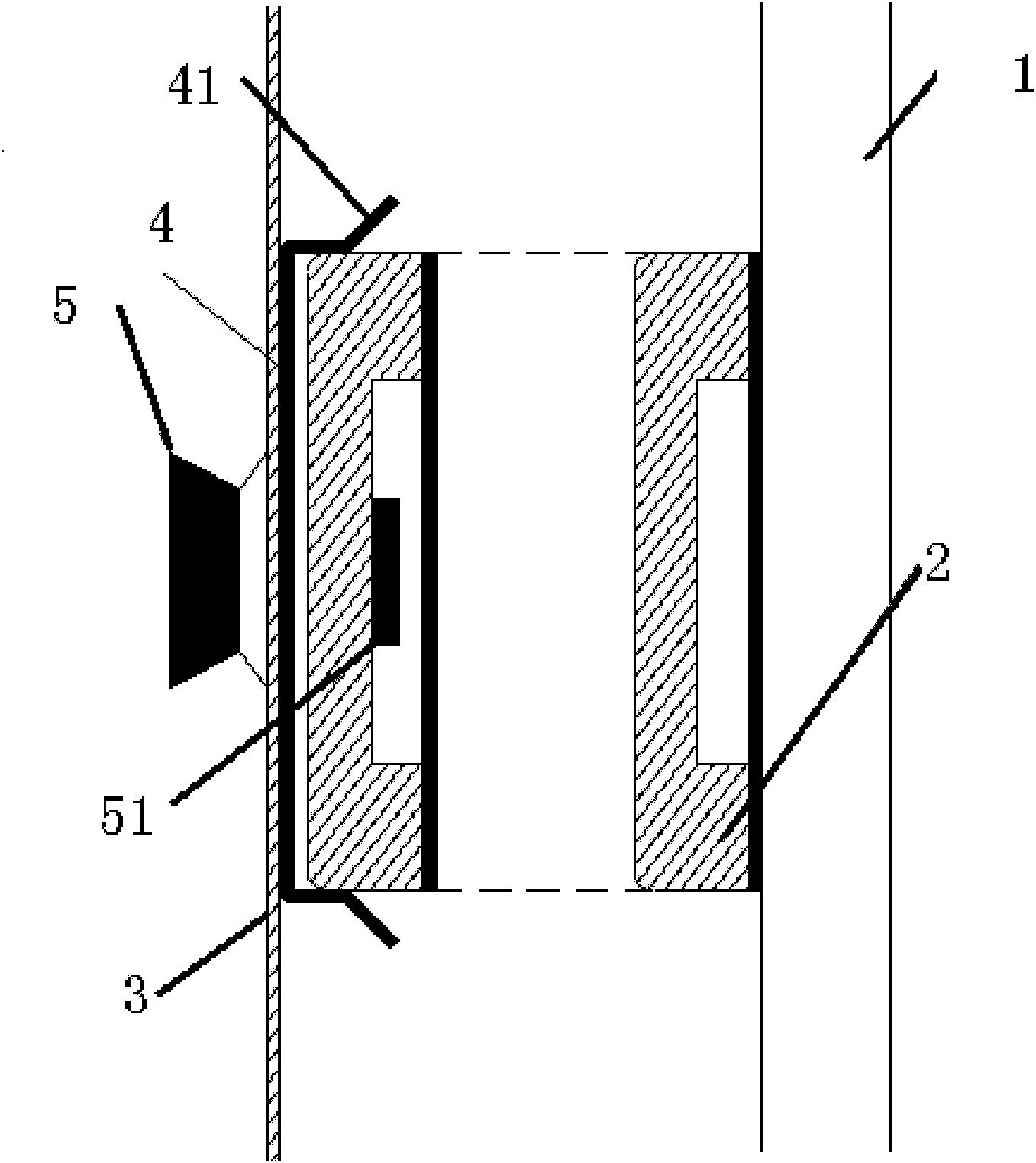

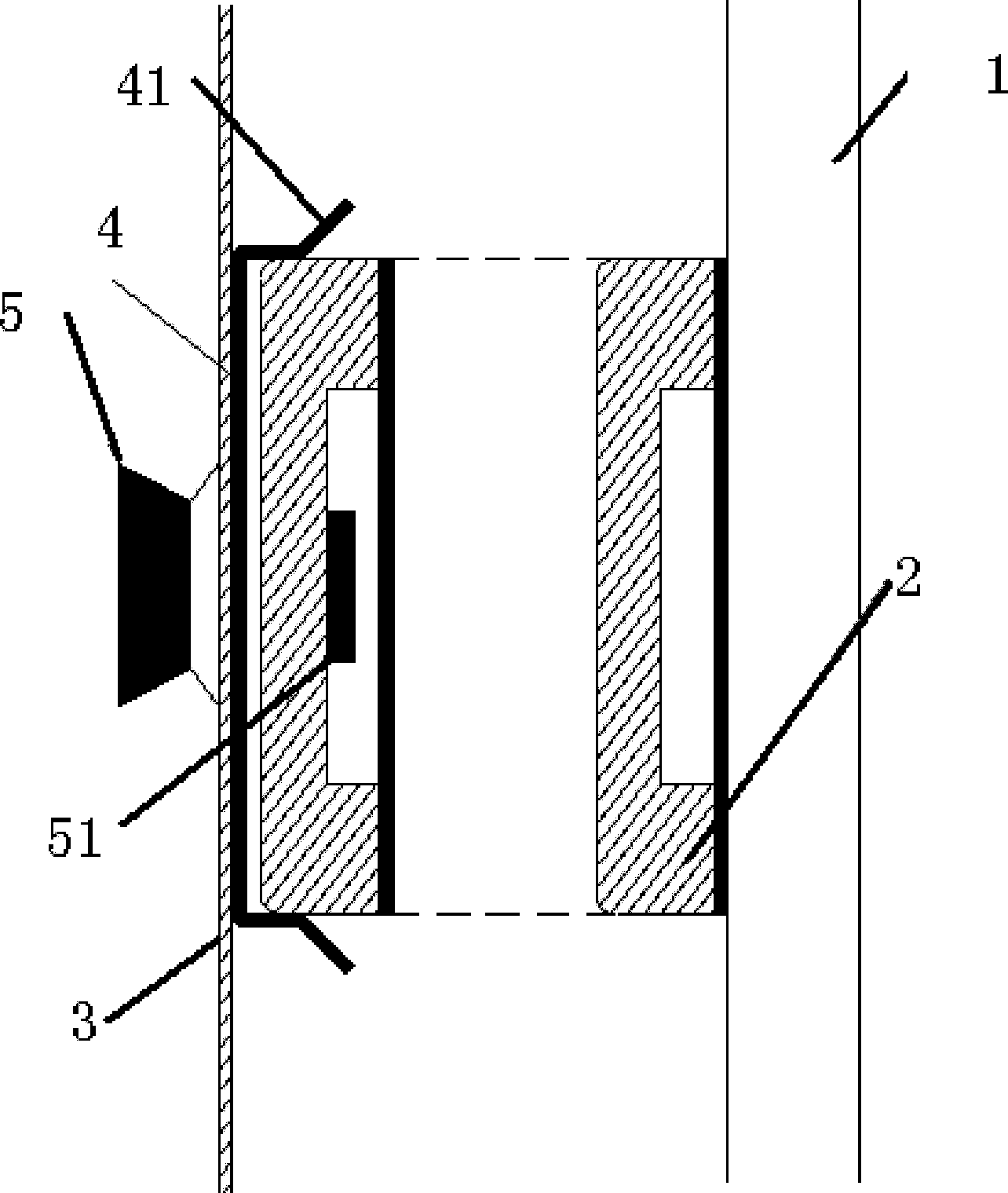

Combined type energy-saving window

InactiveCN101560868AImprove comfortAchieve the effect of enteringDoor/window protective devicesVentilation arrangementWindow shutterEngineering

The invention relates to a combined type energy-saving window which comprises a glass window arranged at the inner side of a window hole and a blind arranged at the outer side of the window hole. The glass window is a lift-type glass window. A piece of lifting glass is clamped tightly by a strip-shaped clamping plate and is lifted and dropped by using a steel wire rope, a pulley and a turbine worm assembly. Three steel wires are arranged inside each blade of the blind, the steel wires at the two lateral sides of each blade are connected with hinge sheets which are connected with an angle regulator arranged at the top of a window frame so as to realize the angle control of the blades. The middle steel wires of the blades are connected with a connecting rod of a universal wheel by spring sleeves, the connecting rod of the universal wheel is sleeved with a retraction sheet, and the lifting pulley of the universal wheel moves upwards and downwards along a sliding way; the upper end of the retraction sheet is fixed on a fixing rod, and the lower end thereof is fixed with a lifting rope; and the blind is lifted and dropped by using the lifting rope, the pulley and the turbine worm assembly. The combined energy-saving window has the advantages of capability of automatic operation, great lighting and ventilation quantity, energy conservation, safe performance and beautiful appearance.

Owner:沈洪

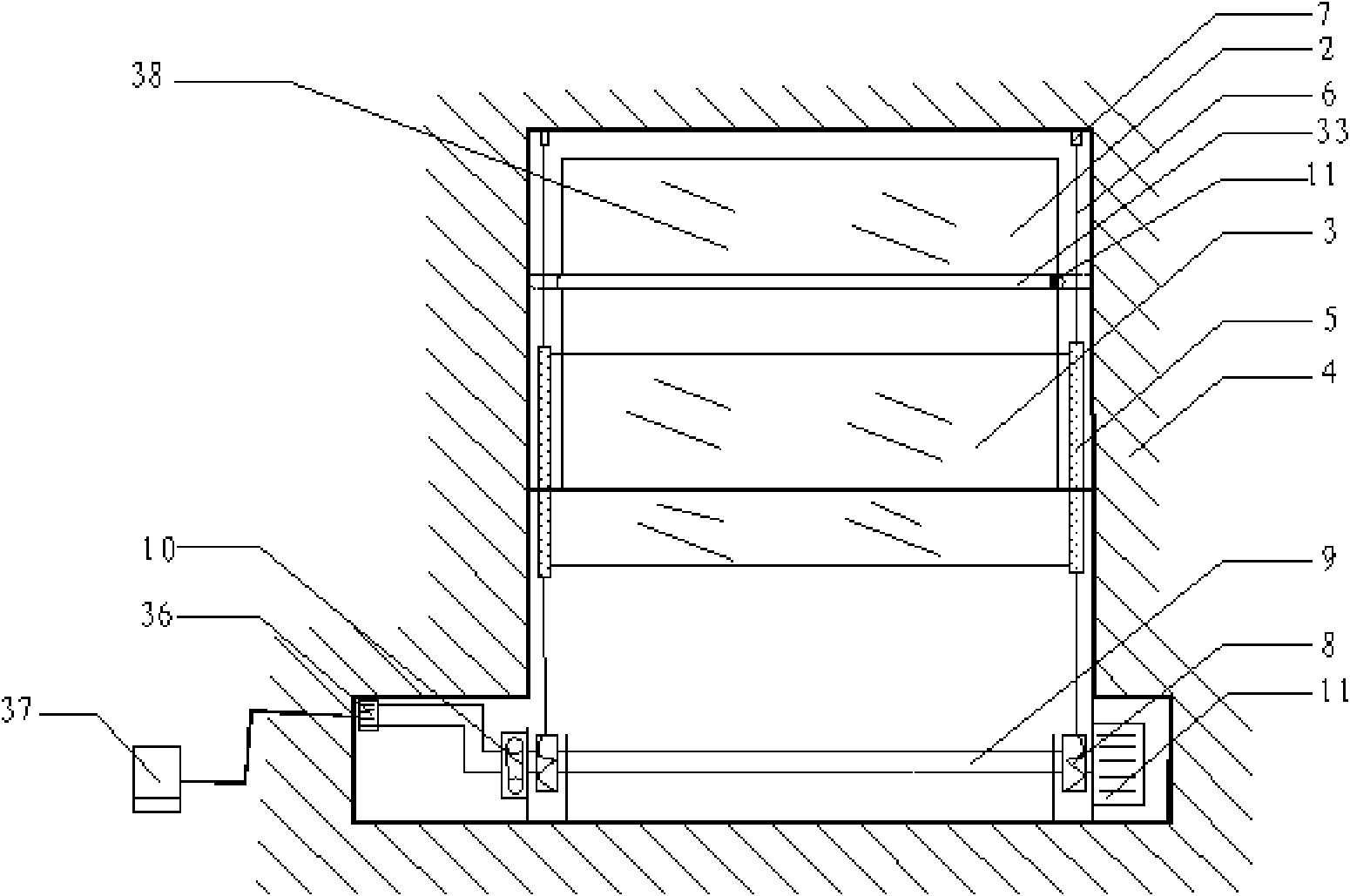

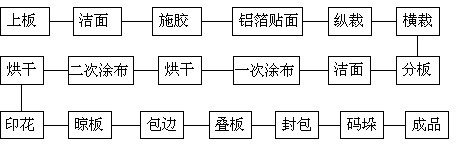

Color coating decorative gypsum board and production method thereof

ActiveCN104005529AHigh strengthImprove waterproof performanceLamination ancillary operationsCovering/liningsKeelThermal radiation

The invention discloses a color coating decorative gypsum board and a production method thereof. The gypsum board serves as a board core; an aluminum foil layer is attached to the back side; the front side is provided with a coating film layer and a color coating ink layer. According to the color coating decorative gypsum board and the production method thereof, the aluminum foil layer is conductive and is matched with a keel and accordingly the electrostatic leakage performance is good and the strength and the waterproof performance of the gypsum board are increased and the heat radiation prevention performance of the aluminum foil layer is achieved and accordingly the heat radiation heat transfer is reduced after ceiling and the temperature regulation function is good; the coating film layer and front side protective paper of the gypsum board are fully combined and accordingly the waterproof, anti-static and decay prevention effects are achieved; various exquisite patterns can be printed on the color coating ink layer and accordingly the color coating decorative gypsum board is obvious in decorative effect, easy to clean, suitable for various places such as offices, shopping malls, families, schools and entertainment places, simple in process, rapid in construction, solid in integral structure, not easy to sag, long in service life and good in decorative effect.

Owner:TAISHAN GYPSUM CO LTD

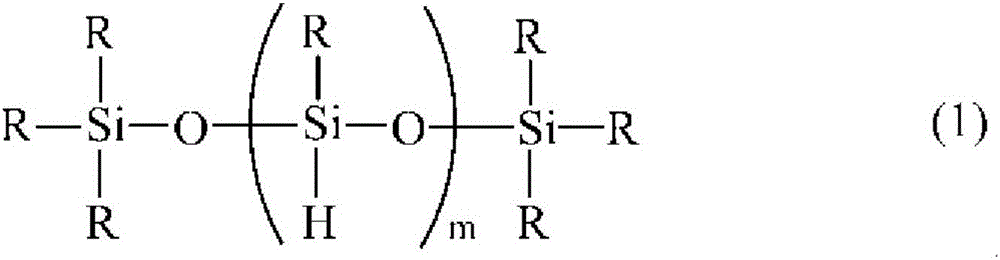

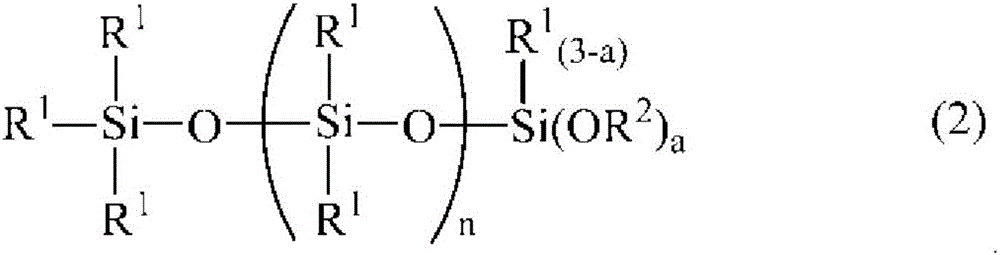

Uv-thickening thermally conductive silicone grease composition

InactiveCN106715592ANot easy to sagConducive to preservationHeat-exchange elementsAdditivesPlatinum complexHydrogen atom

A UV-thickening thermally conductive silicone grease composition: which has (A) an organopolysiloxane, the viscosity at 25 DEG C of which is 50-100,000 mPa*s and which contains at least one alkenyl group in a single molecule, (B) an organohydrogen polysiloxane, a single molecule of which contains a hydrogen atom directly bonded to at least two silicon atoms, (C) a photoactive platinum complex curing catalyst, and (D) a thermally conductive filler with a thermal conductivity of at least 10 W / m*DEG C as essential components; and the viscosity at 25 DEG C of which is 30-800 Pa*s when measured at a 10 rpm rotation rate using a Malcom viscometer. For this UV-thickening thermally conductive silicone grease composition, shape-retaining properties at low viscosity are high, deep curing properties can be adjusted using the UV irradiation dose, and the composition after being thickened by irradiating UV rays does not become hard but sets so as to be malleable.

Owner:SHIN ETSU CHEM CO LTD

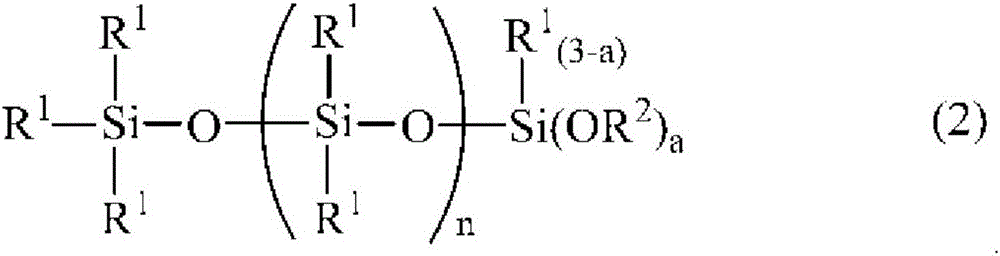

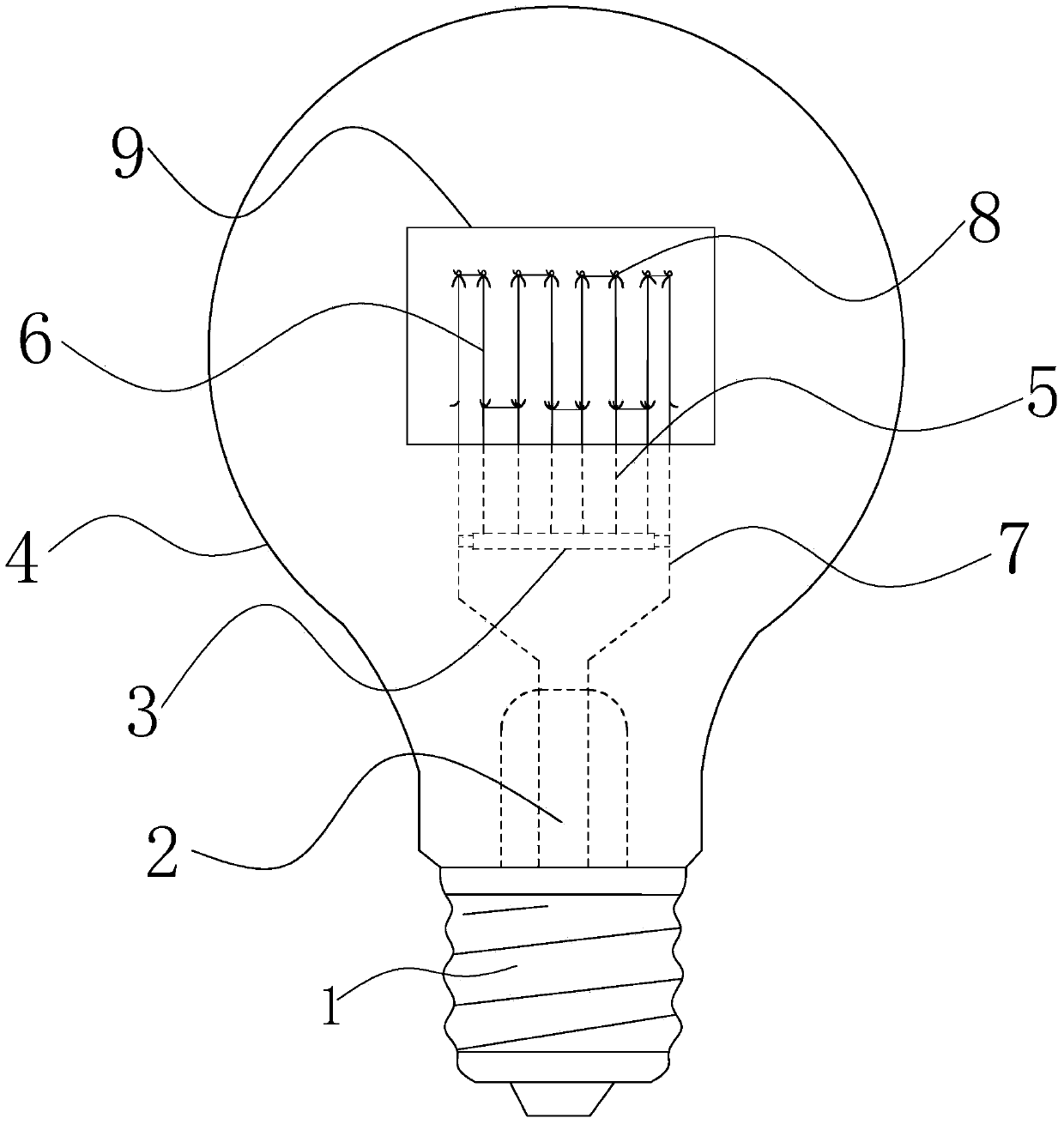

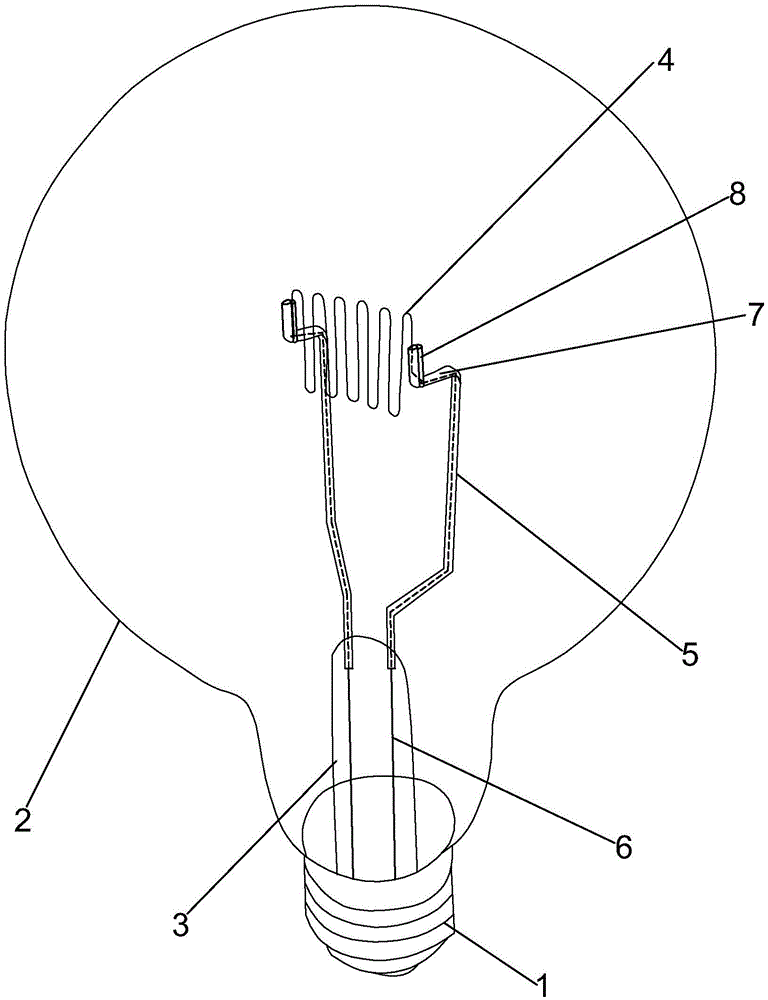

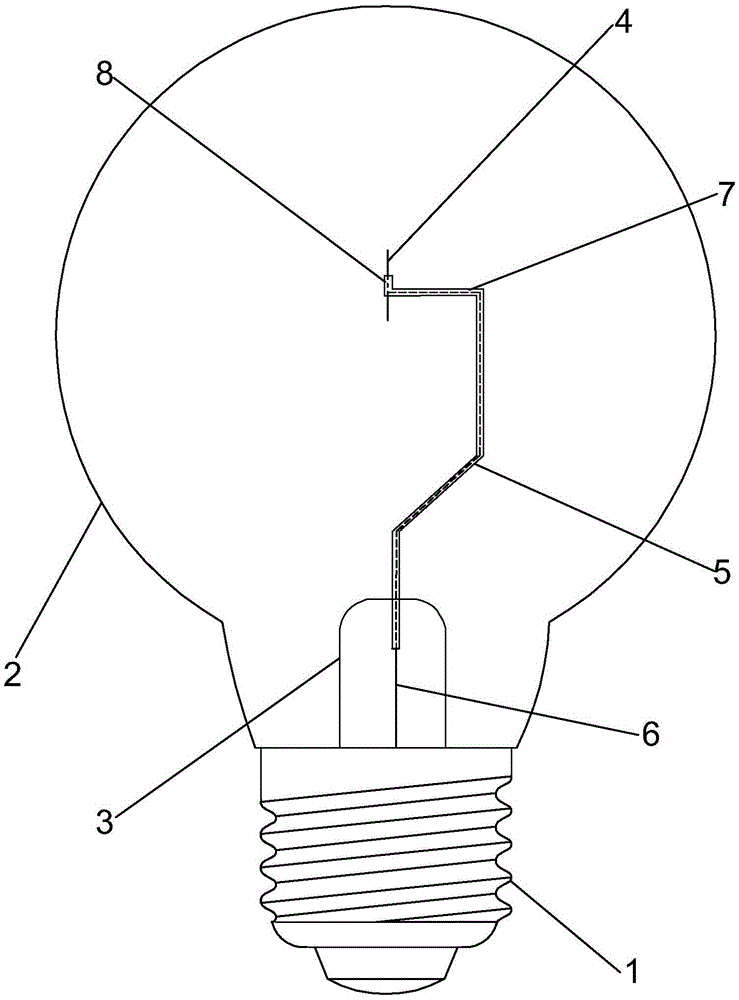

Standard lamp for detection

InactiveCN103681221ANot easy to sagExtended service lifeLamp incadescent bodiesIncadescent envelopes/vesselsEngineeringGuide wires

The invention relates to a standard lamp for detection. The standard lamp comprises a lamp cap and a glass bulb. A stem and lamp filaments are arranged in the glass bulb. Two guide wires are led out from the interior of the stem. The two ends of the lamp filaments are connected with the guide wires respectively. The upper end face of the glass bulb is of an arc-face back taper shape. A fixing base is connected between the two guide wires and provided with a plurality of molybdenum wire hook sets. Each molybdenum wire hook set comprises a high molybdenum wire hook and a low molybdenum wire hook. The hook portion of each high molybdenum wire hook and the hook portion of each low molybdenum wire hook are located on the same vertical line. The lamp filaments sequentially penetrate through the hook portions of the tops of the molybdenum wire hooks from left to right according to a square wave shape, and are arranged on the same plane. The standard lamp reduces influence of stray light, avoids the processing difficulty that the influence of the lamp filaments is reduced on the condition that the lamp filaments are located in the center of the glass bulb when the spherical glass bulb is adopted, and improves the qualified rate.

Owner:詹云翔

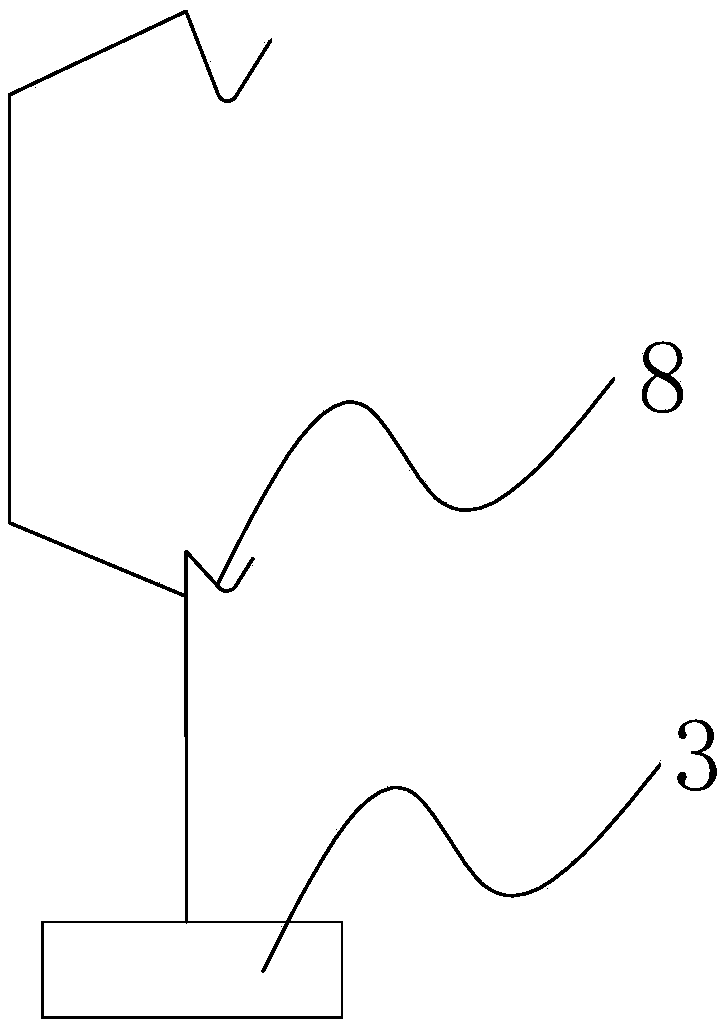

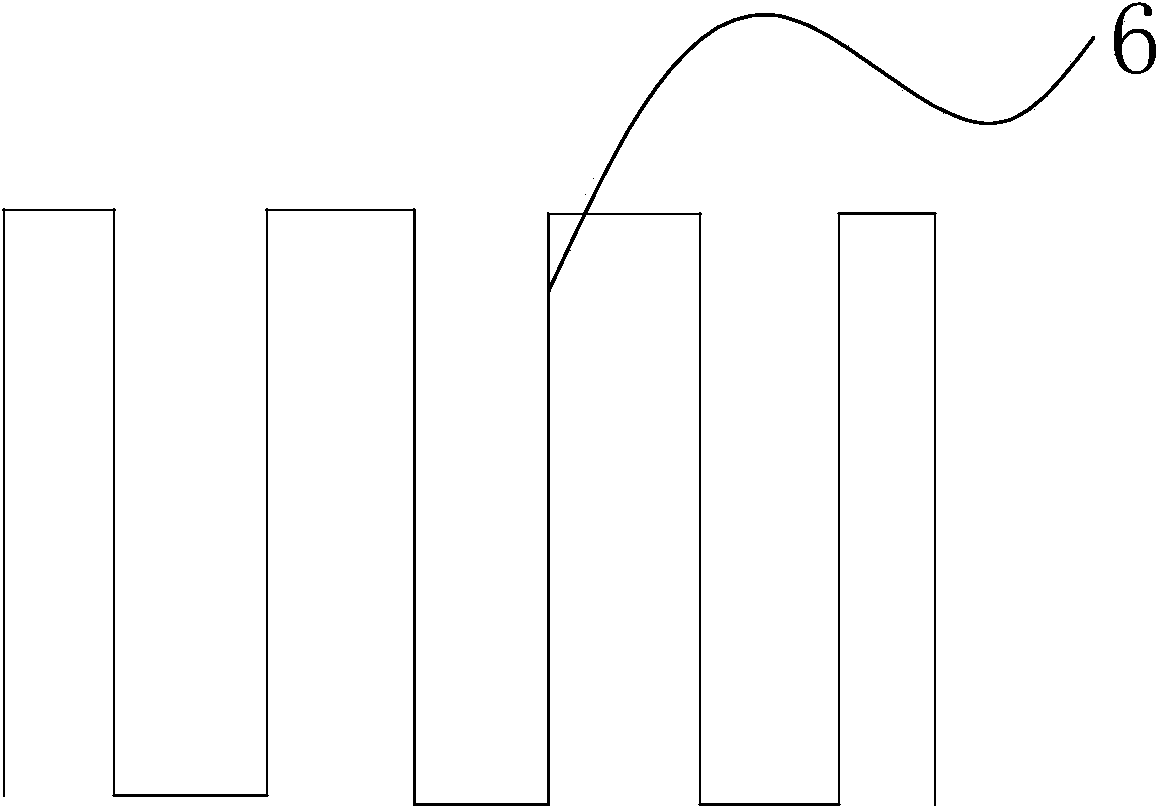

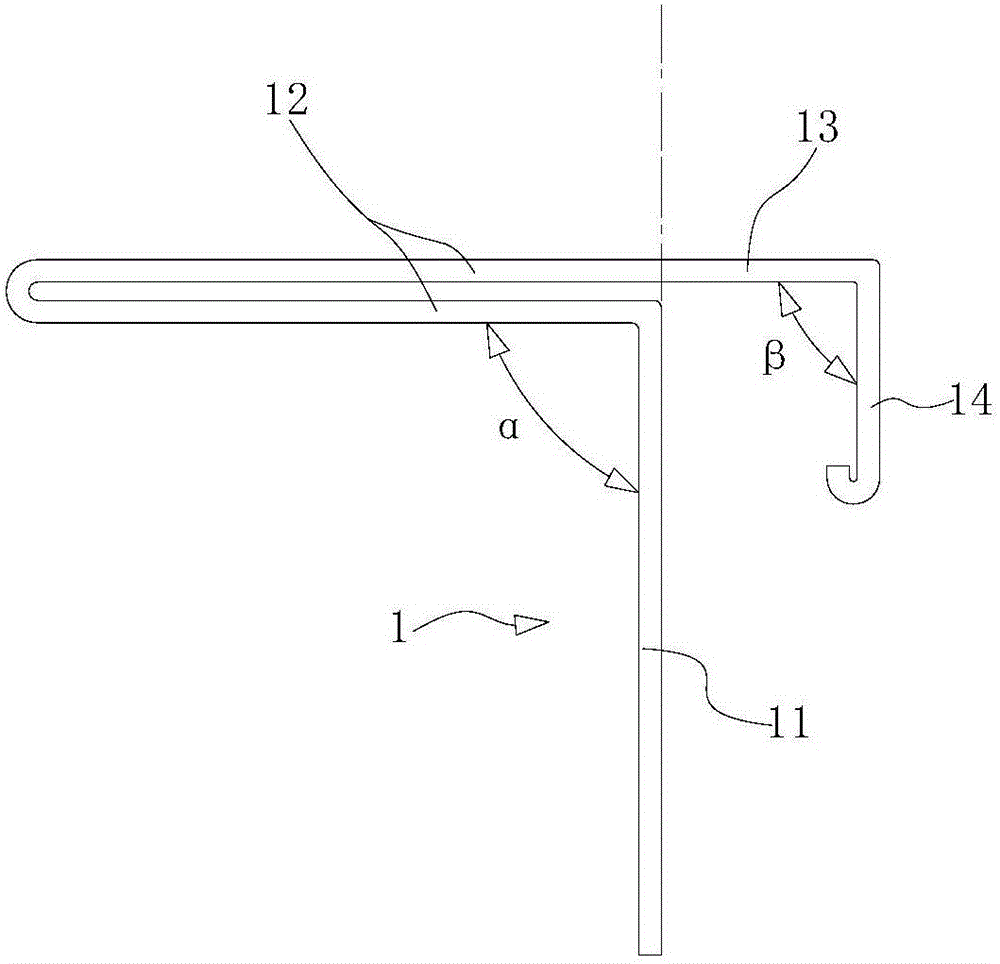

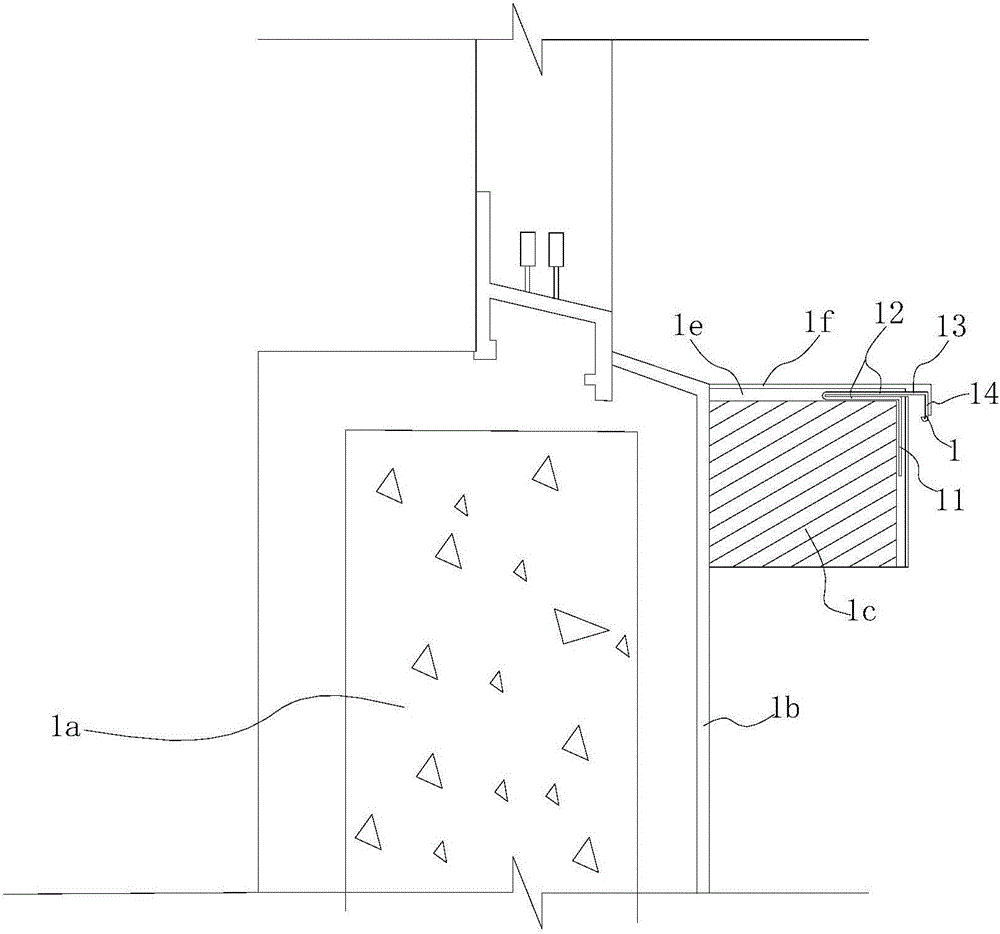

Metal water dripping line for preventing pollution of wall and wall bulging structure

The invention specifically relates to a metal drip line installed on the upper part of the protruding structure of the wall to prevent the wall and the protruding structure from hanging and polluting. It includes two attachment sheets, and the opening angle α between the two attachment sheets is 0° <α<180°; the intersecting ridges of the two attachment sheets are connected with an overhanging piece extending along the horizontal direction, and the edge of the overhanging piece relative to the intersecting ridge is connected with a deflector extending below the overhanging piece; The diversion angle β between the guide sheet and the overhanging sheet is α≤β<180°; the lengths of the guide sheet, the attachment sheet and the extension sheet are equal. The overhanging sheet extending along the horizontal line can change the direction of rainwater flow, keeping the rainwater away from the facade of the protruding structure on the wall, and then fall along the guide sheet. The deflector angle β is α≤β<180°, so that the deflector is located in the area between the two limit positions where sagging occurs: the horizontal position parallel to the wall surface protruding the facade of the structure and coplanar with the deflector , so as to prevent the phenomenon that the wall and the protruding structure of the wall are hanged and polluted by rainwater.

Owner:CHONGQING GESHANG BUILDING MATERIALS CO LTD

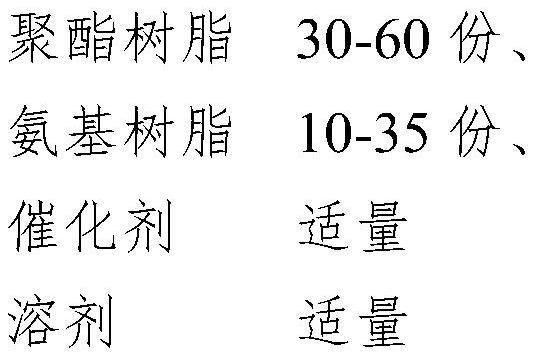

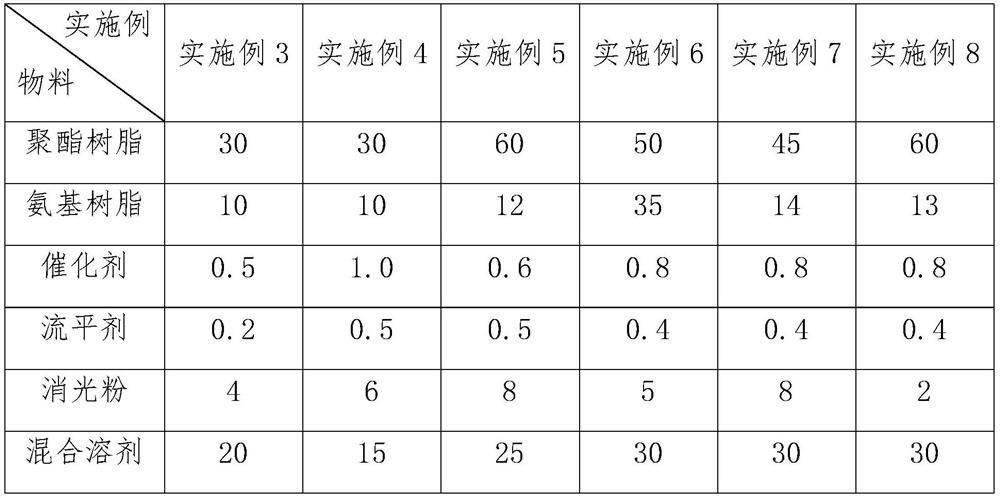

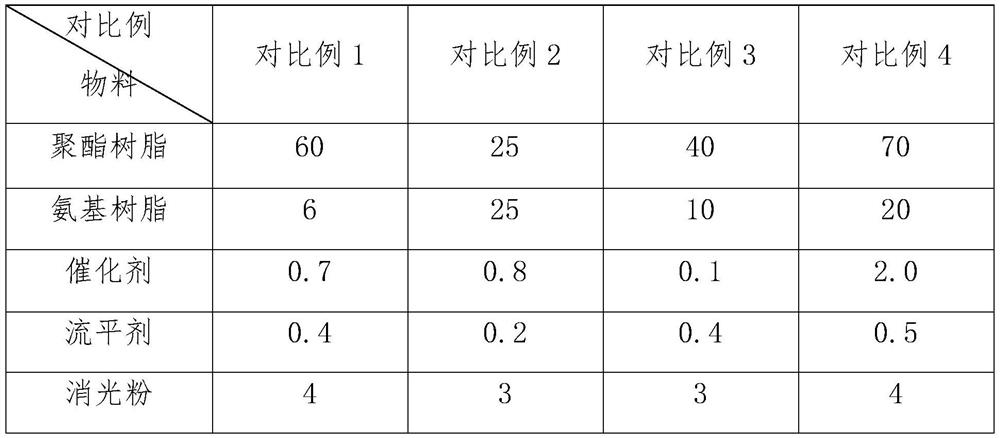

Heat transfer printing coating and preparation method thereof

InactiveCN112457749AReduce lossUniform film thicknessFireproof paintsPolyester coatingsCoated membraneMetallic aluminum

Aiming at the problems of low spraying efficiency, high labor intensity, high coating loss, non-uniform coating film thickness and the like due to the fact that a thermal transfer coating is formed onthe surface of a metal aluminum base material and a polyurethane powder spraying process is mostly used for construction in the prior art, performance indexes cannot meet thermal transfer requirements in practical application, and a transfer image effect is not ideal. The invention provides a heat transfer printing coating which is prepared by mixing the following components in parts by weight: 30-60 parts of polyester resin, 10-35 parts of amino resin, a proper amount of catalyst and a proper amount of solvent. The heat transfer printing coating is used in cooperation with polyester resin primer of a metal aluminum base material, the surface of the primer is coated with the heat transfer printing coating through a roller coating process, the thermal transfer coating can be formed throughcontinuous high-speed production, and the heat transfer printing coating has the advantages of being high in roller coating production efficiency, high in yield, small in environmental harm and the like and has a good thermal transfer effect.

Owner:清远慧谷新材料技术有限公司

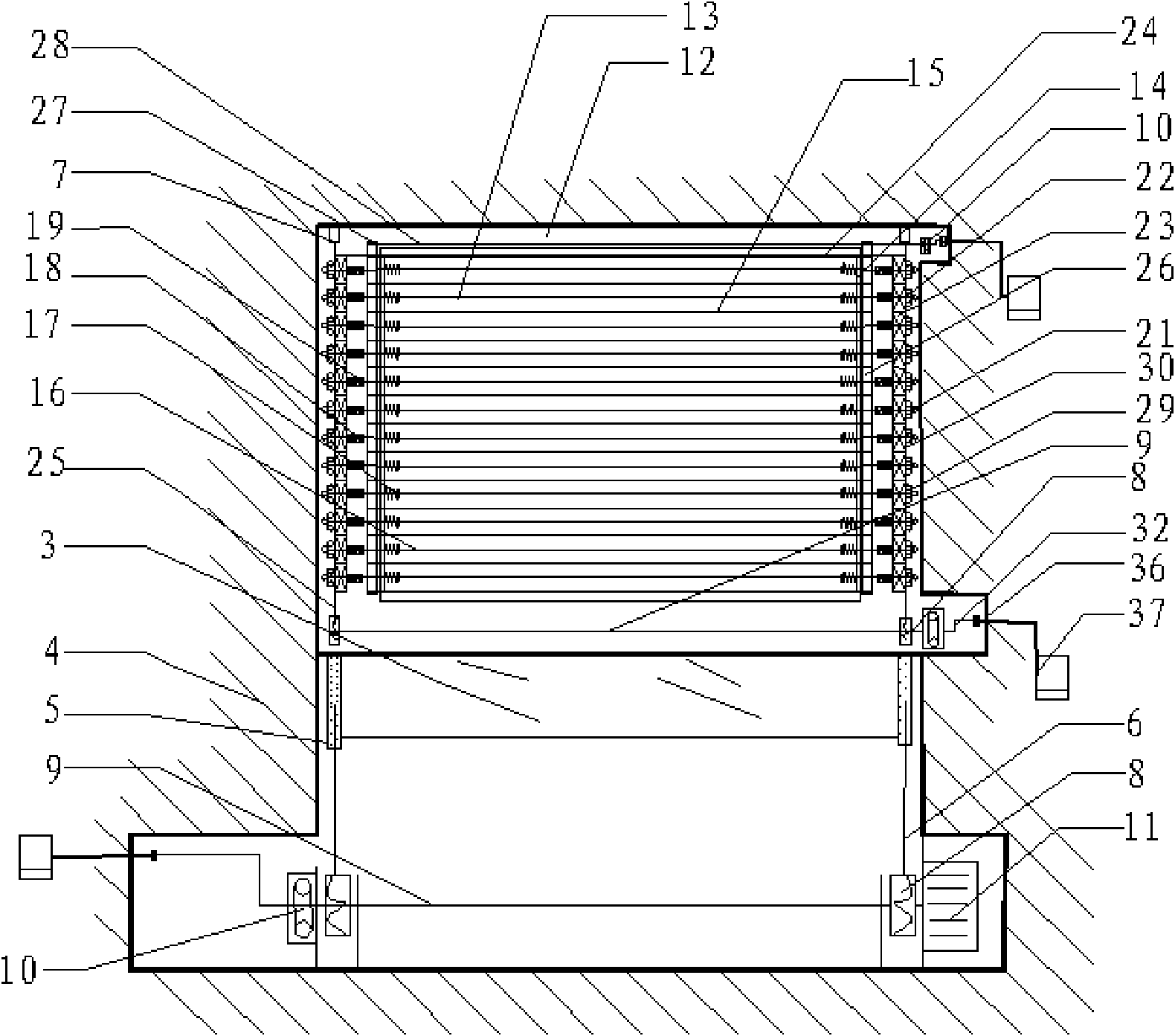

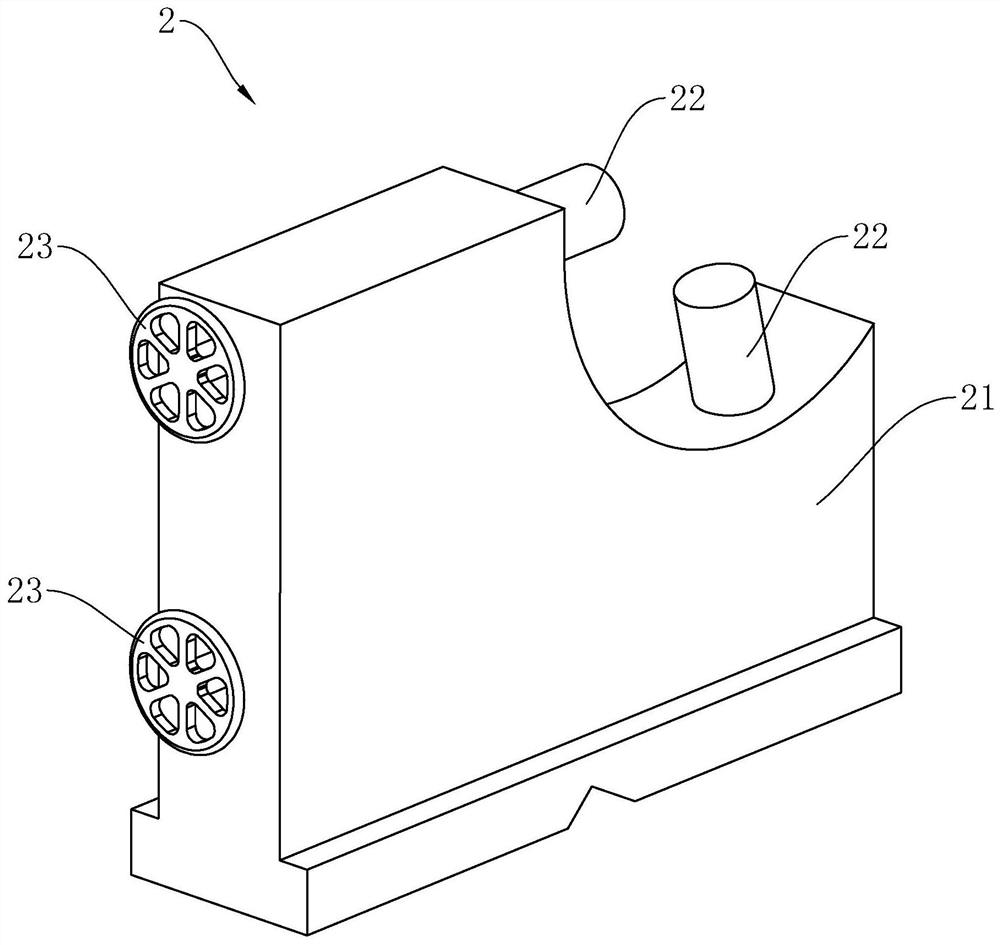

Power distribution cabinet framework

ActiveCN103384047APrecise positioningHigh strengthSubstation/switching arrangement detailsBusbarUltimate tensile strength

The invention discloses a power distribution cabinet framework which comprises lateral plates and a connecting beam between the lateral plates. Each lateral plate is formed by connecting a busbar clamp mounting beam, a stand column and a cross beam, wherein the cross beam and the stand column are connected in an inserted mode and then connected through self-tapping screws to form the lateral plate; the two ends of the connecting beam are provided with mountings holes respectively, and the end portions of the self-tapping screws extend out of the lateral plate and then extend into the mountings holes; the connecting beam is connected with the lateral plate through bolts; a structural strengthening support is arranged between the cross beam and the connecting beam; the two ends of the busbar clamp mounting beam are connected with the stand column respectively through the self-tapping screws. According to the power distribution cabinet framework, the cross beams and the stand columns are connected in the inserted mode and then tightly pressed and connected through the self-tapping screws, and therefore accurate positioning of the lateral plates is realized; after the end portions of the self-tapping screws are inserted in the mounting holes of the connecting beam, the lateral plates and the connecting beam are connected in a fastening mode through the high-strength bolts, and therefore the connection strength and stability of the lateral plates and the connecting beam are good; due to the connection structure between the stand columns, the cross beams and the connecting beam, the power distribution cabinet framework is high in installation accuracy, easy to install and operate, and capable of guaranteeing the quality of a power distribution cabinet product.

Owner:ANHUI MINGYUAN POWER EQUIP MFR

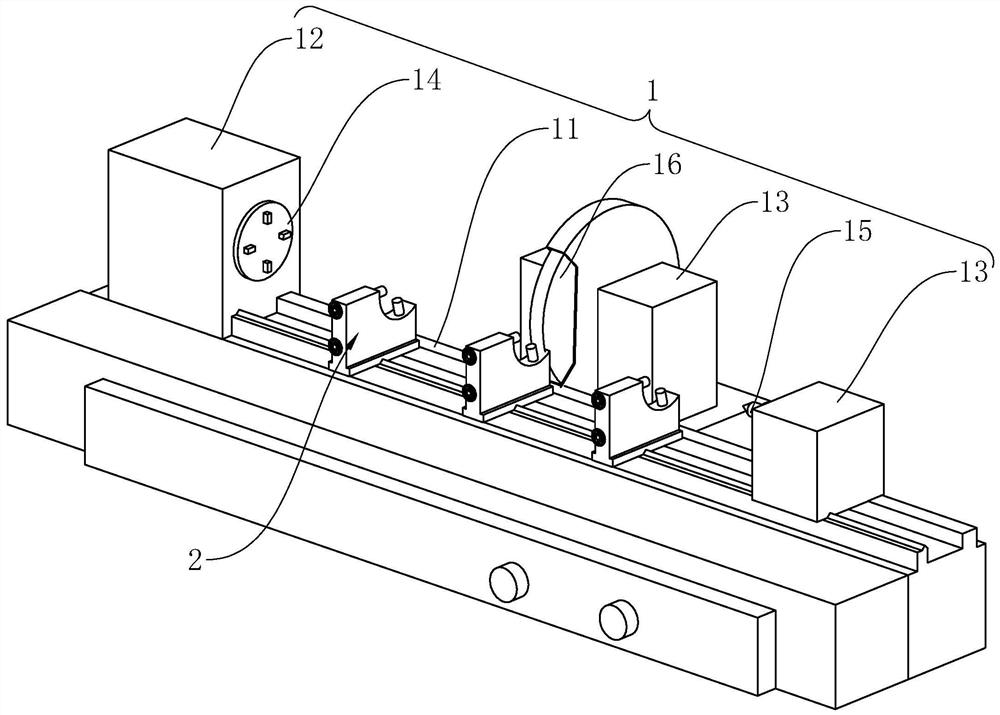

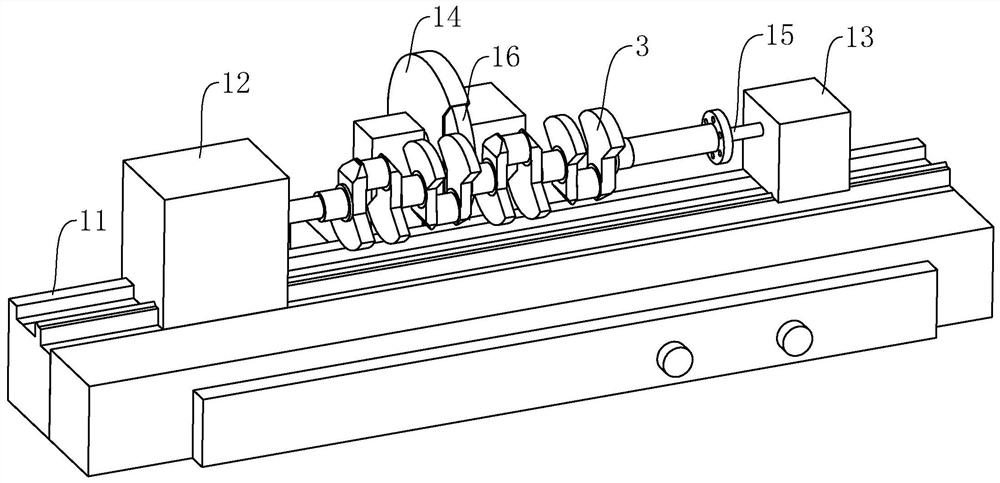

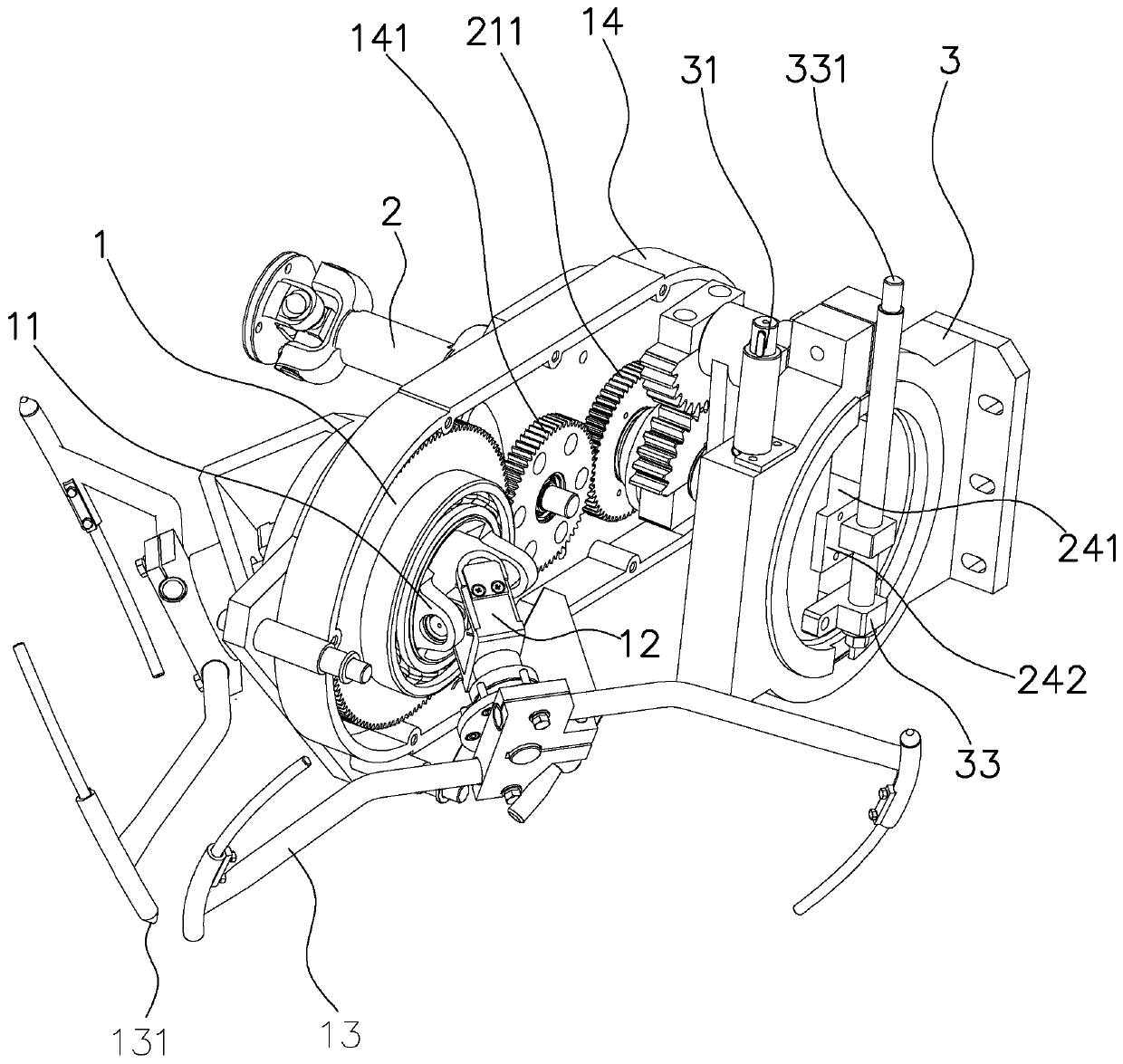

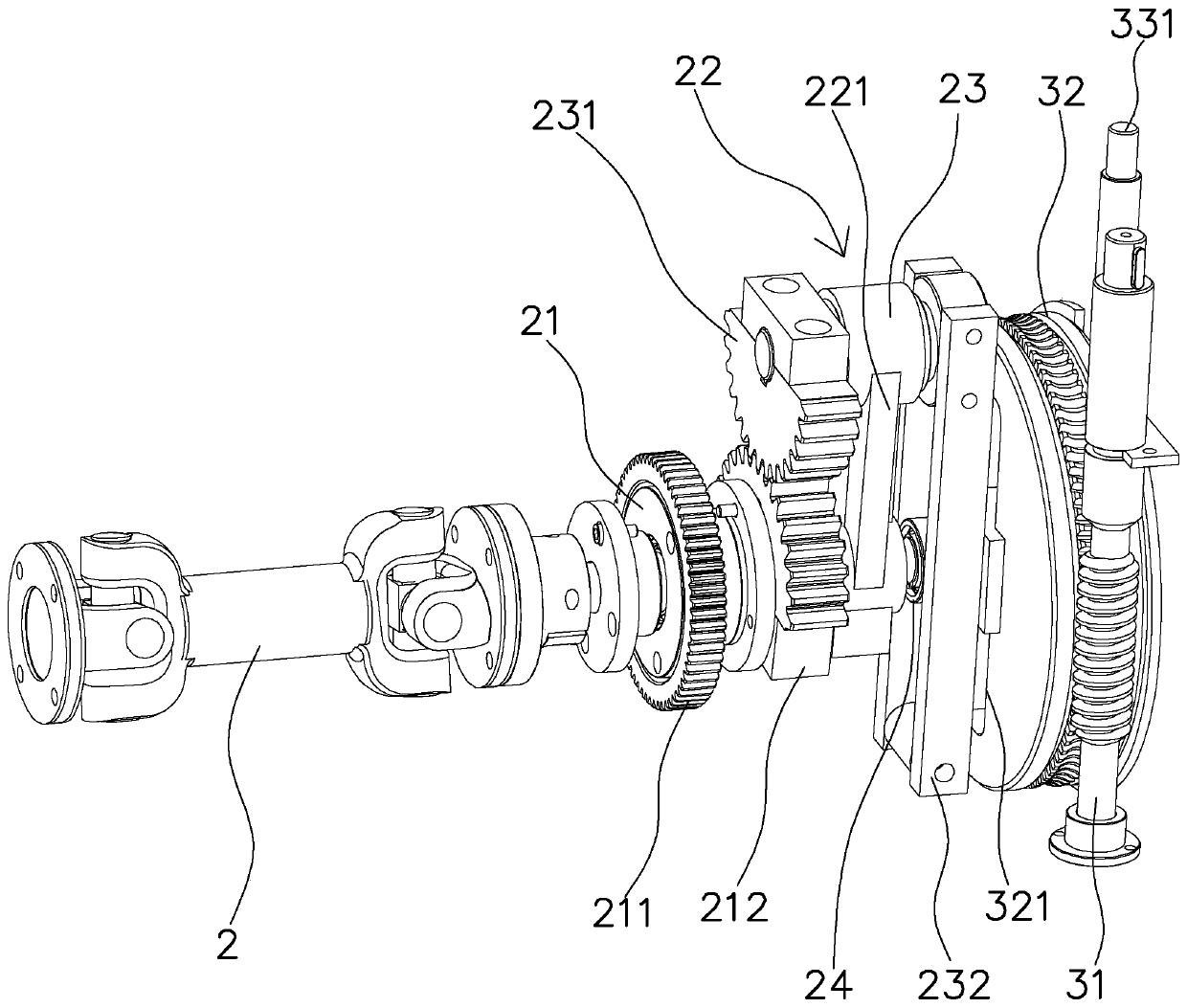

Machining process for improving coaxiality of crankshaft journals

InactiveCN112975589AImprove coaxialityNot easy to sagRevolution surface grinding machinesGrinding feed controlPhysicsEngineering

The invention relates to a machining process for improving the coaxiality of crankshaft journals, and belongs to the technical field of crankshaft machining. The process comprises the machining steps that a crankshaft is placed above a machine body of a grinding machine; a plurality of central frames are installed on the machine body of the grinding machine, and each central frame supports one journal at the corresponding position of the crankshaft on the grinding machine; the position of the axis of each journal of the crankshaft relative to the machine body of the grinding machine is measured, and the positions of the axes of all the journals of the crankshaft are consistent by adjusting telescopic feet of the central frames; a universal joint is installed at the shaft end of the crankshaft, and the universal joint and a chuck of the grinding machine are connected together; and the grinding machine is started to operate to grind each journal of the crankshaft to be of designed size. In the process of grinding the crankshaft journals, the crankshaft is supported on the grinding machine only under the action of the central frames, so that the middle portion of the crankshaft is not prone to drooping as a result of gravity, the axis position error of the crankshaft journals and the grinding machine chuck is counteracted under the action of the axis change of the universal joint, and the coaxiality of the crankshaft journals after grinding is improved.

Owner:杭州江滨内燃机配件有限公司

Production technique for manufacturing boot by polypropylene particles with fusion blowing forming method

The invention relates to a production technique for manufacturing boot by polypropylene particles through fusion blowing forming method, and is characterized in that the production technique comprises the following steps: (1) spraying water to the fabric, and hanging the fabric on one side of a mould after spraying water; (2) setting a reinforcing rib plug board and a blowing pin on the outer part of the other side of the mould; (3) heating the polypropylene particles by a vacuum machine for fusing; and extruding the fused polypropylene particles to form fused particles; (4) stretching the reinforcing rib plug board into the mould; sending the fused particles to the mould; closing two side moulds to form the fused particles into mould material; returning the reinforcing rib plug board to the outer part of the mould after closing the mould; stretching the blowing pin to the inner part of the mould to pierce the mould material; and simultaneously blowing compression air by the blowing pin; (5) after blowing the compression air, punching the circumferential remainder on a punch; (6) trimming the circumferential fabric filament by a pneumatic trimming machine to obtain the boot. The invention solves the performance indexes of the boot assembly such as bearing performance, light weight, high strength and low odor.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

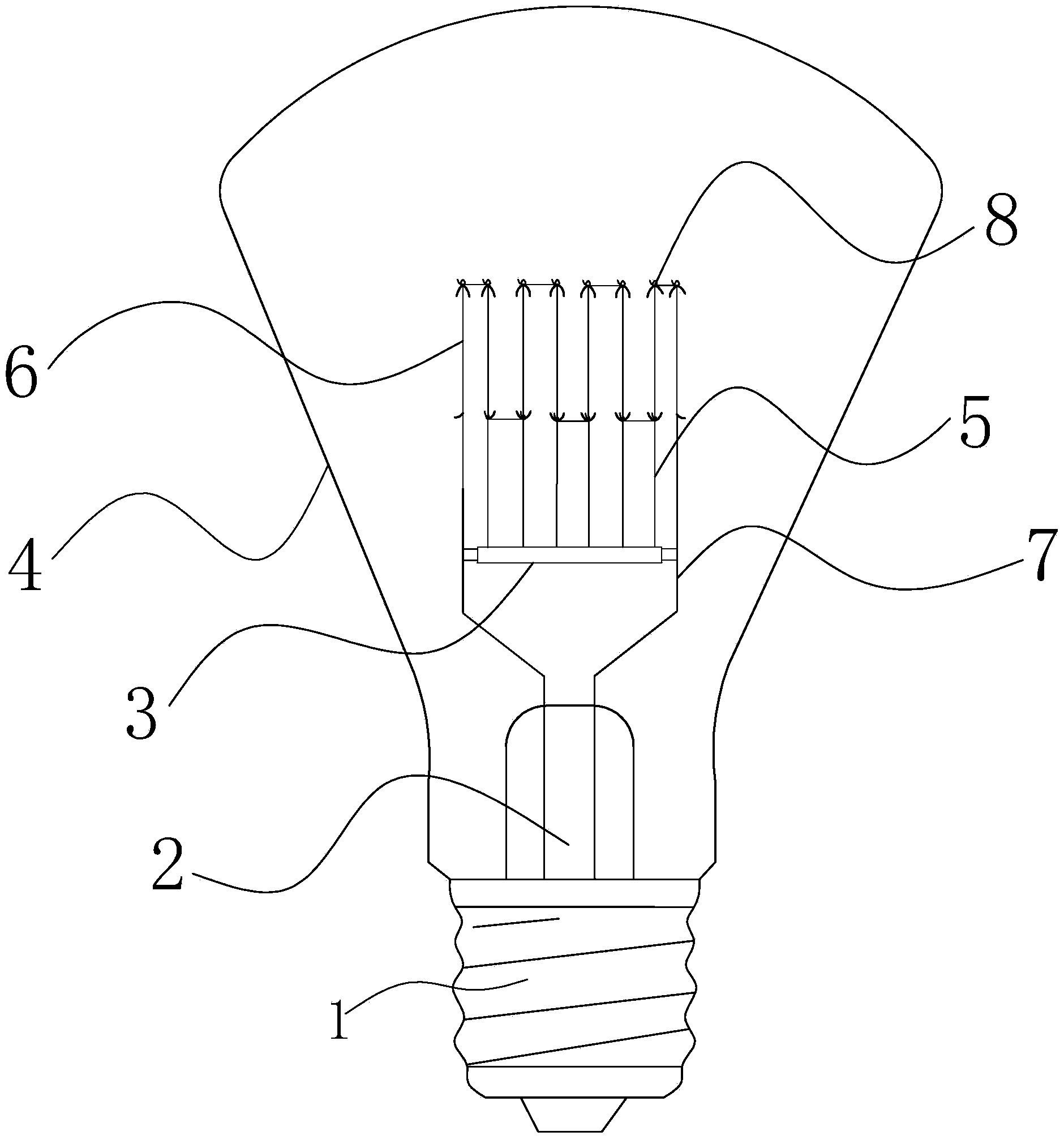

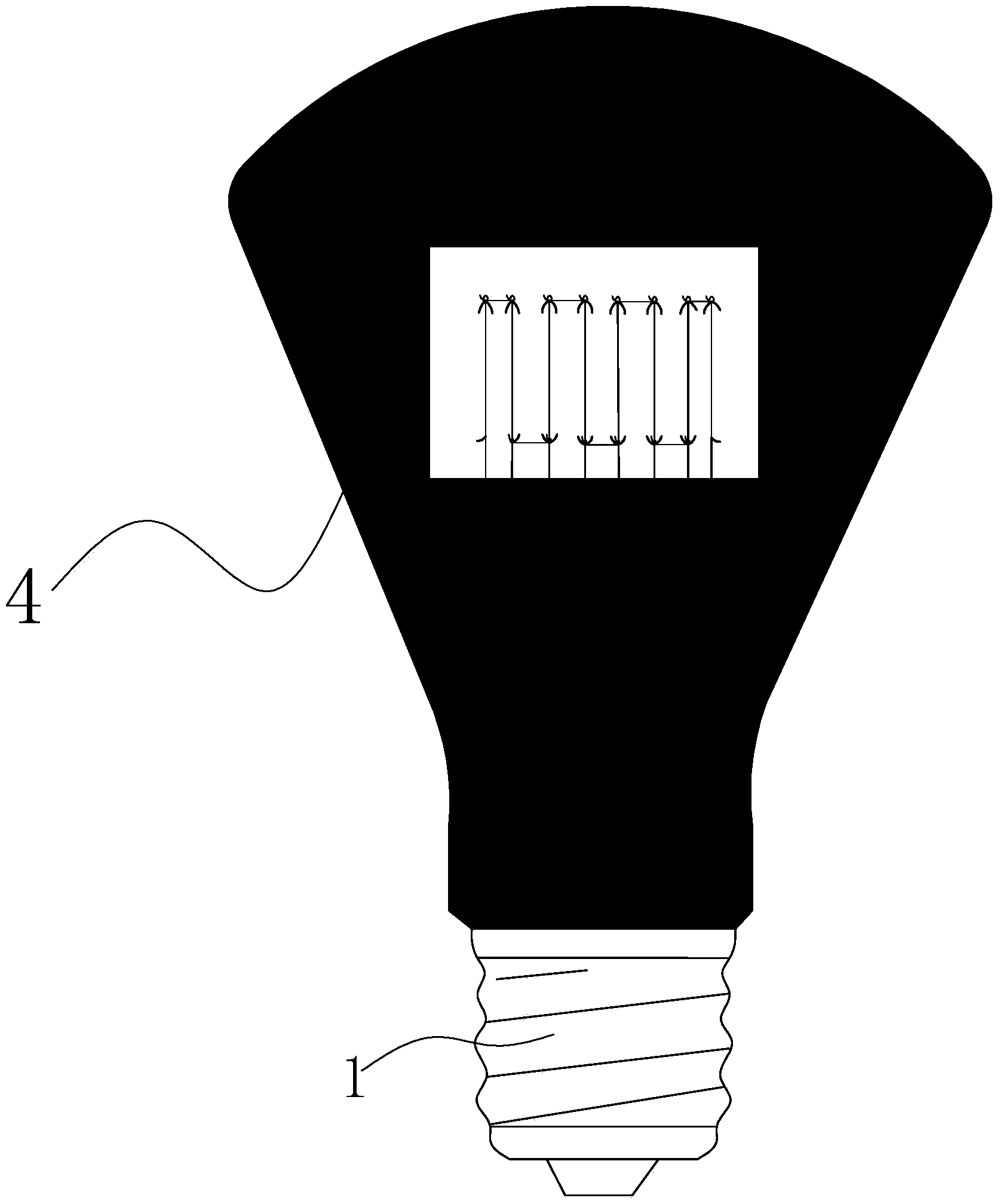

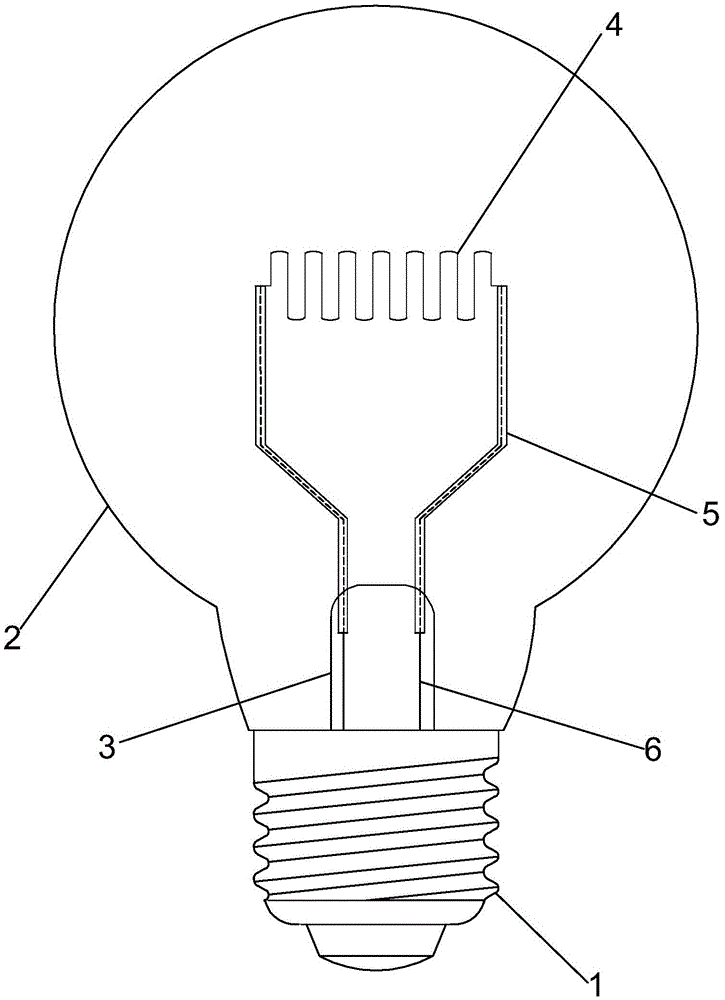

Luminous intensity detection standard lamp

InactiveCN103681219AReduce the effect of reflected lightEasy to adjustLamp incadescent bodiesIncadescent envelopes/vesselsLuminous intensityEngineering

The invention relates to a luminous intensity detection standard lamp. The luminous intensity detection standard lamp comprises a lamp holder and a glass bulb, wherein a core column and filaments are arranged in the glass bulb, the upper end face of the glass bulb is a circular-arc-shaped surface, the glass bulb is of an inverted-cone shape, the inner wall of the glass bulb is blackened, only one rectangular or square light-pervious window is formed in the portion, arranged in front of the plane where the filaments are located, of the glass bulb, a fixing base is connected between two guide wires, a plurality of molybdenum wire hook sets are arranged on the fixing base, each molybdenum wire hook set comprises a high molybdenum wire hook and a low molybdenum wire hook, the hook portion of the high molybdenum wire hook and the hook portion of the low molybdenum wire hook of each molybdenum wire hook set are arranged on the same vertical line, the filaments penetrate through the hook portions arranged on the tops of the molybdenum wire hooks in sequence from left to right in a square wave shape mode, the filaments are arranged on the same plane, and the filaments are arranged in the center of the light-pervious window. According to the luminous intensity detection standard lamp, adjustment of the filaments is simplified, and only the situation that the filaments are located in the center of the light-pervious window needs to be ensured; due to the facts that the filaments are of a square-wave shape, and the length of the portion, in the perpendicular direction, of each filament is larger than that of the portion, in the horizontal direction, of the filament, the filaments cannot easily fall off, working stability is good, and the service life is long.

Owner:詹云翔

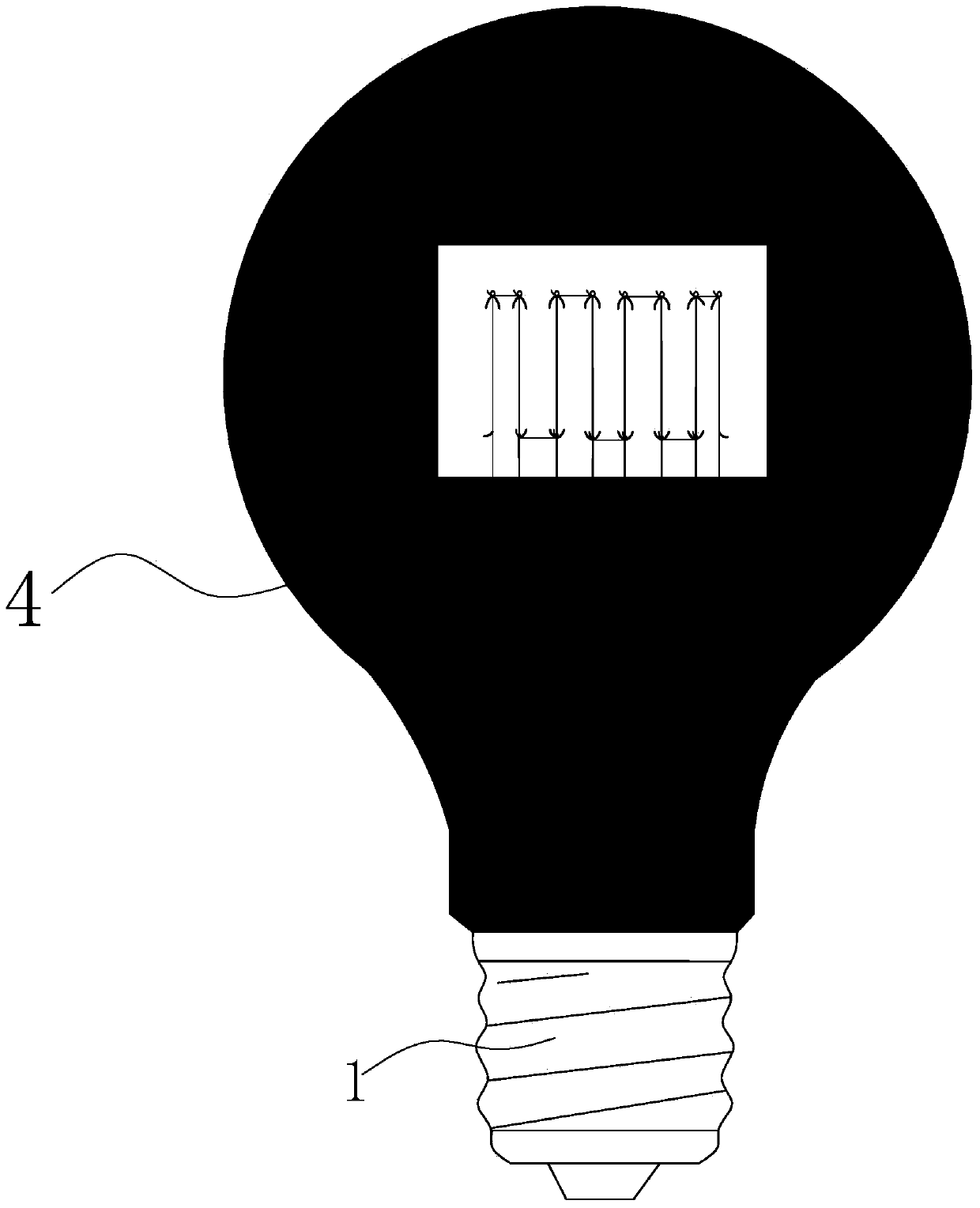

Luminous intensity detection standard lamp

InactiveCN103745911AReduce the effect of reflected lightEasy to adjustIncadescent body mountings/supportLamp incadescent bodiesLuminous intensityEngineering

The invention relates to a luminous intensity detection standard lamp comprising a lamp head and a glass housing. The glass housing is internally provided with a core column and lamp filaments. The glass housing is in a ball shape. The inner wall of the glass housing is painted black; and only the glass housing, right ahead of the plane where the lamp filaments locate, is provided with a rectangular or square light-transmitting window, wherein the length of the light-transmitting window is 18-20 mm, and the width is 18 mm. A fixation base is connected between two guide wires. The fixation base is provided with a plurality of molybdenum wire hook groups. Each molybdenum wire hook group comprises upper and lower two molybdenum wire hooks. The hook portions of the upper and lower two molybdenum wire hooks are in the same vertical line. The lamp filaments sequentially pass through the hook portion on the top of each molybdenum wire hook from left to right in a square-wave shape, and the lamp filaments are in the same plane. The lamp filaments are located right in the center of the light-transmitting window. The influence of reflection light from every direction on the glass housing is reduced; and the adjustment of the lamp filament is simpler, with just guaranteeing the filaments to be in the center of the light-transmitting window, thereby reducing the processing difficulty that the filaments must be in the center of the glass housing in the past.

Owner:詹云翔

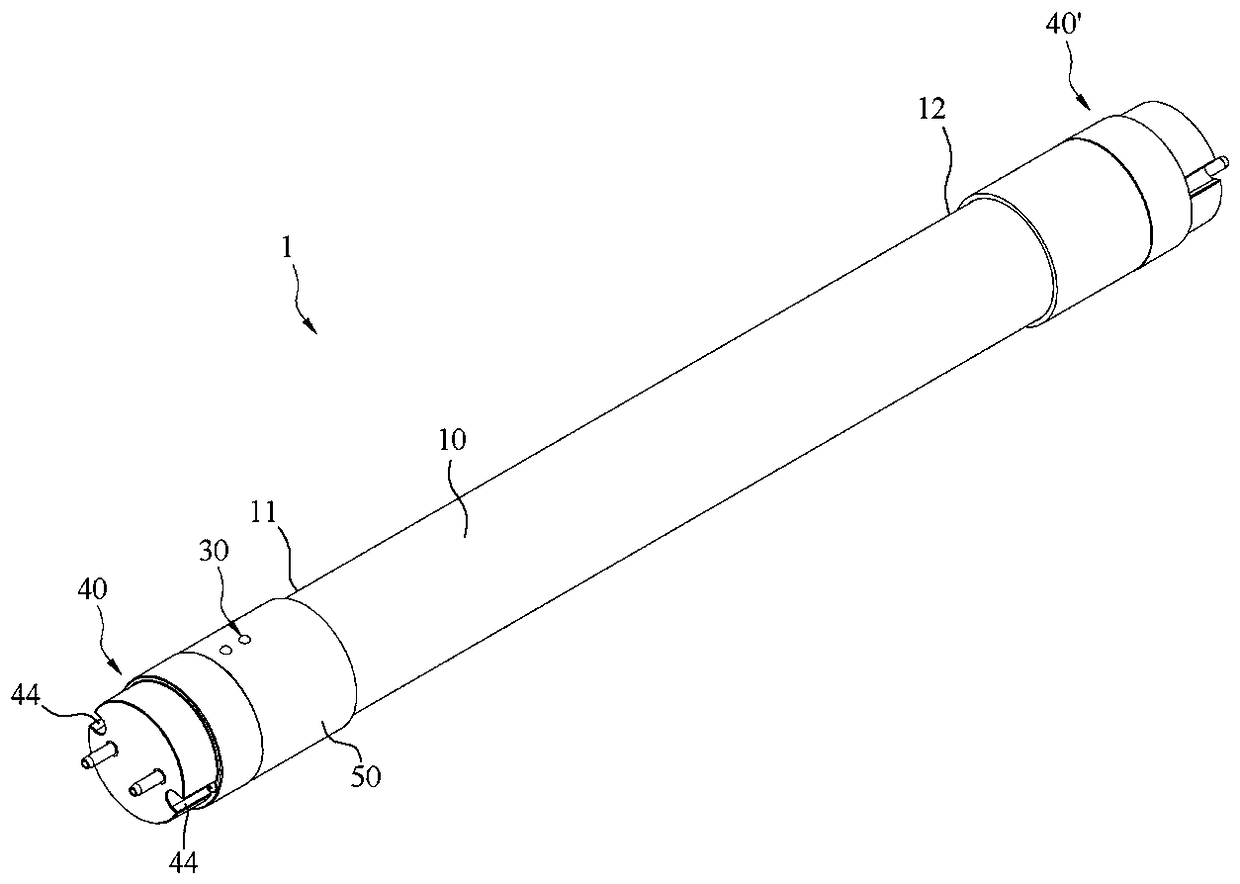

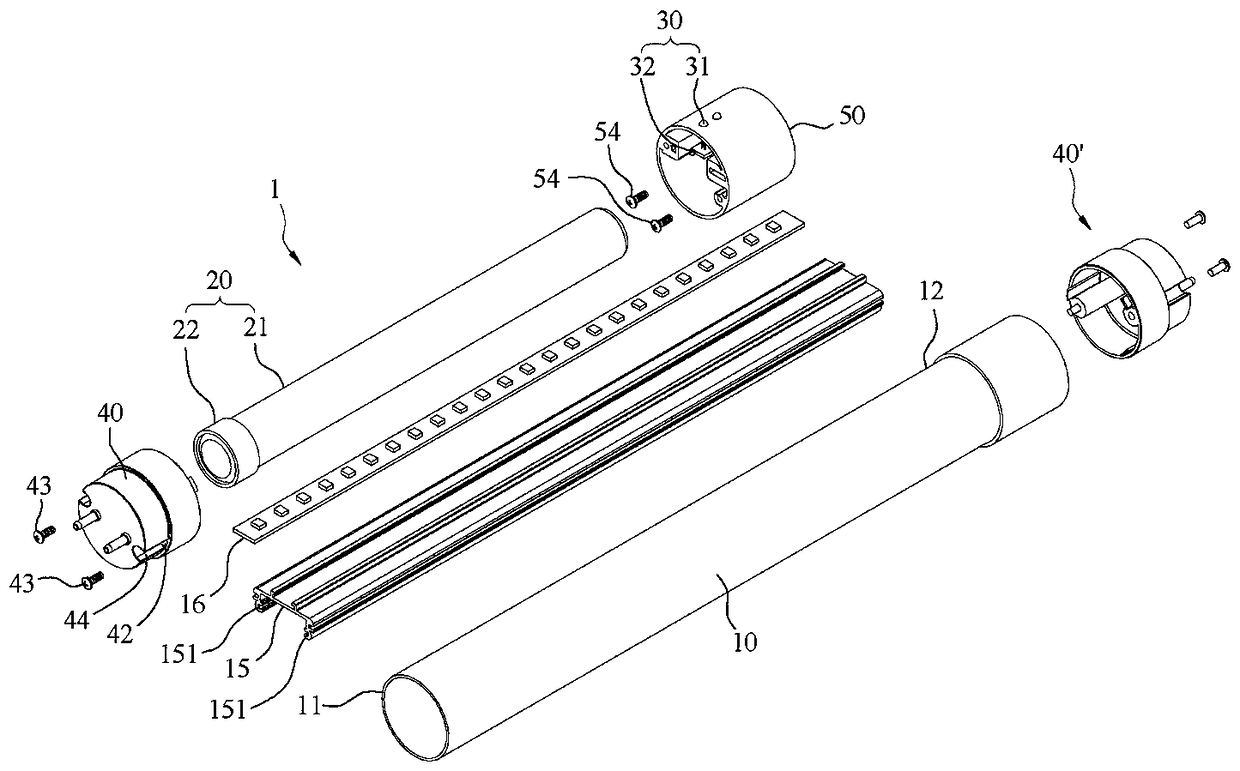

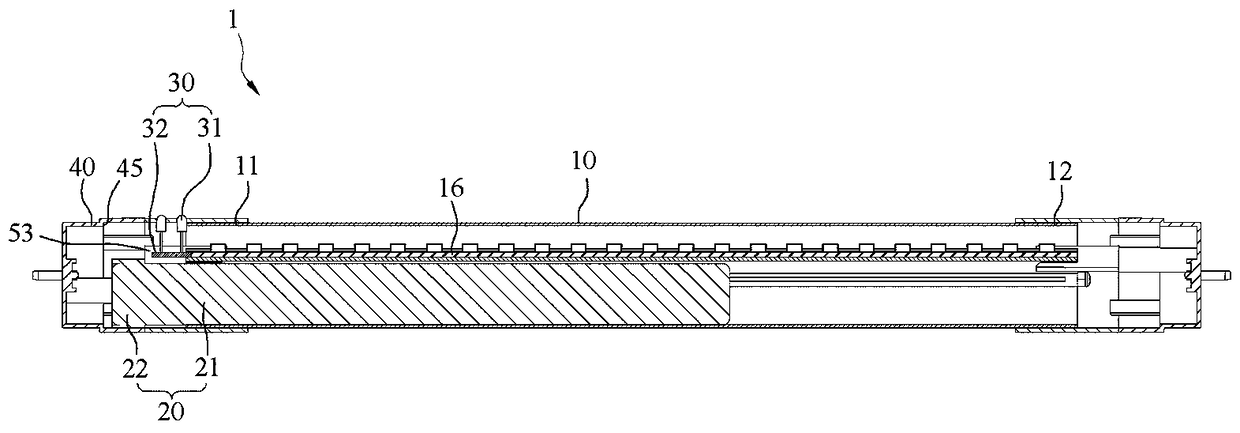

Glass emergency lamp

InactiveCN108488725AHigh strengthImprove convenienceElectric circuit arrangementsGlobesTransmittanceEngineering

The invention provides a glass emergency lamp. The glass emergency lamp comprises a glass modulator tube, a battery, an emergency lamp set and a detachable lamp holder. The glass modulator tube is provided with a first end and a second end which are opposite. The battery is arranged in the glass modulator tube and is adjacent to the first end. The emergency lamp set is electrically connected to the battery. The detachable lamp holder is assembled to the first end of the glass modulator tube so as to cover the battery, the detachable lamp holder is selectively dismounted from the first end, andaccordingly, the battery can move relative to the glass modulator tube so as to disengage from the glass modulator tube. Accordingly, the glass modulator tube is used in the glass emergency lamp, light transmittance is high, a good light emitting effect is achieved, and the modulator tube is high in strength, low in flexibility and not prone to drooping. In addition, the battery is arranged in the glass modulator tube, the detachable lamp holder is selectively dismounted from the glass modulator tube, the integral size of the glass emergency lamp can be reduced, the battery can be easily replaced, and accordingly, using and installing convenience is improved.

Owner:XIAMEN PVTECH

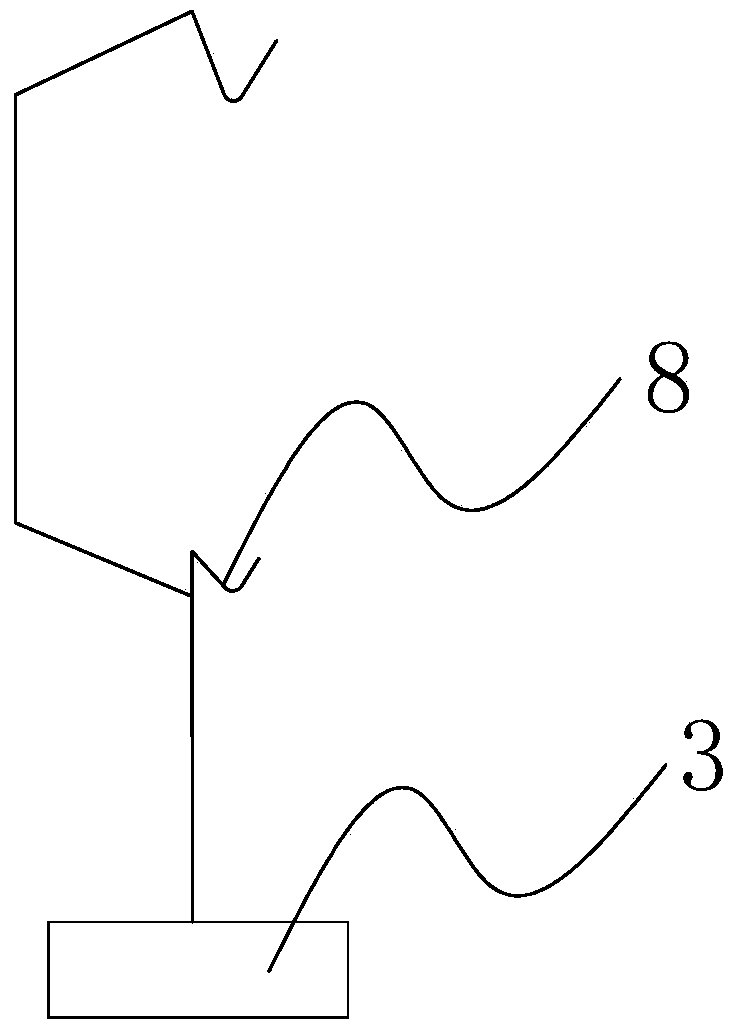

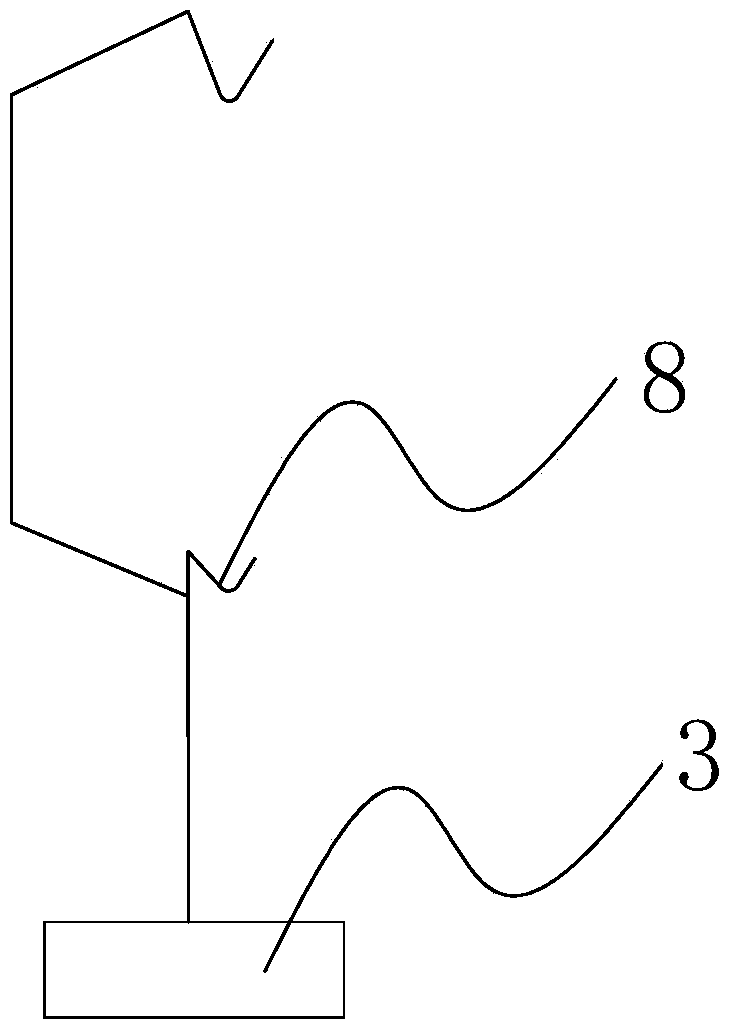

A light intensity standard lamp

ActiveCN104217923BReduce occlusionImprove luminescence stabilityIncadescent body mountings/supportLamp incadescent bodiesLeading edgeSquare waveform

The invention relates to a light intensity standard lamp, which comprises a lamp cap and a lamp housing. A glass core column and a filament are arranged inside the lamp housing. The glass core column also leads to two hollow brackets, and the guide wire is installed inside the hollow bracket; the hollow bracket is in a vertical state as a whole, and the top of the hollow bracket is first bent to form a horizontal section, and the front edge of the horizontal section Fold to form a vertical section, the filament and the guide wire are connected at the vertical section at the top of the hollow bracket, the overall height of the filament is greater than the length of the vertical section; the filament is square-wave from left to right, and the filaments are all on the same plane. The distance from the plane to the front and rear lamp housings is equal, and the distance from the left end of the filament to the left lamp housing is equal to the distance from the right end of the filament to the right lamp housing. The invention arranges the filament and the support in different planes, solves the defect that the light is blocked by the support, and increases the detection accuracy.

Owner:ZHEJIANG ZHANZI PHOTOELECTRICITY

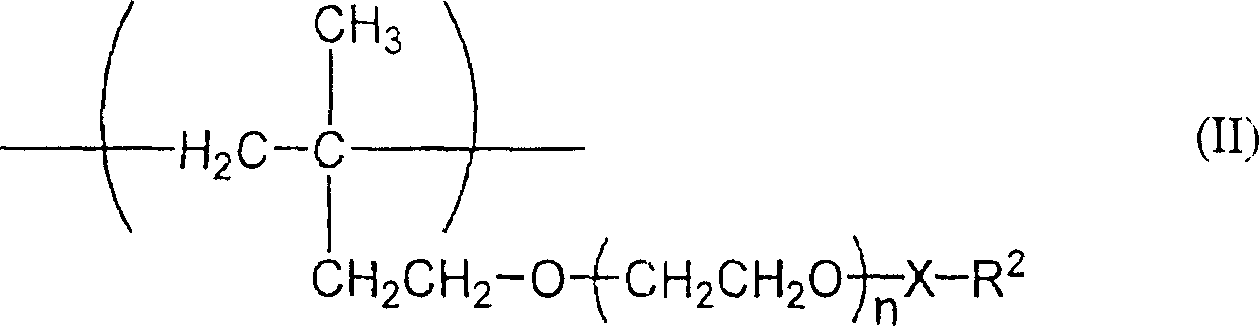

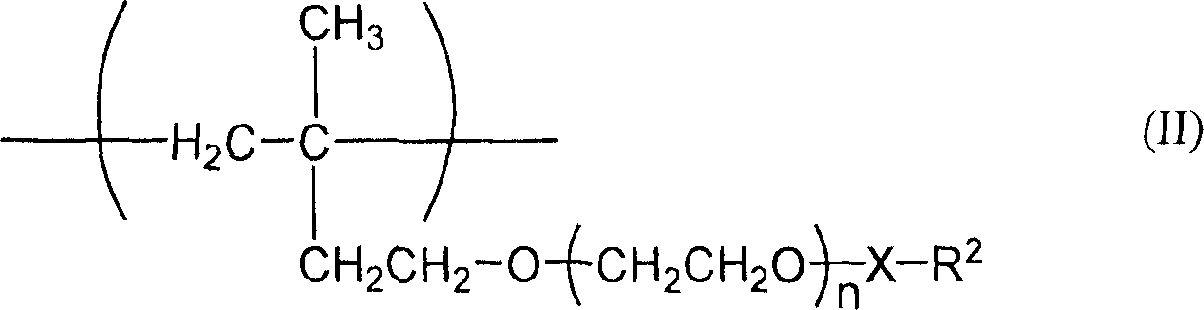

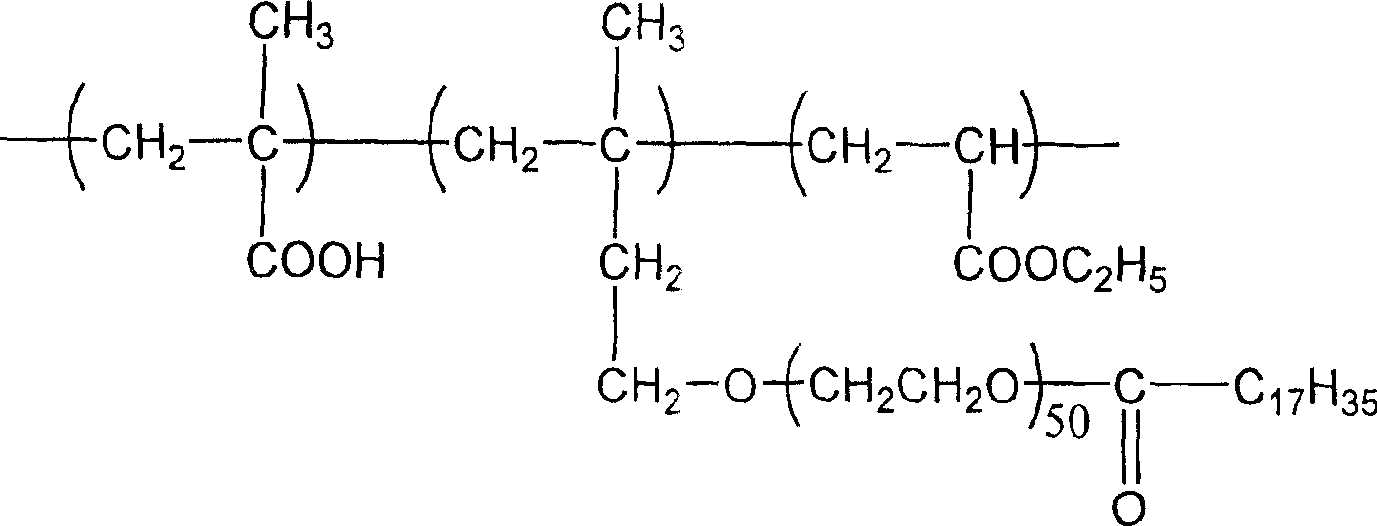

Thickening agent used for aqueous vibration absorbing material

Owner:NIPPON SHOKUBAI CO LTD

Switch cabinet door plank lifting mechanism

InactiveCN102611009AConsistent clearanceQuality assuranceSubstation/switching arrangement casingsEngineeringSwitchgear

The invention relates to a switch cabinet door plank lifting mechanism, comprising a cabinet body frame and a door plank. A first door lifting fixed part is fixed on one side of a cabinet body frame lock and is plate-shaped; a second door lifting fixed part is arranged on one side of a door plank lock; and the middle part of the second door lifting fixed part is linear, and each of two ends of the second door lifting fixed part has a buckle structure corresponding to the plate shape of the first door lifting fixed part. The switch cabinet door plank lifting mechanism has the beneficial effects that after the door plank is closed, the gap of the door plank is automatically adjusted to ensure that the gap of each door plank is the same, so that the door plank of a switch cabinet is not easy to droop, and the quality of the switch cabinet is ensured.

Owner:SHANGHAI PEOPLE ELECTRICAL APPLIANCE GROUP

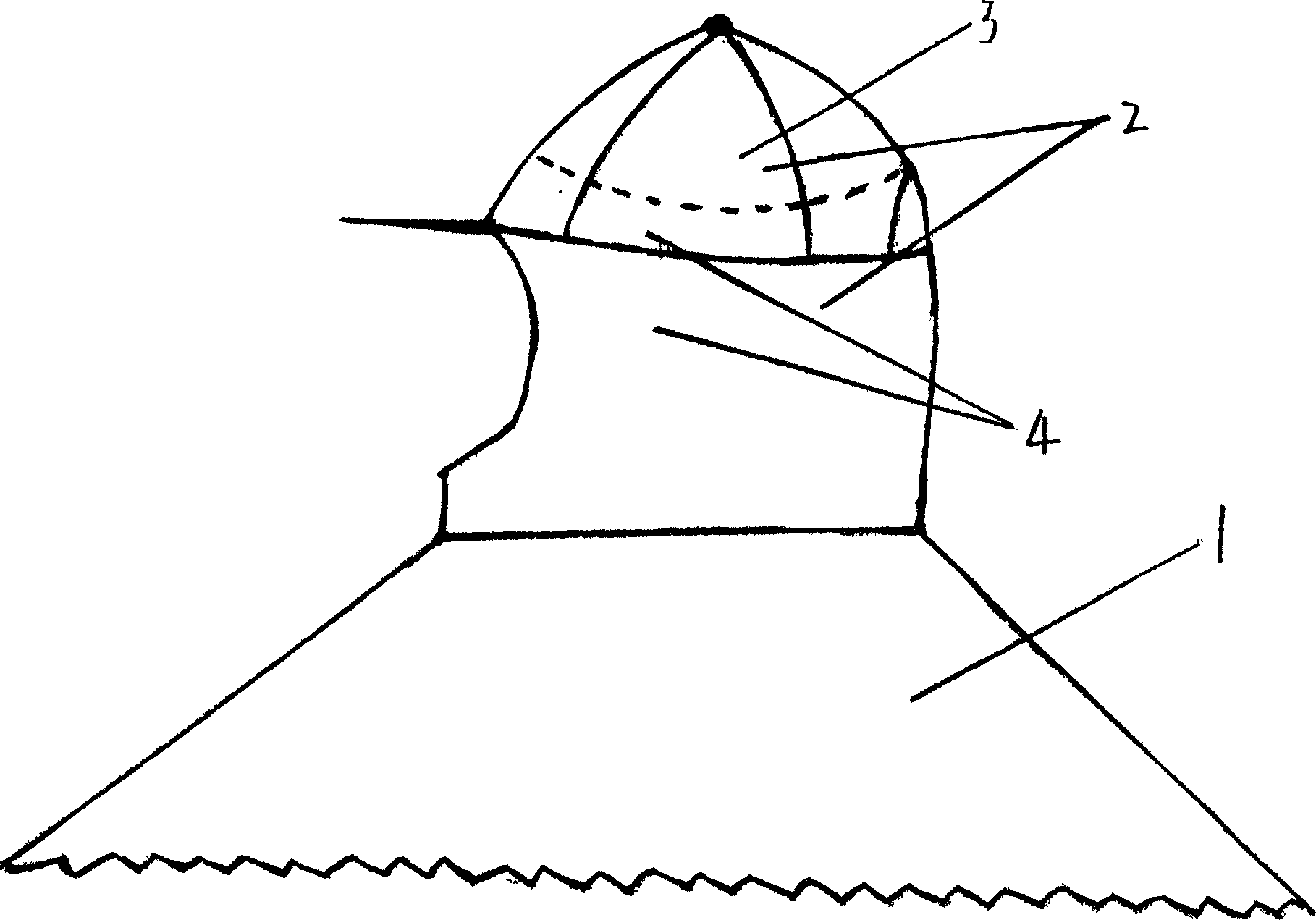

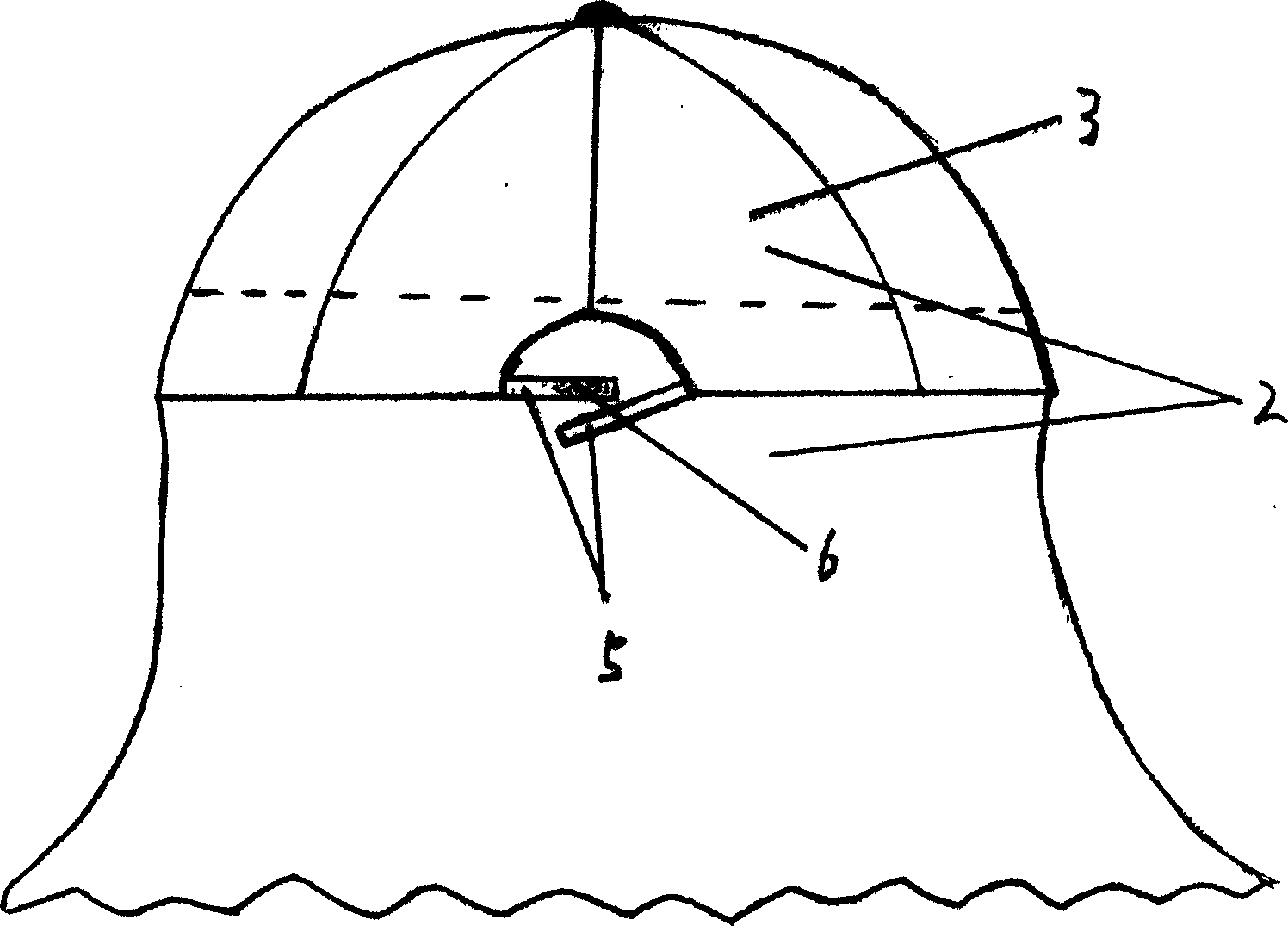

Rain hat of rain cape

The invention relates to a poncho rainhat, which realizes the rainhat with a style of an upper half and a lower half combination. the upper half being made sunbonnet-shaped, and the lower half being made of waterproof cloth. Owning to the sunbonnet shape of the upper half, the rainhat can be safely worn on head, realizes non-slouch in spite of the rainhat brim length, has no influence on visual line, and does well in protecting people from the head-on rain.

Owner:刘郑华

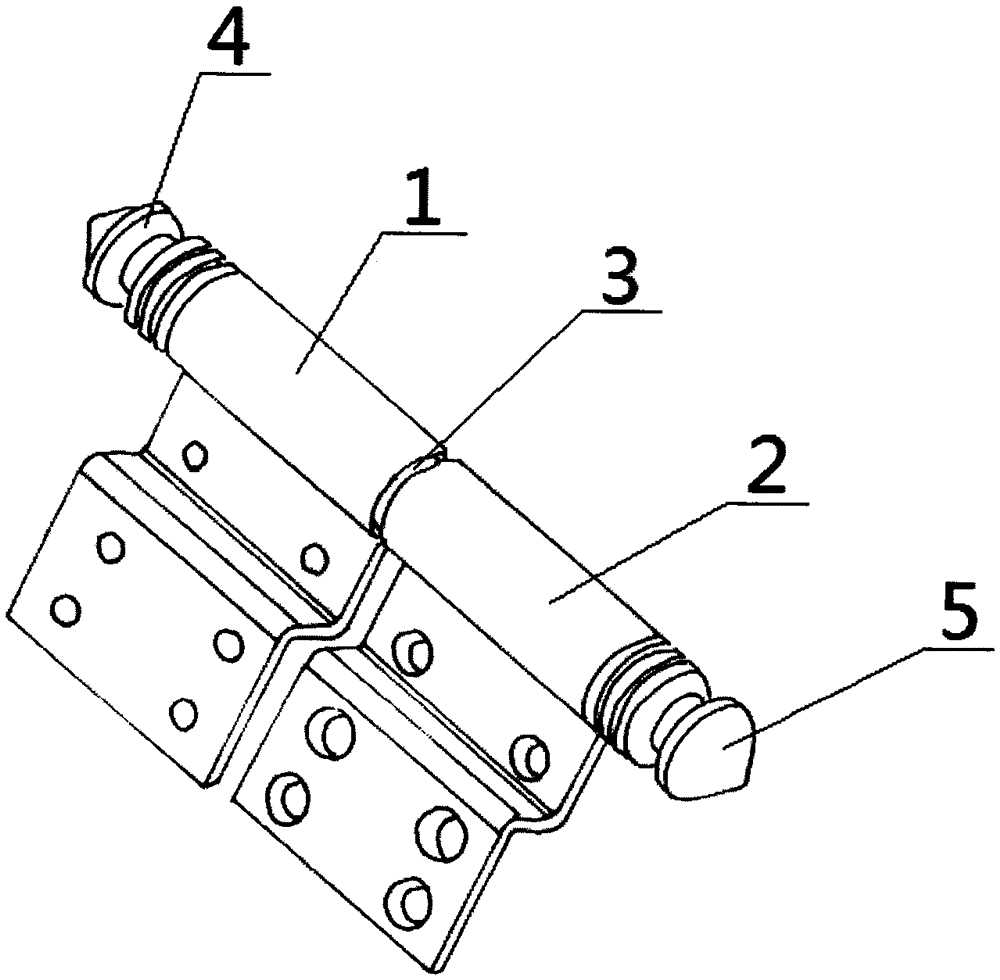

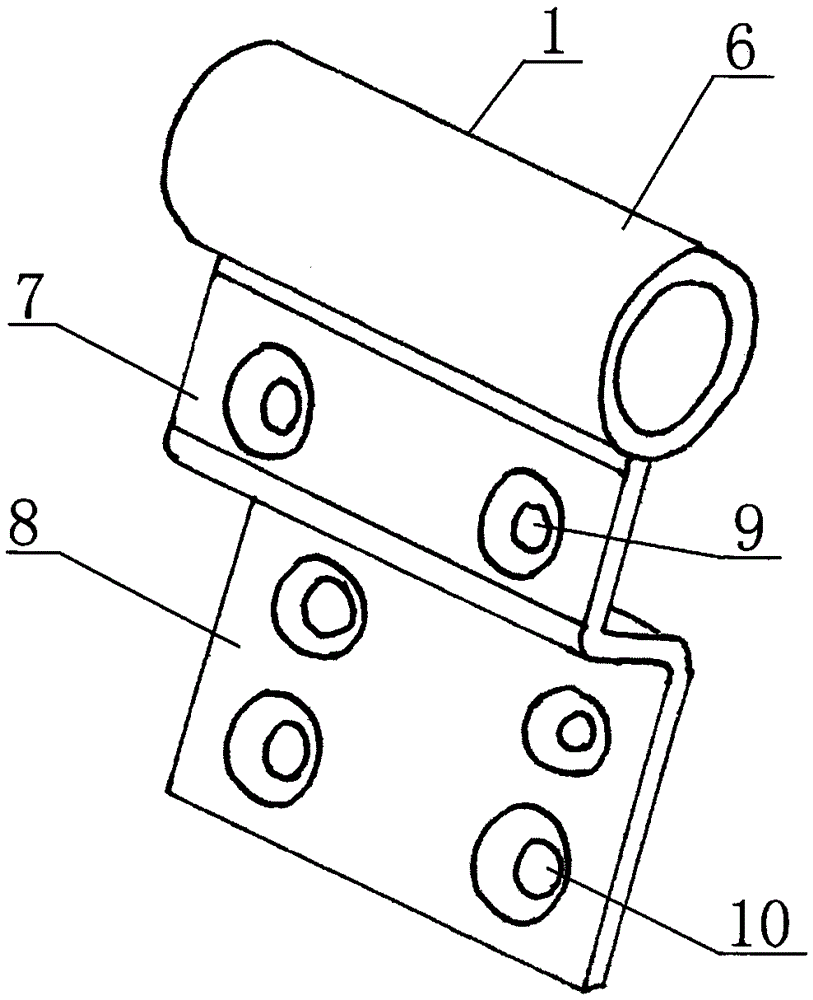

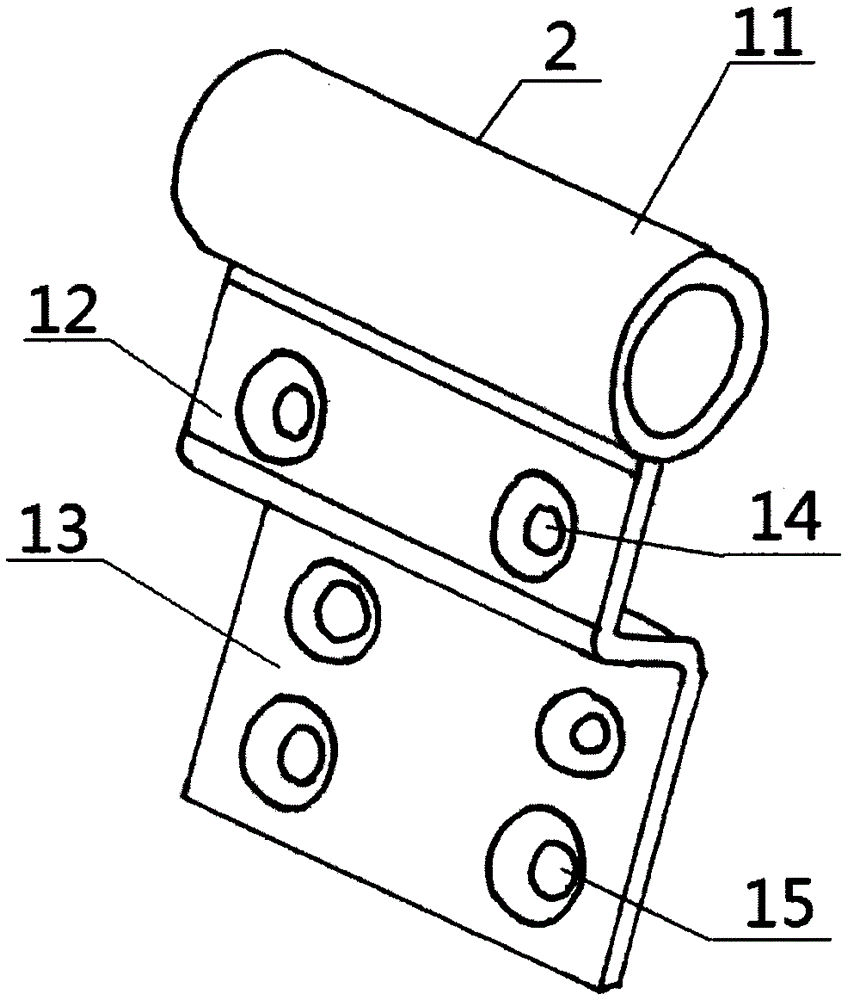

Double-working hinge

InactiveCN105298268AThe structure is novel and uniqueNot easy to pry openPin hingesEngineeringMechanical engineering

Owner:GUANGXI SHUANGYING DOORS CO LTD

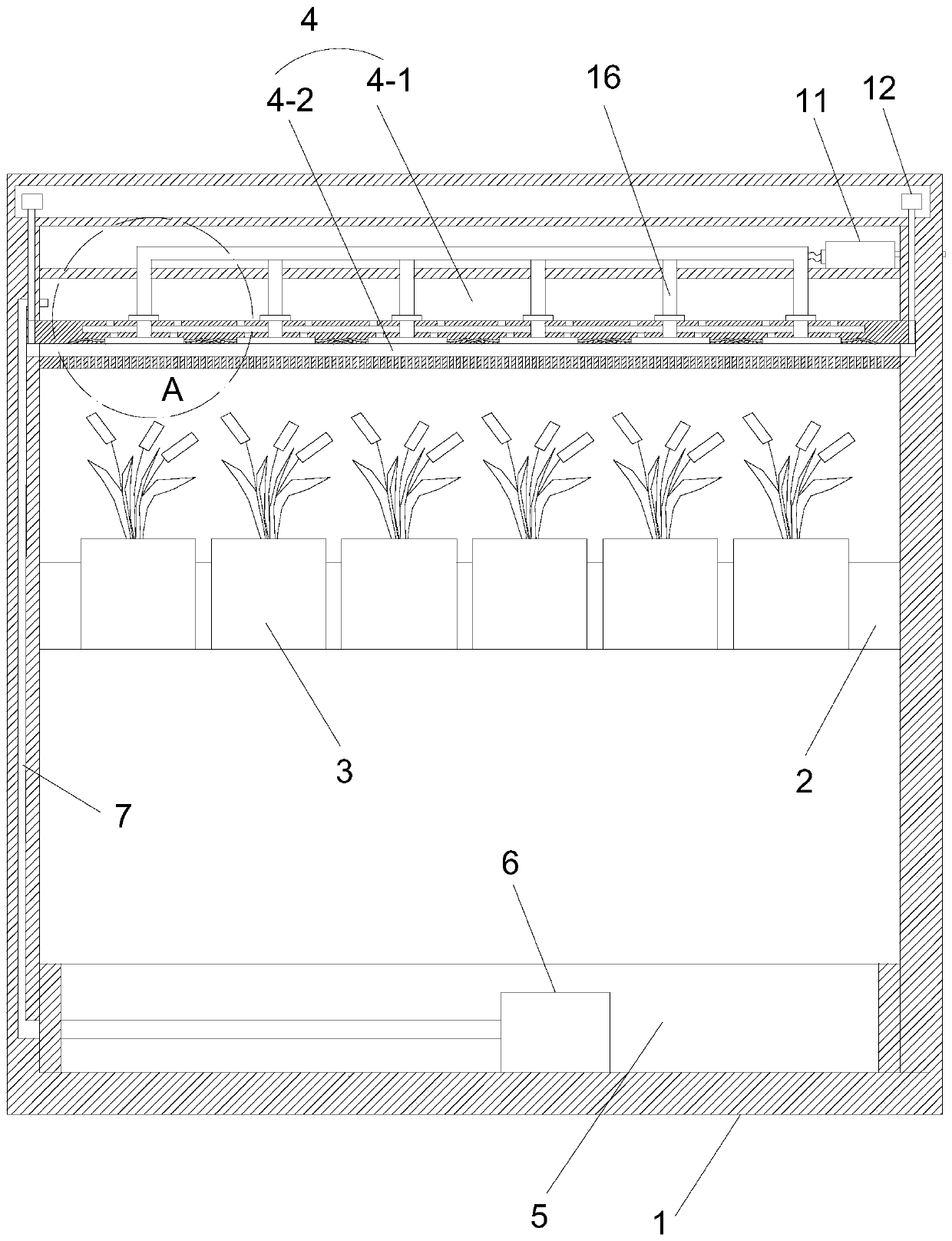

Fresh cut flower storage and preservation equipment

ActiveCN111099179ANon-perishableExtended storage timeLiving organism packagingPackaging under vacuum/special atmosphereCut flowersAgricultural engineering

The invention relates to fresh cut flower storage and preservation equipment. The fresh cut flower storage and preservation equipment comprises an equipment body, wherein a supporting frame is mountedin the equipment body, a container with an opening in the upper end is mounted on the supporting frame, a first water tank is arranged above the container, a plurality of holes are formed in the bottom surface of the first water tank, a partition plate is horizontally arranged in the first water tank, the partition plate is in sliding connection and sealing connection with the side wall of the first water tank, the first water tank is divided into an upper water tank and a lower water tank, a lifting device for driving the partition plate to move up and down is mounted in the equipment body,a second channel for communicating the upper water tank with the lower water tank is formed in the partition plate, a first elastic shielding sheet is arranged at an outlet of the second channel, andthe first elastic shielding sheet covers the outlet of the second channel; and a ventilating pipe is fixed on the partition plate, one end of the ventilating pipe extends out of the first water tank and is connected with an air pump, the other end of the ventilating pipe is fixedly connected with the first elastic shielding sheet and is exposed out of the first elastic shielding sheet, and a one-way exhaust structure is further arranged at the other end of the ventilating pipe. The fresh cut flower storage and preservation equipment prolongs the storage time of fresh cut flowers.

Owner:XINYANG AGRI & FORESTRY UNIV

A paper bag opening mechanism

ActiveCN109514926BNot easy to sagAvoid mistakesBag making operationsPaper-makingDrive shaftGear wheel

The invention relates to the technical field of paper bag bottom pasting machines, in particular to a paper bag expanding mechanism. The paper bag expanding mechanism comprises a frame, and a box mounted on the frame; a main gear is mounted in the box; and a bag expanding module is embedded in the main gear. The paper bag expanding mechanism further comprises a delay mechanism, and an external driving shaft; a gear set is arranged between the delay mechanism and the main gear; the delay mechanism comprises a swing arm; a positioning shaft is embedded in the end part of the swing arm; a first delay gear and a slide rod are fixed at two ends of the positioning shaft; a rotating shaft is inserted in the slide rod; the rotating shaft is rotationally connected with the slide rod; a second delaygear relatively rotated sleeves the driving shaft; and the second delay gear is in engaged connection to the first delay gear, and drives the gear set to synchronously rotate. The paper bag expandingmechanism is provided with the delay mechanism for maintaining the opening expanding gesture of paper bags, so that the openings of the paper bags are not easy to drop down when the paper bags are fed in a subsequent indentation roller set, and the possibility of generation of wrong indentation positions is effectively prevented.

Owner:FOSHAN TECON PACKAGE MACHINERY

Productive technology of automobile rear shelf

ActiveCN101954774BSolve the carrying capacitySolve heat resistanceLamination ancillary operationsSynthetic resin layered productsGlass fiberFiber bundle

The invention relates to a productive technology of an automobile rear shelf, which comprises the following steps: (1) laying a glass fiber mat on a lower die and fixing the glass fiber mat and a reinforcing rib on an upper die; (2) evenly spraying polyurethane on the glass fiber mat on the lower die; (3) compressing the glass fiber and the reinforcing rib in a die to form semi-finished products;(4) taking the semi-finished products subject to compression moulding out of the die, and placing the semi-finished products on a cooling jig for carrying out cooling and moulding at normal temperature; (5) polishing the semi-finished products subject to cooling and moulding to smooth the surfaces of the semi-finished products; (6) evenly spraying glue on the two sides of the polished semi-finished products; (7) binding linings on the two sides of the semi-finished products on which glue is sprayed; (8) punching fiber bundles of the glass fiber mat exposed at the edge of the semi-finished products subject to lining binding; (9) installing pull ropes on the punched semi-finished products to obtain the finished products; and (10) inspecting and carrying out vanning. The productive technology of the invention can save manufacturing cost and has the advantages of environmental protection and no pollution.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Wet-method roof producing process of spreaded glass fibers with adhesive

ActiveCN102381256BReduce weightMeet the requirements of lightweight designSuperstructure subunitsGlass fiberPolyurethane adhesive

The invention relates to wet-method roof producing process by glass fibers spread with adhesive, which comprises steps: firstly, spreading polyurethane adhesive on one surface of a glass fiber felt by an adhesive spreader so as to produce a glass fiber felt with adhesive, secondly, sequentially laying non-woven cloth, the glass fiber felt with adhesive, hard polyurethane, another glass fiber felt with adhesion and another non-woven felt from top to bottom, realizing pressing forming and producing a semi-finished product, thirdly, cooling and shaping the semi-finished product produced after pressing forming at normal temperature to produce a formed semi-finished product, fourthly, sequentially laying a fabric, an adhesive film and the formed semi-finished product from top to bottom prior to laminating the fabric, fifthly, cooling and shaping the formed semi-finished product, which is produced by means of laminating the fabric, at constant temperature, and sixthly, cutting the formed semi-finished product which is shaped by means of cooling by a water jet. Accordingly, a roof is produced. By the aid of the wet-method roof producing process, the weight of the roof is greatly lightened, and adhesive spreading quantity can be precisely controlled by means of spreading the adhesive on the single surfaces of the glass fibers.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com