Standard lamp for detection

A lamp and standard technology, applied in the direction of the shell/shell of the luminous body, luminous body, etc., can solve the problems of increasing production costs, difficulty in obtaining stable light intensity values, complex structures, etc., to improve the pass rate and reduce the impact of stray light , Strong work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

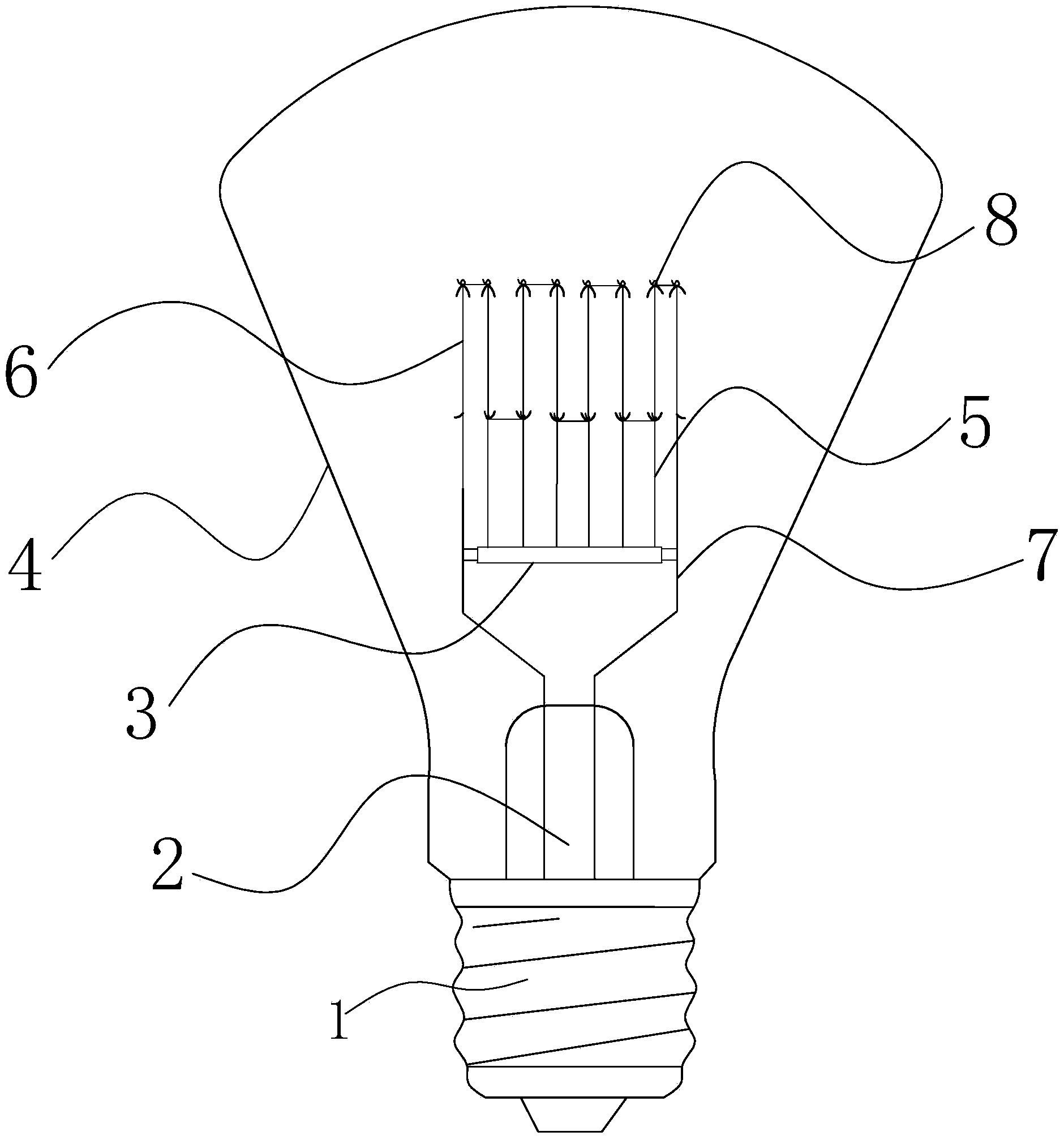

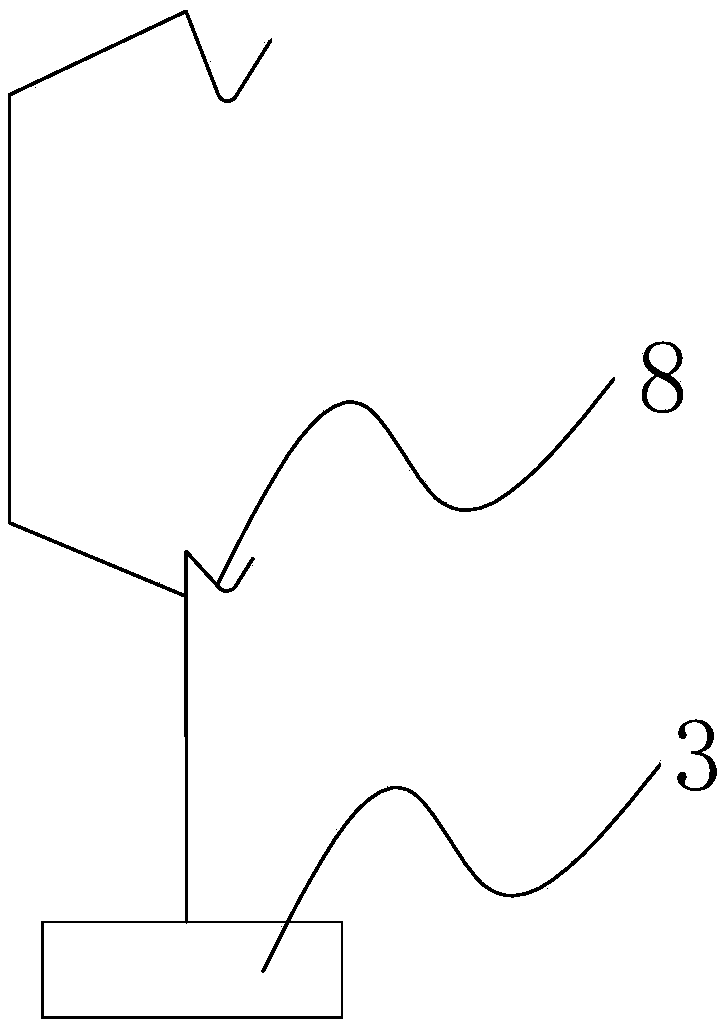

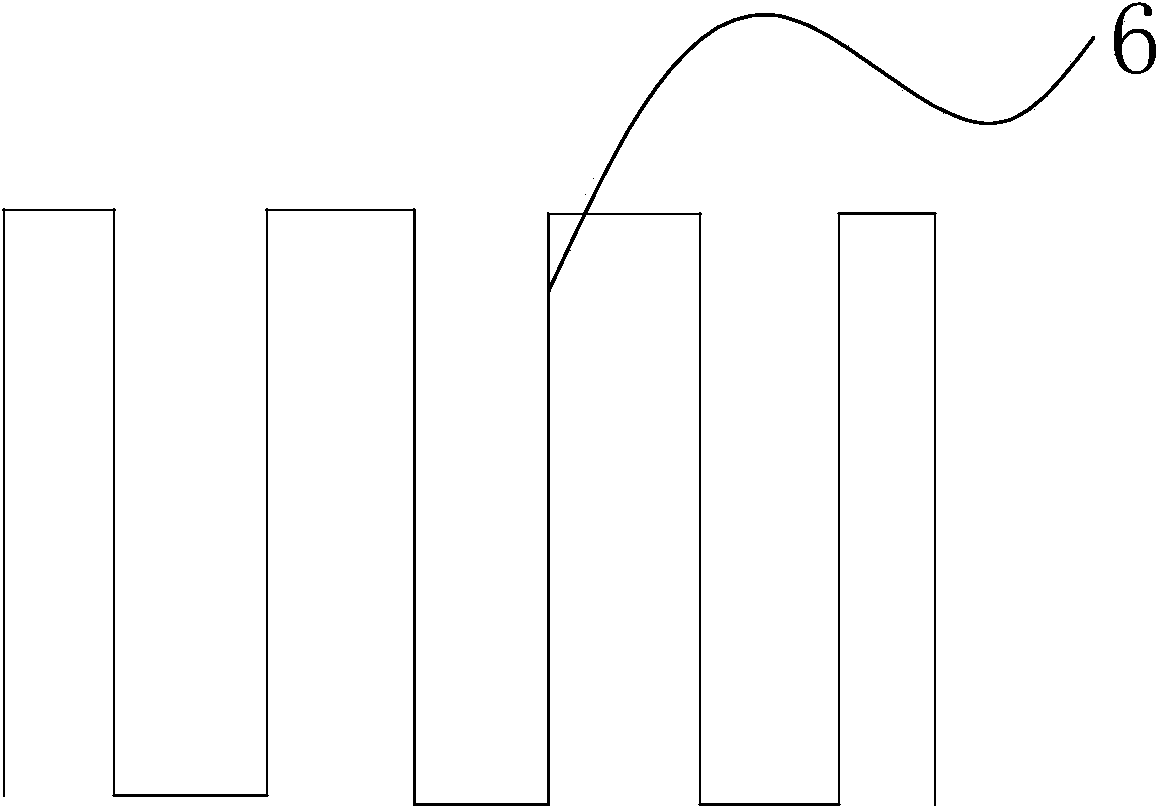

[0012] like figure 1 , figure 2 and image 3 The shown standard lamp for detection includes a lamp cap 1 and a glass bulb 4. The glass bulb 4 is provided with a stem 2 and a filament 6. Two guide wires 7 are drawn from the stem 2. The ends are respectively connected with two guide wires 7. When the lamp cap 1 is on the bottom and the glass bulb 4 is on the top, the lamp is in the shape of a rounded cone or a rounded truncated cone as a whole, and the upper end face of the glass bulb 4 is an arc surface; the two A fixed seat 3 is connected between the guide wires 7, and several molybdenum wire hook groups are arranged on the fixed seat 3. Each molybdenum wire hook group includes two high and low molybdenum wire hooks 5. The hooks of the two high and low molybdenum wire hooks 5 The parts 8 are in the same vertical line, and the fila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com