Pressing type air lance

An air nozzle and air technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of unsightly texture, uneven spraying, pollution of the environment, etc., and achieve the effect of not easy to sag, improve spraying quality, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

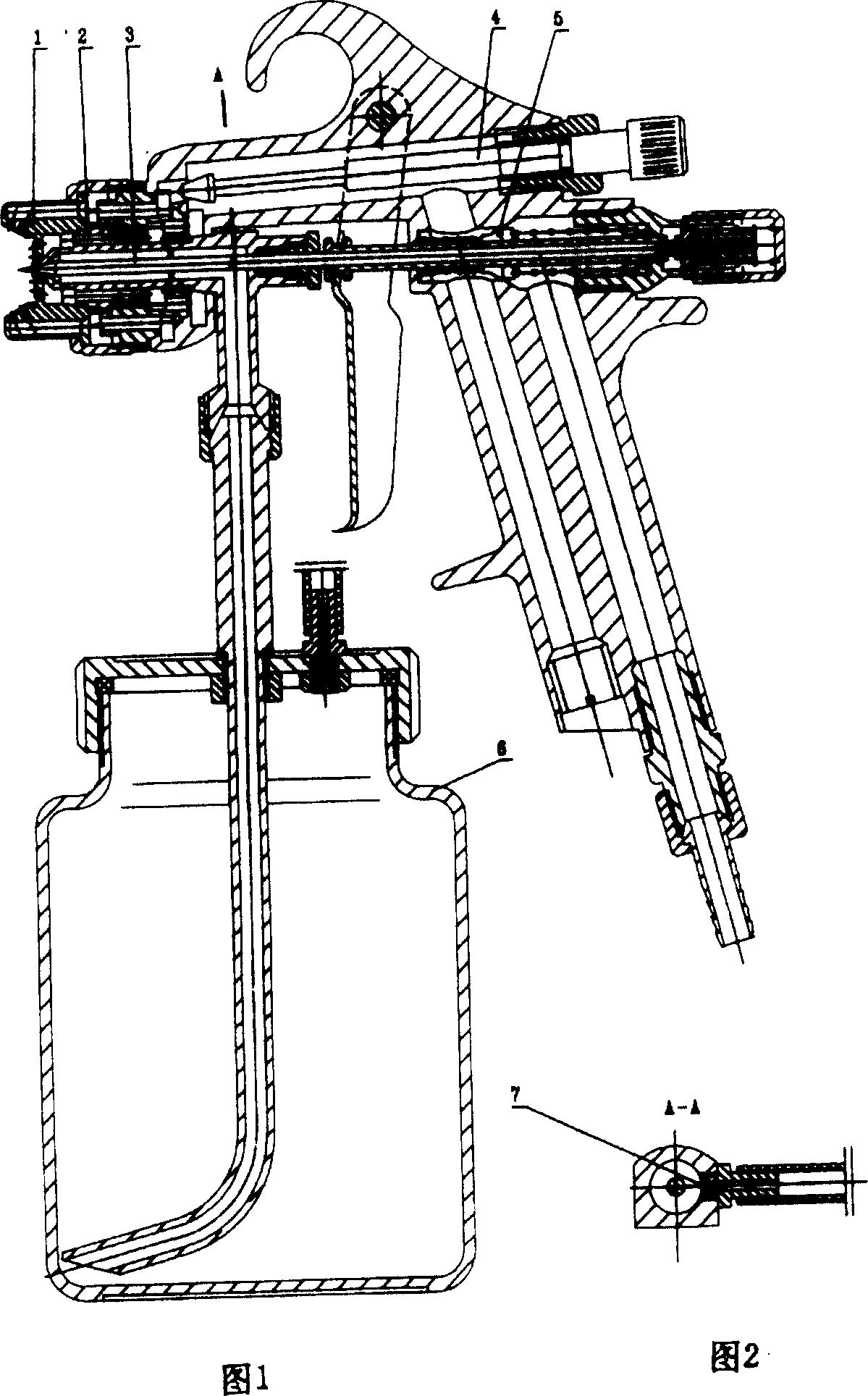

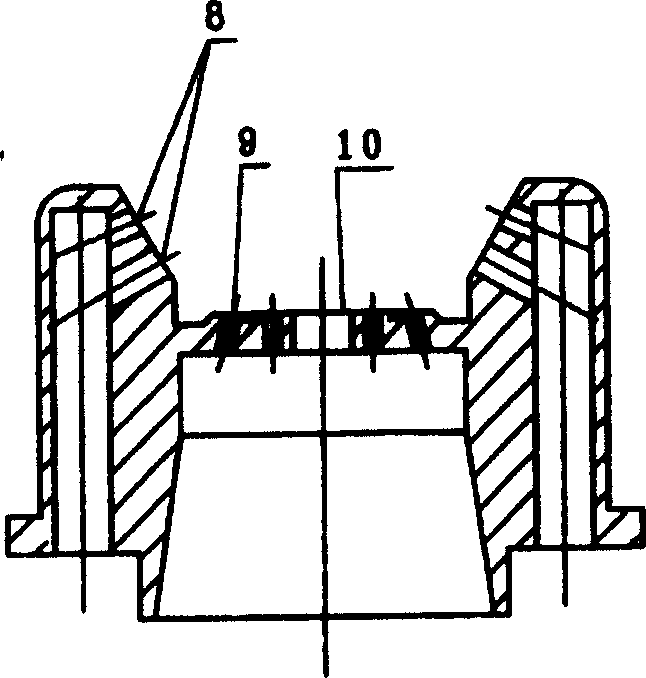

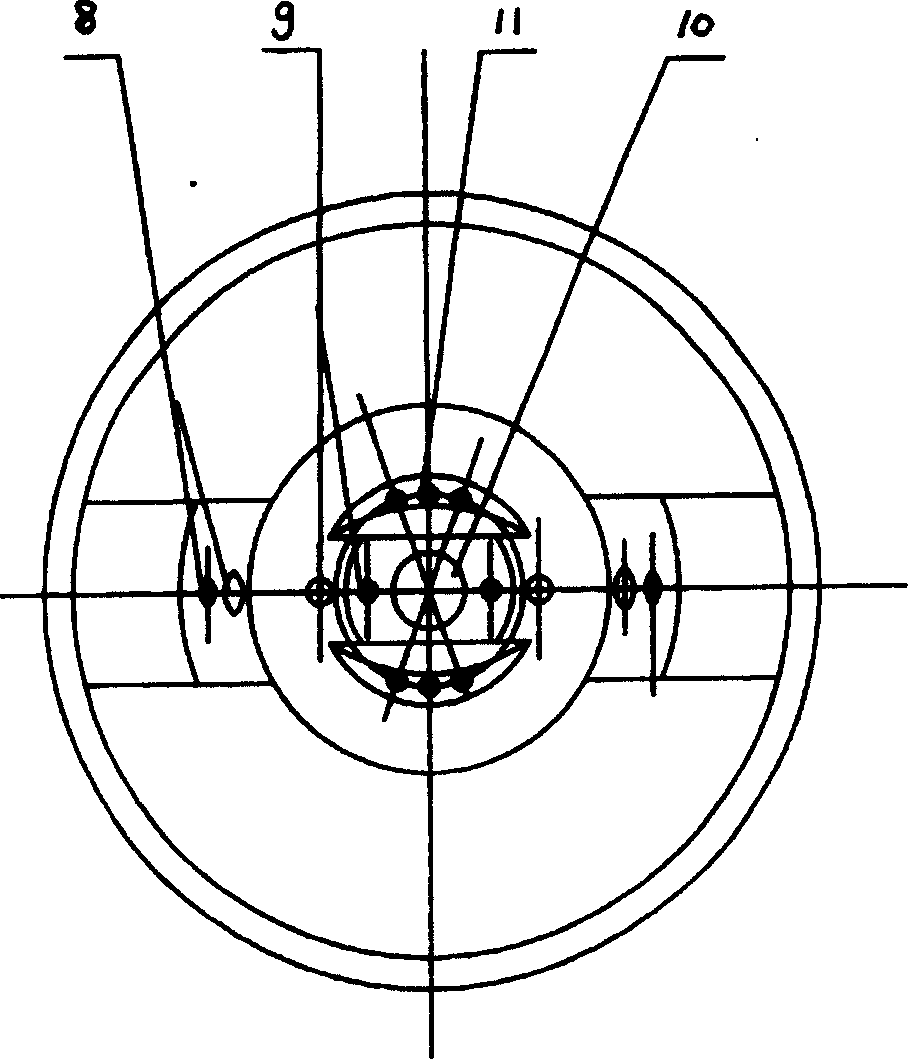

[0010] With reference to the accompanying drawings, the air valve 5 and the paint valve 3 are arranged on the same axis. An air passage 7 is provided in the air passage to communicate with the pressure tank 6. The connection between the pressure cover and the pressure tank is a threaded connection. The road applies power to the pressure tank to press the paint, and a part of the air is injected from the air nozzle 1, which can ensure the paint to be atomized three times. There is a ring hole 10 in the middle of the nozzle mouth to atomize the paint for the first time, the second atomization hole is the reverse flattening hole 11 and the protection hole 9, the third atomization hole is a side hole, and the paint mist fan-shaped regulator 4 runs through the air passage, and is made of a sliding core, O-shaped sealing ring and fixed seat, and the sliding core enters and exits to adjust the size of the air flow in the side hole 8, and the 2nd is a paint nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com