Machining process for improving coaxiality of crankshaft journals

A processing technology, the technology of the crankshaft journal, which is applied in the field of processing technology to improve the coaxiality of the crankshaft journal, can solve the problems of falling, the inability to guarantee the coaxiality of the crankshaft journal, and the large machining error of the crankshaft journal, etc., so that it is not easy to wear , The connection method is simple and stable, and the effect of improving the coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

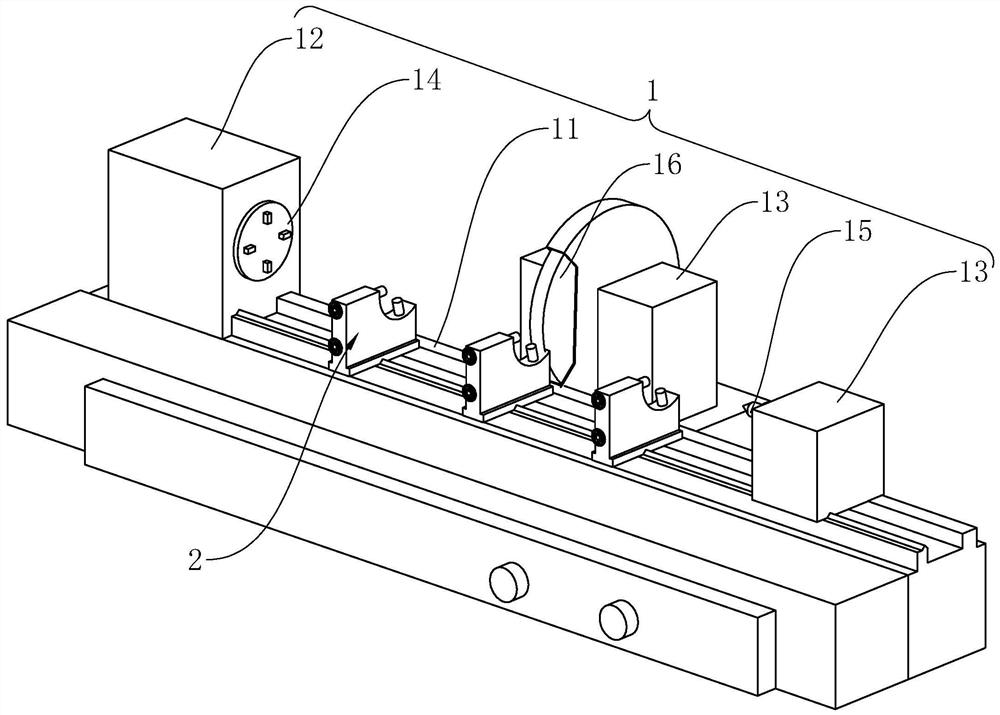

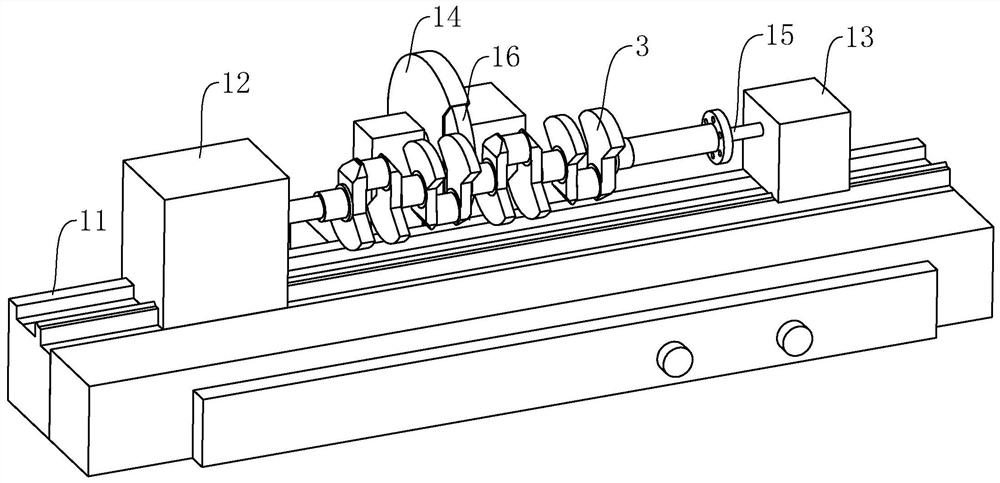

[0051] S1. Install the crankshaft

[0052] refer to image 3 , lift the crankshaft 3 and place it on the grinding machine 1, and make the two ends of the crankshaft 3 cooperate with the chuck 15 and the top 16 of the grinding machine 1 respectively, support the crankshaft 3 on the bed 11 of the grinding machine 1, and initially determine the crankshaft 3 The height of the axis relative to the bed 11 of the grinding machine 1 .

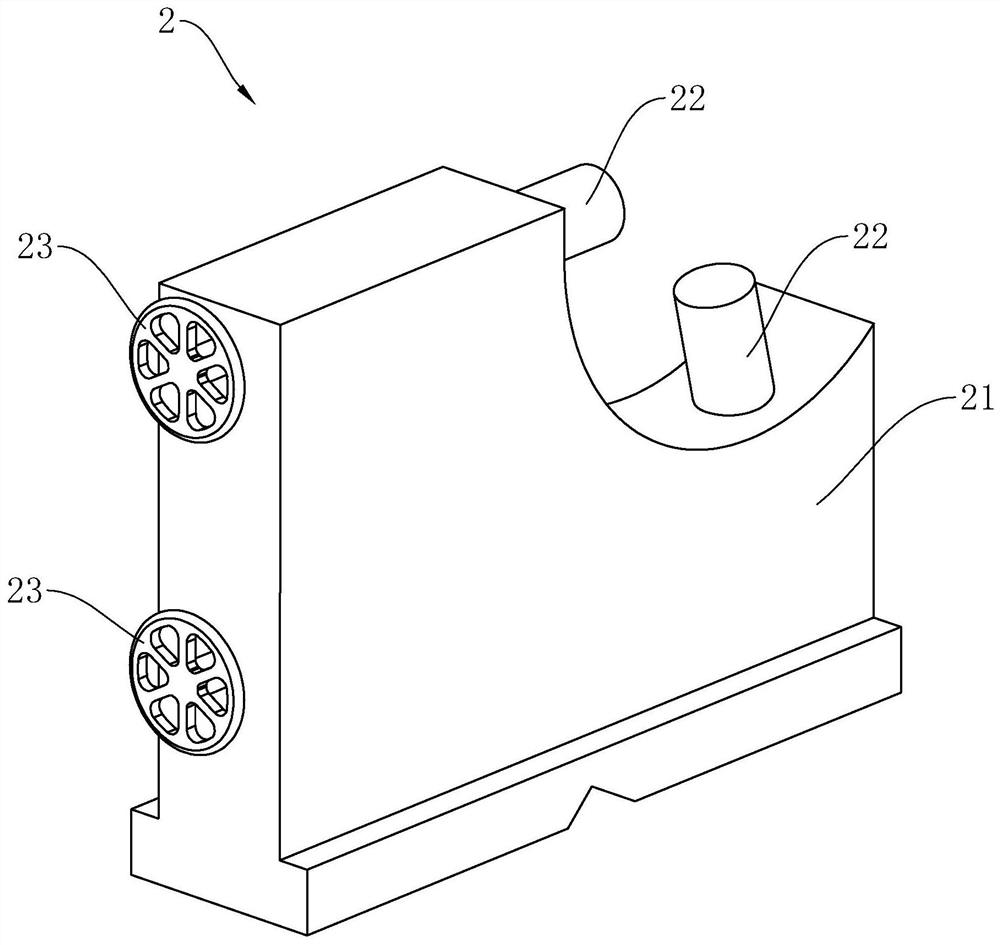

[0053] S2. Install center frame 2

[0054] refer to Figure 4 with Figure 5 , install a plurality of center frames 2 on the bed 11, so that the center frames 2 are evenly arranged along the circumference of the crankshaft 3, and the number of center frames 2 is selected according to the number of journals of the crankshaft 3 to be ground, such as grinding a six-cylinder crankshaft Three center frames 2 are adopted at 3 o'clock, and four center frames 2 are selected for use when grinding the eight-cylinder crankshaft 3. Then turn the two handwheel...

Embodiment 2

[0076] The difference between this embodiment and Embodiment 1 is that step S4 is performed first, and then step S3 is performed.

[0077] If step S3 is performed first and then step S4 is performed, when the universal joint 5 is installed in step S4, it will inevitably contact the crankshaft 3, which will easily cause the position of the crankshaft 3 to move during the installation process, resulting in the axial position of the journal of the crankshaft 3. Changes affect the subsequent grinding process.

[0078] First connect the universal joint 5 between the chuck 15 and the crankshaft 3, and then measure and adjust the position of the crankshaft 3 journal, so as to avoid the impact on the journal position of the crankshaft 3 when installing the universal joint. Make sure that all journal axes of the crankshaft 3 are coincident when grinding.

Embodiment 3

[0080] The difference between Embodiment 3 and Embodiment 1 and Embodiment 2 is that when installing the crankshaft 3 on the grinding machine 1, first install the center frame 2 on the bed 11 of the grinding machine 1, and then directly lift the crankshaft 3 and place it to a plurality of center frames 2, and finally the axial position of the journal of the crankshaft 3 is adjusted and positioned by adjusting the telescopic feet 22 of the center frame 2.

[0081] Although the position of the axis of the journal of the crankshaft 3 can be positioned in the above manner, after the crankshaft 3 is placed on the center frame 2, the relative position of the axis of the journal of the crankshaft 3 and the axis of the chuck 15 of the grinding machine 1 cannot be guaranteed, which is easy The large deviation between the journal axis of the crankshaft 3 and the axis of the chuck 15 of the grinding machine 1 will cause the deformation of the universal joint 5 to be too large, resulting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com