Luminous intensity detection standard lamp

A luminous intensity detection and standard technology, applied in the direction of luminous body, luminous body shell/tube shell, etc., can solve the problems of difficult to obtain stable luminous intensity value, complex structure, increase production cost, etc., to achieve not easy to sag and work stability. Strong, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

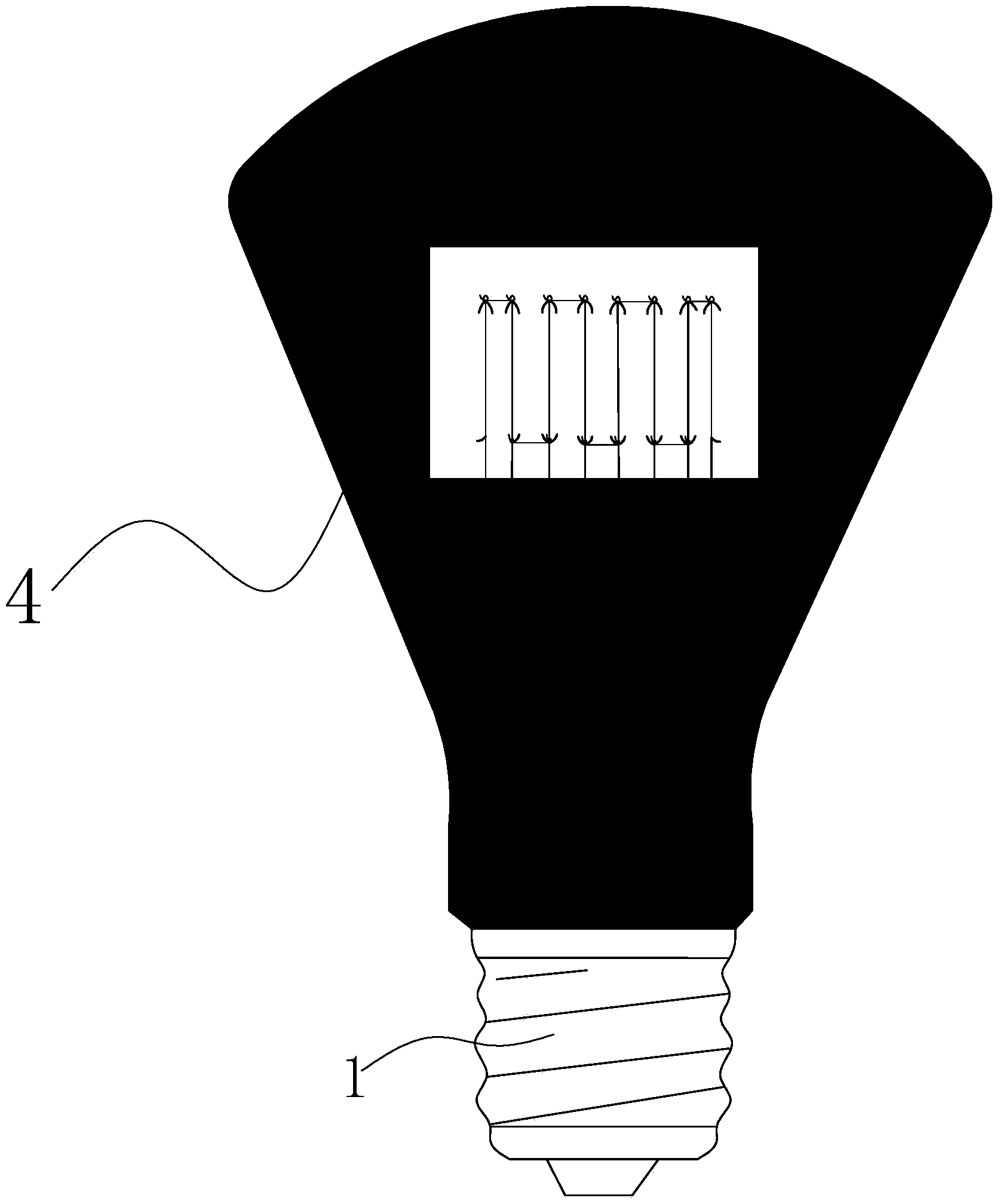

[0013] Such as figure 1 , figure 2 , image 3 and Figure 4 A standard lamp for detecting luminous intensity shown includes a lamp cap 1, a glass bulb 4, a stem 2 and a filament 6 are arranged inside the bulb 4, two guide wires 7 are drawn out of the stem 2, and the filament 6 The two ends are respectively connected with two guide wires 7. When the lamp cap 1 is on the bottom and the glass bulb 4 is on the top, the lamp as a whole is in the shape of an inverted cone or a rounded table, and the upper end surface of the glass bulb 4 is an arc surface; the glass bulb 4 The inner wall of the wall is blackened, and only a rectangular or square light-transmitting window 9 is provided on the glass bulb 4 directly in front of the plane where the filament 6 is located. The length of the light-transmitting window 9 is 18-20mm, and the width is 18mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com