Luminous intensity detection standard bulb

A luminous intensity detection and standard technology, applied in the direction of the shell/tube shell of the luminous body, the fixing part/support of the luminous body, etc., can solve the problems of difficulty in obtaining stable luminous intensity value, blackening of the surface of the bulb, and increasing production costs. , to achieve the effect of improving the service life, reducing the area and not easy to sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

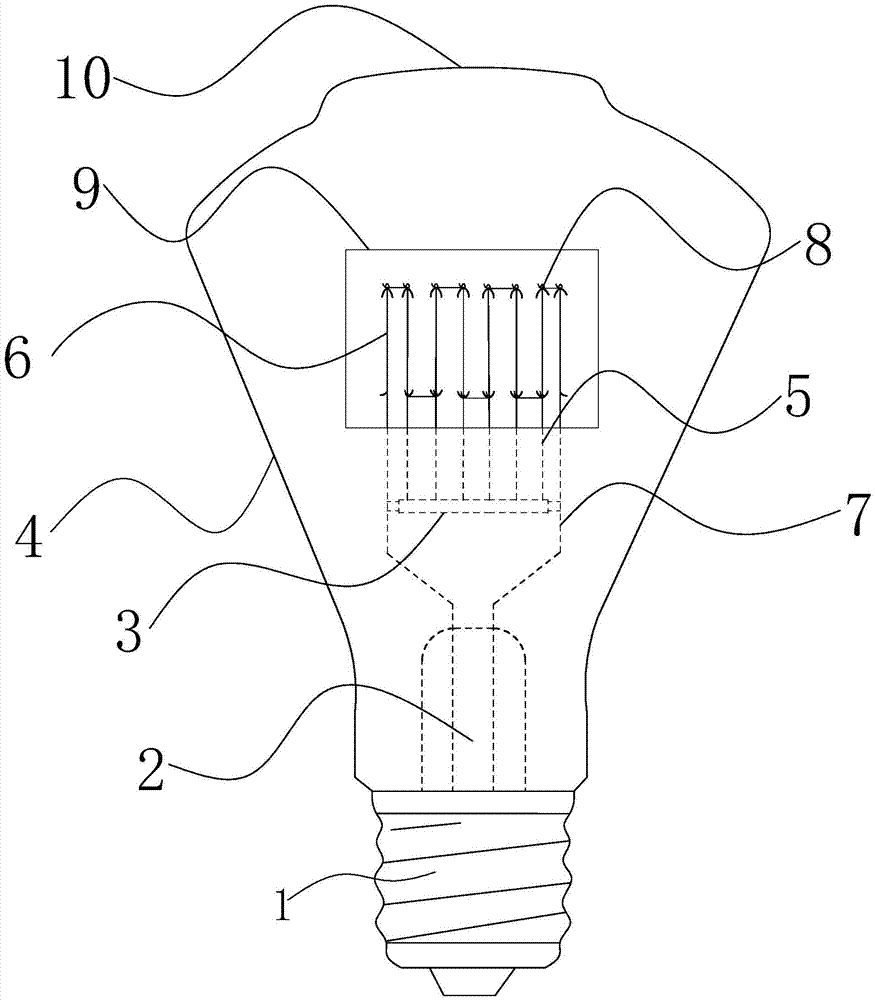

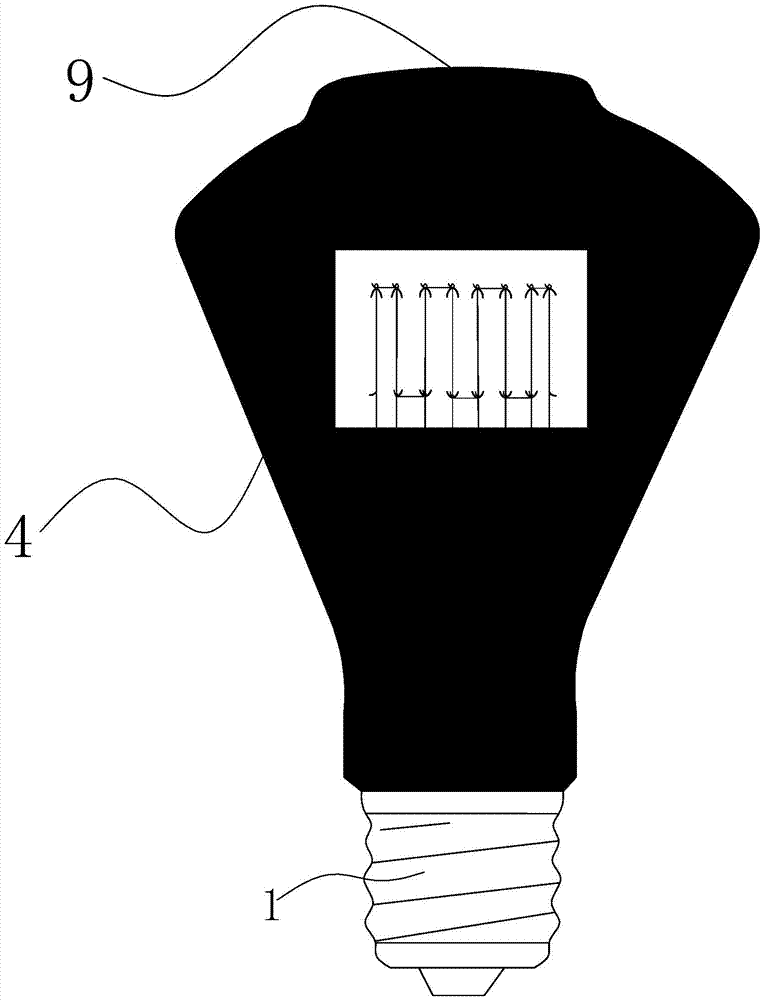

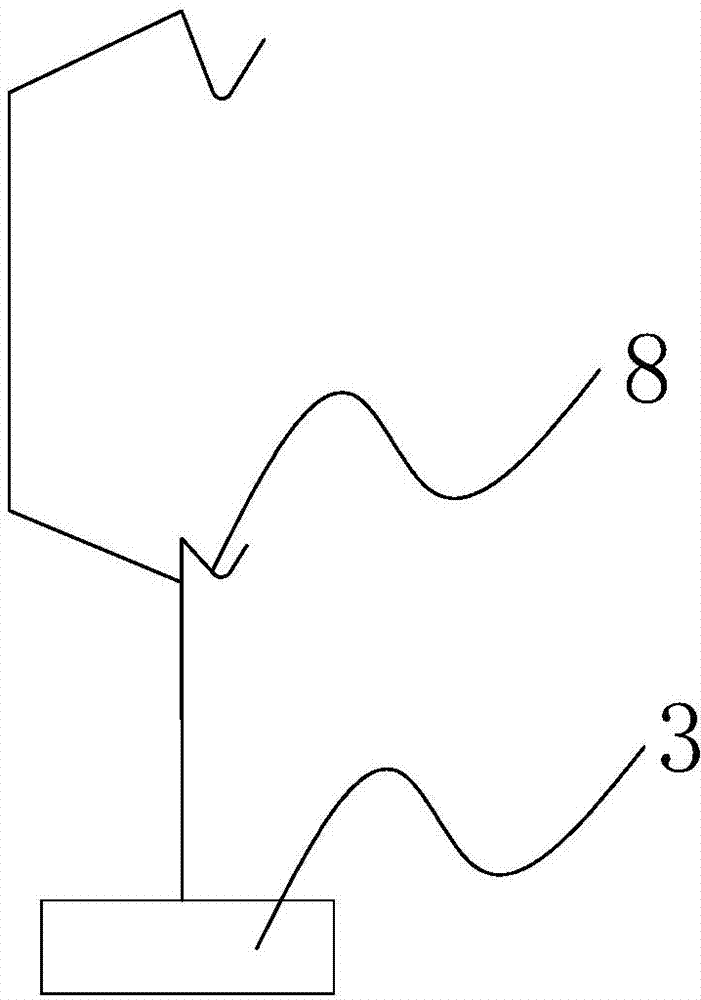

[0013] Such as figure 1 , figure 2 , image 3 with Figure 4 A standard light bulb for luminous intensity detection shown includes a lamp cap 1, a glass bulb 4, a stem 2 and a filament 6 are arranged inside the bulb 4, two guide wires 7 are drawn out of the stem 2, and the filament 6 The two ends are respectively connected with two guide wires 7. When the lamp cap 1 is on the bottom and the glass bulb 4 is on the top, the lamp as a whole is in the shape of an inverted cone or a rounded table, and the upper end surface of the glass bulb 4 is an arc surface; and the arc The center of the surface is provided with an arched protrusion 10, which accounts for 1 / 2-2 / 3 of the entire arc surface, and the height of the arched protrusion 10 is 3-8cm, and the inner wall of the glass bulb 4 Blackened, only a rectangular or square light-transmitting wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com