Heat transfer printing coating and preparation method thereof

A thermal transfer printing and coating technology, which is applied in fireproof coatings, polyester coatings, coatings, etc., can solve the problems of not getting thermal transfer printing effects, and achieve the effects of low cost, uniform coating film thickness, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

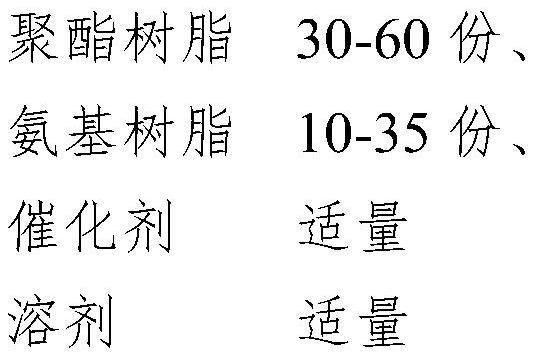

[0034] 1. Prepare the thermal transfer coating of this embodiment 1, according to the following weight component ratios:

[0035] 45 parts of RP7555 type polyester resin, 14 parts of CYMEL 303 type amino resin, 0.8 parts of p-toluenesulfonic acid catalyst, S-100# aromatic hydrocarbon solvent, ethylene glycol butyl ether and propylene glycol methyl ether acetate at 6:2:2 20 parts of mixed solvents obtained by weight ratio.

[0036] 2. Prepare the preparation method of thermal transfer coating according to the following steps:

[0037] Put the polyester resin and amino resin in the required parts by weight into the cylinder, and disperse for 5-10 minutes at a speed of 600-800 rpm;

[0038] Adjust the rotation speed to 400-600 rpm, put in the catalyst of the above-mentioned parts by weight and the mixed solvent of half of the above-mentioned parts by weight, and disperse for 10-15 minutes at a rotation speed of 600-800 rpm;

[0039] Adjust the rotation speed to 400-600 rpm and ...

Embodiment 2

[0042] Prepare the thermal transfer paint of present embodiment 2, by following weight component ratio:

[0043] 55 parts of RP7555 polyester resin, 30 parts of CYMEL 303 amino resin, 0.8 parts of p-toluenesulfonic acid catalyst, 0.4 parts of EFKA-3777 leveling agent, 5 parts of OK520S matting powder, S-100# aromatic hydrocarbon solvent and 30 parts of mixed solvents obtained by butyl glycol ether in a weight ratio of 5:5.

[0044]Referring to the preparation steps of Example 1, in the input step of the catalyst and part of the solvent, 0.4 parts of the leveling agent are synchronously added; then an additional step is added: adjust the speed to 400-600 rpm, put in 5 parts of matting powder, Disperse at 600-800 rpm for 10-15 minutes, and the detection fineness is below 10 μm; other steps remain unchanged, and the thermal transfer coating of Example 2 can be obtained.

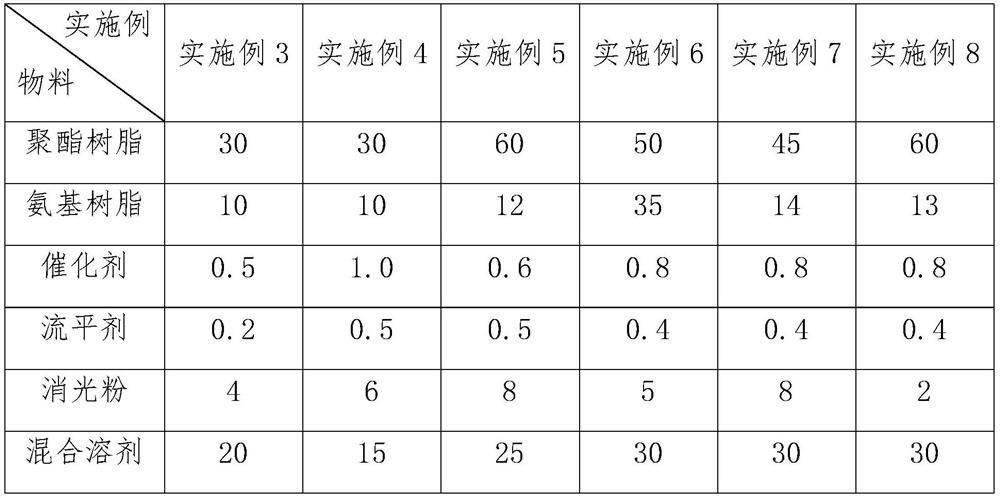

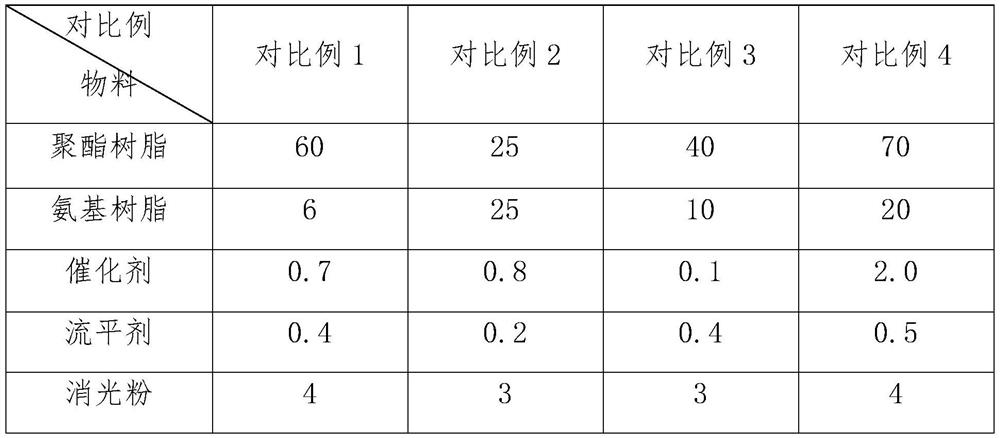

Embodiment 3-8

[0046] With reference to the material component model of embodiment 2, the weight components of the thermal transfer coating of embodiment 3-8 are listed as follows respectively in tabular form:

[0047]

[0048] Referring to the preparation steps of Example 2, the thermal transfer coatings of Examples 3-8 were prepared respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com