Patents

Literature

58results about How to "Fast painting speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

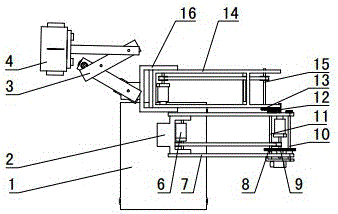

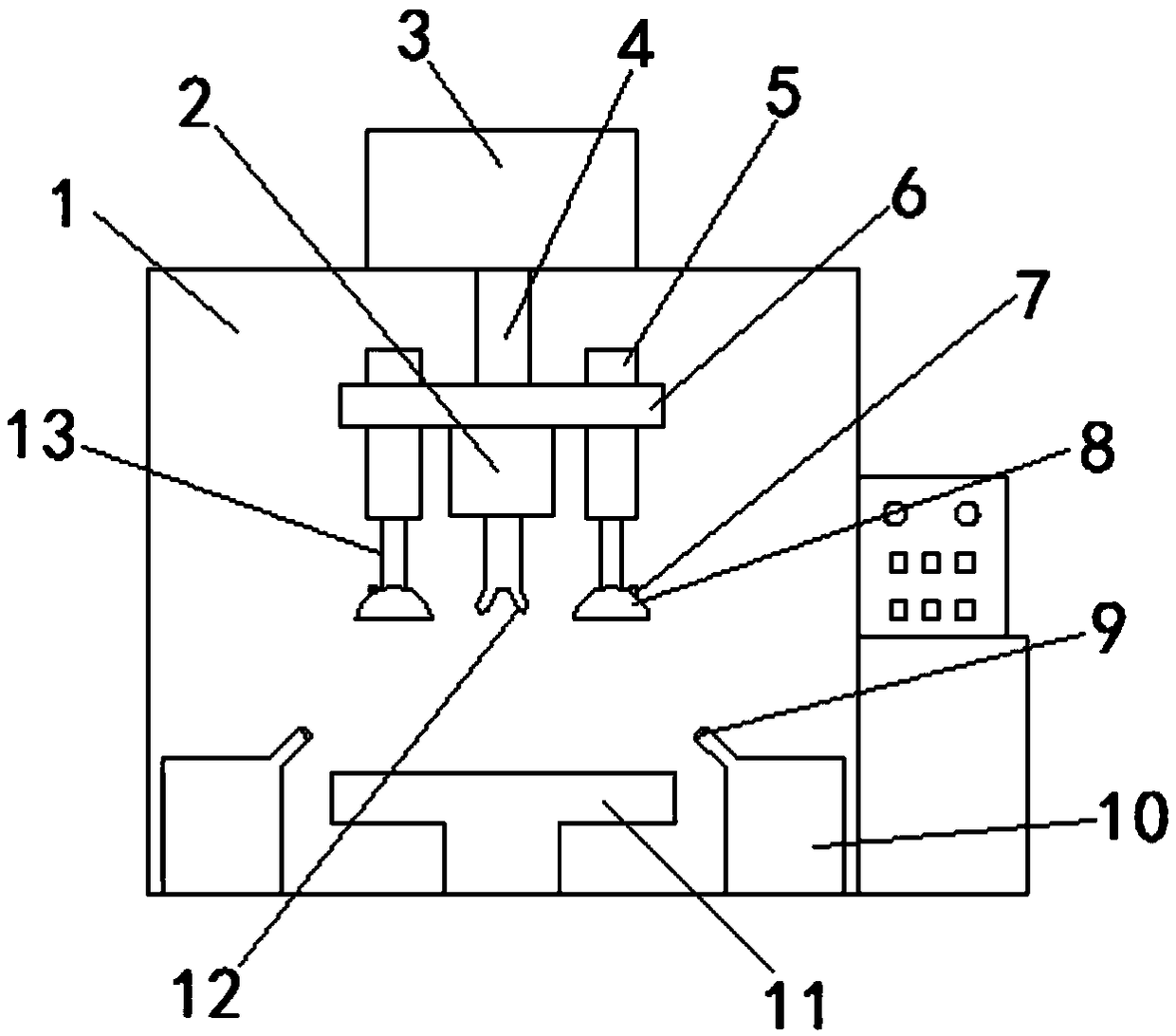

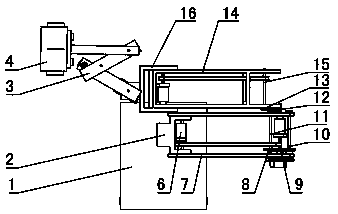

Efficient paint spraying device for spanner for hardware manufacturing

ActiveCN106140538ASave resourcesPrevent fallingLiquid surface applicatorsSpraying apparatusLacquerWrench

The invention relates to a paint spraying device, in particular to an efficient paint spraying device for a spanner for hardware manufacturing. The efficient paint spraying device for the spanner for hardware manufacturing can spray paint more uniformly. The efficient paint spraying device for the spanner for hardware manufacturing comprises a paint inlet hopper, a first sliding rail, a second bearing seat, a framework, a lead screw, a first sliding block, a second sliding rail, a movable rod, a paint box, a paint pump, a hose, a connecting rod and the like, wherein the lead screw is installed on the second bearing seat and provided with a nut; the nut is matched with the lead screw; the lower end of the lead screw is connected with a second bevel gear; the first sliding rail is provided with the first sliding block; and the left end of the nut is connected with the right end of the first sliding block. The efficient paint spraying device for the spanner for hardware manufacturing sprays paint more uniformly. A collecting tank is arranged, so that resources are effectively saved. A covering plate is arranged, so that impurities or dust is prevented from falling into the paint box through the paint inlet hopper.

Owner:无锡市丰伟金属制品有限公司

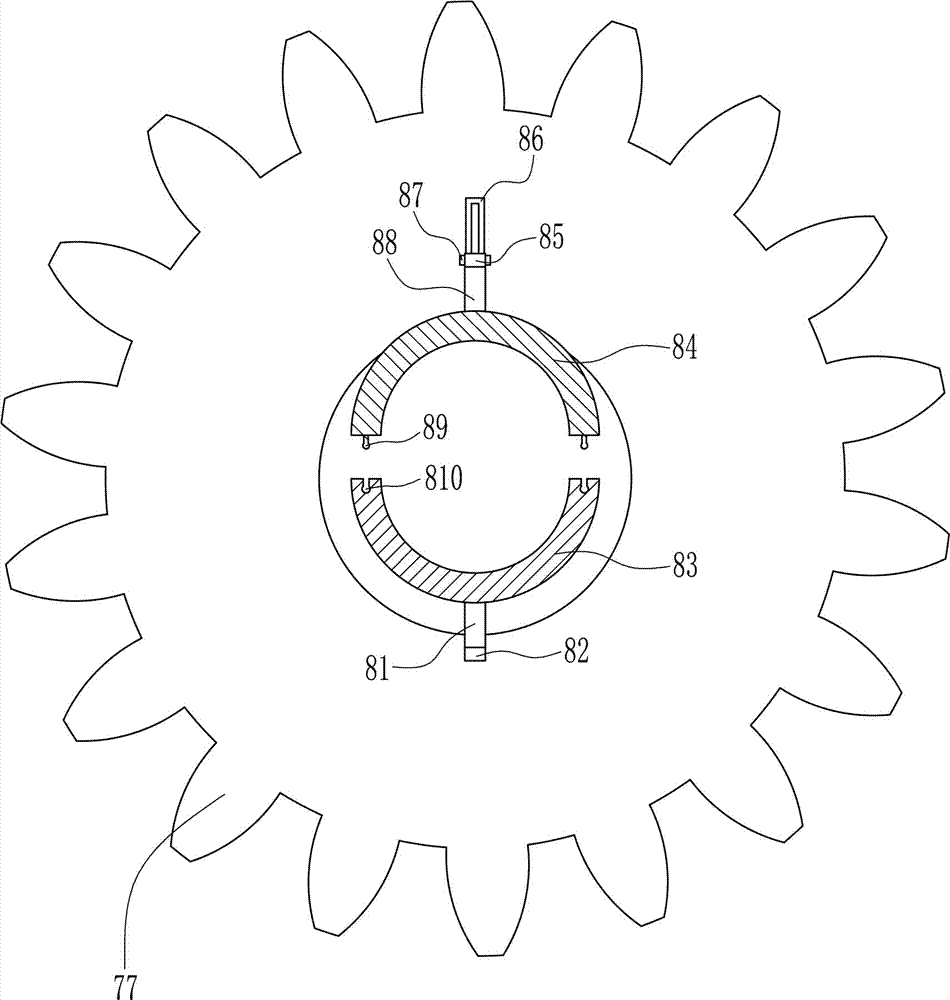

Water-using water-pipe portable paint sprayer

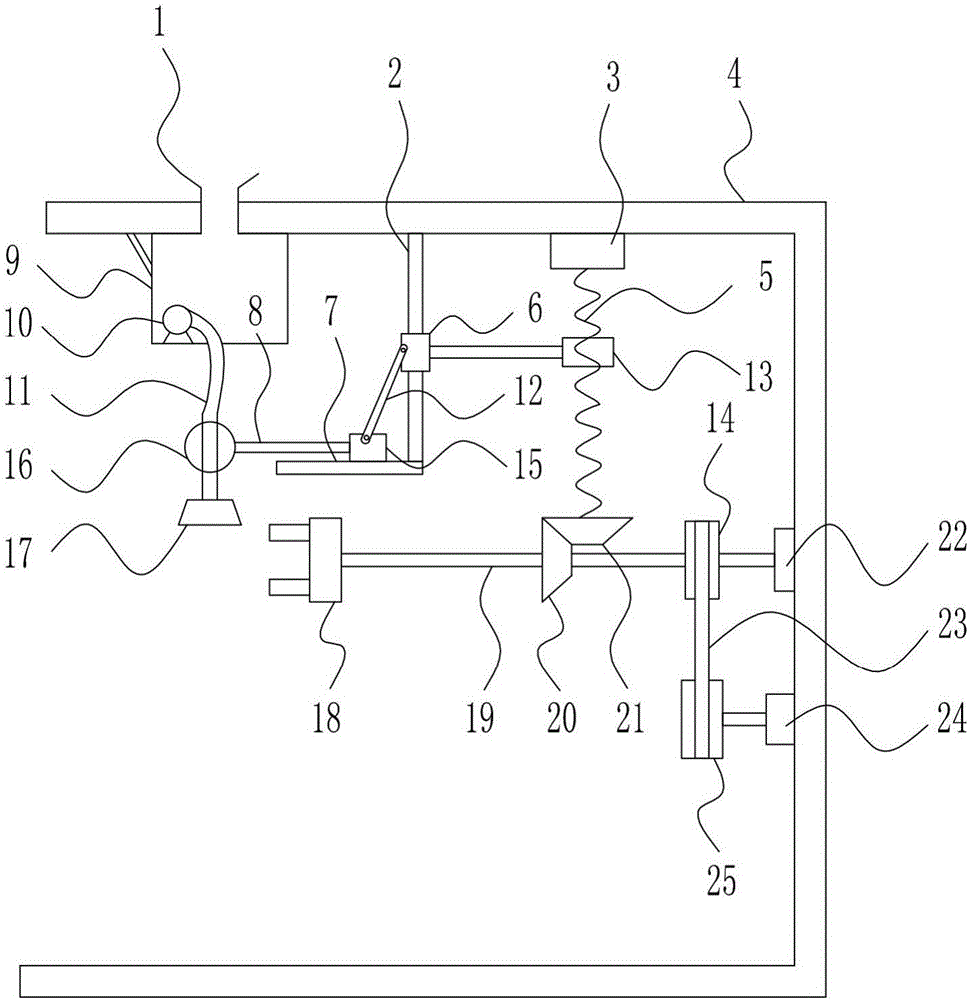

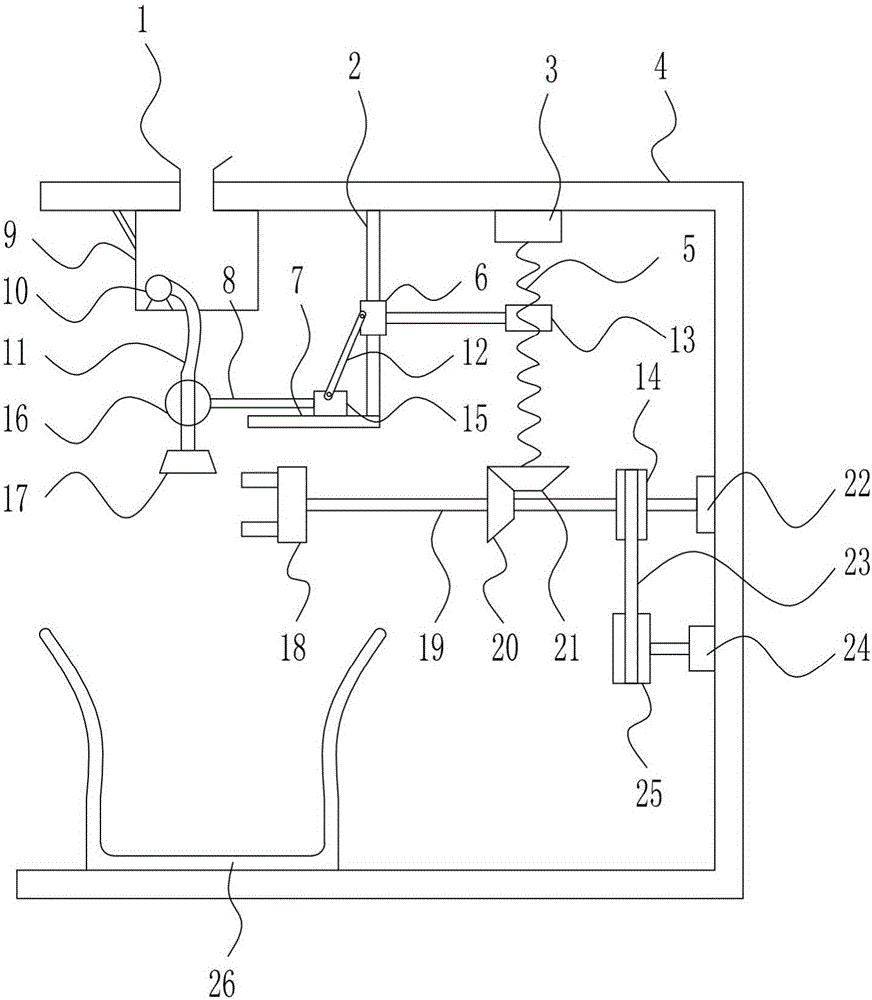

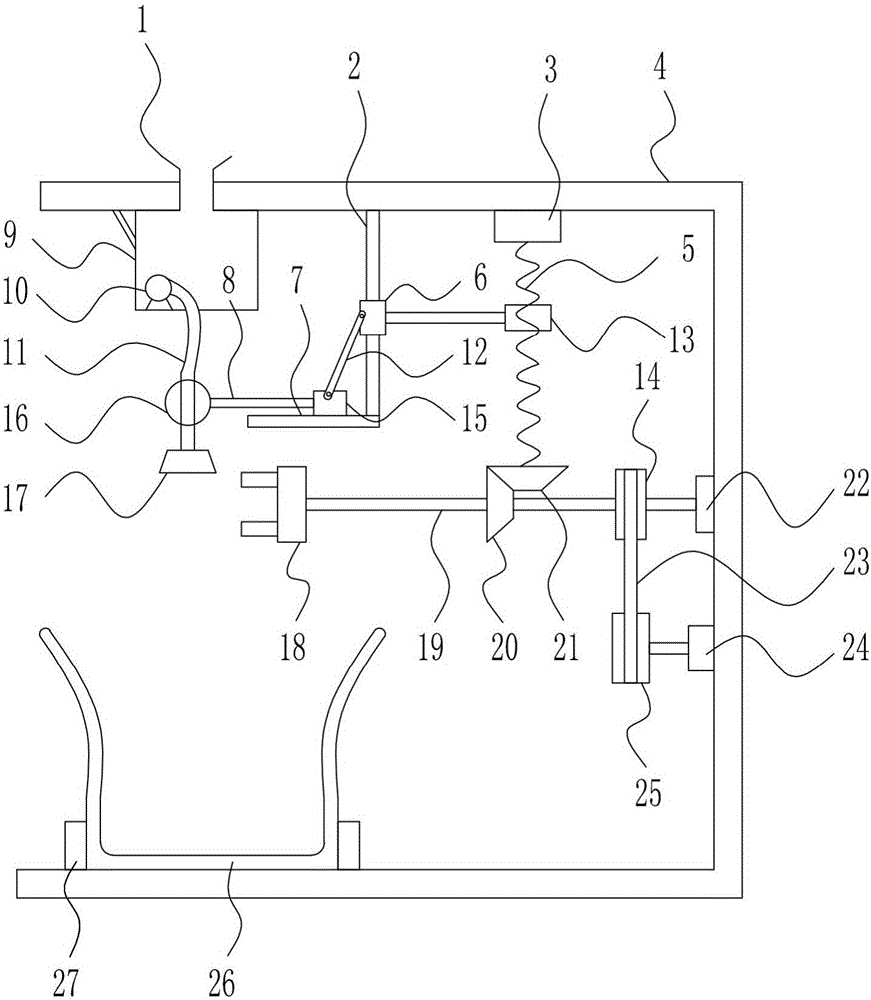

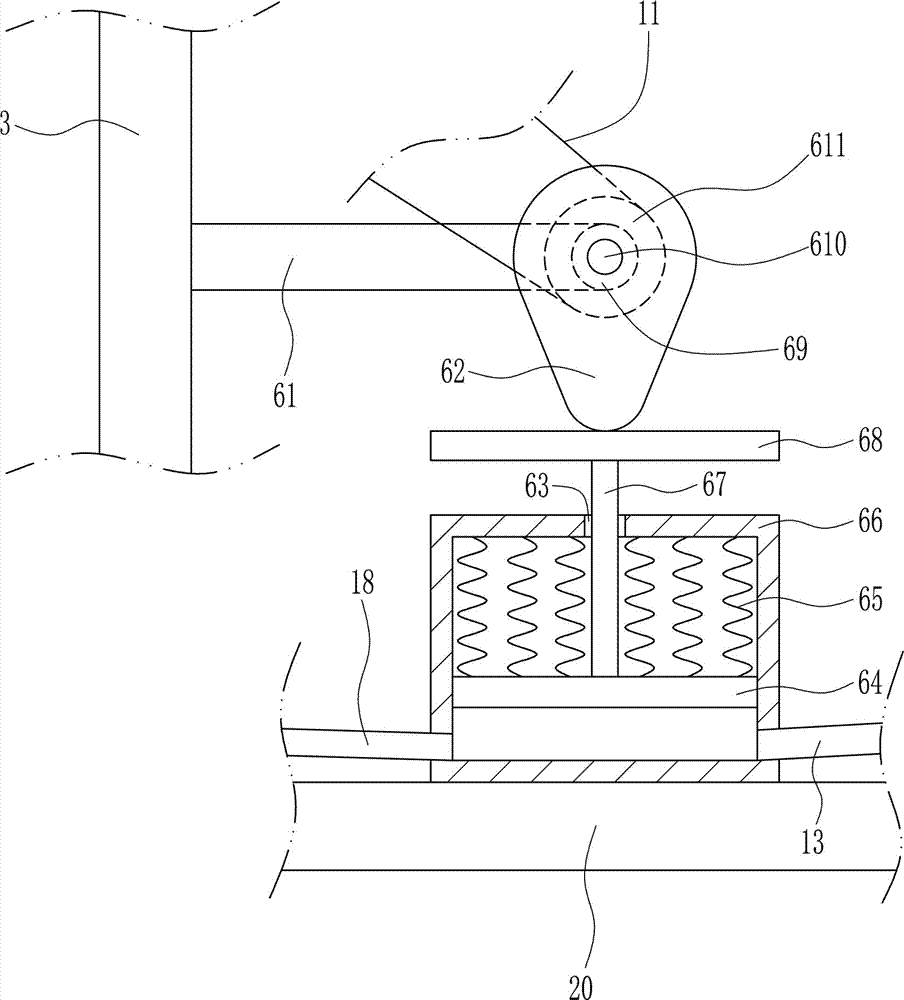

The invention relates to a paint sprayer, and particularly to a water-using water-pipe portable paint sprayer. The technical problem to be solved in the invention is to provide the water using water-pipe portable paint sprayer with uniform paint spraying and a high painting speed. In order to solve the technical problem, the invention provides the water-using water-pipe portable paint sprayer, which comprises a first flat belt, a first mounting plate, a height adjusting mechanism, a linkage mechanism, a paint conveying mechanism, a rotating mechanism, a clamping mechanism, a spraying head, an L-shaped rod, a second flat belt, a paint drawing pipe, a first supporting plate, a third through hole, a collection box, a second supporting plate, a paint conveying tube, a first one-way valve, a second mounting plate, a second one-way valve and a paint storage tank; the first mounting plate is vertically fixed on the top of the second mounting plate. The invention achieves the effect of uniform paint spraying and high painting speed.

Owner:刘明付 +4

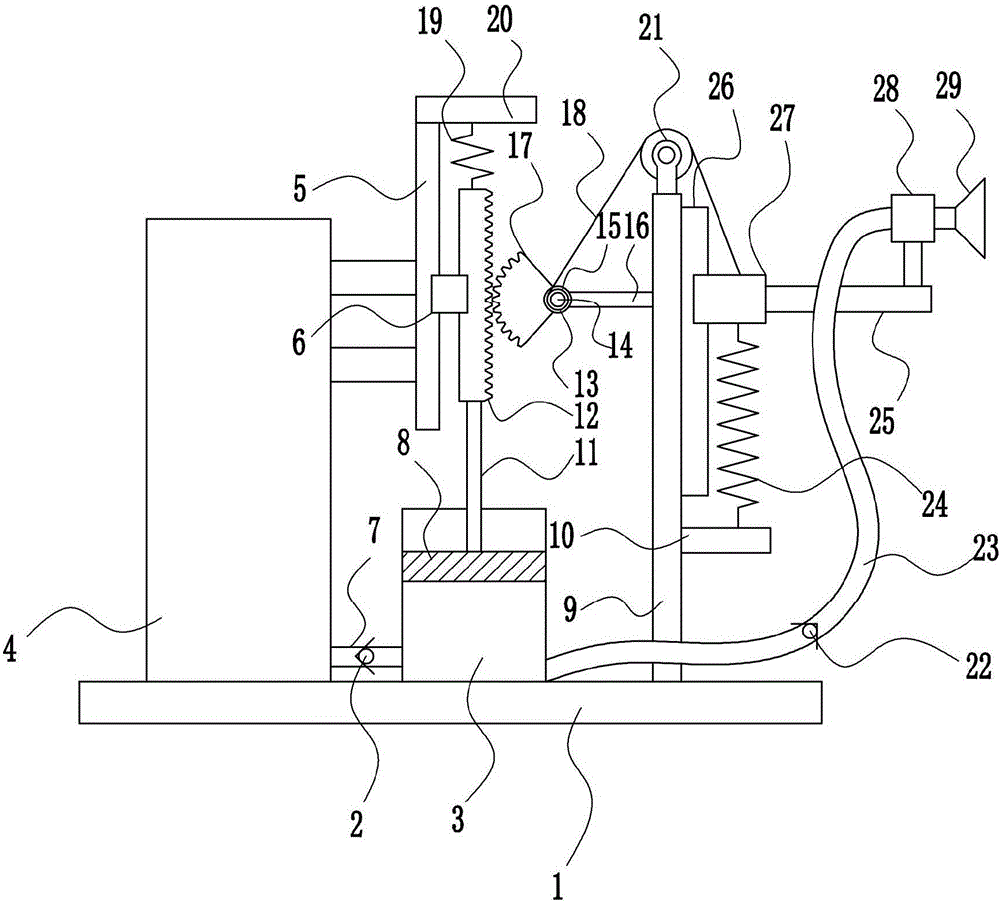

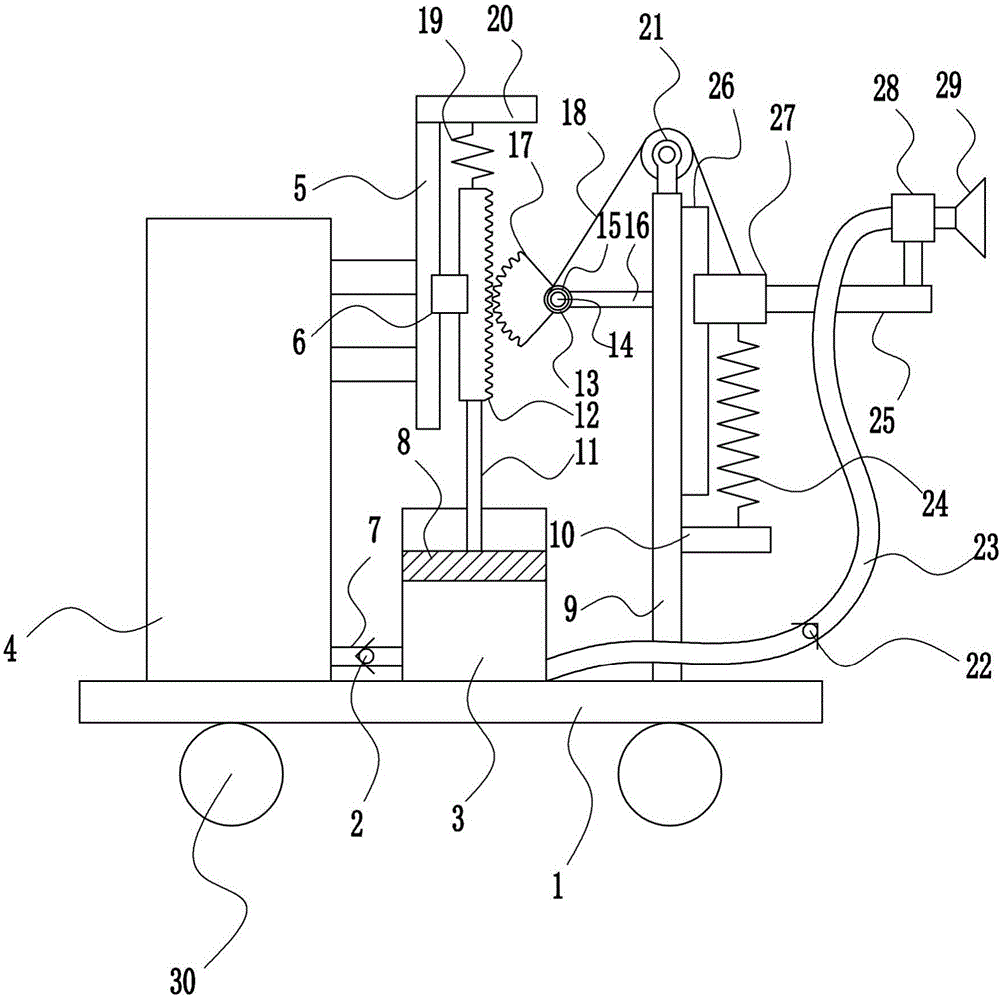

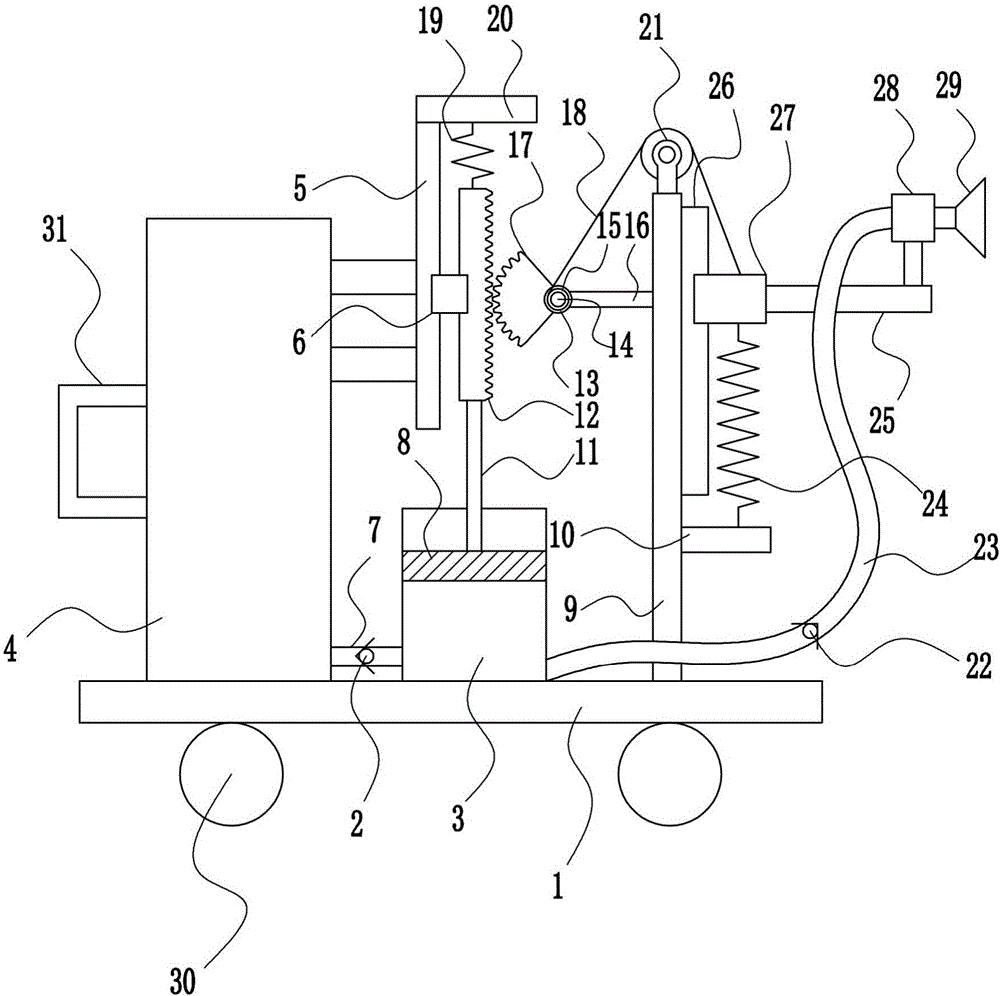

Driverless car shell paint spraying device

InactiveCN106378275AImprove work efficiencySimple structureLiquid spraying apparatusEngineeringCheck valve

The invention relates to the technical field of unmanned equipment, in particular to a driverless car shell paint spraying device. The driverless car shell paint spraying device needs to solve the technical problem of providing a driverless car shell paint spraying device which is simple in structure, high in paint spraying speed and uniform paint spraying. In order to solve the above technical problem, the driverless car shell paint spraying device comprises a bottom plate, a first check valve, a first cylinder body, a second cylinder body, a first slide rail, a first slider, a first pipeline, a piston, a first fixing plate, a first baffle and the like; the left side of the top of the bottom plate is connected with the first cylinder body in a bolt connection manner; and the middle of the top of the bottom plate is connected with the second cylinder body in a bolt connection manner. The driverless car shell paint spraying device achieves the effects that the structure is simple, the paint spraying speed is high, and paint spraying is uniform, a worker can achieve fast paint spraying operation of a shell of a driverless car by means of the device, and operation is easy.

Owner:梁海英

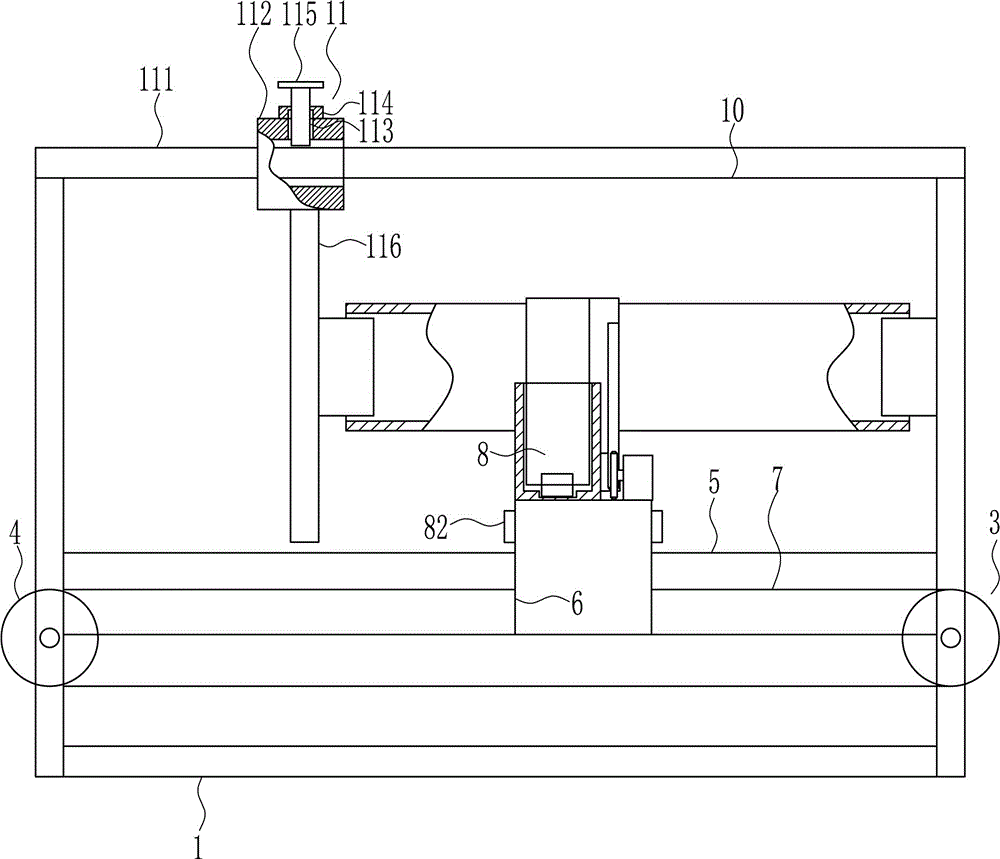

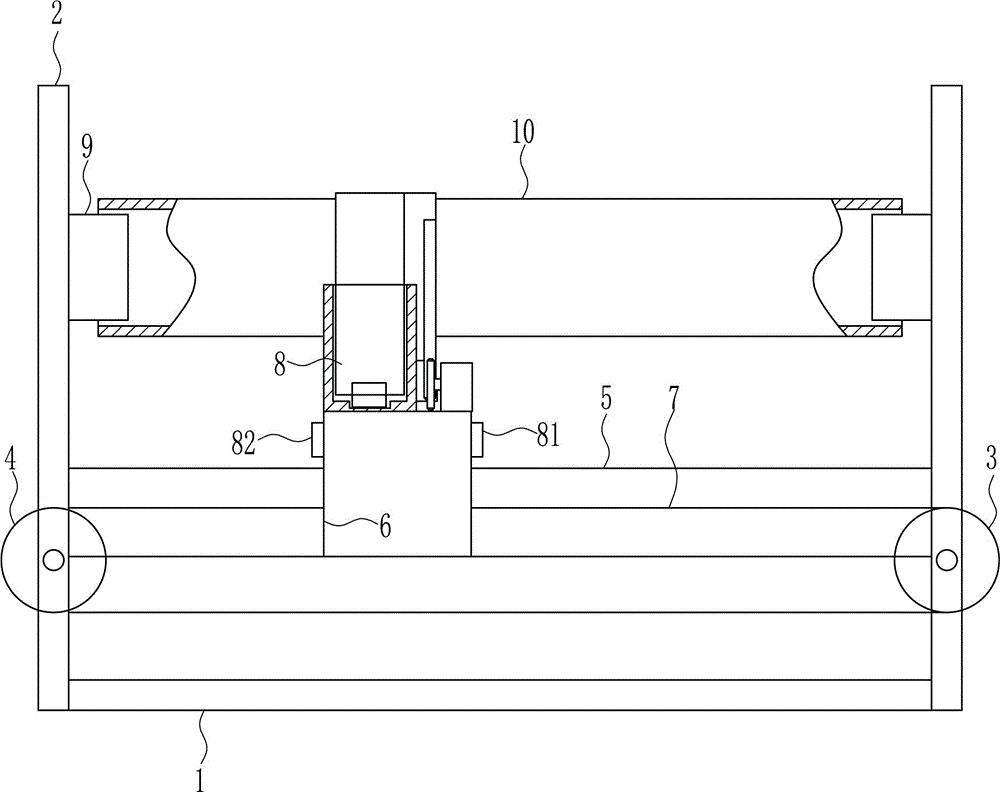

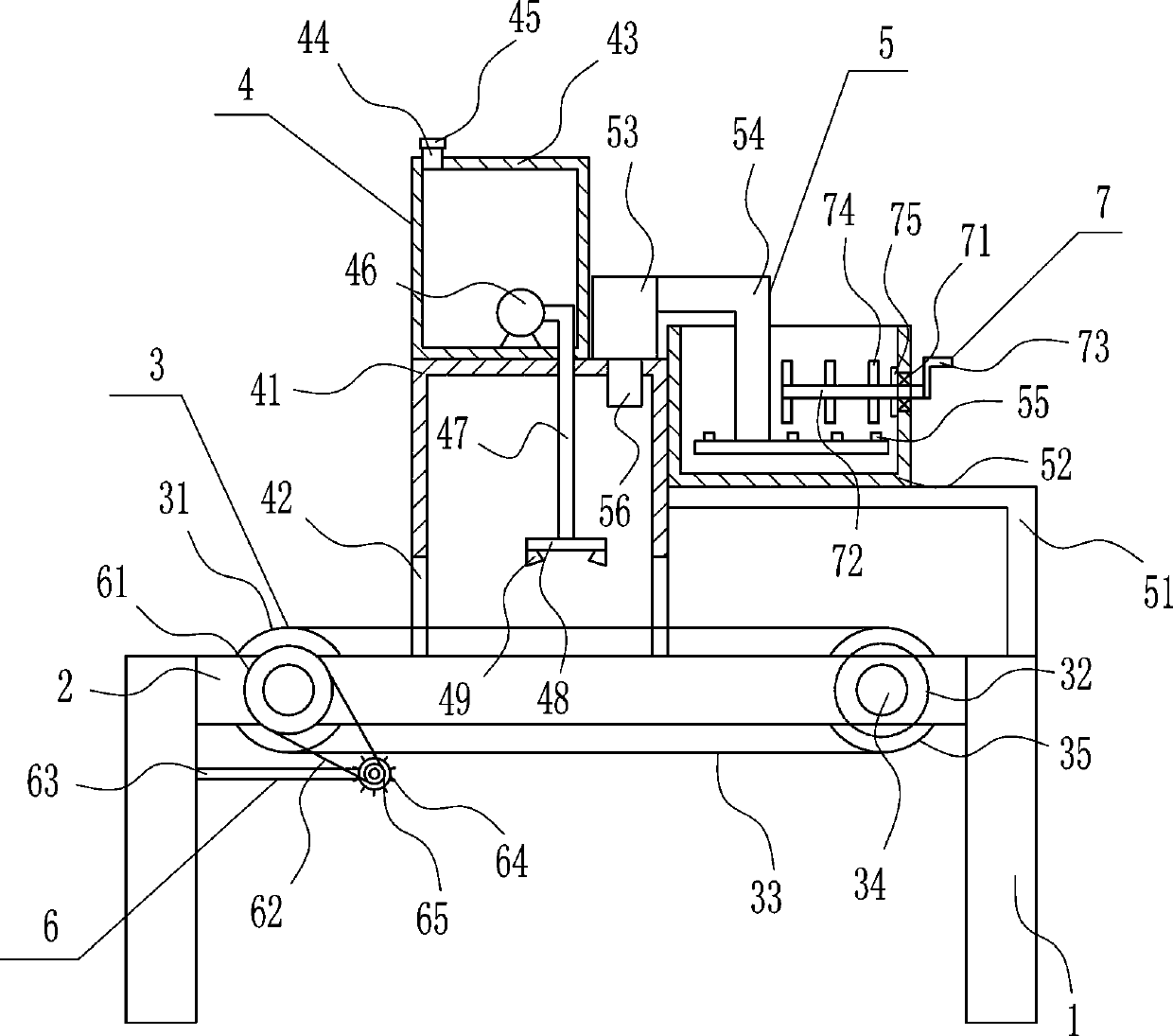

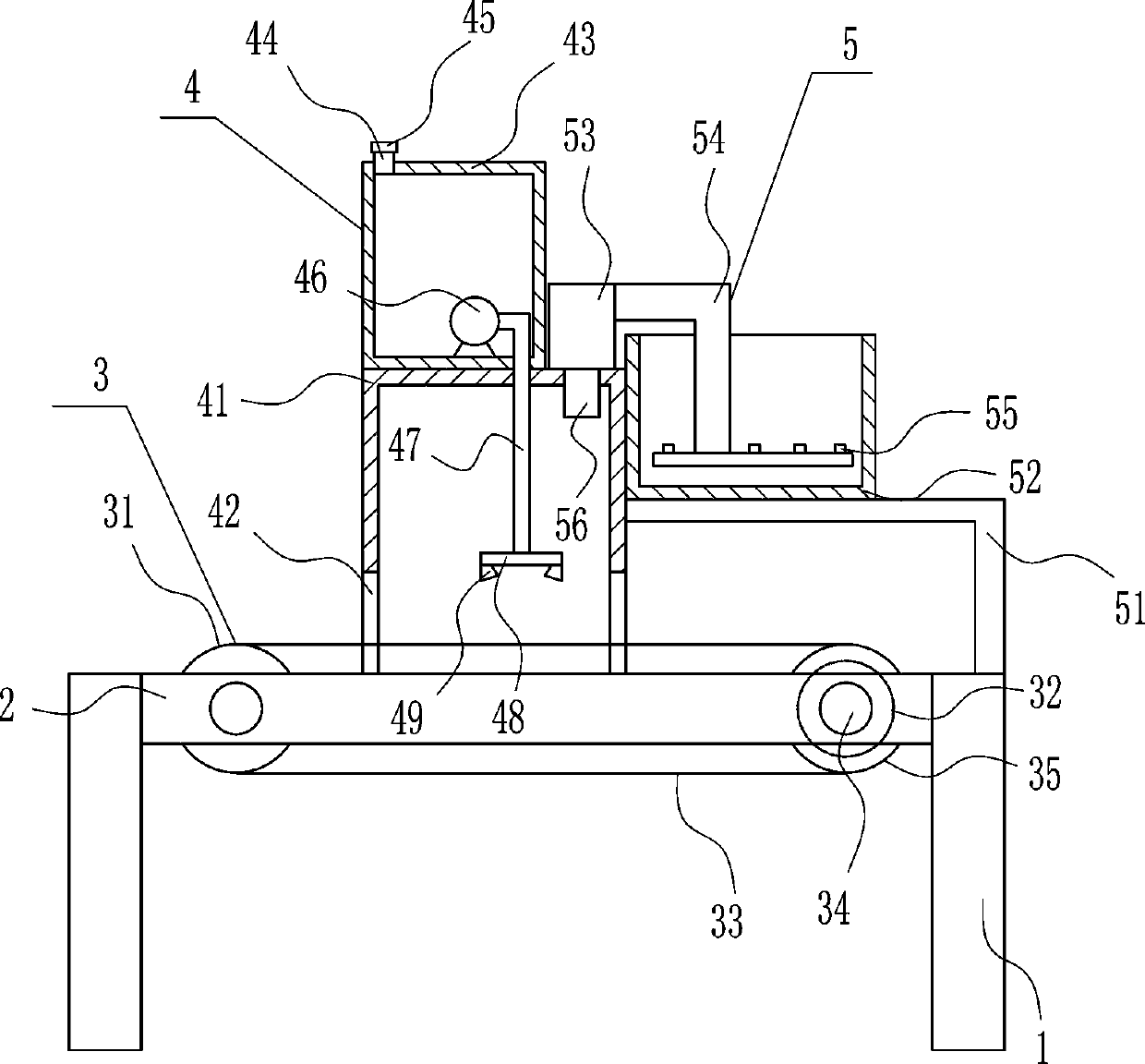

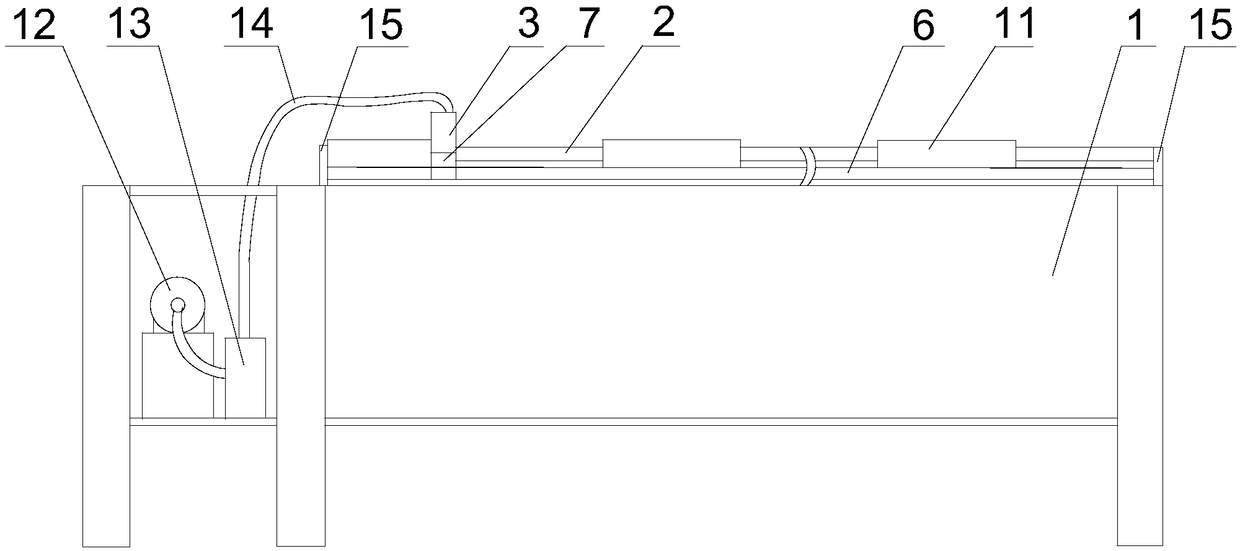

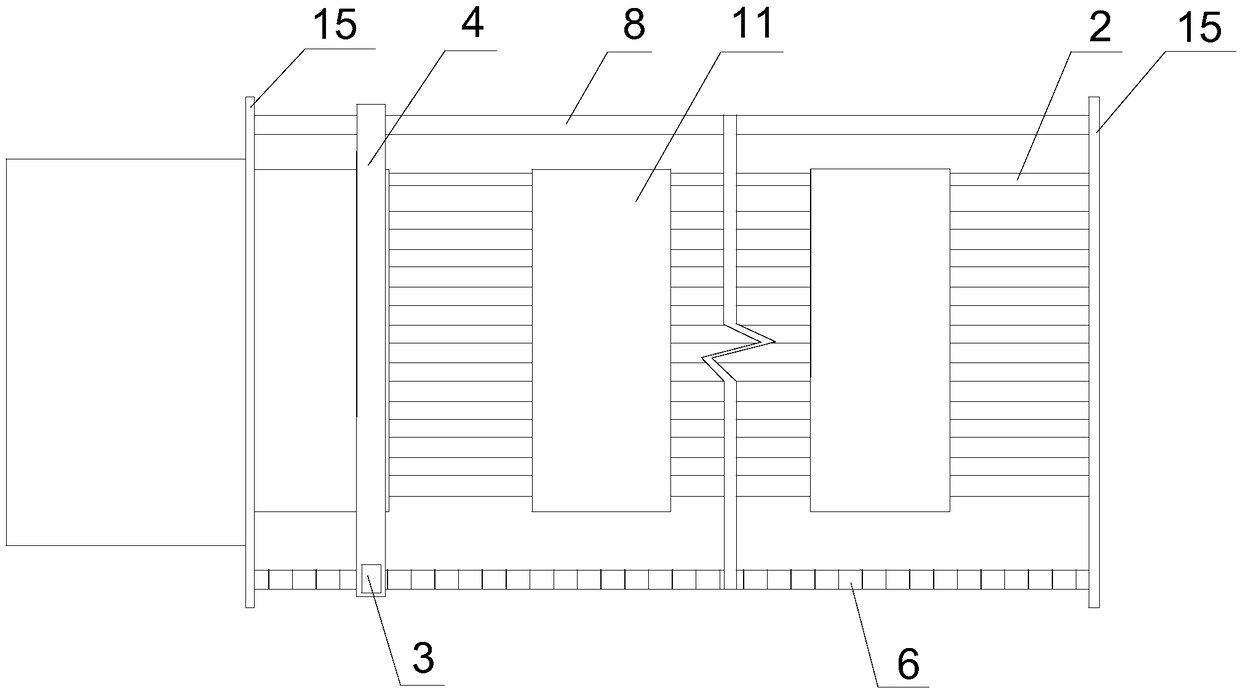

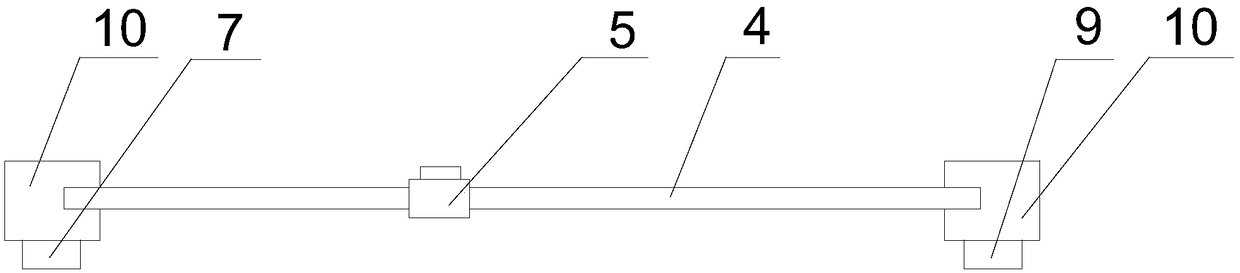

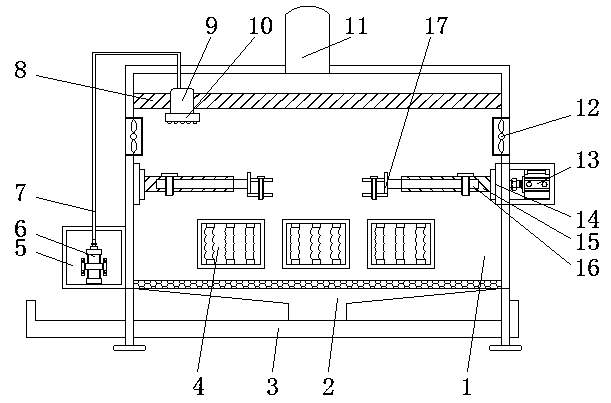

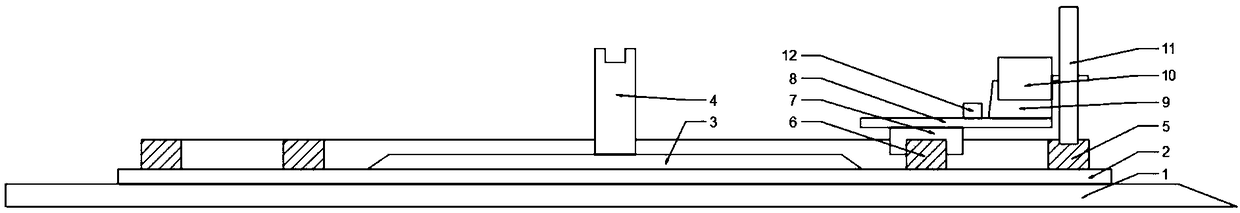

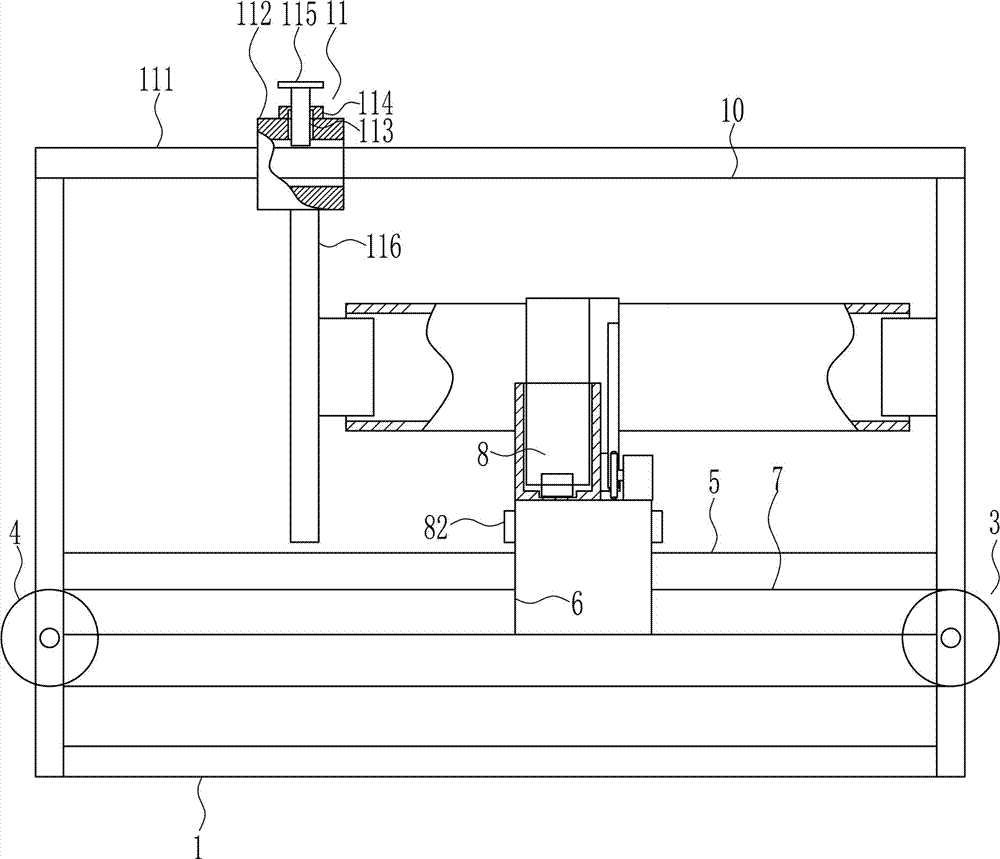

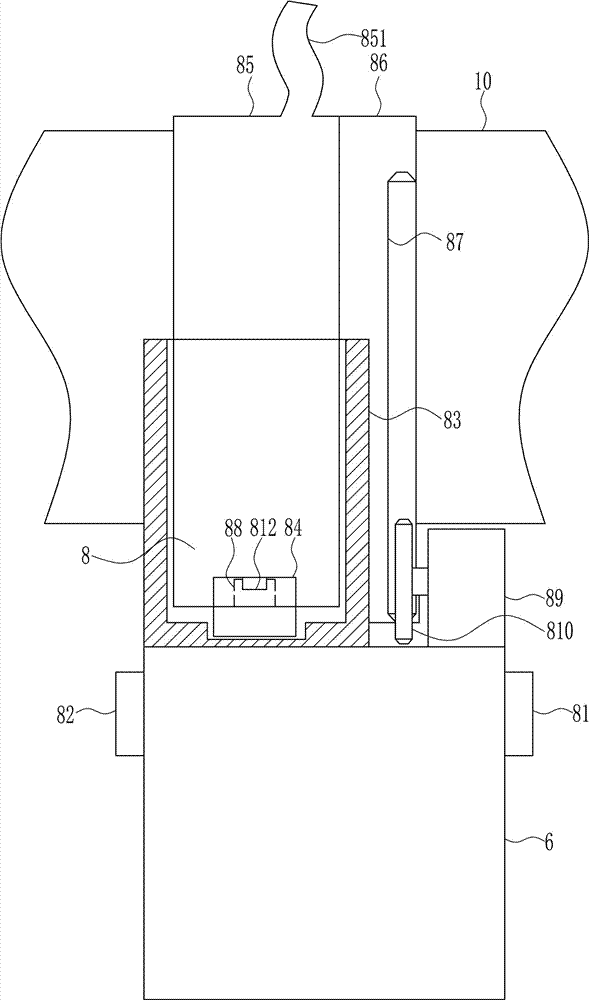

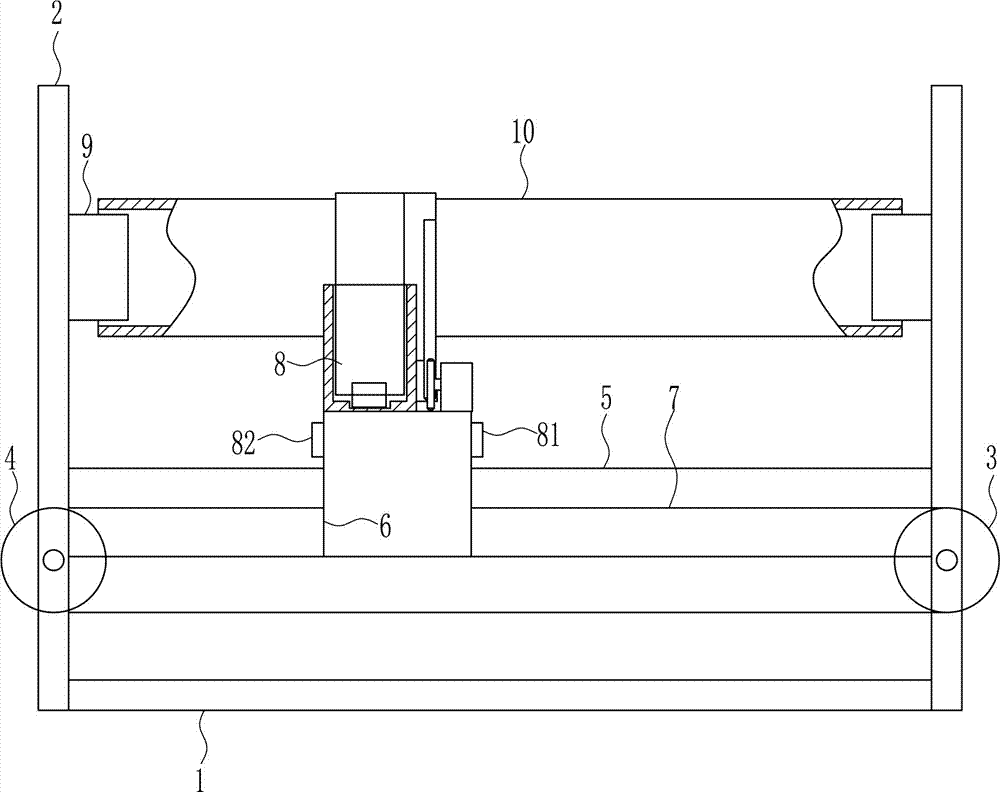

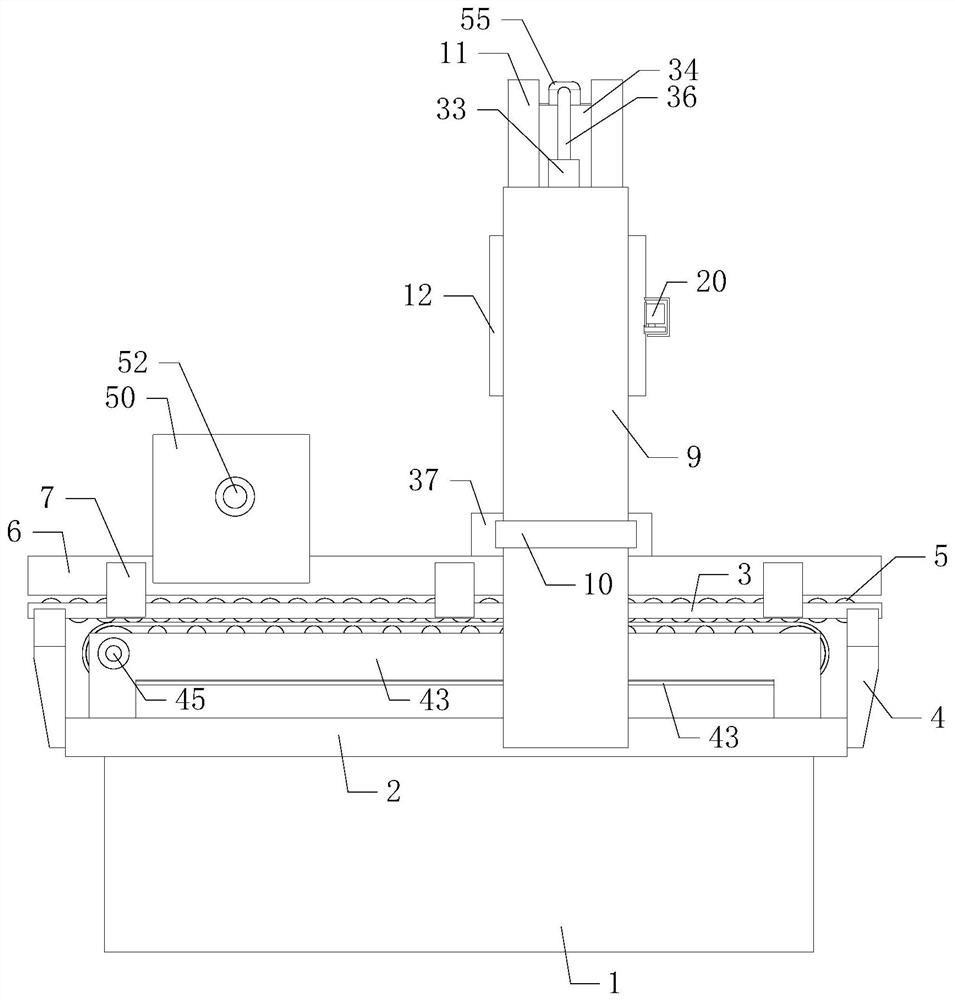

Industrial paint spraying equipment for surface of steel pipe

The invention relates to paint spraying equipment, in particular to industrial paint spraying equipment for the surface of a steel pipe. According to the industrial paint spraying equipment for the surface of the steel pipe, paint spraying is comprehensive, the paint spraying speed is high, and harm to workers in the paint spraying process is small. The industrial paint spraying equipment for the surface of the steel pipe comprises a base plate, supporting plates, a driving wheel, a driven wheel, a first sliding rail, a first sliding block and the like. The supporting plates are symmetrically mounted at the left end and the right end of the base plate in a welded mode. The driving wheel is rotatably connected to the front side of the lower portion of the supporting plate on the right side. The driven wheel is rotatably connected to the front side of the lower portion of the left supporting plate. The first sliding rail is connected between the supporting plates on the left side and the right side in a welded mode. By adoption of the paint spraying equipment, the effects of comprehensive paint spraying, high paint spraying speed, and little harm to the workers in the paint spraying process are achieved.

Owner:江苏新大高空工程有限公司

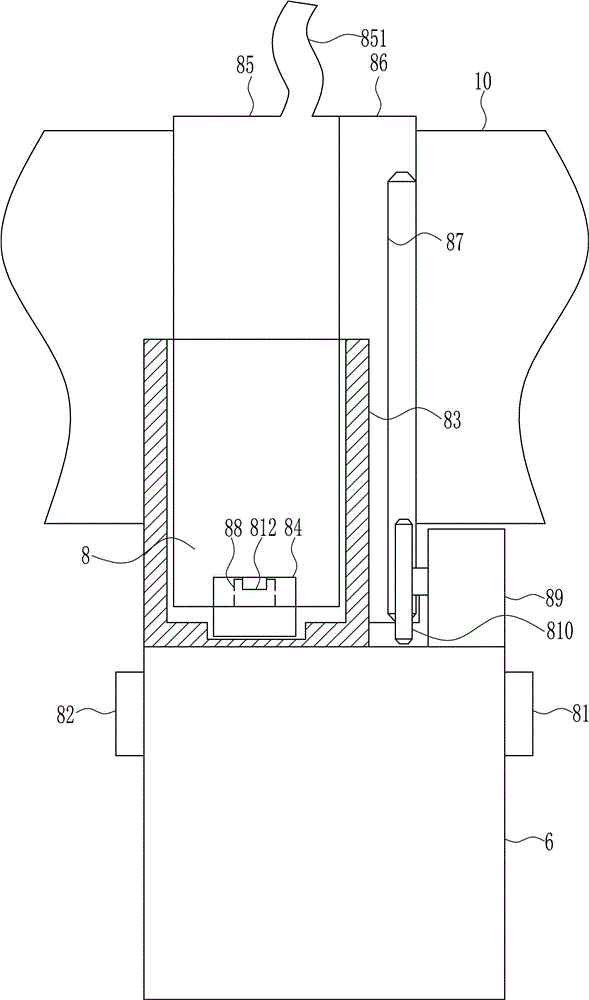

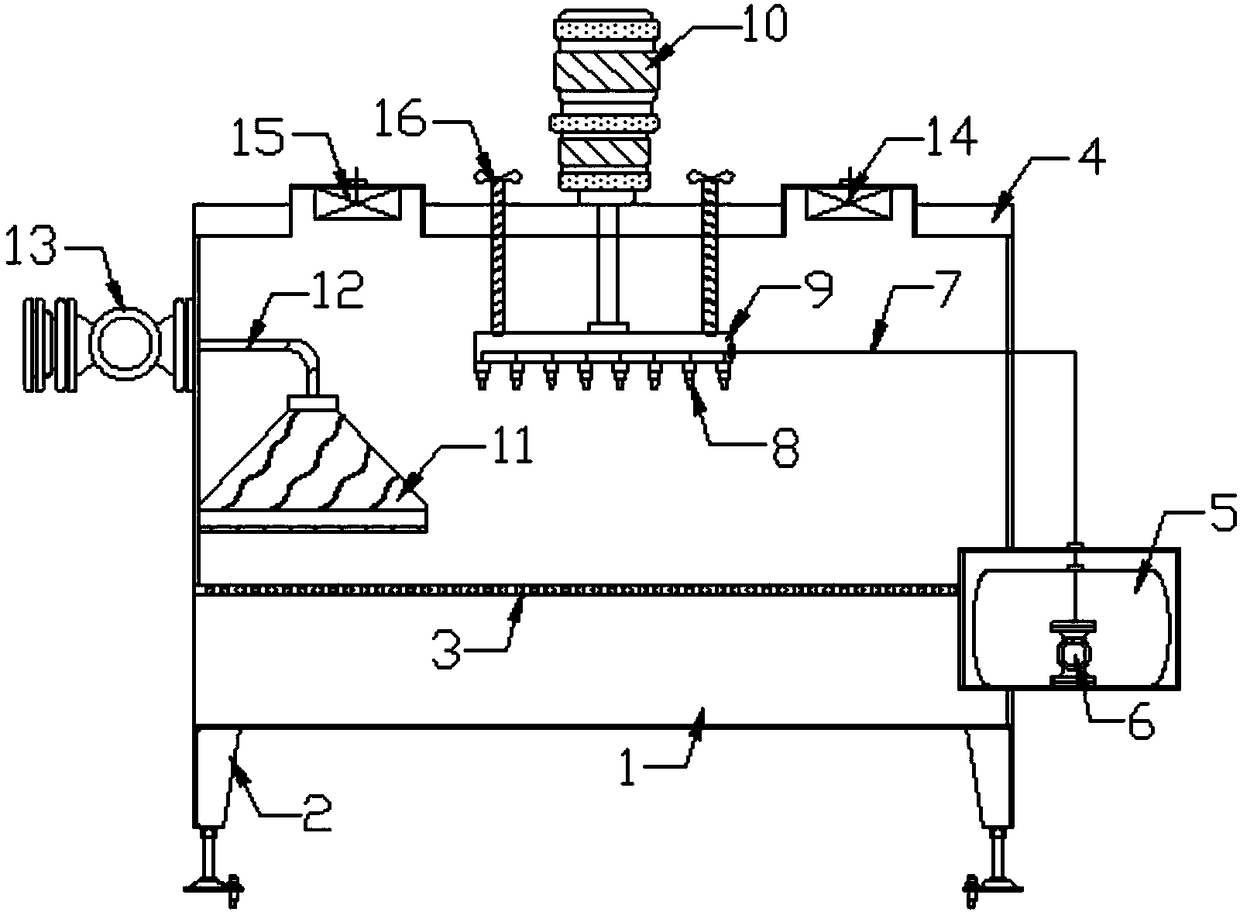

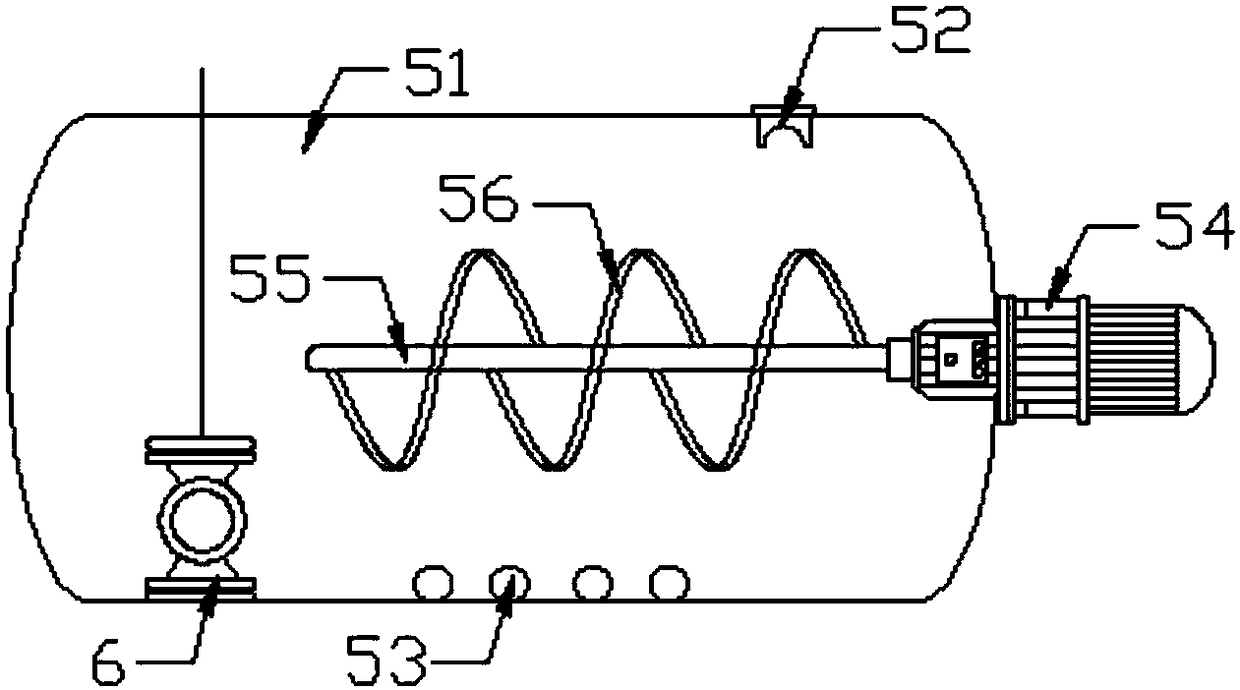

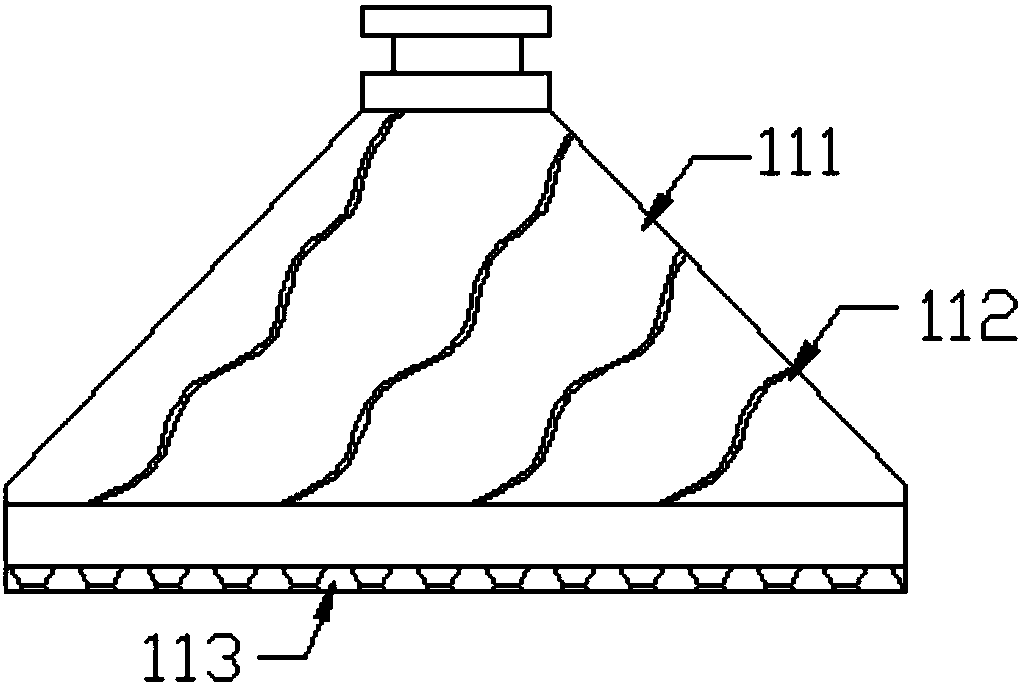

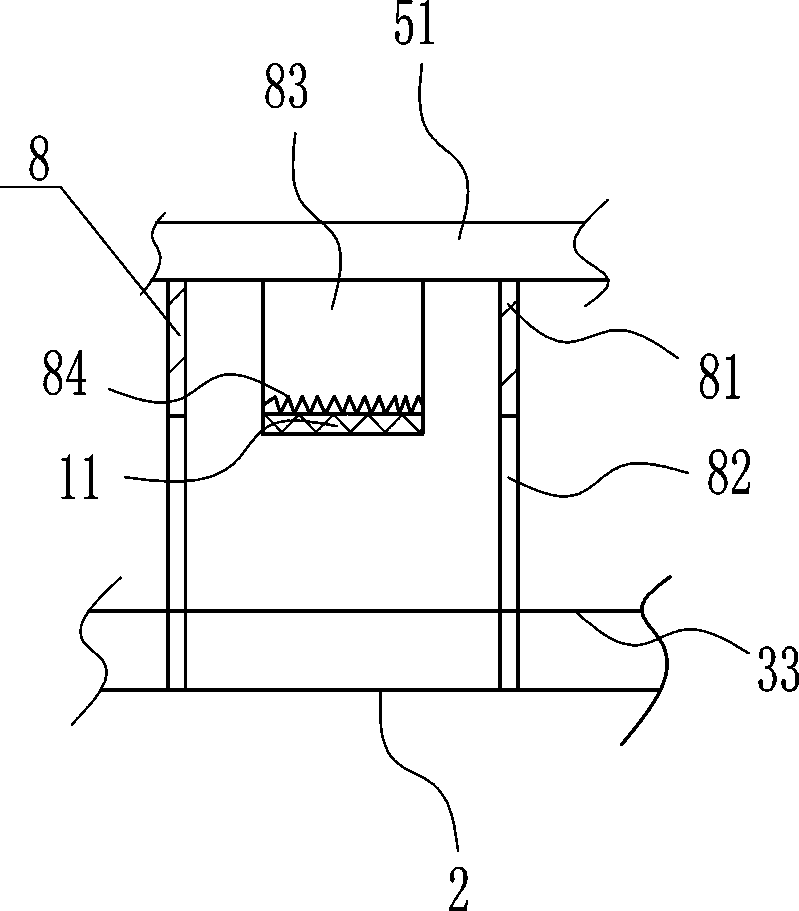

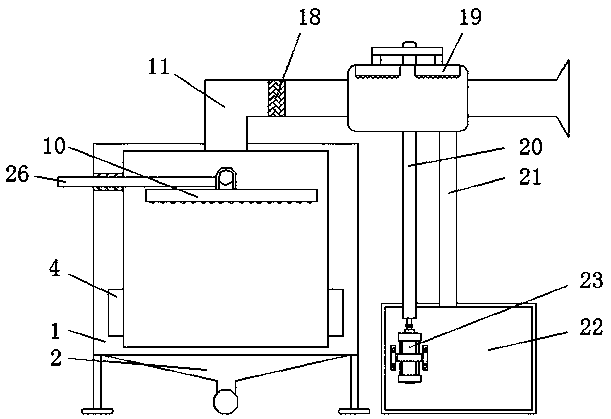

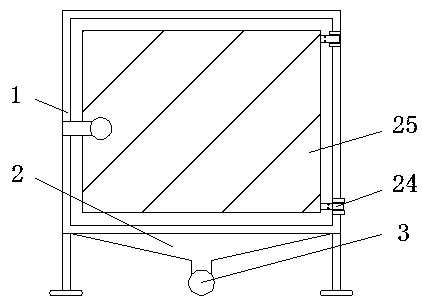

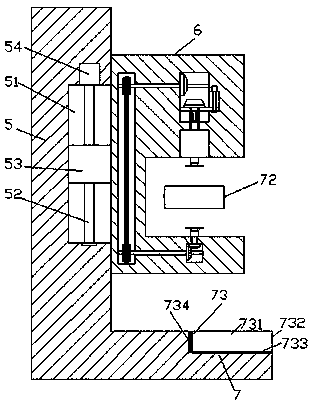

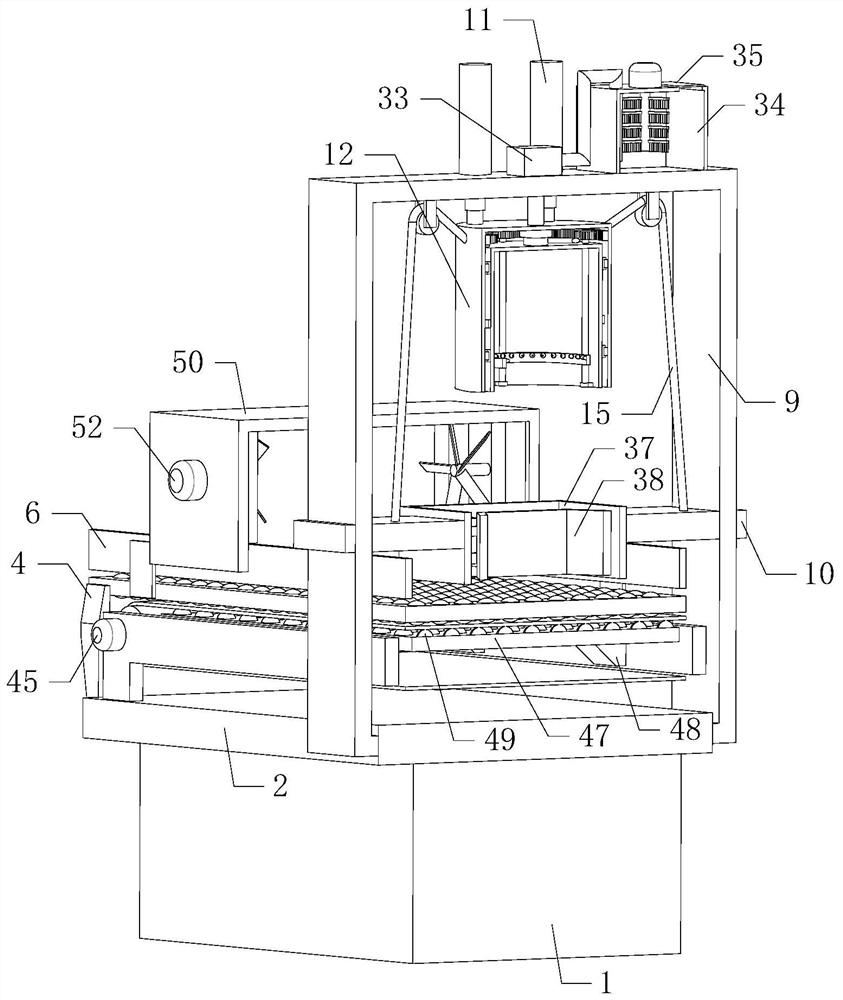

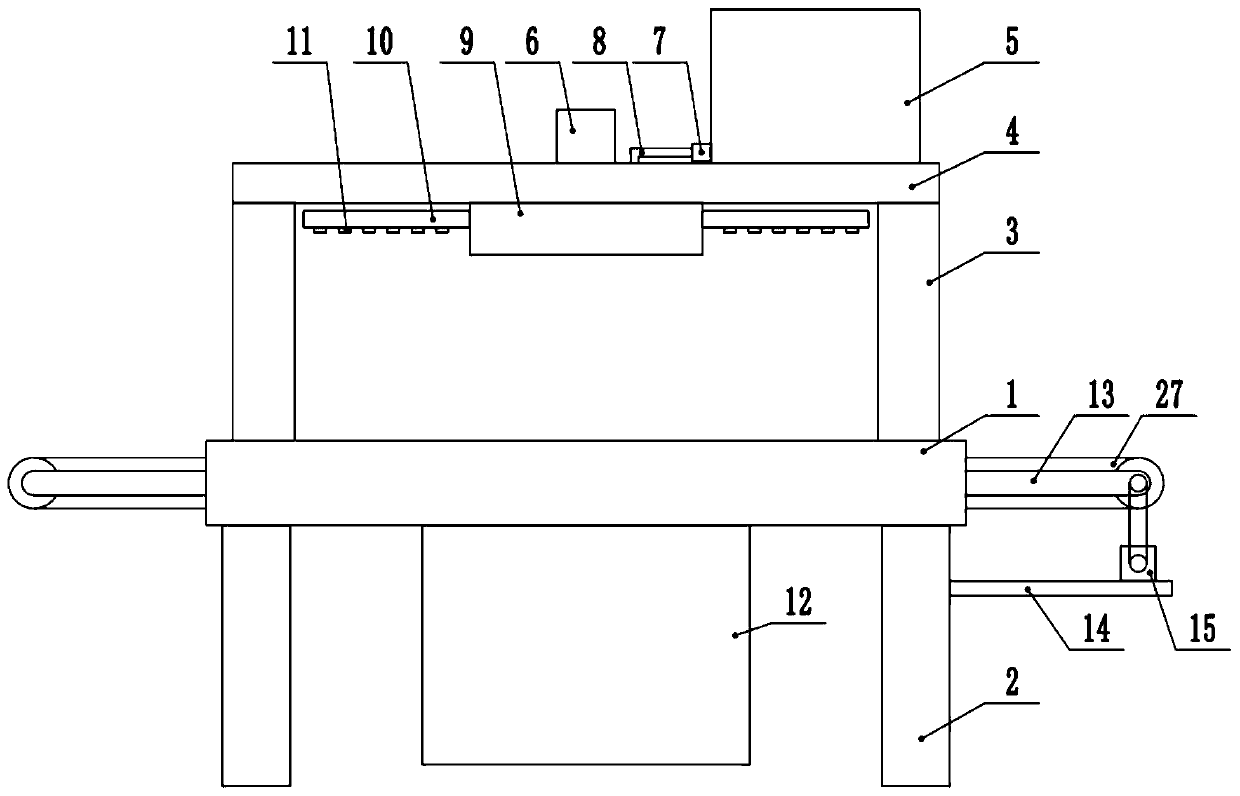

Rapid surface paint spraying device for hardware plates

InactiveCN108284013ASpray evenlyAvoid condensationPretreated surfacesLiquid spraying apparatusSprayerEngineering

The invention discloses a rapid surface paint spraying device for hardware plates. The rapid surface paint spraying device comprises a base, a protective cover, a paint storage device and a paint sprayer; the bottom of the base is fixedly mounted with the ground through the supporting base, the top of the base is provided with a conveyor belt, and the conveyor belt is in transmission connection with a motor through a transmission wheel; and a protective cover is arranged on the base, and the paint storage device is arranged at one end of the base. The distance between the paint sprayer and thehardware plates is adjusted through a telescopic air cylinder, so that the paint spraying area and the paint spraying thickness of the hardware plates can be conveniently adjusted, and paint in a paint tank can be stirred and heated; the paint in the paint tank can be prevented from being precipitated and solidified, or the surface of the paint can be prevented from being condensed into blocks, so that the paint can be uniformly sprayed on the surfaces of the hardware plates; and the quality of the hardware plates paint spraying is effectively improved, and the paint spraying and drying speedof the hardware board is accelerated, so that the paint spraying treatment efficiency of the surfaces of the hardware plates is effectively improved.

Owner:温岭温高教育科技有限公司

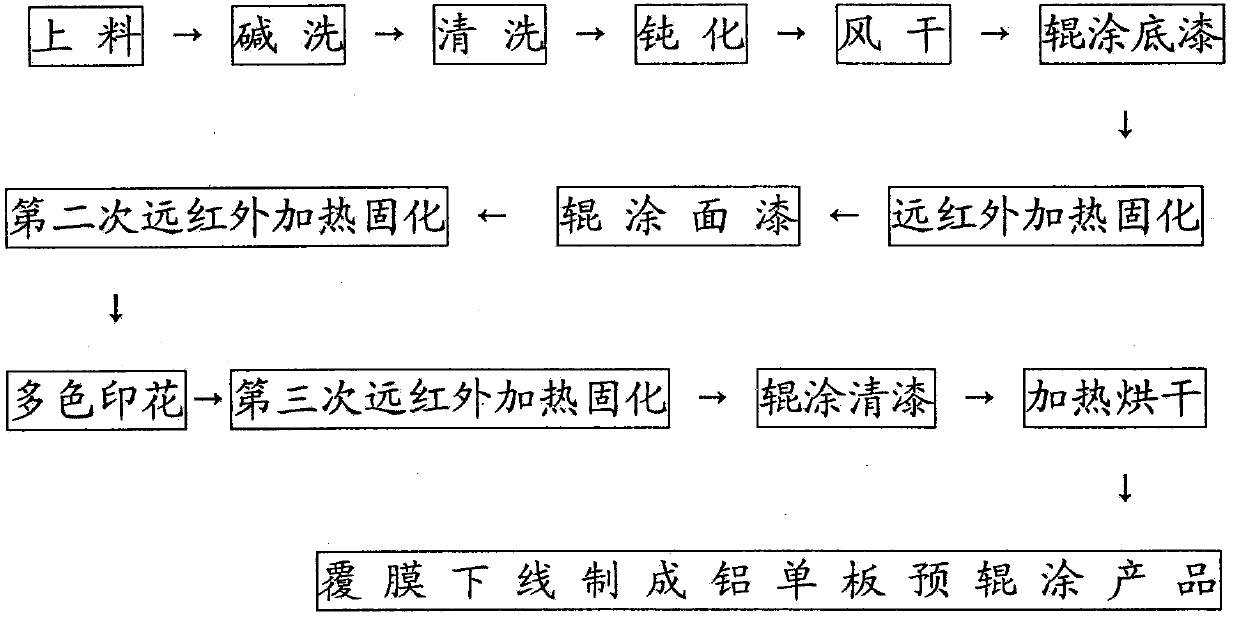

Novel aluminum veneer pre-roll-coating production line and process technology

InactiveCN103990589AEasy to changeSolve problemsPretreated surfacesCoatingsProduction lineColor printing

The invention provides a novel aluminum veneer pre-roll-coating production line and a process technology and relates to the technical field of machinery. A series of key technologies including alkaline washing, cleaning, passivation, coating, printing and drying are adopted, and a front conveying belt, an alkaline washing machine, a cleaning machine, a chromate-free passivation device, a baking oven, a precise single-roller priming paint coating machine, a far infrared baking oven, a three-roller coating machine, a far infrared device, a multi-color stereoscopic printing machine, a far infrared machine, a precise single-roller priming paint coating machine, a curing baking oven and a rear conveying belt are sequentially placed to form the novel aluminum veneer pre-roll-coating production line. The process technology is that an aluminum veneer pre-roll-coating product is manufactured through feeding, alkaline washing, cleaning, passivation, air-drying, priming paint roll-coating, far-infrared heating and curing, finishing coat roll-coating, secondary far-infrared heating and curing, multi-color printing, third far-infrared heating and curing, varnish roll-coating, heating and drying and film coating and off-line operation. The novel aluminum veneer pre-roll-coating production line and the process technology are used for aluminum veneer roll-coating and are novel in concept, reasonable in design, simple and ingenious in structure, stable and reliable in effect and low in cost and facilitating manufacture, usage and popularization.

Owner:肇庆鑫盈装饰材料有限公司

Concave and convex hand feeling texture printing method with high simulation degree

InactiveCN109823071AHigh degree of simulationClose to the real pattern effectDuplicating/marking methodsPattern printingSurface layerHeight difference

The invention discloses a concave and convex hand feeling texture printing method with the high simulation degree. The method comprises following steps that A, a plan pattern with textures is generated on printing software; B, through digital printing equipment, multiple layers of UV ink are printed on the position, with the texture position, of the surface of the plane base material to be machined; C, through an ultraviolet lamp, the UV ink is cured to form a texture layer, and a height difference exists between the texture layer and the surface of the plane base material; D, through the digital printing equipment, the plane patterns are printed on the surface layer of the plane base material and the texture layer. According to the printing method, the surface of the made board has the concave and convex hand feeling, particular hand feeling and visual effects of true wood, stone, fabric and the like can be simulated on the plane base material, the plane pattern is directly printed onthe surface of the plane base material and the surface of the texture layer, the pattern effect and the hand feeling get close to the reality, and the simulation degree is high;

Owner:HOPE CERAMICS MACHINERY

Efficient paint spraying device for processing injection mold

The invention relates to the technical field of production of plastic molds and discloses an efficient paint spraying device for processing an injection mold. The efficient paint spraying device comprises a transverse plate, wherein the upper end of the transverse plate is fixedly connected with a gantry; the center of the lower end of a transverse beam of the gantry is rotatably connected with aconnection rod through a rotary shaft; one end, far away from the gantry, of a connection rod is fixedly connected with a mounting plate; a plurality of spraying nozzles, which are uniformly distributed, are fixedly connected with one end, far away from the connection rod, of the mounting plate; a connection block is fixedly connected with the right end of the mounting plate; the upper end of theconnection block is connected with the transverse beam of the gantry through an adjustment mechanism; a groove is formed in the upper end of the transverse plate; a placement plate matched with the groove is arranged above the transverse plate; and a placement groove is formed in the upper end of the placement plate. According to the efficient paint spraying device for processing the injection mold, provided by the invention, a mold in a paint spraying process can be conveniently turned over, the paint spraying speed is remarkably improved and the labor intensity of workers is effectively alleviated; and a paint spraying angle also can be adjusted and the efficient paint spraying device is applicable to paint spraying of molds with abnormal surfaces.

Owner:ANHUI ANLAN MOLD

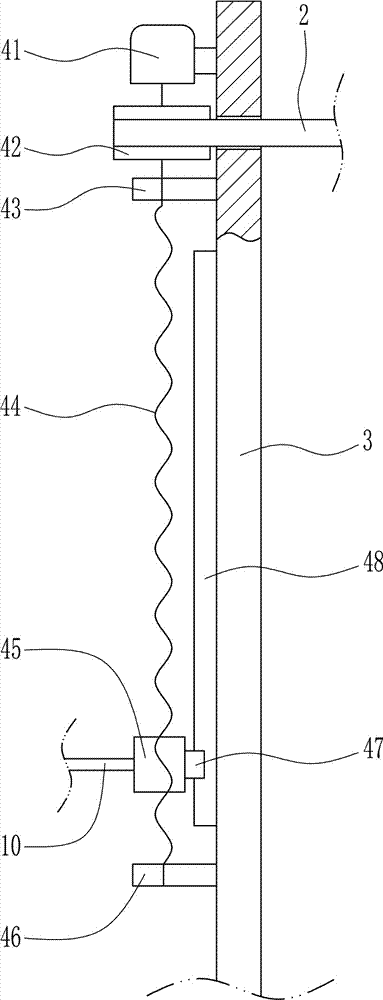

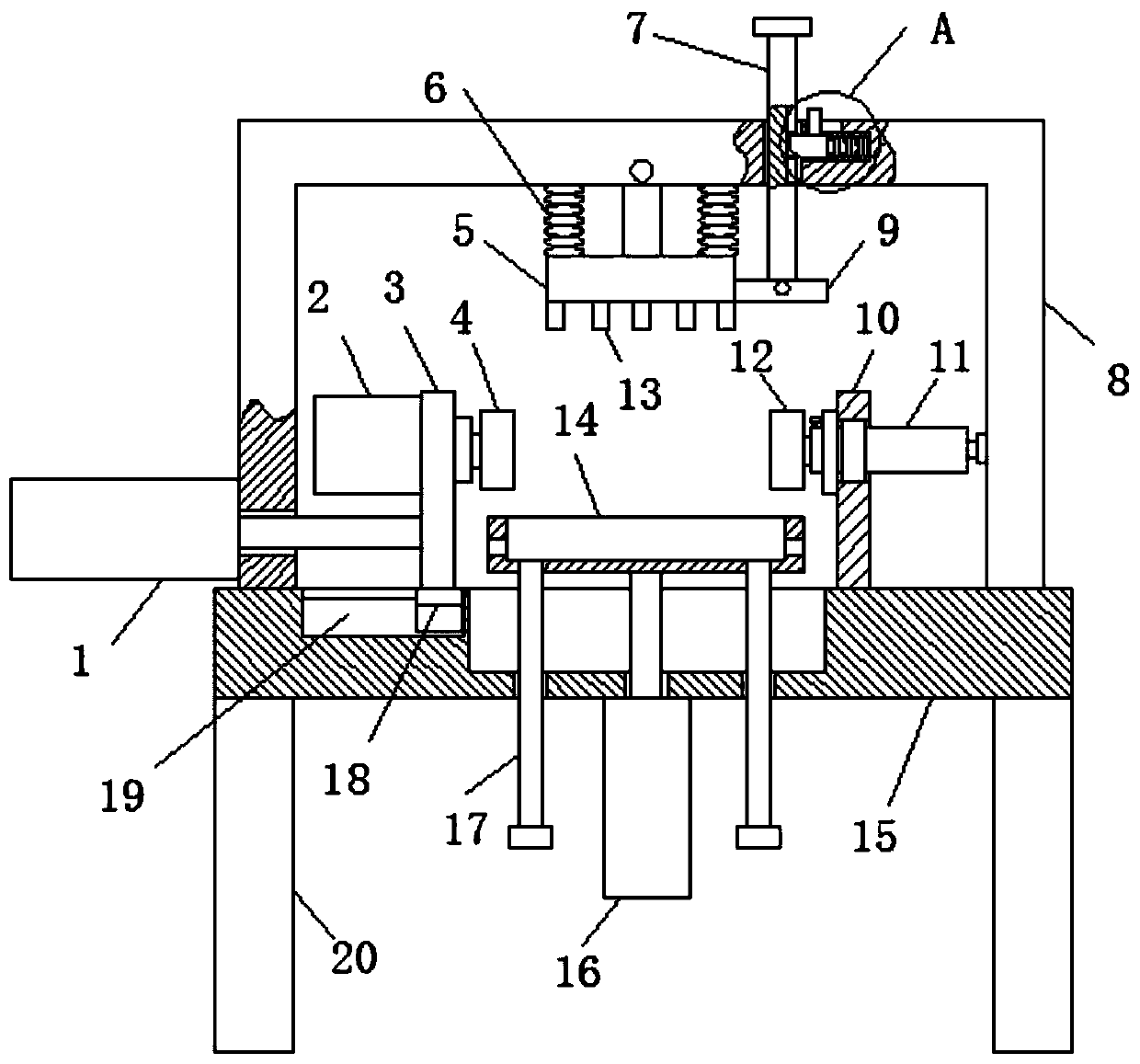

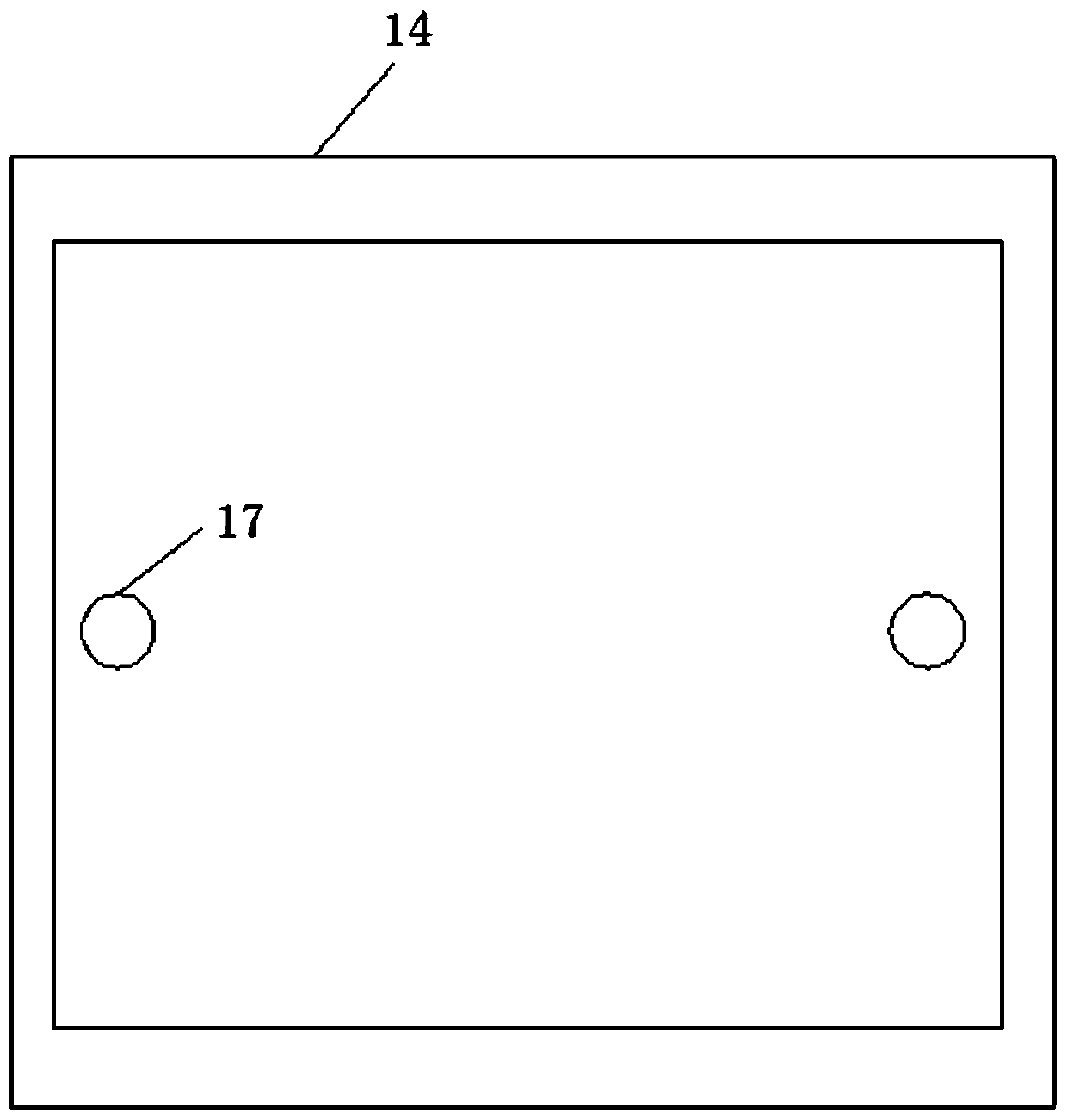

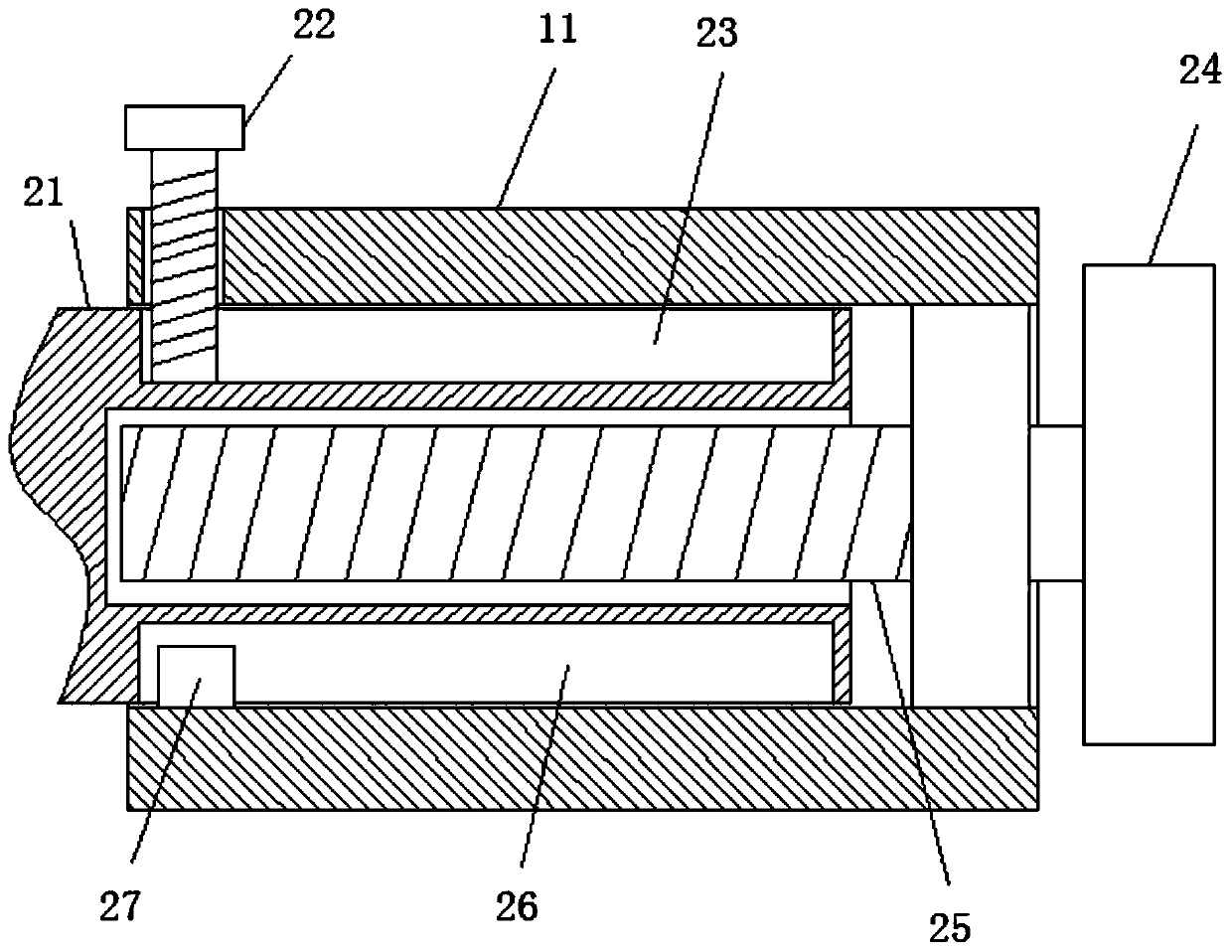

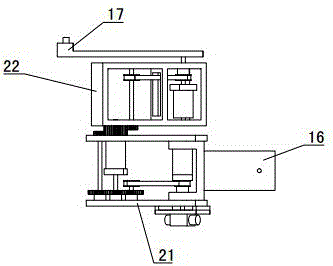

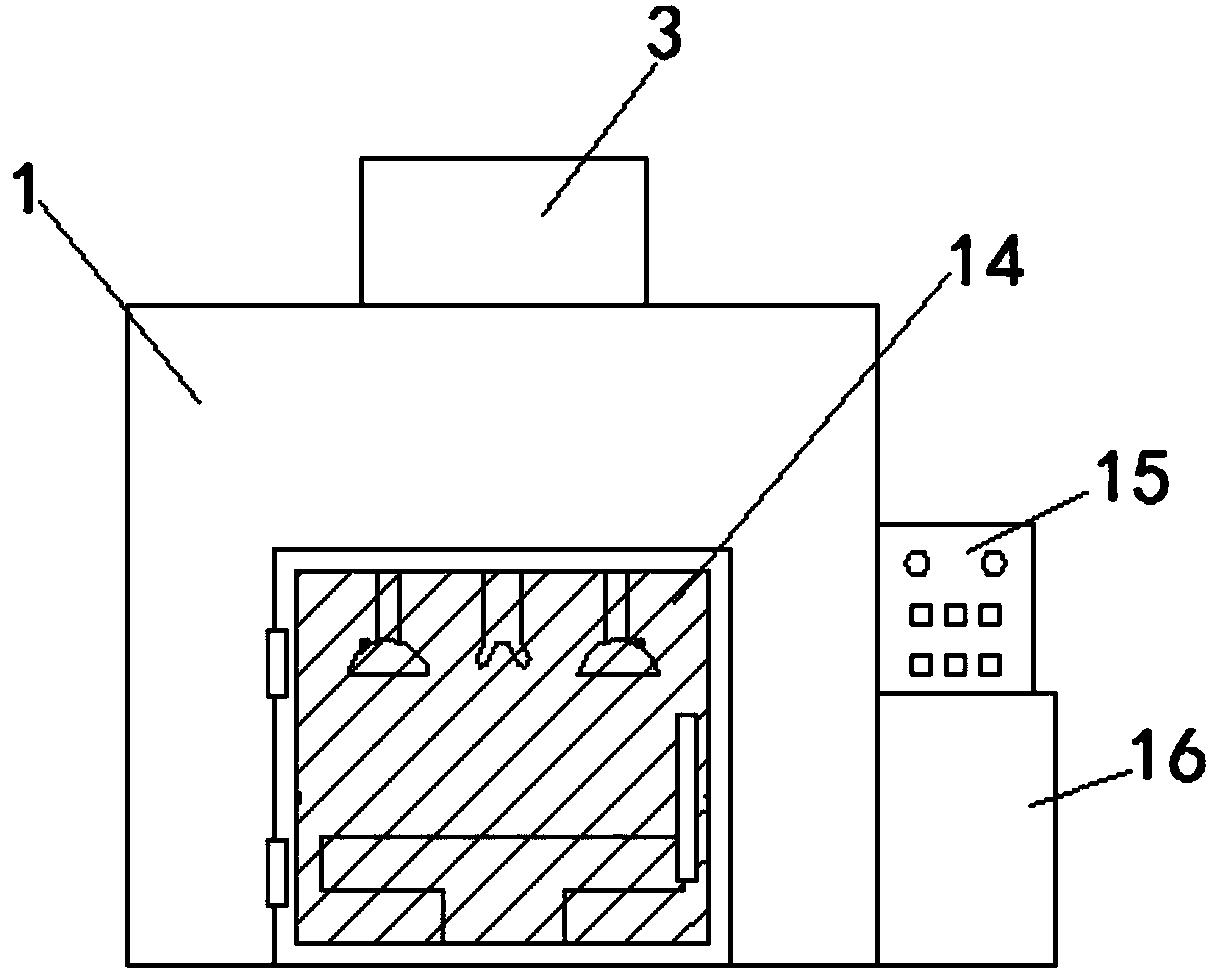

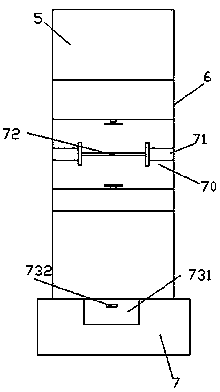

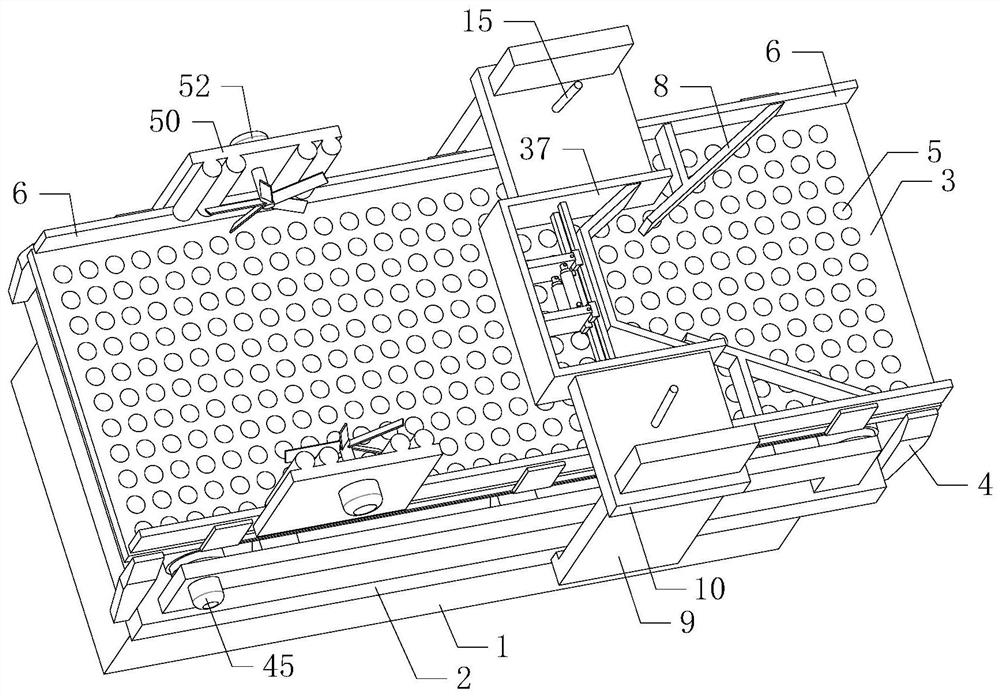

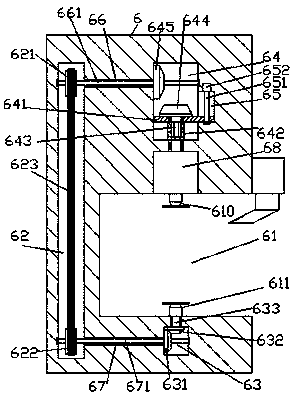

Paint spraying device for hardware product door handle

InactiveCN107626513AFast dryingFast painting speedLiquid spraying apparatusSpray boothsEngineeringMechanical engineering

The invention relates to a paint spraying device, in particular to the paint spraying device for a hardware product door handle. The technical effect of providing the paint spraying device which savesboth time and labour, is high in paint spraying speed and is capable of purifying the smell of the paint in the process of painting for the hardware product door handle is achieved. In order to achieve the technical effect, the paint spraying device for the hardware product door handle is provided by the invention, and the paint spraying device comprises supporting legs and the like. The front and rear sides of the upper portions of the inner side surfaces of the left and right supporting legs are symmetrically provided with horizontal plates, and a conveying device is arranged between the front horizontal plate and the rear horizontal plate. The position, on the left sides of the tops of the horizontal plates, between the front horizontal plate and the rear horizontal plate is provided with the paint spraying device, and a paint spraying component of the paint spraying device is located above the conveying device. According to the paint spraying device for the hardware product door handle, the smell of the paint in the process of painting can be filtered by a filtering device, the paint on the door handle can be dried by a drying device, the drying speed of the paint is increased, and the effects that both time and labour are saved, the paint spraying speed is high and the smell of the paint in the process of painting can be purified are achieved.

Owner:肇庆市威泰五金企业有限公司

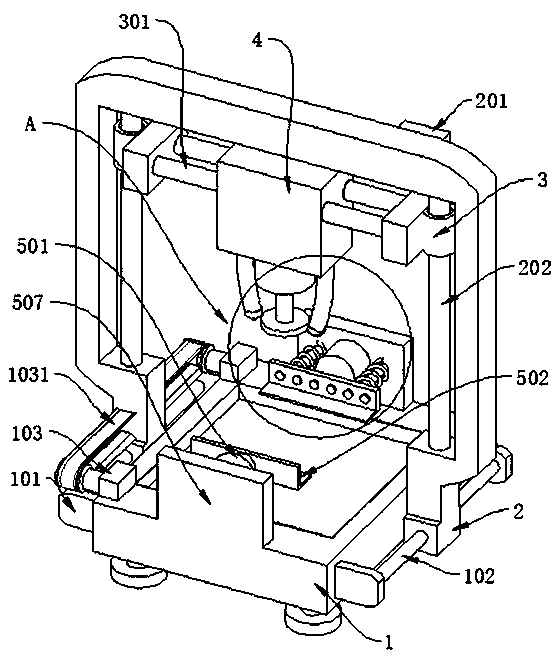

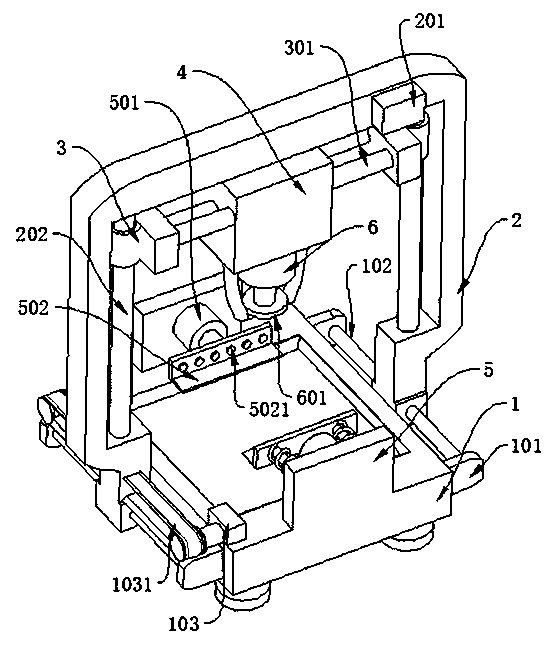

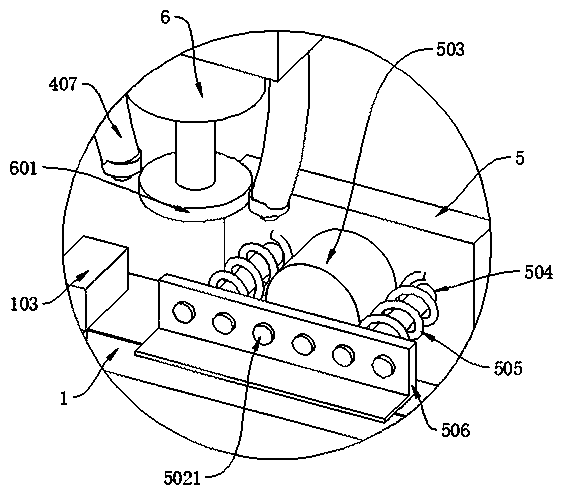

Paint spraying device for processing of high-voltage distribution box

InactiveCN109201397AEasy to paintEasy to dryLiquid spraying apparatusSpray boothsSpray nozzleEngineering

The invention discloses a paint spraying device for processing of a high-voltage distribution box, which comprises a base. The top of the base is provided with a box body and a paint pump; the inner bottom wall of the box body is provided with a stirring barrel; the box body is internally welded with a horizontal partition plate; the top of the partition plate is provided with an annular collecting groove, a rotating motor, a lifting motor and a limiting rod; the output shaft of the rotating motor is connected with a rotating shaft; a circular platform is welded on the rotating shaft; the output shaft of the lifting motor is connected with a vertical threaded rod; a moving block is in threaded sleeving connection on the threaded rod; a spraying nozzle is arranged on the moving block; and the box body is internally provided with a heating plate. The paint spraying speed is quick, drying is easy, the paint can be recovered and used, the working efficiency is effectively improved, and thecost is saved.

Owner:浙江亚鼎科技有限公司

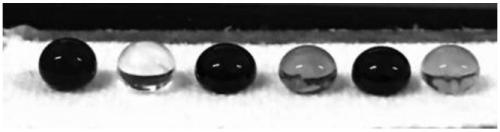

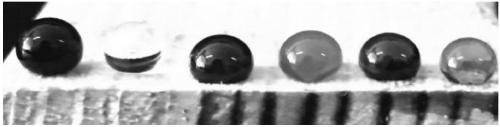

Preparation method of super-amphiphobic long-lived coating of waterborne system

ActiveCN109233482AExcellent superhydrophobicityImprove self-cleaning effectAnti-corrosive paintsPolymer scienceNanoparticle

The invention provides a preparation method of a super-amphiphobic long-lived coating of a waterborne system. The method comprises the following steps: placing a seed emulsion into a vessel, adding fluoroalkyl silane and a surfactant, and carrying out stirring at room temperature for 0.5-1 h; next, carrying out dispersion in water to obtain an emulsion; then, spraying the emulsion on the surface of a base material, wherein the spraying thickness is 200-800 nm; and then, carrying out heating at 125-135 DEG C for 0.5-2 h to obtain the super-amphiphobic coating. The super-amphiphobic coating is directly prepared from an industrial product emulsion; and compared with a method in which nanoparticles are used, the preparation method is simple in operation, and the prepared super-amphiphobic coating is better in dispersion and stable in performance.

Owner:HEBEI UNIV OF TECH

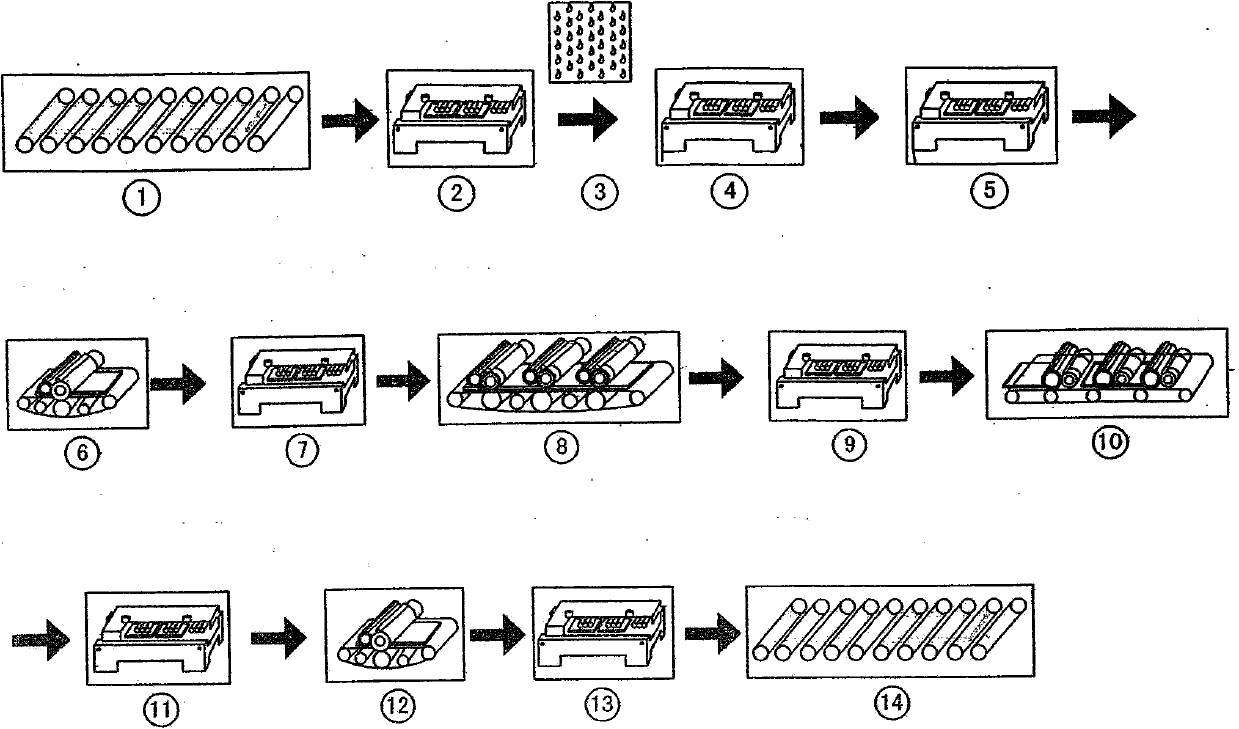

Novel paint spraying equipment for steel pipes

PendingCN109433466AImprove spraying effectColor seams are straight and beautifulSpraying apparatusEngineeringMechanical engineering

The invention discloses novel paint spraying equipment for steel pipes. The equipment comprises a workbench; a plurality of the steel pipes are laid on the workbench in parallel; the equipment furthercomprises a moving mechanism I moving in the axial direction of the steel pipes and a moving mechanism II moving in the radial direction of the steel pipes; and a paint spraying gun is arranged on the moving mechanism I or the moving mechanism II and is driven to move in the axial direction and the radial direction of the steel pipes through cooperation with the moving mechanism I or the moving mechanism II. The equipment is applicable to spraying of the steel pipes with two colors alternating with each other and is the efficient and automatic paint spraying equipment capable of meeting requirements of the steel pipes with the two colors alternating with each other.

Owner:CHINA NUCLEAR IND 24 CONSTR

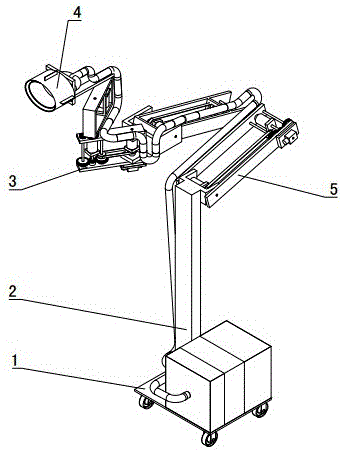

Automatic paint spraying device

ActiveCN105772299AGuaranteed paint effectExtended range of movementSpraying apparatusEngineeringMechanical engineering

Owner:淄博奧冠交通科技有限公司

Multi-angle paint spraying device for production of wooden products

PendingCN109332068ACreate pollutionEasy to cleanLiquid spraying apparatusSpray boothsWastewaterEngineering

The invention discloses a multi-angle paint spraying device for production of wooden products. The multi-angle paint spraying device for production of the wooden products comprises a paint spraying booth and a door spindle; a discharge outlet is formed in the lower end of the paint spraying booth; a discharge pipe is arranged at the lower end of the discharge outlet; a heating pipe is inlaid at the lower end of the front side of the paint spraying booth; the lower end of the left side of the paint spraying booth is connected with a paint tank which is internally provided with a booster pump; apaint pipe is fixed to the upper end of the booster pump; a sliding track is arranged at the upper end of the interior of the paint spraying booth; a sliding block is arranged on the left side of thefront side of the sliding track; and a paint spraying valve is inlaid at the lower end of the sliding block. According to the multi-angle paint spraying device for production of the wooden products,the paint spraying booth is arranged, mesh holes are formed in the lower end of the paint spraying booth, waste paint generated in the paint spraying process can permeate through the mesh holes, wastewater can also permeate into the discharge pipe via the mesh holes when the interior is cleaned, and therefore, both the waste paint and the waste water can be discharged and treated in a unified way.

Owner:湖州南浔蚕乡原牧食品有限公司

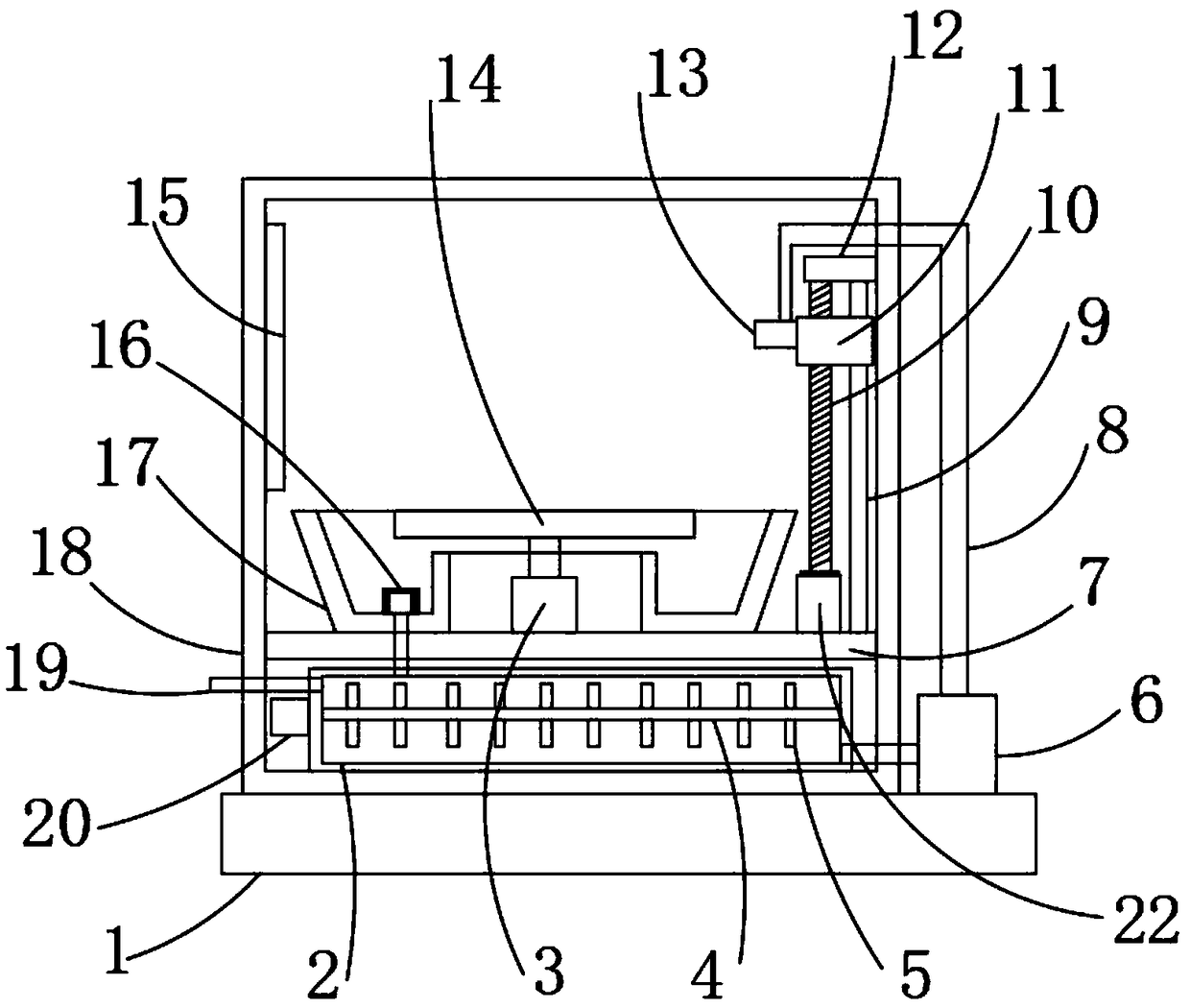

Plate paint-spraying device for building engineering decoration

ActiveCN109015236AStir wellFast painting speedSpraying apparatusGrinding machinesMotor driveArchitectural engineering

The invention discloses a plate paint-spraying device for building engineering decoration and belongs to the field of paint-spraying devices. The plate paint-spraying device for building engineering decoration comprises a base, a supporting frame and a controller. The supporting frame is slidably connected to the top of the base, a paint-spraying box is slidably connected to the supporting frame,the top of the paint-spraying box is connected with a first motor, the output end of the first motor is connected with stirring blades, and the stirring blades are located in the paint-spraying box. The inner wall of the paint-spraying box is in sealing connection with an arc-shaped plate, the bottom of the arc-shaped plate is connected with a water pump, and the water pump is connected with symmetrical paint-spraying pipes through pipelines. The bottom of the paint-spraying box is connected with a second motor, and the output end of the second motor is connected with a polishing disc. The topof the base is connected with a clamping mechanism. The first motor drives the stirring blades to stir in the paint-spraying box, so that paint is stirred uniformly, the paint is pumped through the water pump after polishing, and then a plate is sprayed with the paint through the paint-spraying pipes.

Owner:浙江湖科知识产权服务有限公司

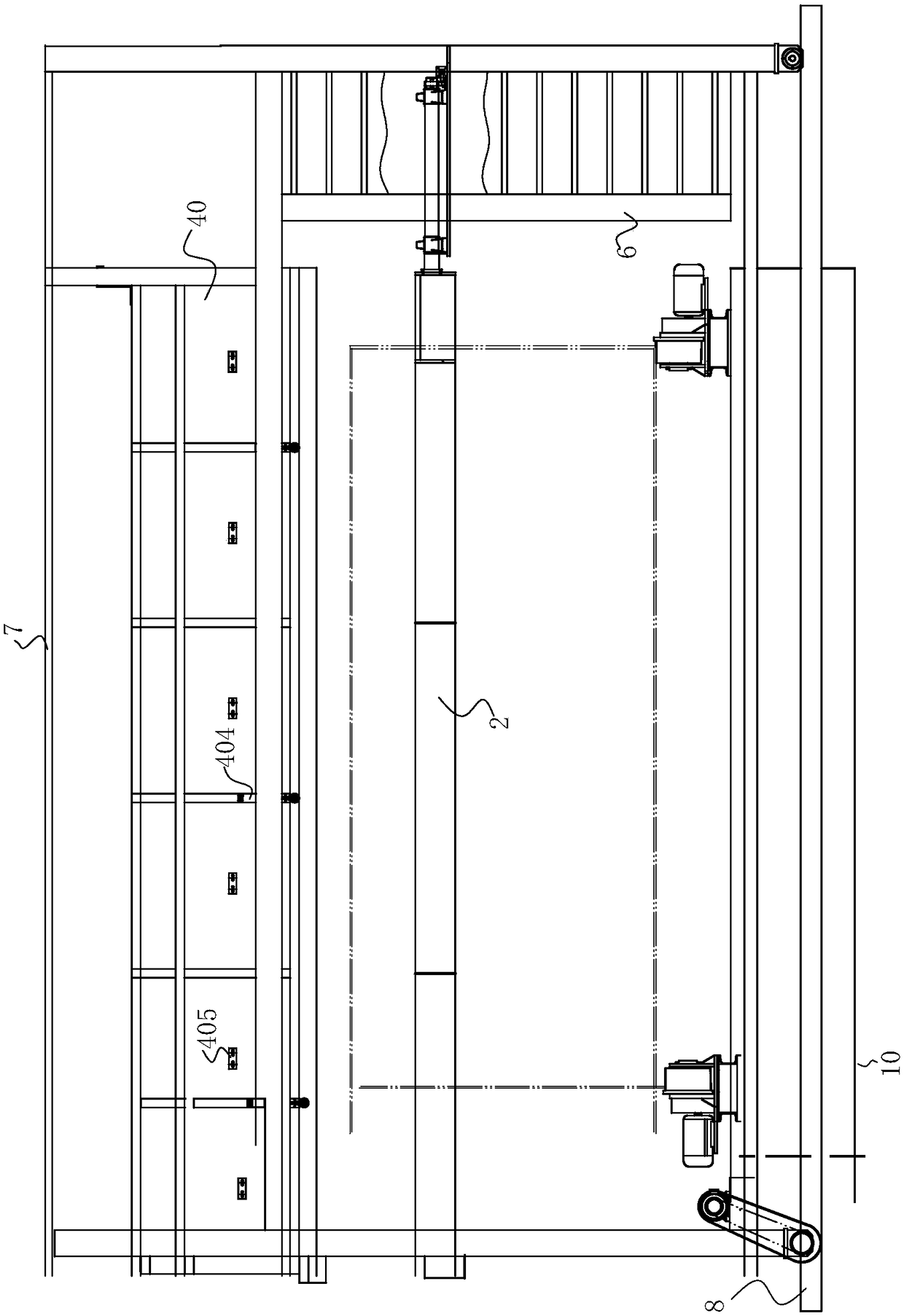

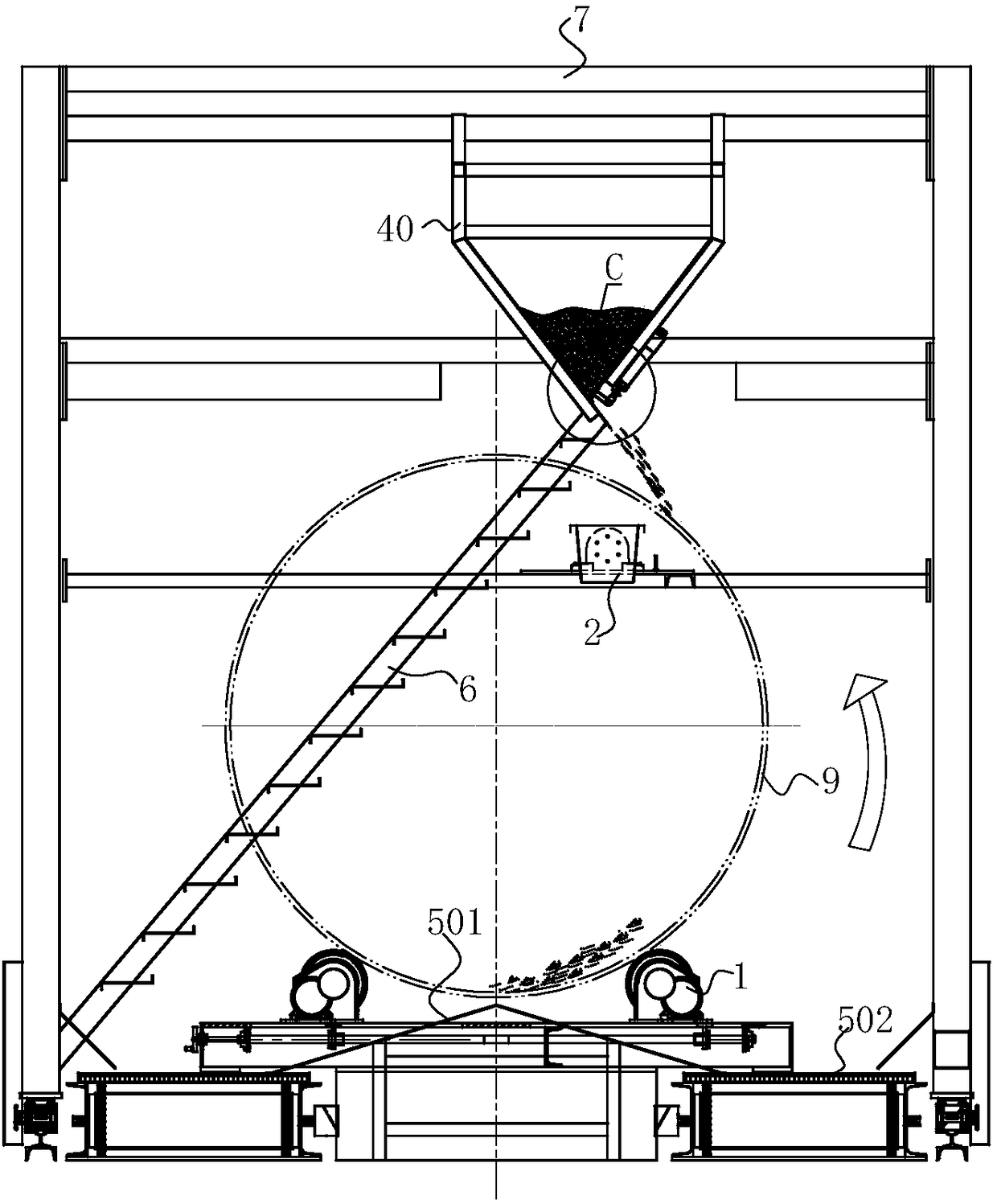

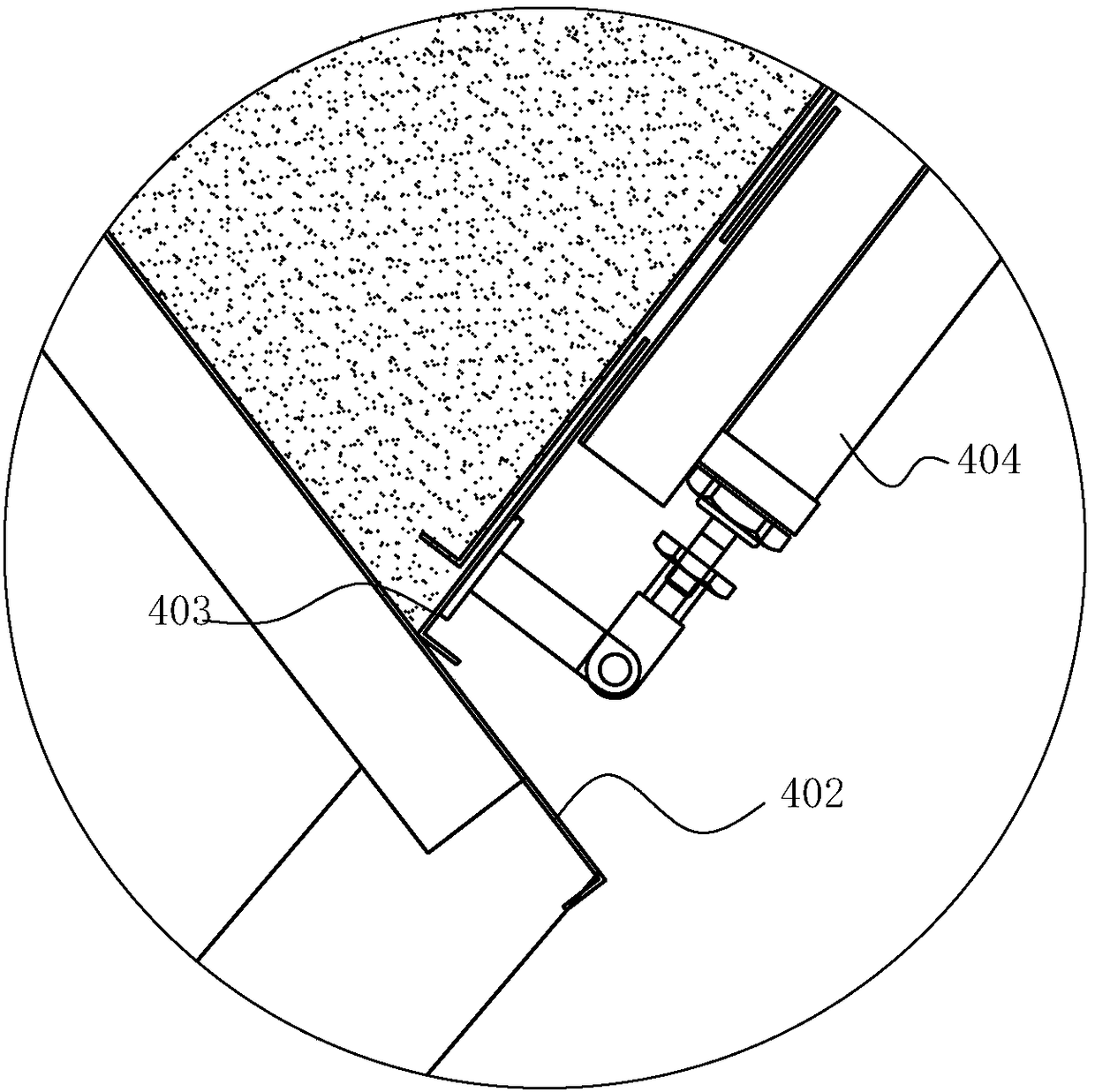

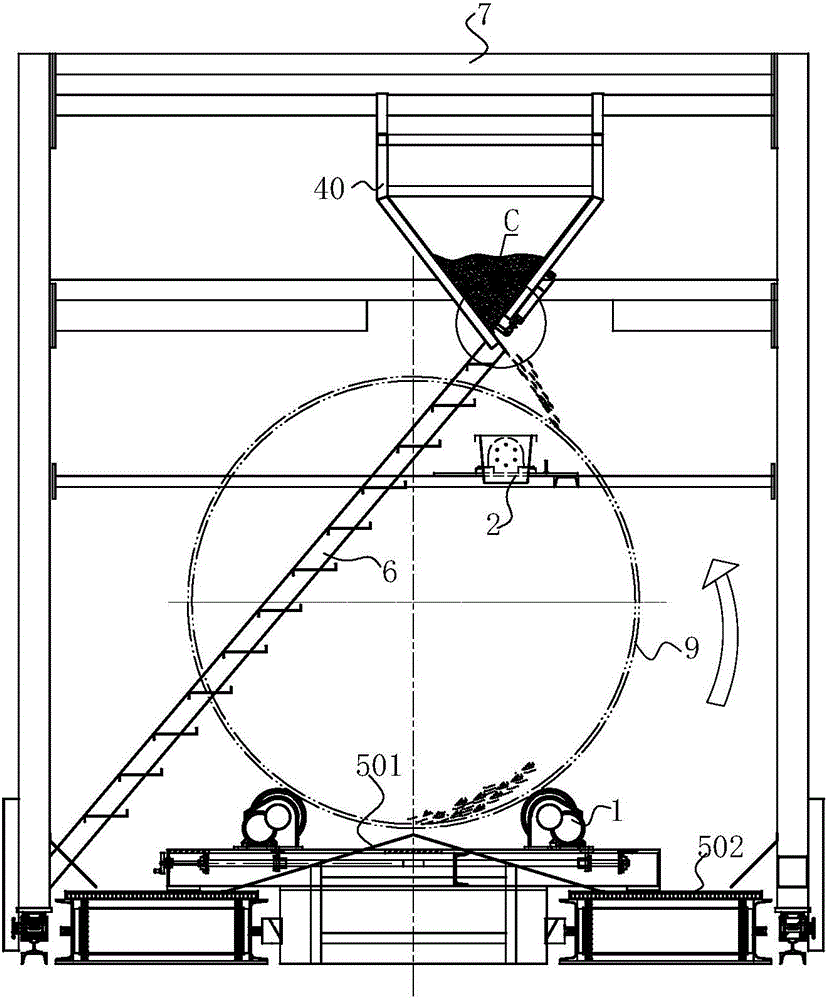

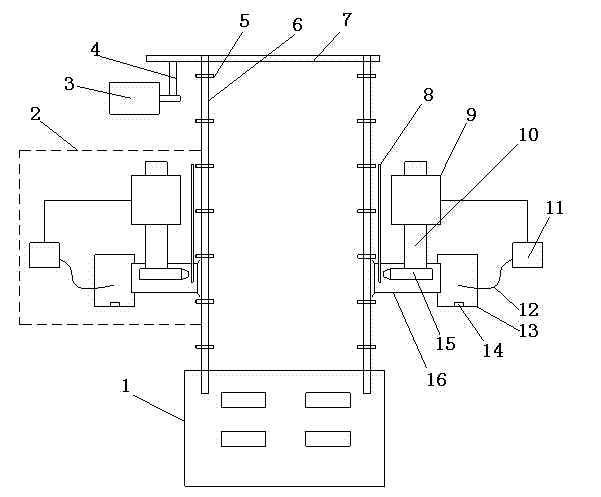

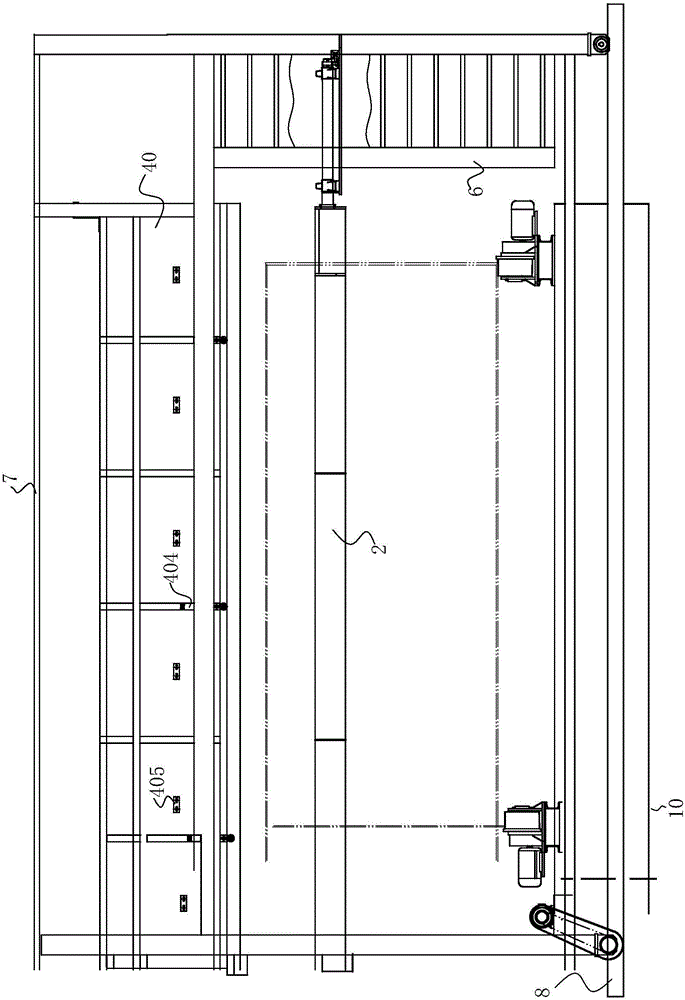

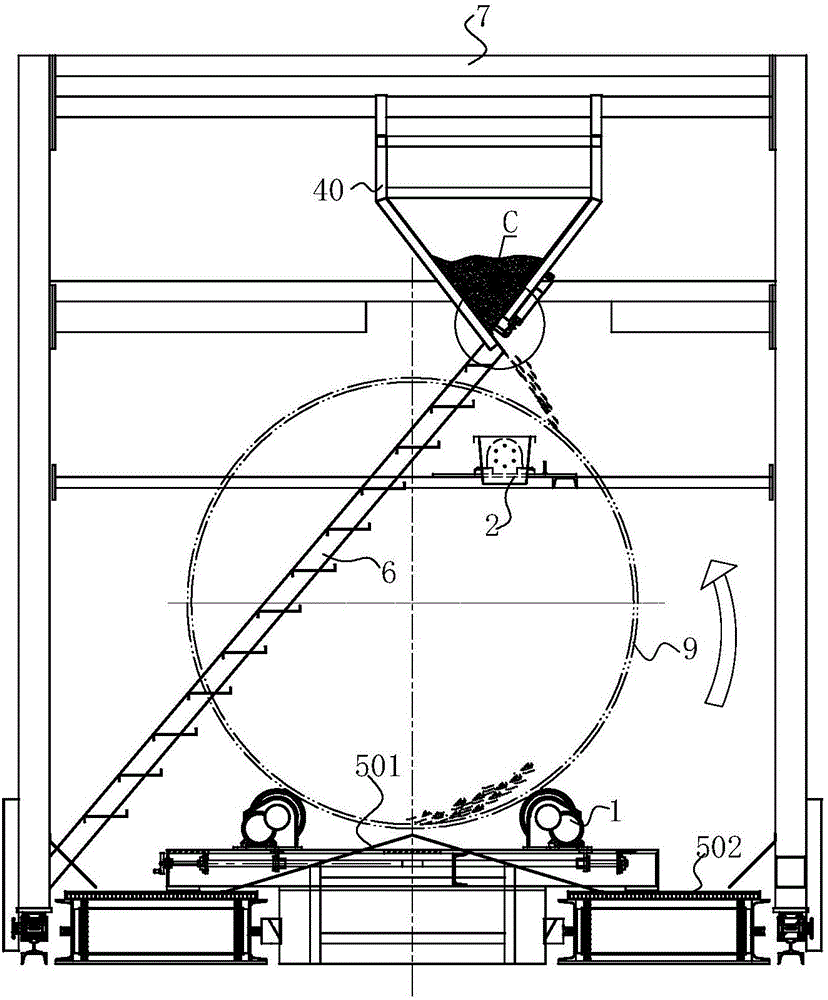

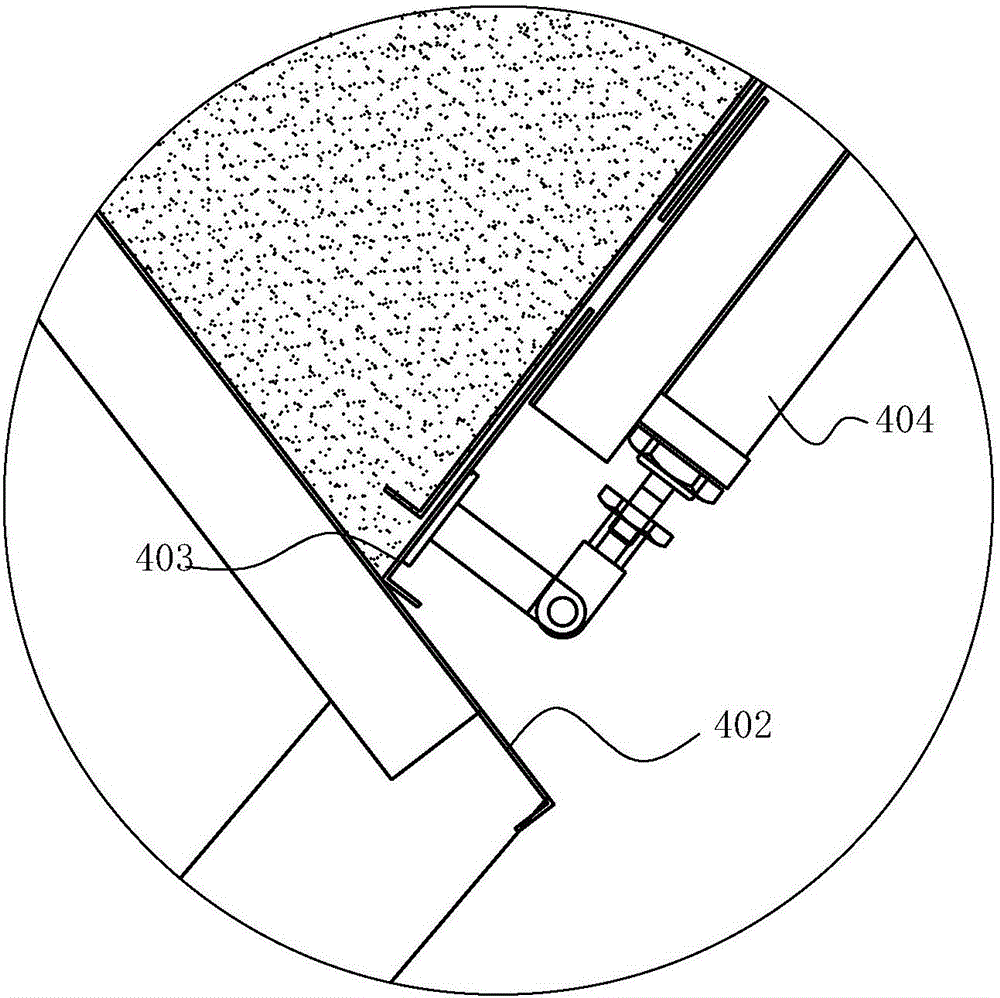

Large diameter steel pipe plastic coating equipment

The invention discloses a plastic coating device for a large-diameter steel pipe. The plastic coating device for the large-diameter steel pipe comprises a base frame. The base frame is provided with steel pipe rotating devices. A guide rail is arranged and parallel to the rotation axis of the steel pipe borne by the steel pipe rotating devices. Walking frames driven by a power device are arranged on the guide rail. The walking frame is provided with external plastic coating device bodies and internal plastic coating device bodies. Each internal plastic coating device body is located below the corresponding external plastic coating device body. Each external plastic coating device body comprises a powder material groove. The powder material grooves are fixed to the walking frames. Valve plates driven by the power device are arranged at feeding openings of the powder material grooves. Each internal plastic coating device body comprises a material overturning shaft. The material overturning shafts are rotationally installed on the walking frames. One end of each material overturning shaft is connected with an overturning drive mechanism. The other ends of the material overturning shafts are fixedly connected with material overturning hoppers capable of axially extending into the steel pipe. The plastic coating device can conduct internal plastic coating and external plastic coating on the large-diameter steel pipe at the same time and is high in coating speed, the coatings on the steel pipe are uniform, and the powder recovery rate is high.

Owner:高密天一机械科技有限公司

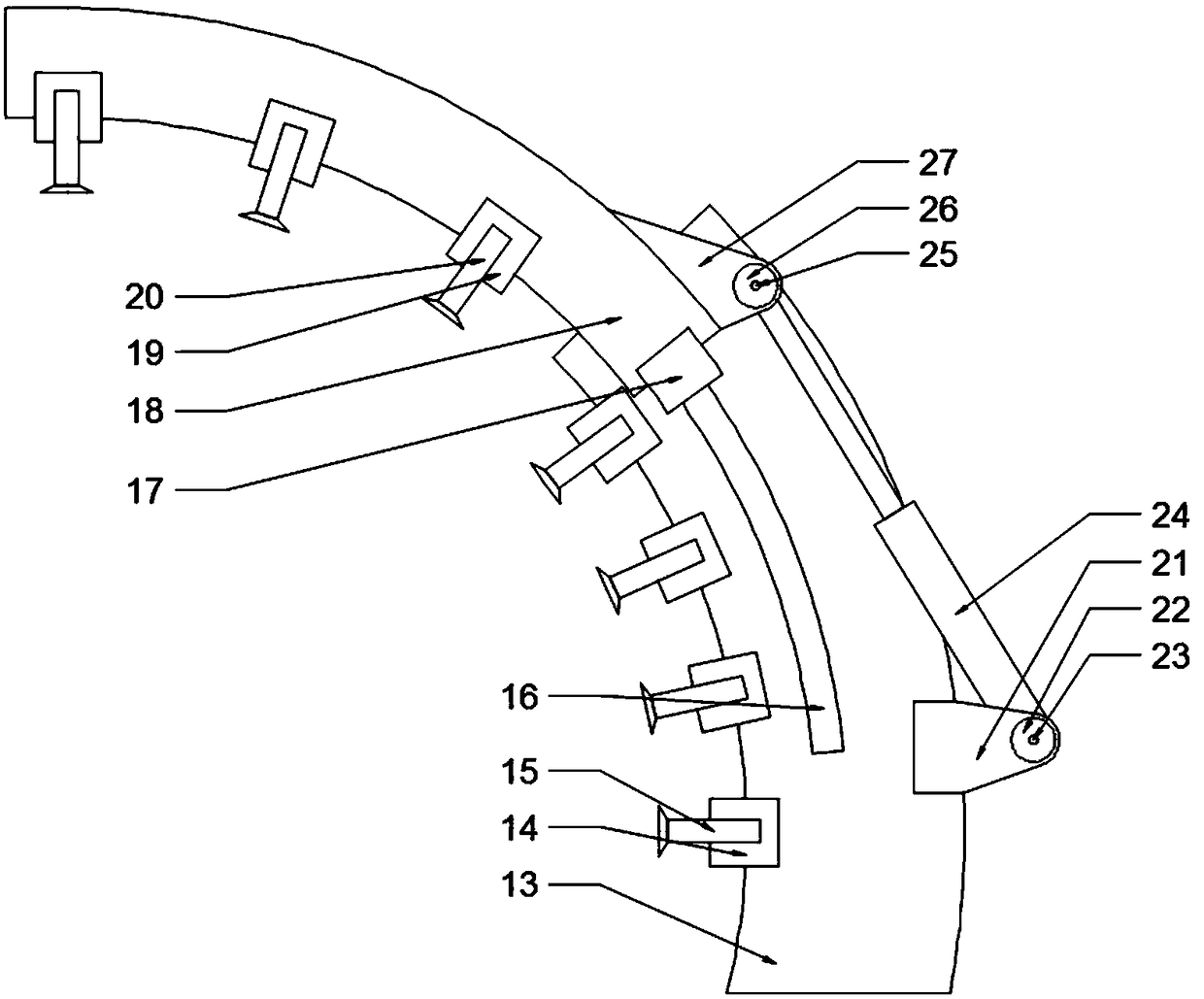

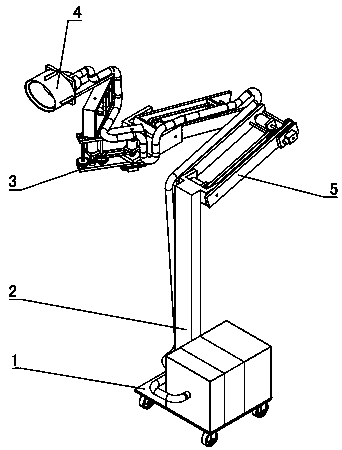

All-direction paint spraying device

ActiveCN108686848AFast painting speedLiquid spraying apparatusSpray boothsProtection mechanismLinear motor

The invention discloses an all-direction paint spraying device. The all-direction paint spraying device comprises a base, wherein the base is located above the ground; a rotating mechanism is arrangedon the base; an arc-shaped paint spraying mechanism is arranged above the rotating mechanism; a protection mechanism and a material conveying mechanism are arranged on the base; a controller and a battery box are respectively arranged on the base; a power input end of the controller is electrically connected with a power output end of the battery box; a power output end of the controller is electrically connected with a rotary movable stepping motor, an electronic compass sensor, fixed arm paint spraying heads, upper arm paint spraying heads, an upper arm movable linear motor and the materialconveying mechanism respectively; a signal output end of the controller is electrically connected with the rotary movable stepping motor, the fixed arm paint spraying heads, the upper arm paint spraying heads, the upper arm movable linear motor and the material conveying mechanism respectively; a signal input end of the controller is electrically connected with the electronic compass sensor. Theall-direction paint spraying device has the advantages of simple structure and high practicability.

Owner:DERRY FURNITURE CO LTD

Plastic coating device for large-diameter steel pipe

The invention discloses a plastic coating device for a large-diameter steel pipe. The plastic coating device for the large-diameter steel pipe comprises a base frame. The base frame is provided with steel pipe rotating devices. A guide rail is arranged and parallel to the rotation axis of the steel pipe borne by the steel pipe rotating devices. Walking frames driven by a power device are arranged on the guide rail. The walking frame is provided with external plastic coating device bodies and internal plastic coating device bodies. Each internal plastic coating device body is located below the corresponding external plastic coating device body. Each external plastic coating device body comprises a powder material groove. The powder material grooves are fixed to the walking frames. Valve plates driven by the power device are arranged at feeding openings of the powder material grooves. Each internal plastic coating device body comprises a material overturning shaft. The material overturning shafts are rotationally installed on the walking frames. One end of each material overturning shaft is connected with an overturning drive mechanism. The other ends of the material overturning shafts are fixedly connected with material overturning hoppers capable of axially extending into the steel pipe. The plastic coating device can conduct internal plastic coating and external plastic coating on the large-diameter steel pipe at the same time and is high in coating speed, the coatings on the steel pipe are uniform, and the powder recovery rate is high.

Owner:高密天一机械科技有限公司

An industrial steel pipe surface painting equipment

The invention relates to paint spraying equipment, in particular to industrial paint spraying equipment for the surface of a steel pipe. According to the industrial paint spraying equipment for the surface of the steel pipe, paint spraying is comprehensive, the paint spraying speed is high, and harm to workers in the paint spraying process is small. The industrial paint spraying equipment for the surface of the steel pipe comprises a base plate, supporting plates, a driving wheel, a driven wheel, a first sliding rail, a first sliding block and the like. The supporting plates are symmetrically mounted at the left end and the right end of the base plate in a welded mode. The driving wheel is rotatably connected to the front side of the lower portion of the supporting plate on the right side. The driven wheel is rotatably connected to the front side of the lower portion of the left supporting plate. The first sliding rail is connected between the supporting plates on the left side and the right side in a welded mode. By adoption of the paint spraying equipment, the effects of comprehensive paint spraying, high paint spraying speed, and little harm to the workers in the paint spraying process are achieved.

Owner:江苏新大高空工程有限公司

Hardware plate quick paint spraying device

The invention discloses a hardware plate quick paint spraying device. The hardware plate quick paint spraying device comprises a paint spraying bin; a motor is arranged at the top of the paint spraying bin; a power output end of the motor penetrates through the paint spraying bin, and is connected with a connecting rod; the bottom of the connecting rod is fixedly connected with a fixed plate; an upper paint spraying machine is arranged at the middle part of the bottom surface of the fixed plate; push rods are arranged on the two sides of the fixed plate; extension rods are arranged on the lower sides of the push rods; suckers are connected to the bottoms of the extension rods; and electromagnetic valves are arranged at the tops of the suckers. Plates are sucked through the suckers; the bottom surfaces and the peripheries of the plates are firstly painted; after painting, the plates are put down; then, the top surfaces of the plates are painted; the painting speed is high; in the painting process, the motor is used for driving the plates to rotate; the plates is painted during rotating, so that the painting uniformity degree is high; and the hardware plate quick paint spraying device is simple in structure and convenient to use, and can improve the painting efficiency.

Owner:FOSHAN JIEYA PLASTIC HARDWARE PROD CO LTD

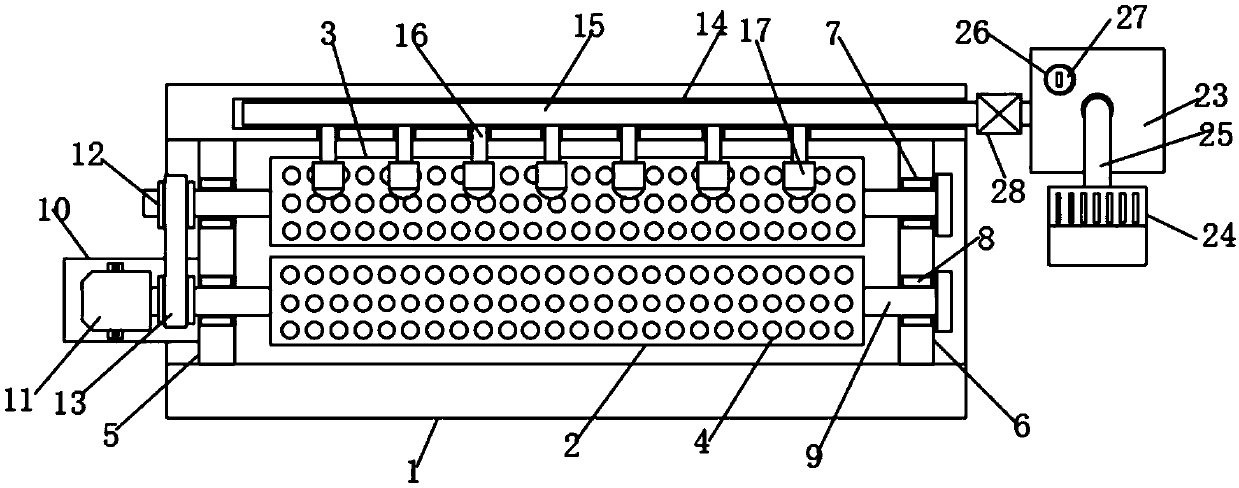

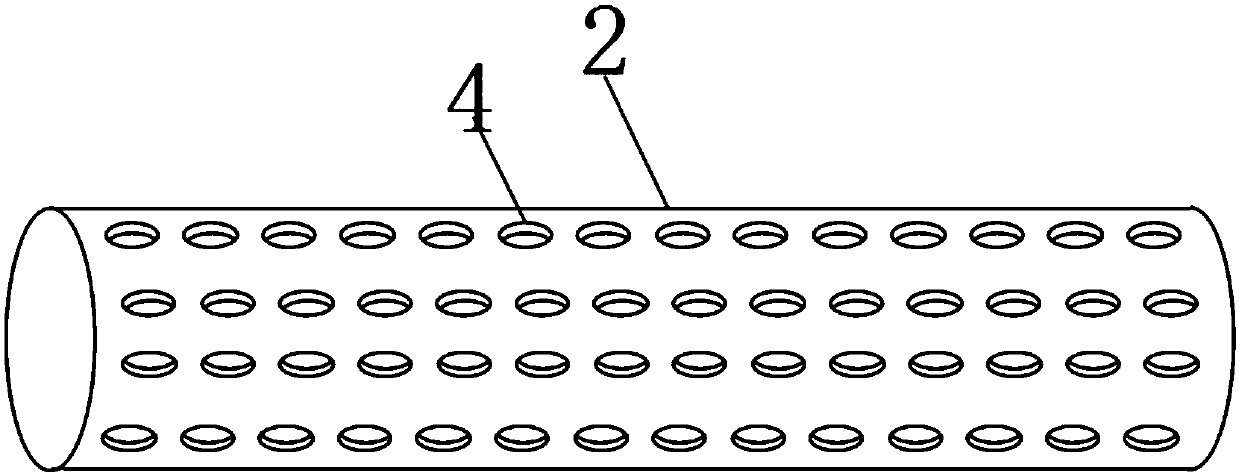

Pneumatic paint-spraying equipment for round steel

The invention discloses pneumatic paint-spraying equipment for round steel. The pneumatic paint-spraying equipment for the round steel comprises a U-shaped installation plate, wherein a first hollow roller and a second hollow roller are transversally arranged in a U-shaped groove of the U-shaped installation plate; a drive motor is fixedly installed on the upper surface of a motor installation plate; a plurality of groups of paint leakage holes are formed in the first hollow roller and the second hollow roller separately; a pneumatic gas compressor is arranged at the other side of a paint storage box; a gas inlet pipe is connected to the pneumatic gas compressor; one end away from the pneumatic gas compressor, of the gas inlet pipe, is connected to the middle part of the upper end of the paint storage box; and a waste box is arranged at the lower end of the U-shaped groove of the U-shaped installation plate. The pneumatic paint-spraying equipment for the round steel is capable of carrying out paint spraying on a plurality of pieces of the round steel in one process, and the paint-spraying speed can be increased due to rotary paint spraying, so that more uniform paint spraying and good coloring effect are achieved, and the paint-spraying efficiency is greatly increased; and moreover, recovery treatment is easily carried out on the excessively-sprayed paint, and the pneumatic paint-spraying equipment for the round steel is energy-saving and environment-friendly, high in practicability, and beneficial to popularization.

Owner:盐城唯宏特通用机械有限公司

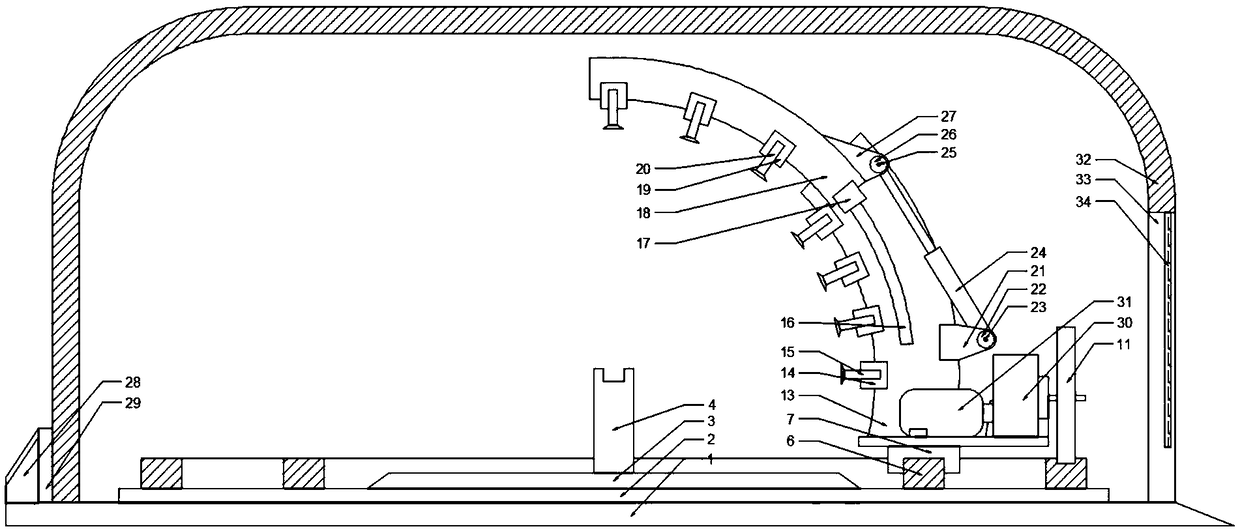

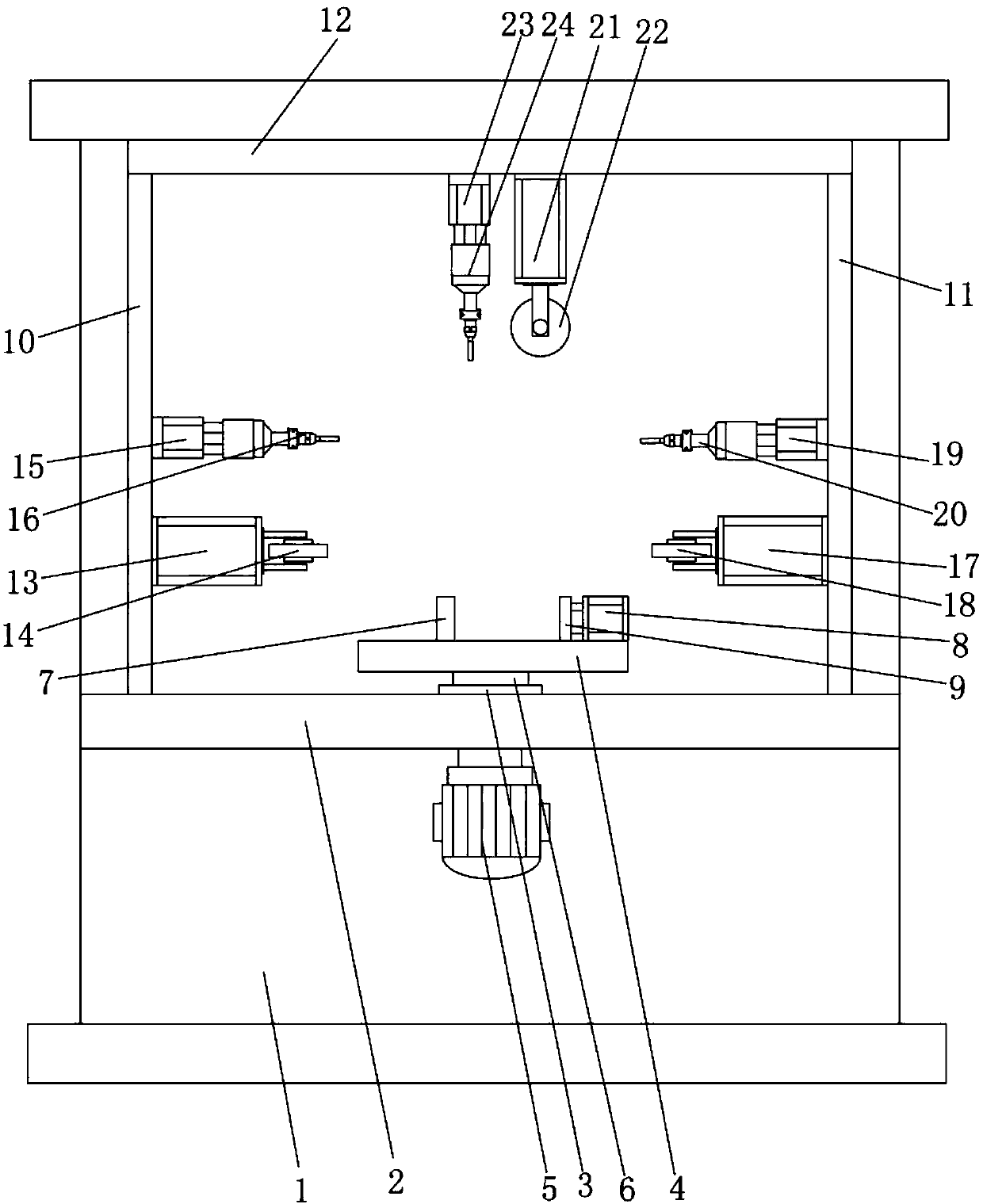

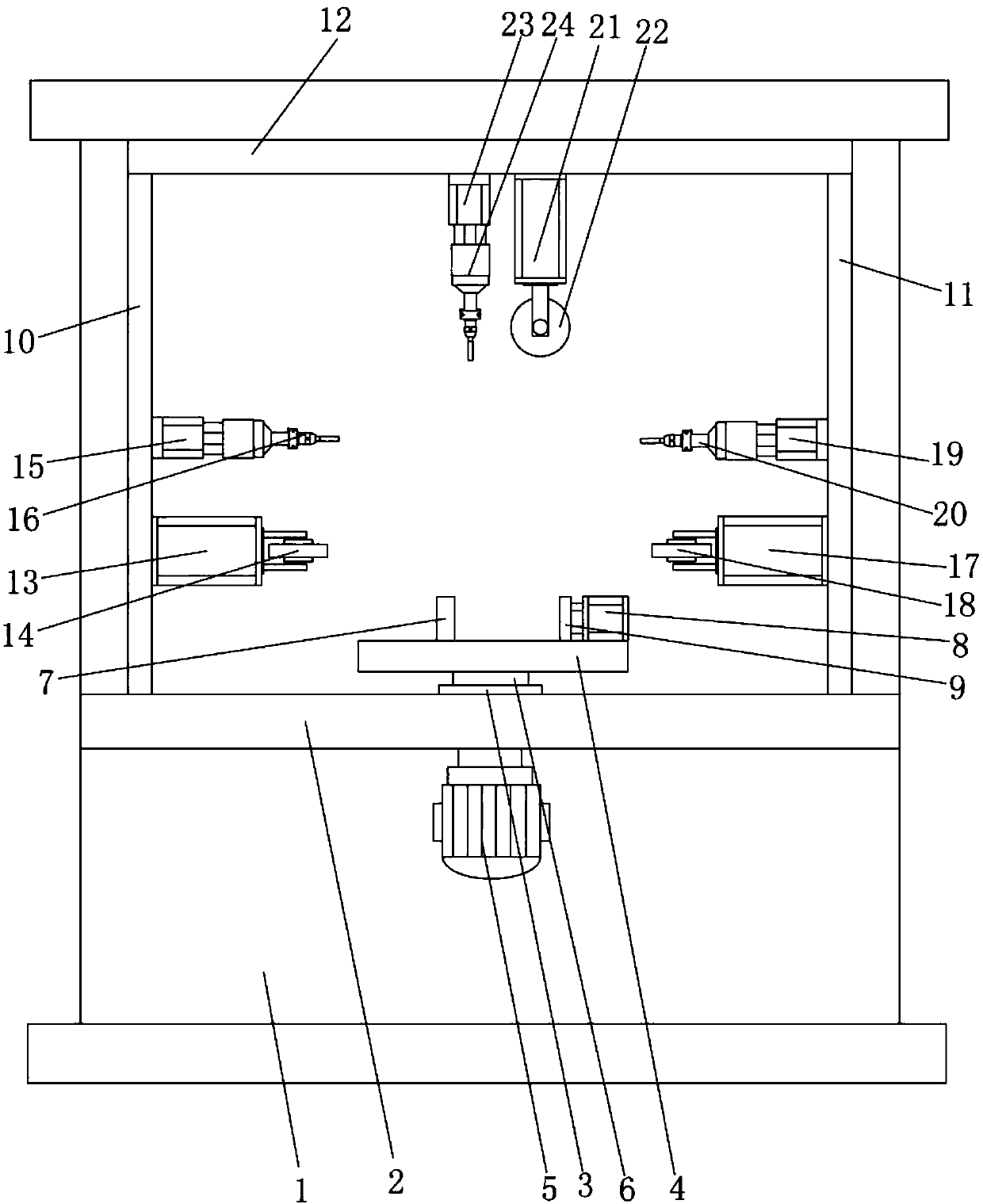

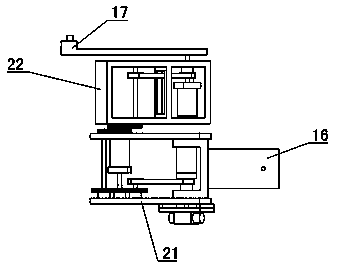

Automatic paint spraying equipment

InactiveCN109955119ASimple structureReduce manufacturing costSpraying apparatusGrinding machinesEngineeringAir compressor

The invention belongs to the field of air compressor production equipment and particularly relates to automatic paint spraying equipment. The automatic paint spraying equipment is characterized in that a motor is located below a machine frame table; one end of a rotary shaft is connected with the motor and the other end of the rotary shaft is connected with a rotary seat; a limiting plate is fixedto the position above the rotary seat; a clamping plate air cylinder is connected with a clamping plate; a first lateral polishing wheel air cylinder is connected with a first lateral polishing wheel; a first lateral paint spraying gun air cylinder is connected with a first lateral paint spraying gun; a second lateral polishing wheel air cylinder is connected with a second lateral polishing wheel; a second lateral paint spraying gun air cylinder is connected with a second lateral paint spraying gun; an upper polishing wheel air cylinder and an upper paint spraying gun air cylinder are mountedon an upper sliding guide rail; the upper polishing wheel air cylinder is connected with an upper polishing wheel; the upper paint spraying gun air cylinder is connected with an upper paint sprayinggun; and the upper polishing wheel and the upper paint spraying gun are located above the rotary seat.

Owner:天津双合盛自行车有限公司

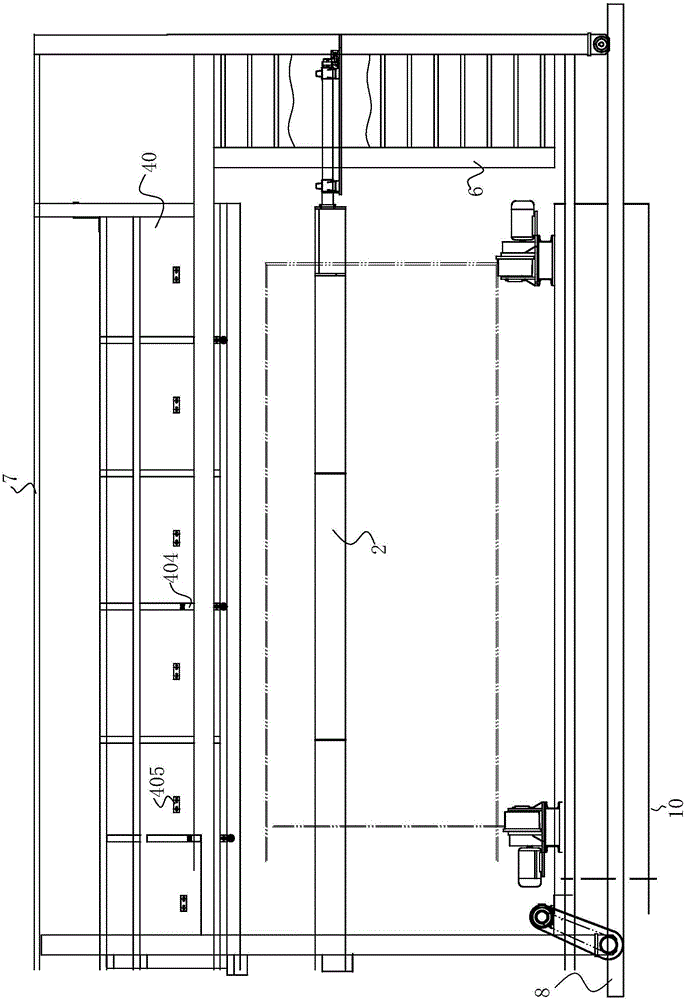

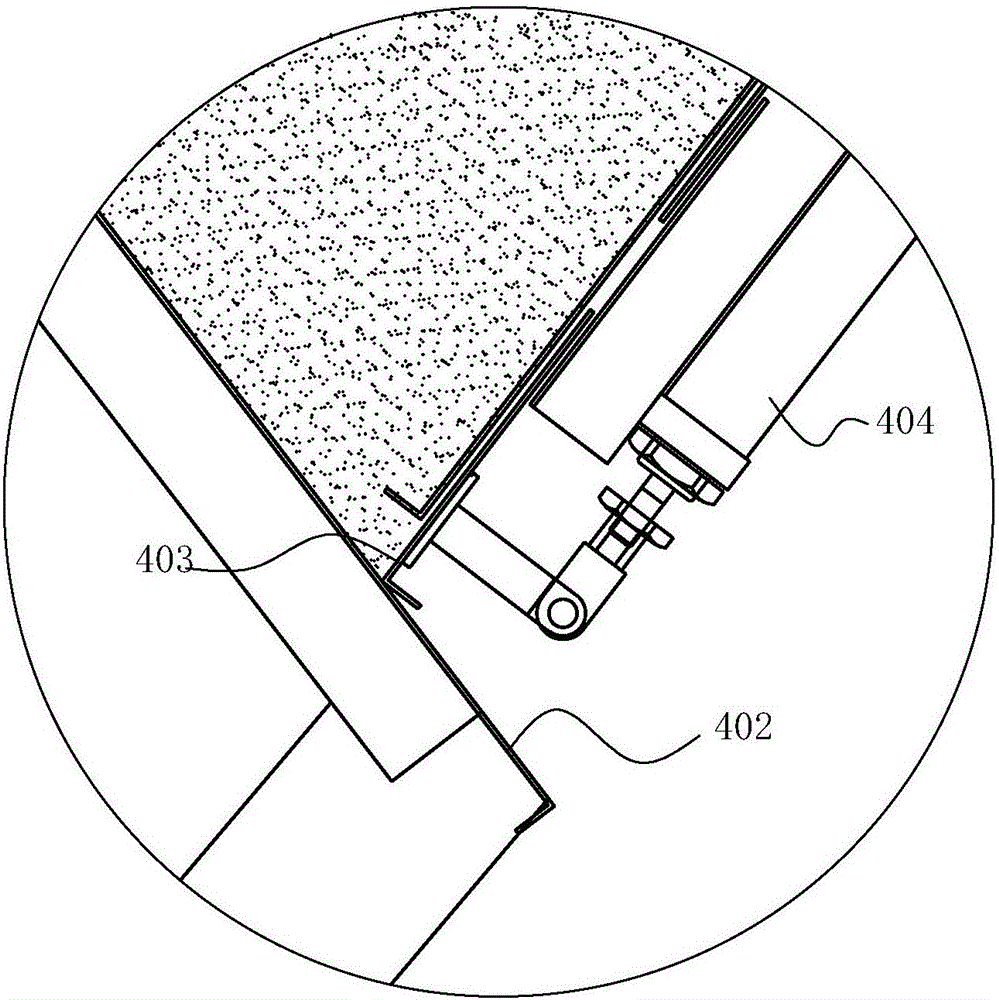

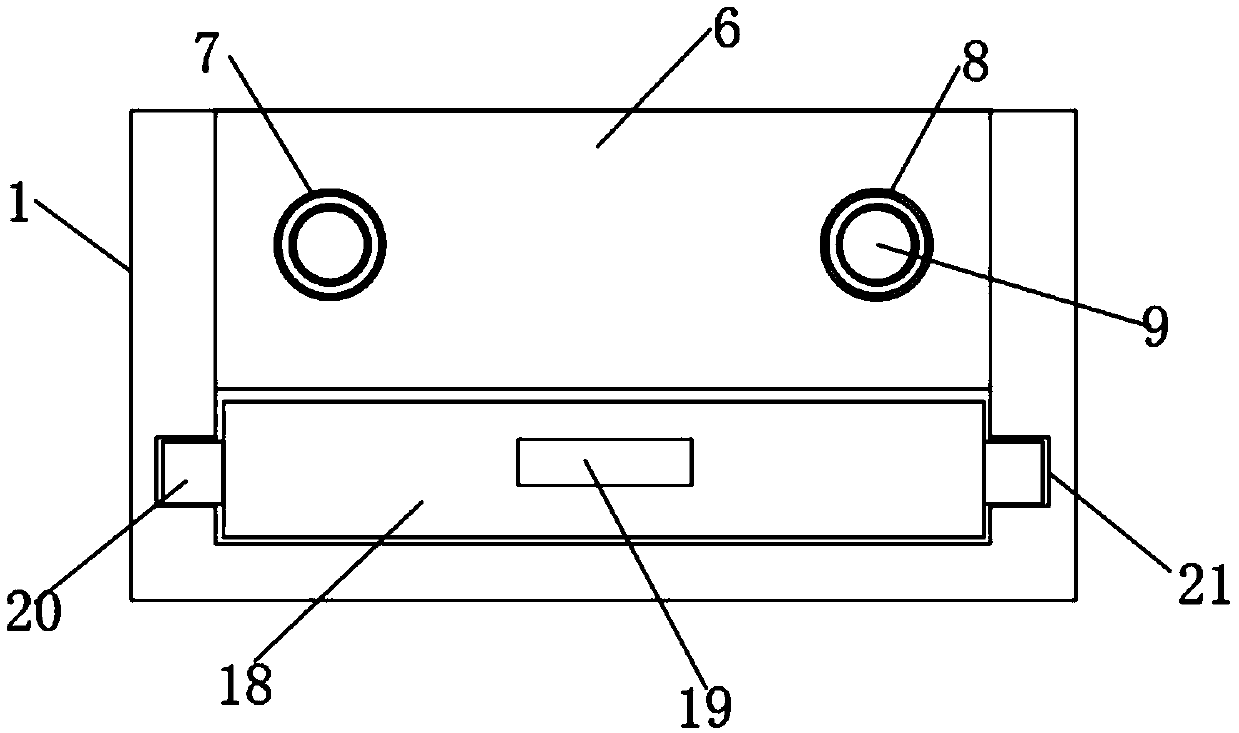

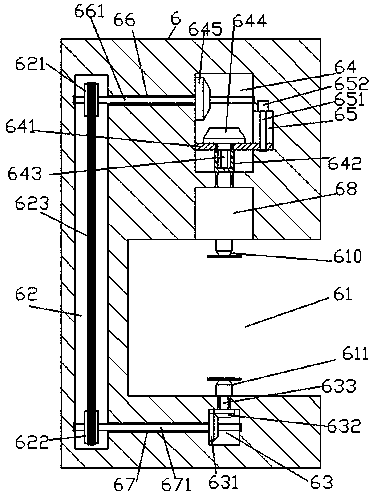

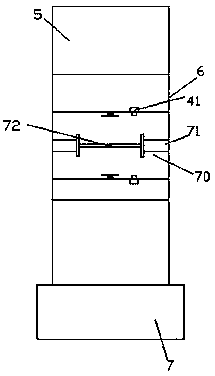

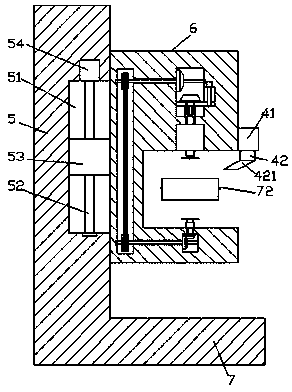

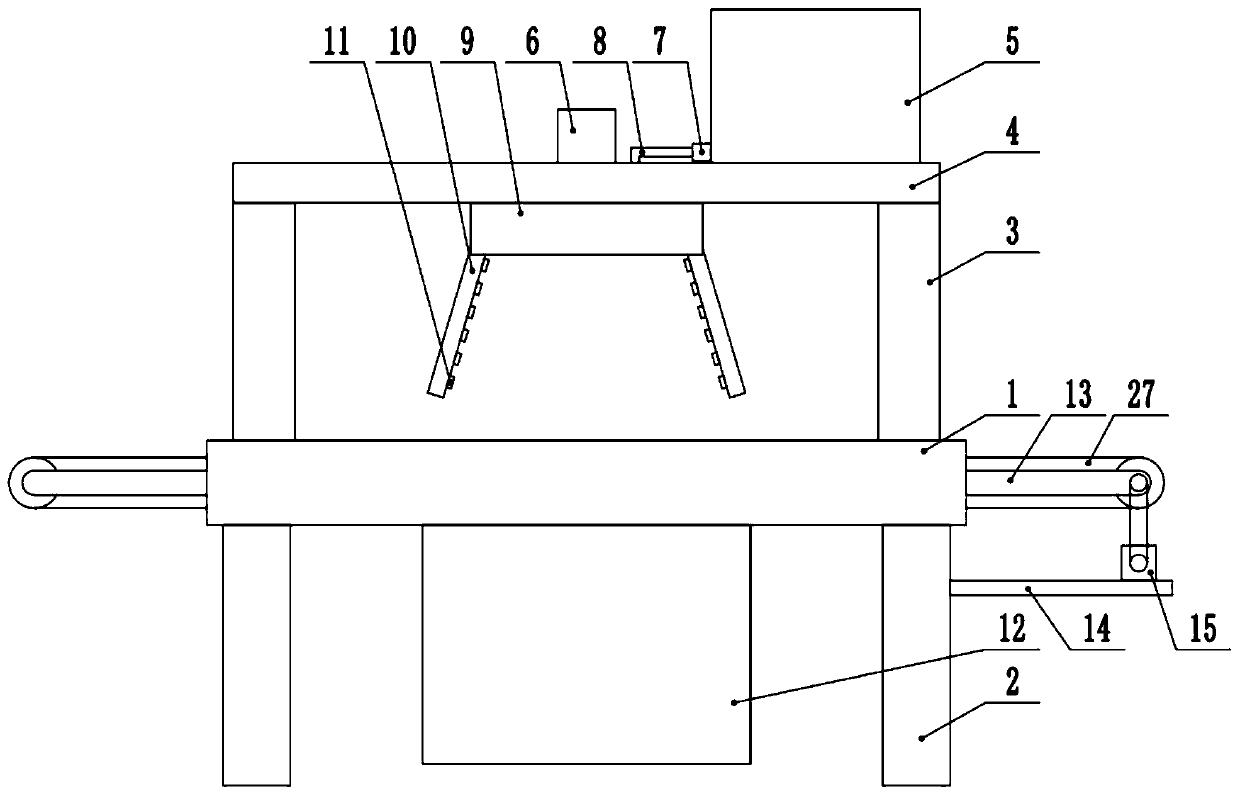

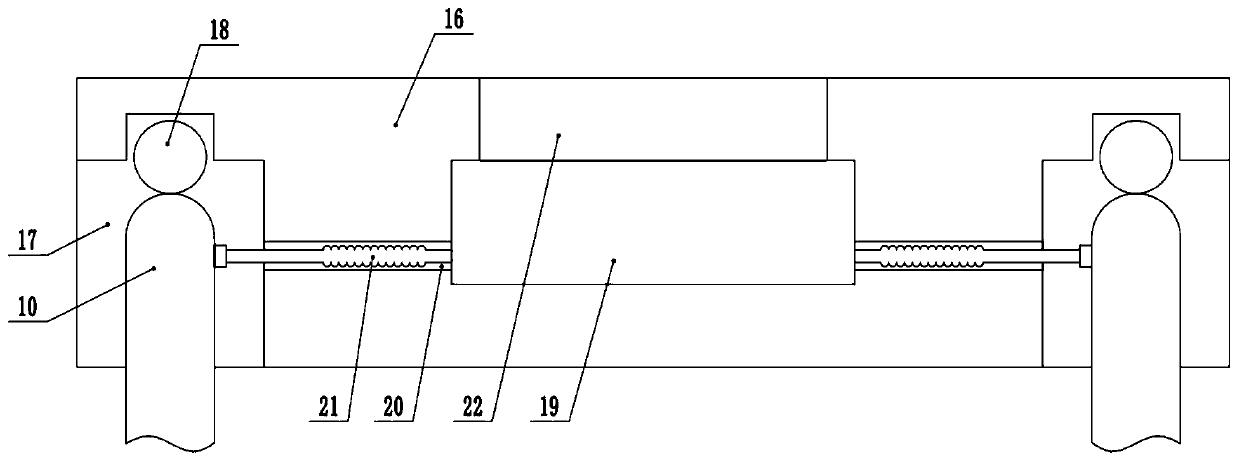

Wood floor chamfering and paint spraying device and application method thereof

InactiveCN104324831AEvenly paintedFast painting speedSpraying apparatusPretreated surfacesDrive motorStructural engineering

The invention discloses a wood floor chamfering and paint spraying device and an application method thereof. The wood floor chamfering and paint spraying device comprises a pair of transmission chains which are arranged in parallel, wherein one ends of the two transmission chains are connected by a main transmission shaft; the main transmission shaft is provided with a driving motor; each transmission chain is provided with separation blocks which are arrayed at equal intervals; a UV (Ultraviolet) photo curing machine is arranged at the tail parts of the pair of transmission chains; chamfering face paint spraying mechanisms are arranged on the two sides of the pair of transmission chains; each chamfering face paint spraying mechanism comprises a UV paint spraying head which is obliquely arranged by a bracket; the UV paint spraying heads are connected with paint storing containers above the UV paint spraying heads by pipelines; separation blades are arranged above the UV paint spraying heads and obliquely-arranged collection grooves are formed below the UV paint spraying heads; collection containers are arranged at outlets of the collection grooves; recycling pipes are arranged in the collection containers and are connected with the paint storing containers by recycling pumps. According to the application method, the chamfering and paint spraying mechanisms are mounted on the two sides of the chamfering and paint spraying device and UV paint is sprayed on chamfering faces on the two sides of a wood floor; then the wood floor enters the UV photo curing machine to be cured.

Owner:浙江大友木业有限公司

Improved all-dimensional paint spraying equipment

InactiveCN108284029AEasy to moveConvenient and stable positioningSpraying apparatusEngineeringMechanical engineering

Owner:南宁盛世凌云电子科技有限公司

Surface rust-proof treatment equipment for metal shell of wind power generation equipment

InactiveCN112403773AEasy to liftPrevent looseningPretreated surfacesCoatingsStructural engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to surface rust-proof treatment equipment for a metal shell of wind power generation equipment. The surface rust-proof treatment equipment has the advantages that paint is continuously and automatically sprayed onto the metal shell, so that the physical strength during manual operation can be effectively saved, thepaint spraying speed can be increased, the working efficiency can be improved, meanwhile, the equipment automatically sprays the paint, the uniformity of the paint attached to the metal shell is improved, the paint thickness consistency is improved, the paint spraying quality is effectively improved, and the practicability and the reliability are improved. The surface rust-proof treatment equipment comprises a base, a workbench, a first flat plate and four groups of first fixing plates, the workbench is arranged at the top of the base, a power device is arranged at the top of the workbench, the first flat plate is located above the power device, the four groups of first fixing plates are evenly arranged on the outer side of the first flat plate, the bottoms of the four groups of first fixing plates are all fixed to the workbench, and multiple groups of conveying balls are evenly arranged on the first flat plate in a penetrating and inserted mode.

Owner:苏州立科工业设计有限公司

Fireproof and wear-proof compounded transparent raw lacquer and making method thereof

InactiveCN106281018AIncrease drying and solidification speedImprove wear resistanceFireproof paintsNatural resin coatingsDecabromobiphenyl etherDecabromodiphenyl ether

The invention discloses a fireproof and wear-proof compounded transparent raw lacquer. The fireproof and wear-proof compounded transparent raw lacquer is characterized by being prepared from A components and B components. The raw materials of the A components are prepared from raw lacquer resin, a solvent and rosin water; the raw materials of the B components are prepared from maleic-anhydride-modified rosin resin, nano-aluminium oxide, a solvent, decabromodiphenyl ether, an antifoaming agent and TDI; the weight ratio of A components to B components is 1:(0.6-1.2). According to the fireproof and wear-proof compounded transparent raw lacquer, the drying solidification speed of the raw lacquer is increased through the TDI, a wood tire plate can be well covered with a bottom lacquer, rapid drying is carried out, and the lacquer distribution speed of the bottom lacquer is increased. As the maleic-anhydride-modified rosin resin and the nano-aluminium oxide are added, the wear resistance of a lacquer film is effectively improved; meanwhile, the transparency of the raw lacquer is conveniently controlled, and lacquer painting is conveniently made; as the decabromodiphenyl ether is added into the raw lacquer, and it can be well prevented that the conditions such as open wire caused by individual factors occur so that irredeemable damage to lacquer painting can be caused.

Owner:哈尔滨漆艺之星科技发展有限公司

Novel paint spraying equipment

InactiveCN108284028AEasy to moveConvenient and stable positioningSpraying apparatusEngineeringMechanical engineering

Owner:南宁盛世凌云电子科技有限公司

Automatic mechanical paint spraying equipment

The invention discloses automatic mechanical paint spraying equipment and belongs to the technical field of mechanical paint spraying. The equipment comprises a workbench; the bottom end of the workbench is fixedly connected with supporting legs; the four corners of the top end of the workbench are fixedly connected with supporting columns respectively; the top ends of the supporting columns are fixedly connected with a top plate; a rotating device is arranged in the center of the bottom end of the workbench; the rotating device is connected with a spraying pipe; a plurality of atomizing nozzles are arranged on the spraying pipe; the top end of the workbench is fixedly connected with a paint box; one side of the bottom of the paint box is fixedly connected with a conveying pump; a conveying pipe is fixedly connected between the conveying pump and the rotating device; a conveying belt is arranged on the workbench; and a lifting device is fixedly connected with the bottom end of the workbench. According to the equipment of the invention, the lifting device is adopted, so that an object to be subjected to paint spraying can be jacked up to stably stay above the workbench; and the rotating device and the spraying pipe are adopted, so that rotating type high-speed uniform paint spraying can be conducted. The equipment of the invention has the advantages of high paint spraying speed,high efficiency, uniform paint spraying amount and high paint spraying quality.

Owner:孟海洋

Plastic-coating method for large-diameter steel tube

InactiveCN106238295AFast painting speedUniform coatingLiquid surface applicatorsCoatingsMetallurgySteel tube

The invention discloses a plastic-coating method for a large-diameter steel tube. The preheated steel tube is driven to rotate, and after a material turning hopper and a powder trough reach the working stations, plastic-coating powder is fed to the inner circumferential face and the outer circumferential face of the steel tube correspondingly; after plastic-coating is completed, the material turning hopper and the powder trough retract, and the steel tube is solidified after plastic powder is slicked on the inner circumferential face and the outer circumferential face of the steel tube and form a continuous coating. According to the method, the large-diameter steel tube can be plastic-coated internally and externally, the coating speed is rapid, and the coating of the steel tube is uniform.

Owner:高密天一机械科技有限公司

An automatic painting device

ActiveCN105772299BExtended range of movementReduce volumeSpraying apparatusEngineeringMechanical engineering

Owner:淄博奧冠交通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com