All-direction paint spraying device

A kind of painting equipment and all-round technology, applied in painting booths, spraying devices, liquid spraying devices, etc., can solve the problems of slow painting time and low efficiency, and achieve the effect of fast painting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

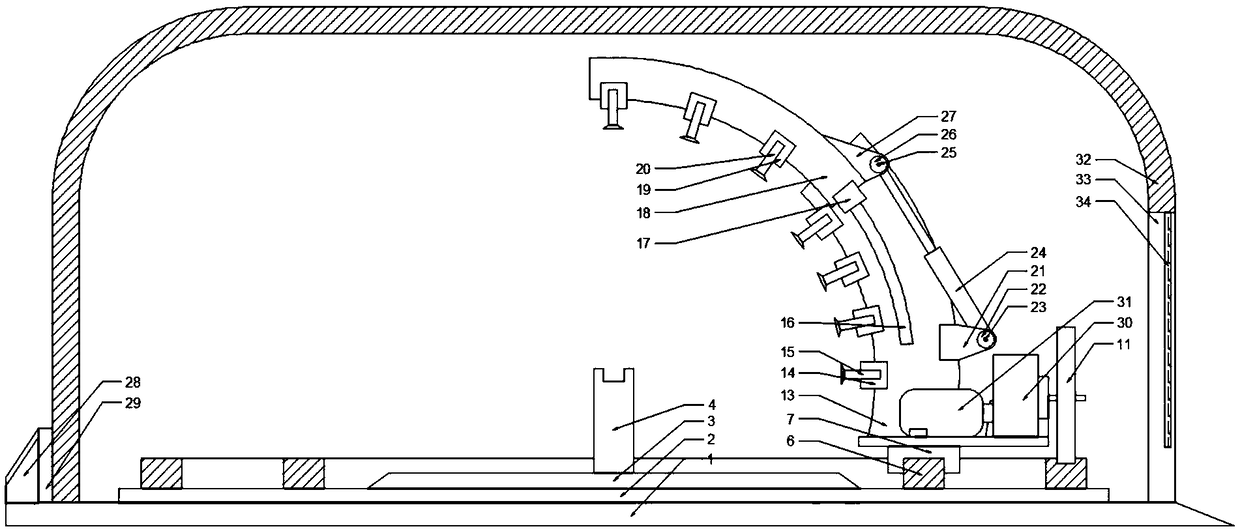

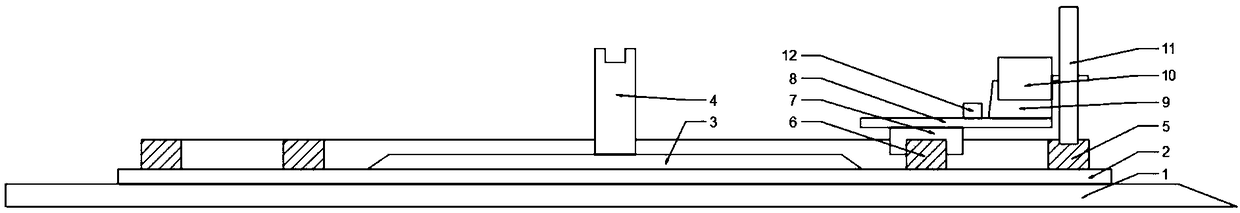

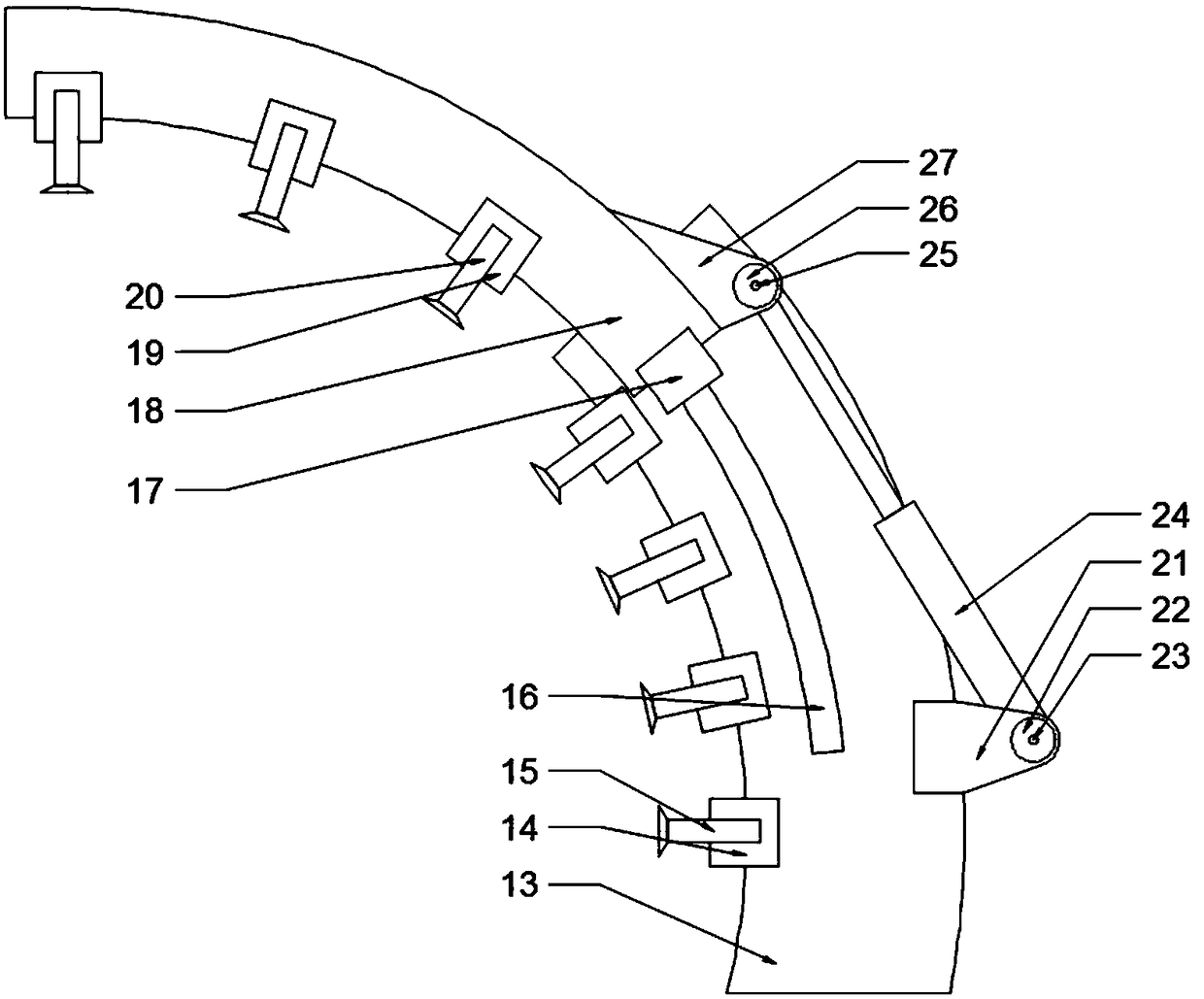

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a kind of all-round painting equipment comprises a base 1, and the base 1 is located above the ground, and a rotating mechanism is arranged above the base 1, and the rotating mechanism is fixedly connected by a painting bracket fixing frame 2 positioned above the base 1, The spray paint bracket installation frame 3 that is installed on the spray paint bracket fixed frame 2, the spray paint product fixed frame 4 that is installed on the paint spray bracket mounting frame 3, the ring rack 5 that is fixedly connected at the top of the paint spray bracket mount 2, is located at the ring rack 5 The inner side is fixedly connected with the ring slide rail 6 of the painting bracket fixing frame 2, the ring slide block 7 that is slidably connected with the ring slide rail 6 above the ring slide rail 6, the paint spray movable frame 8 that is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com