Paint spraying device for processing of high-voltage distribution box

A high-voltage power distribution and box technology, applied in the field of painting, can solve the problems of long paint drying time, uneven painting, and large workload, and achieve the effects of easy recycling, uniform paint liquid, and fast painting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

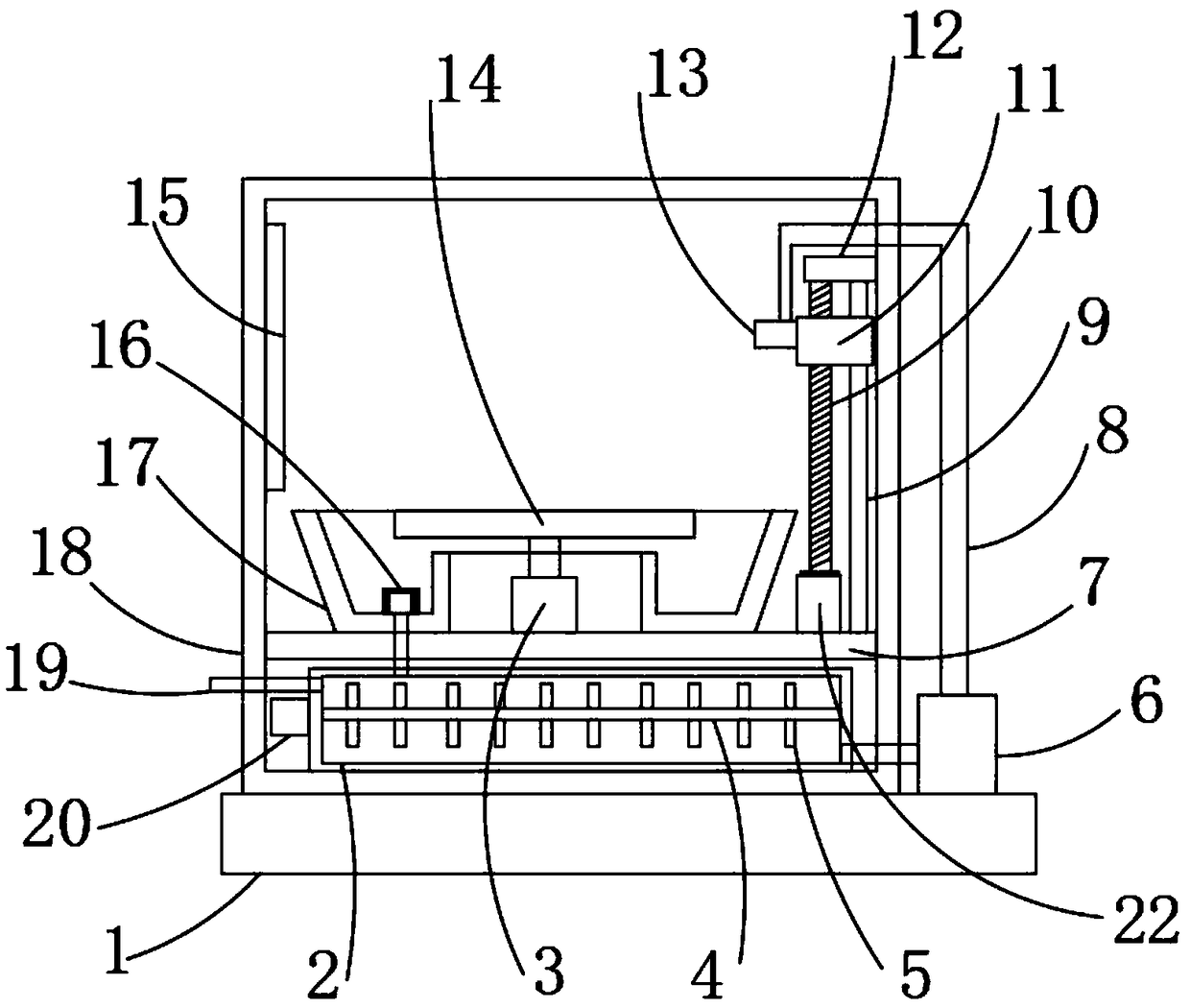

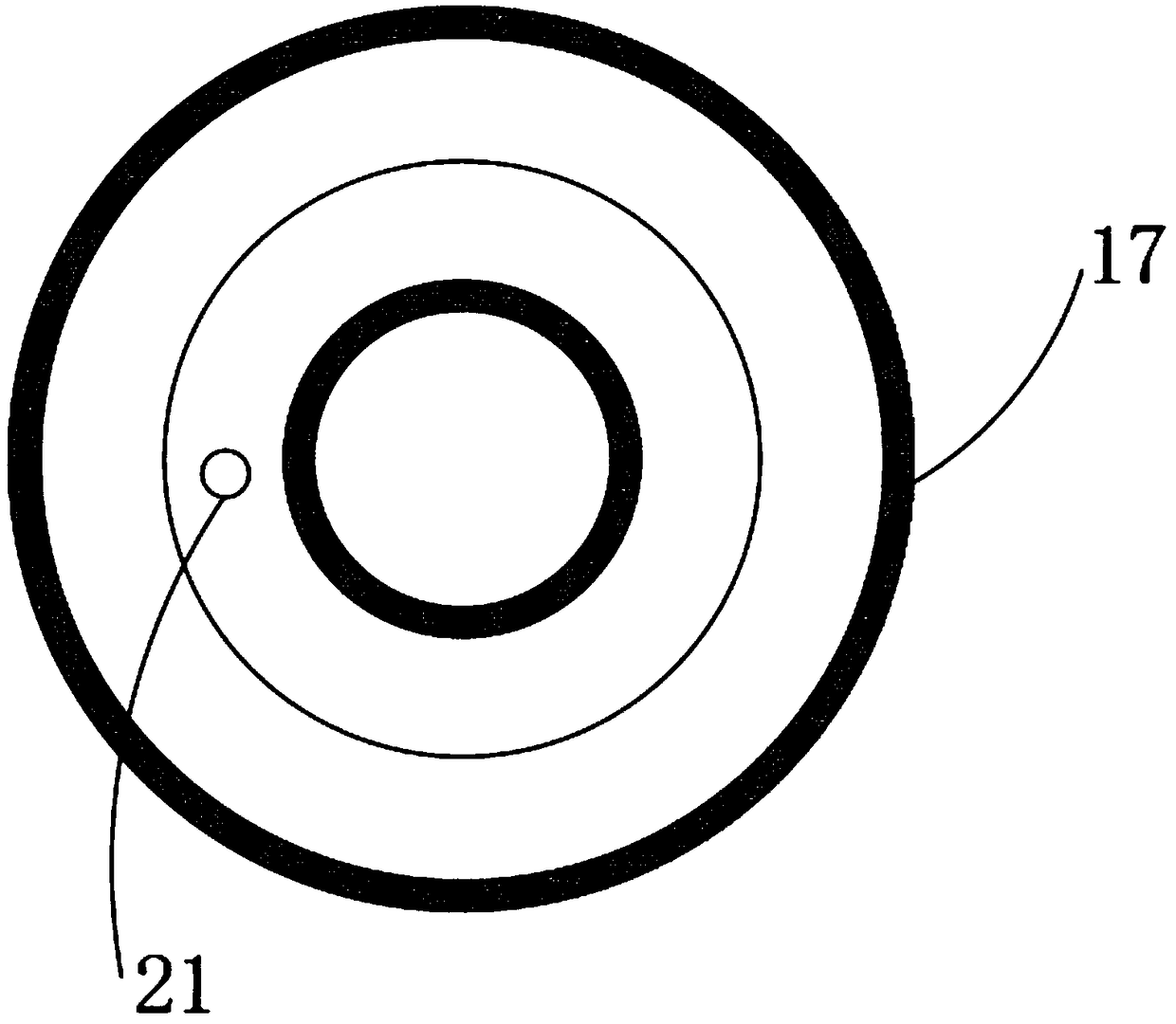

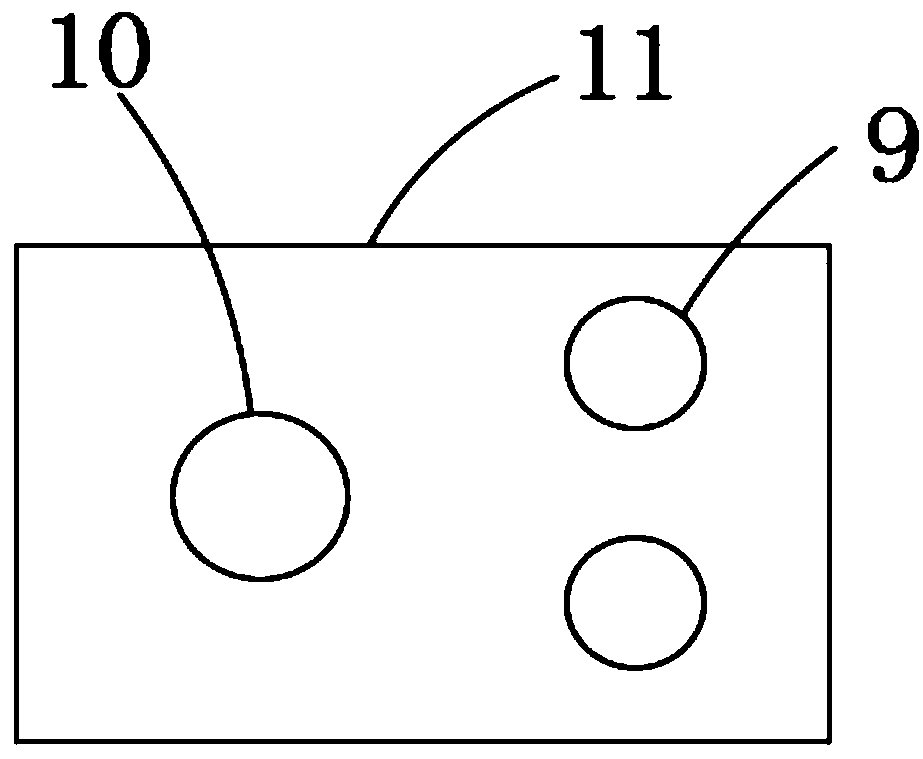

[0021] refer to Figure 1-3 A paint spraying device for processing high-voltage distribution boxes, comprising a base 1, a box 18 and a paint pump 6 are arranged on the top of the base 1, a mixing bucket 2 is arranged on the inner bottom wall of the box 18, and a horizontal setting is welded in the box 18 The partition plate 7, the top of the partition plate 7 is provided with an annular collection tank 17, a rotating motor 3, a lifting motor 22 and a limit rod 9, the output shaft of the rotating motor 3 is connected with a rotating shaft, and a round platform 14 is welded on the rotating shaft, and the lifting motor The output shaft of 22 is connected with the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com