Plate paint-spraying device for building engineering decoration

A technology for construction engineering and boards, which is applied in the direction of spraying devices, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity, low work efficiency, dry cracking and falling off of paint, and achieve the effect of increasing the speed of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

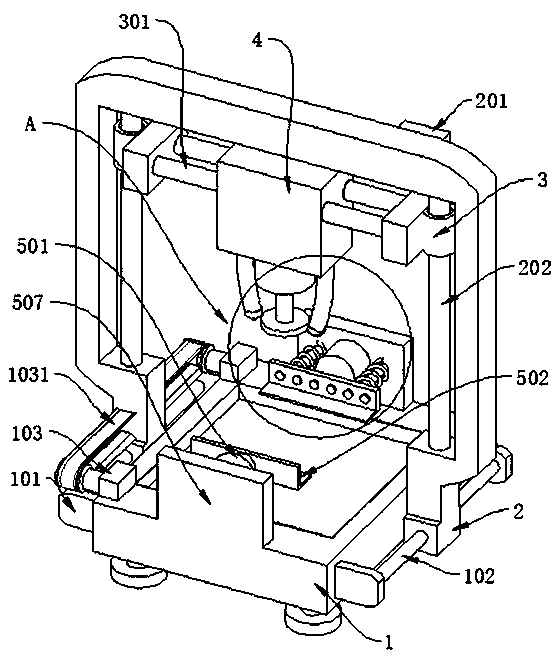

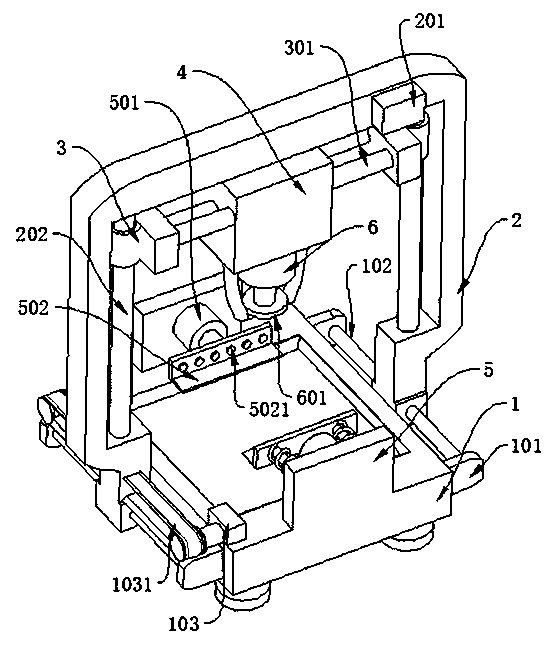

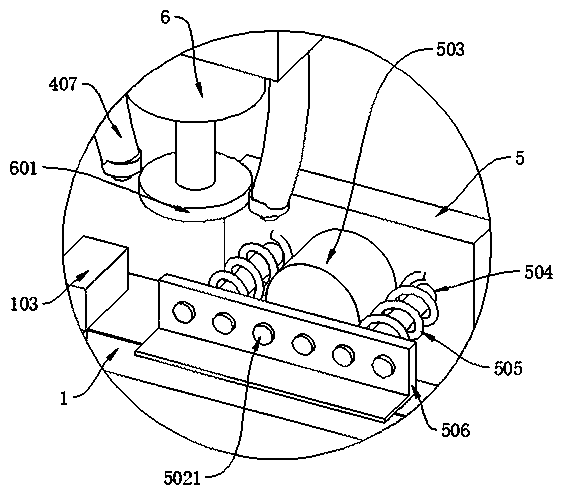

[0035] refer to Figure 1-4 , a kind of plate painting device for building decoration, comprising a base 1, a support frame 2, a controller 201, the support frame 2 is slidably connected to the top of the base 1, the support frame 2 is slidably connected with a paint spray box 4, and the paint spray box 4 The top is connected with a first motor 401, the output end of the first motor 401 is connected with a stirring plate 402, the stirring plate 402 is located in the painting box 4, the inner wall of the painting box 4 is sealed with an arc plate 404, and the bottom of the arc plate 404 is connected There is a water pump 405, and the water pump 405 is connected to a symmetrical paint spraying pipe 407 through a pipeline 406. The bottom of the paint spraying box 4 is connected to a second motor 6, the output end of the second motor 6 is connected to a grinding disc 601, and the top of the base 1 is connected to a clamping mechanism. , when in use, the plate is fixed by the progr...

Embodiment 2

[0037] refer to Figure 1-4 , a kind of plate painting device for building decoration, comprising a base 1, a support frame 2, a controller 201, the support frame 2 is slidably connected to the top of the base 1, the support frame 2 is slidably connected with a paint spray box 4, and the paint spray box 4 The top is connected with a first motor 401, the output end of the first motor 401 is connected with a stirring plate 402, the stirring plate 402 is located in the painting box 4, the inner wall of the painting box 4 is sealed with an arc plate 404, and the bottom of the arc plate 404 is connected There is a water pump 405, and the water pump 405 is connected to a symmetrical paint spraying pipe 407 through a pipeline 406. The bottom of the paint spraying box 4 is connected to a second motor 6, the output end of the second motor 6 is connected to a grinding disc 601, and the top of the base 1 is connected to a clamping mechanism. , when in use, the plate is fixed by the progr...

Embodiment 3

[0040] refer to Figure 1-4 , a panel painting device for building decoration, which is basically the same as that of Embodiment 2, furthermore, the bottom end of the paint spraying pipe 407 is connected with an atomizing filter 4071, and the spraying paint is evenly sprayed through the atomizing filter 4071.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com