Patents

Literature

98results about How to "Fully painted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient paint spraying device of circular anti-collision barrel used for traffic bridge

InactiveCN107185750ADoes not affect the painting effectFully paintedPretreated surfacesLiquid spraying apparatusTraffic crashBolt connection

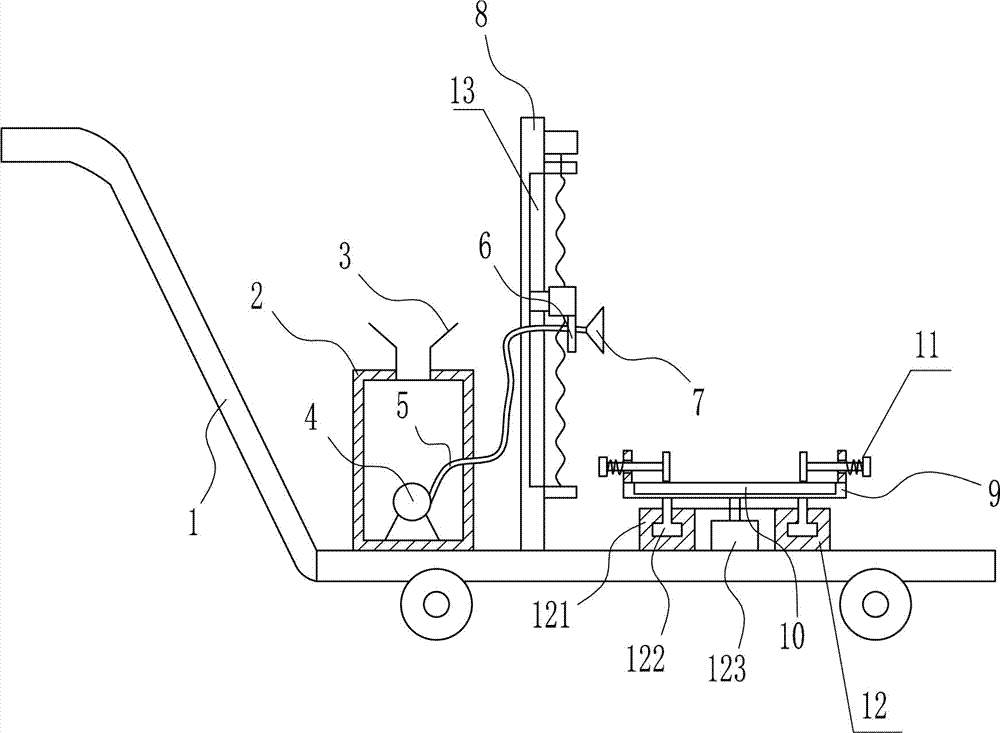

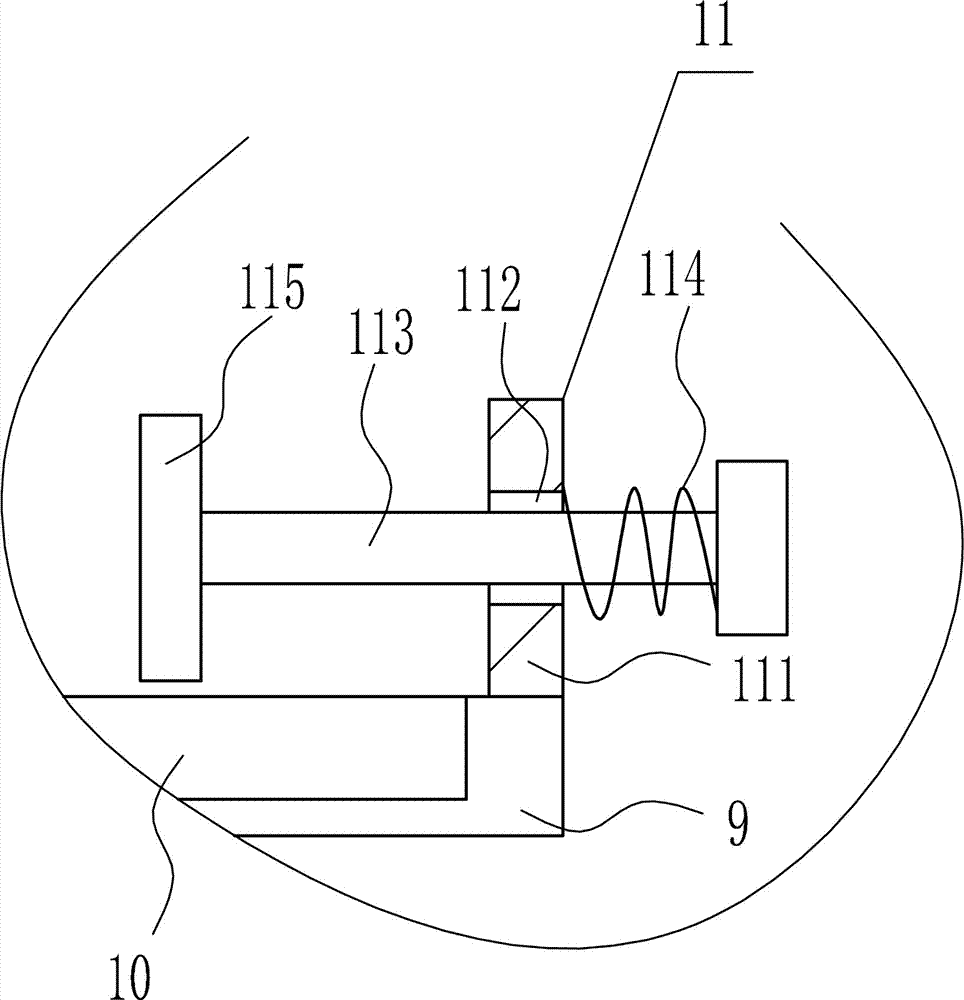

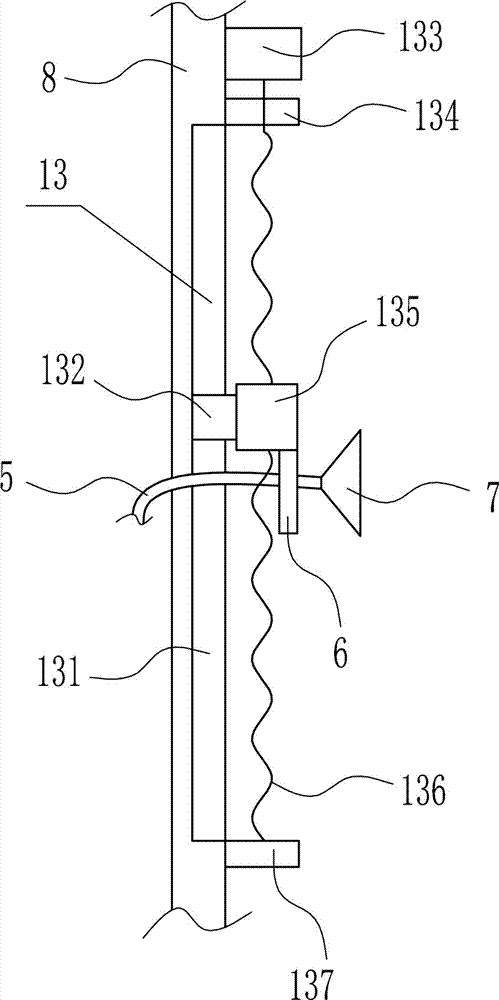

The invention relates to a circular anti-collision barrel paint spraying device for traffic bridges, in particular to a high-efficiency paint spraying device for circular anti-collision barrels for traffic bridges. The technical problem to be solved by the present invention is to provide a high-efficiency painting device for circular anti-collision barrels for traffic bridges, which saves time and labor, sprays paint evenly, does not need to spray paint on the anti-collision barrels manually, and does not cause physical discomfort. In order to solve the above-mentioned technical problems, the present invention provides such a high-efficiency paint spraying device for circular anti-collision buckets for traffic bridges, which includes a cart, a paint box, a lower hopper, a water pump, a discharge pipe, a first fixed sleeve, and a first spray head. etc.; the left side of the top of the trolley is bolted to install a paint box, and the middle of the top of the paint box is bolted to install a lower hopper. The invention achieves the effects of saving time and labor, uniform painting, no need to manually spray paint on the anti-collision barrel, and furthermore, no physical discomfort, and high working efficiency.

Owner:惠安普科优利网络科技有限公司

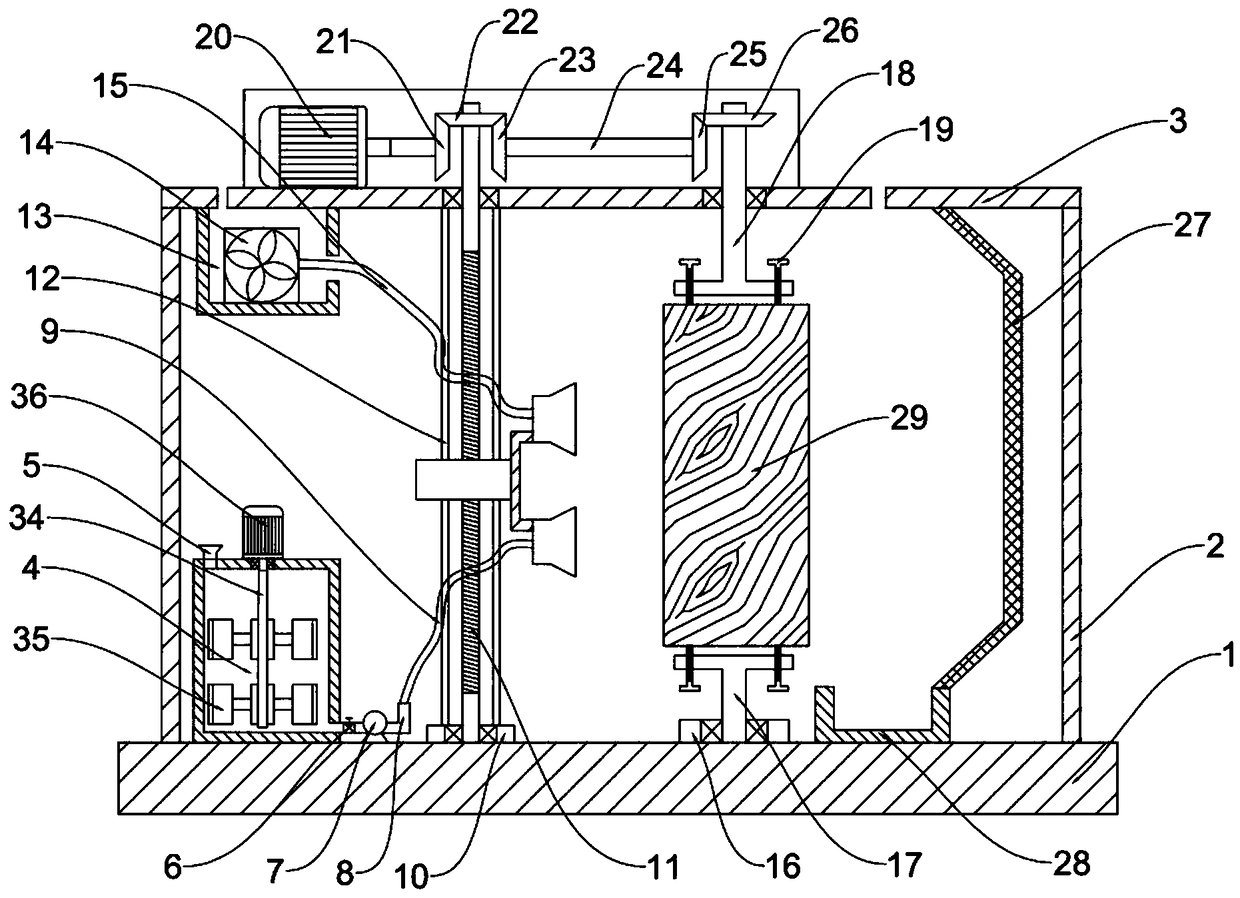

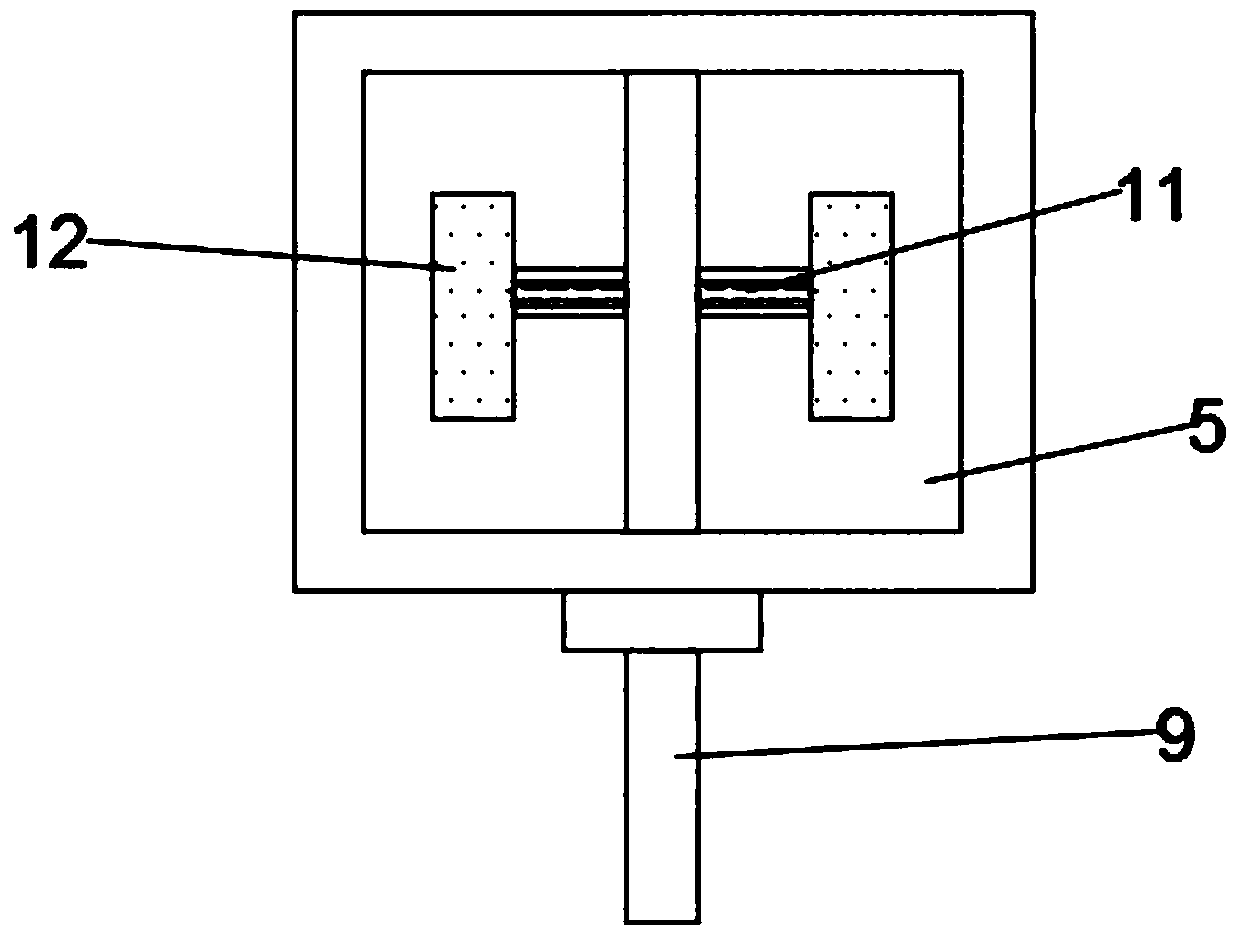

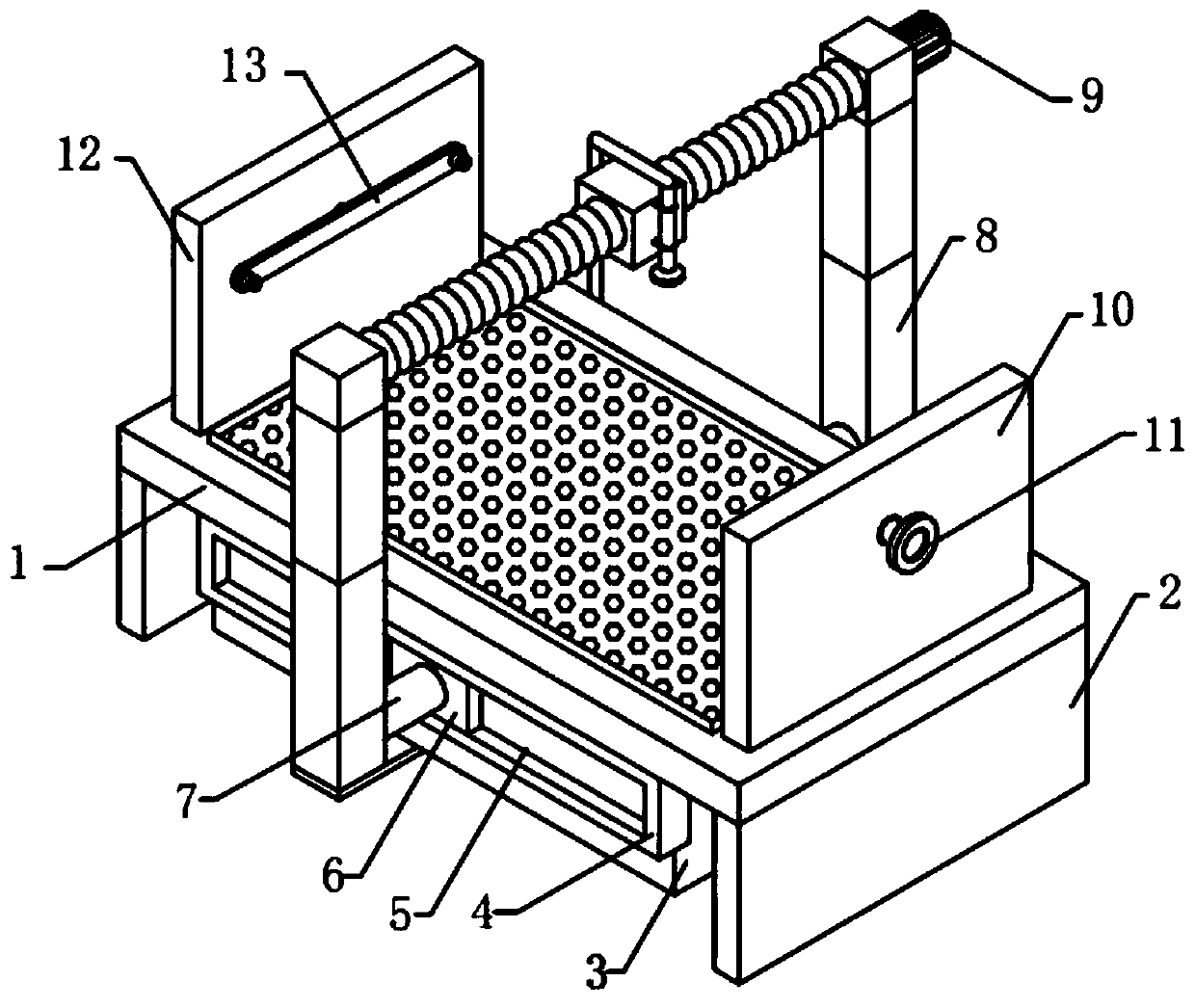

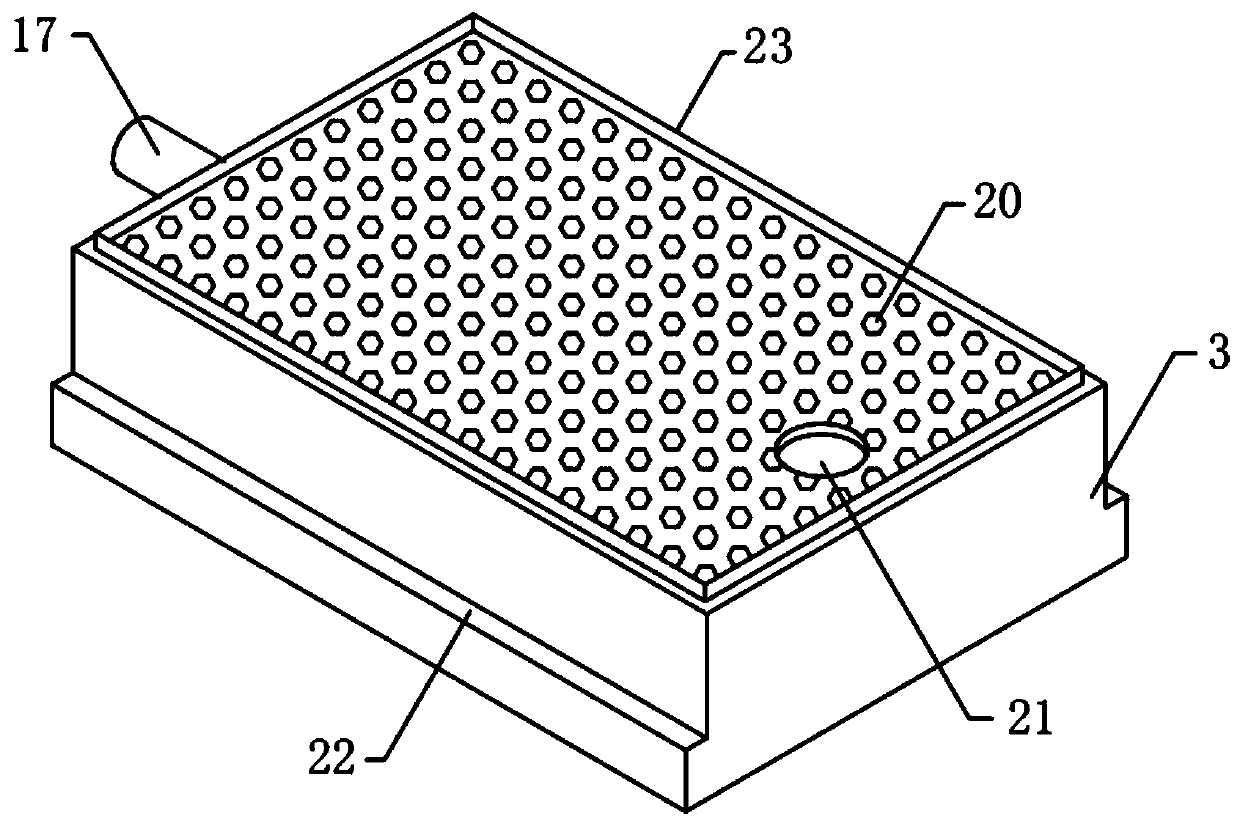

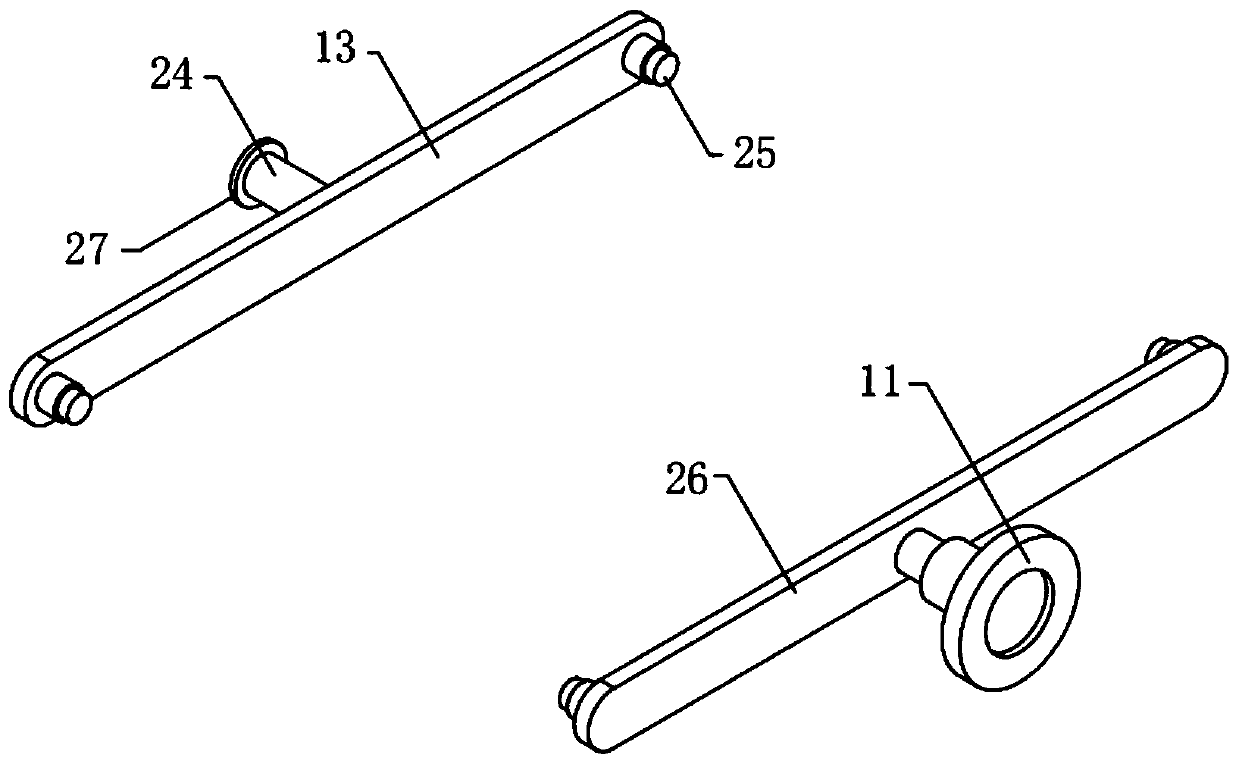

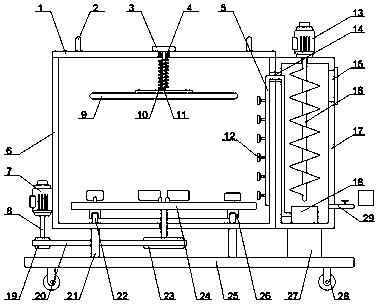

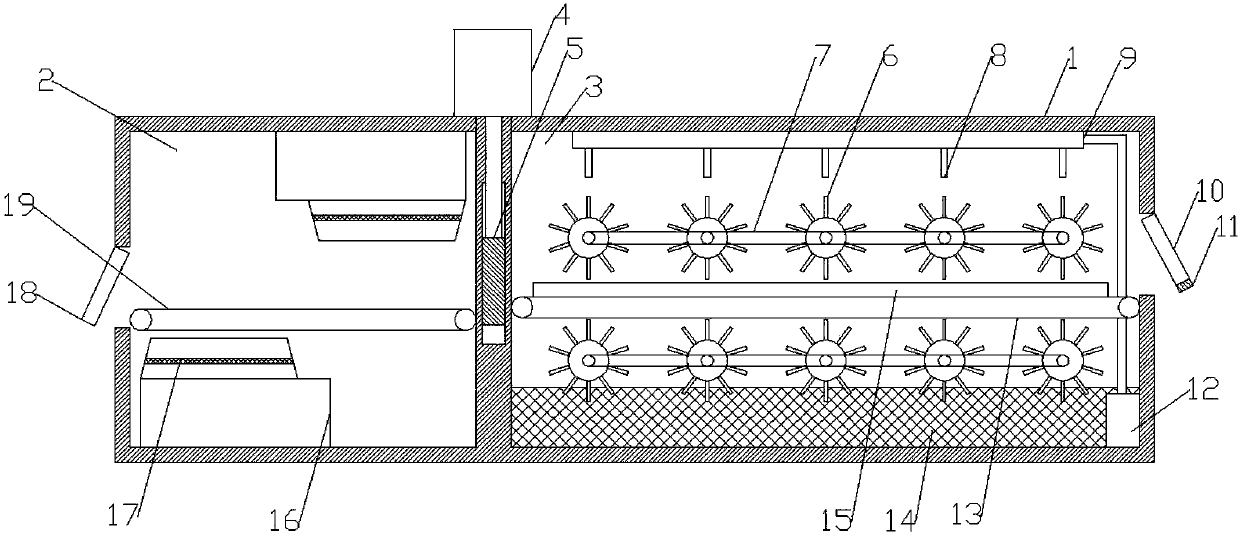

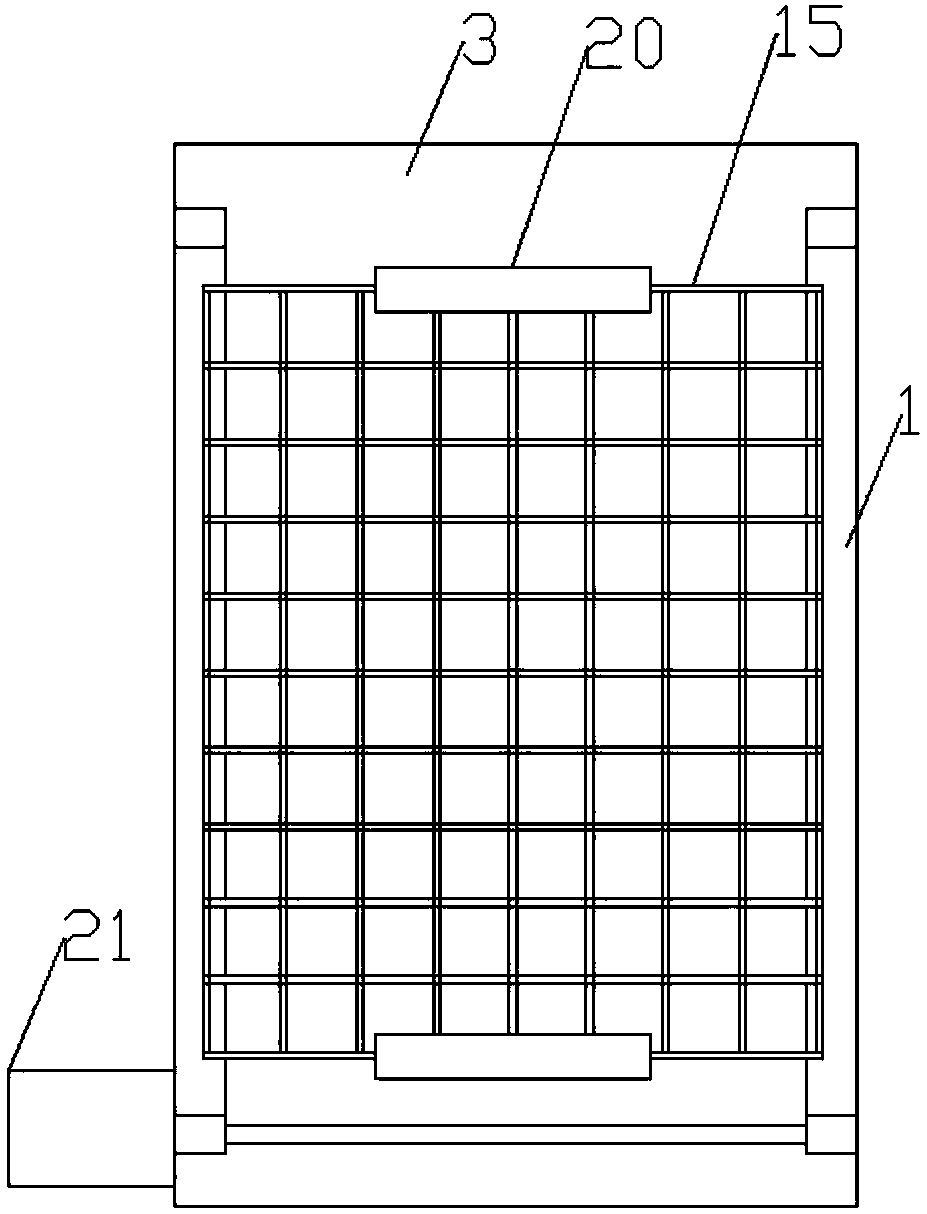

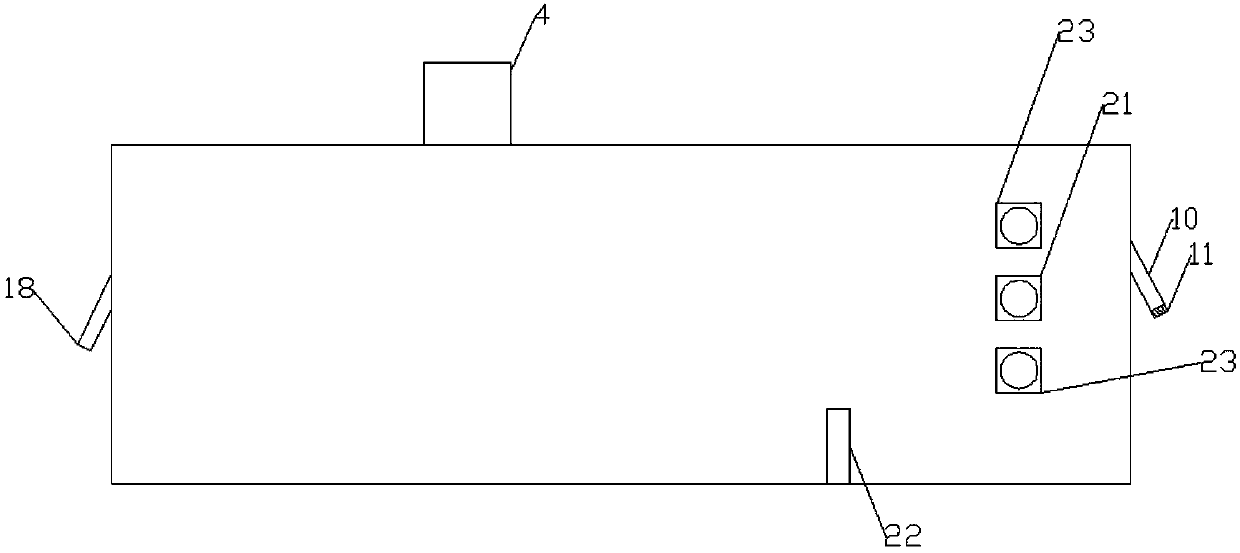

Efficient and uniform wooden product paint spraying equipment

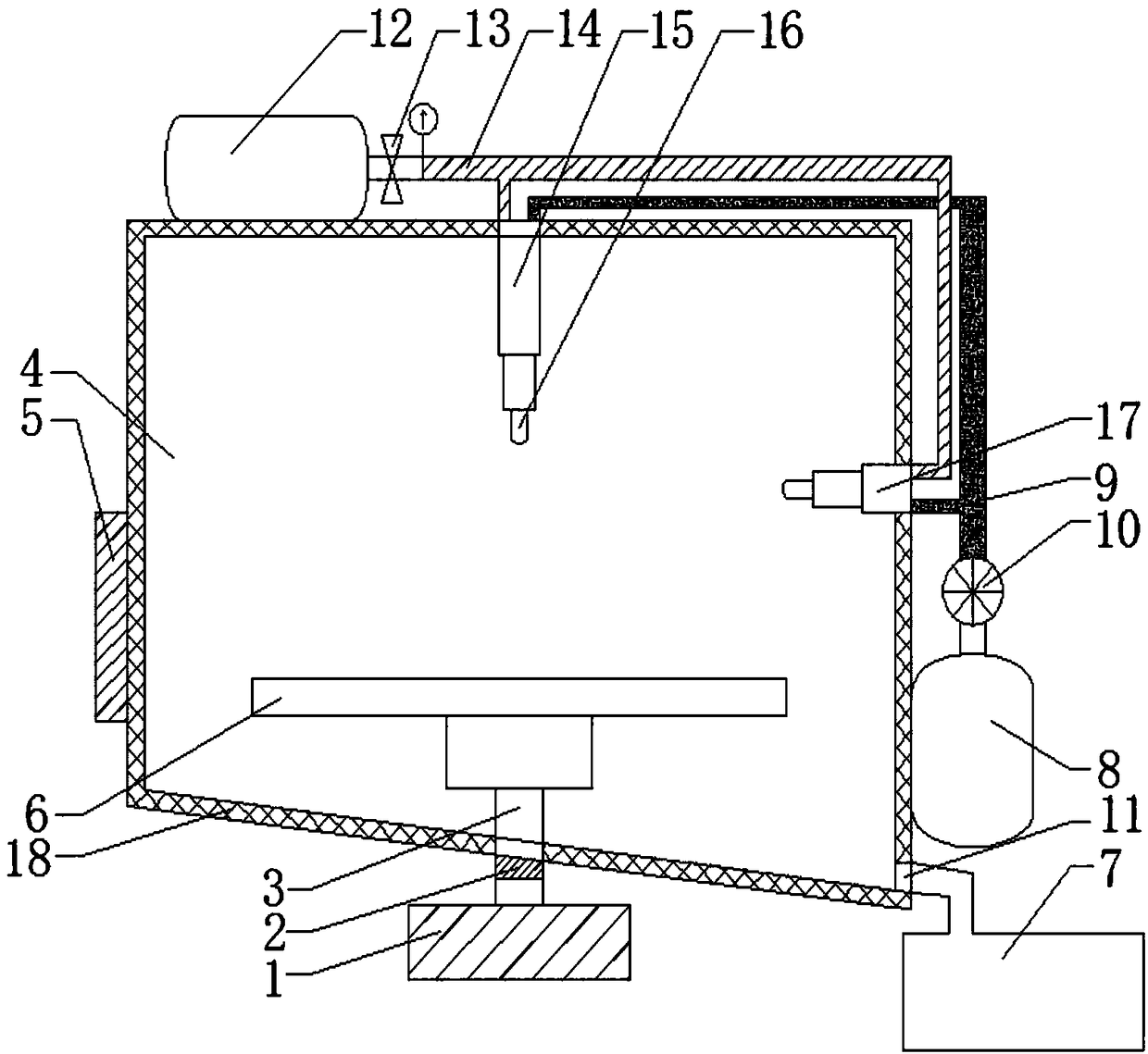

The invention discloses efficient and uniform wooden product paint spraying equipment, and belongs to the field of wooden product machining equipment. The device comprises a base, supporting columns,a top plate, a paint spraying and drying device, a fixing device and a recycling device; the paint spraying and drying device comprises a threaded rod, a positive and negative rotating motor, a threaded sleeve, a paint spraying mechanism and a drying mechanism; an installing rack is fixedly connected to the right end of the threaded sleeve; the paint spraying mechanism comprises a paint box, a paint pump and paint sprayers; the drying mechanism comprises a hot air chamber, a hot air blower and air nozzles; the paint sprayers are fixedly installed at one end of the installing rack; and the airnozzles are fixedly installed at the other end of the installing rack. According to the efficient and uniform wooden product paint spraying equipment, efficient, uniform and comprehensive paint spraying and drying operation can be conducted on wooden products, redundant paint in the paint spraying process can be recycled, and unnecessary waste can be reduced.

Owner:安徽菌仙菇农业开发有限公司

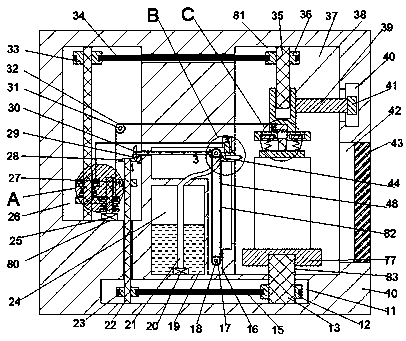

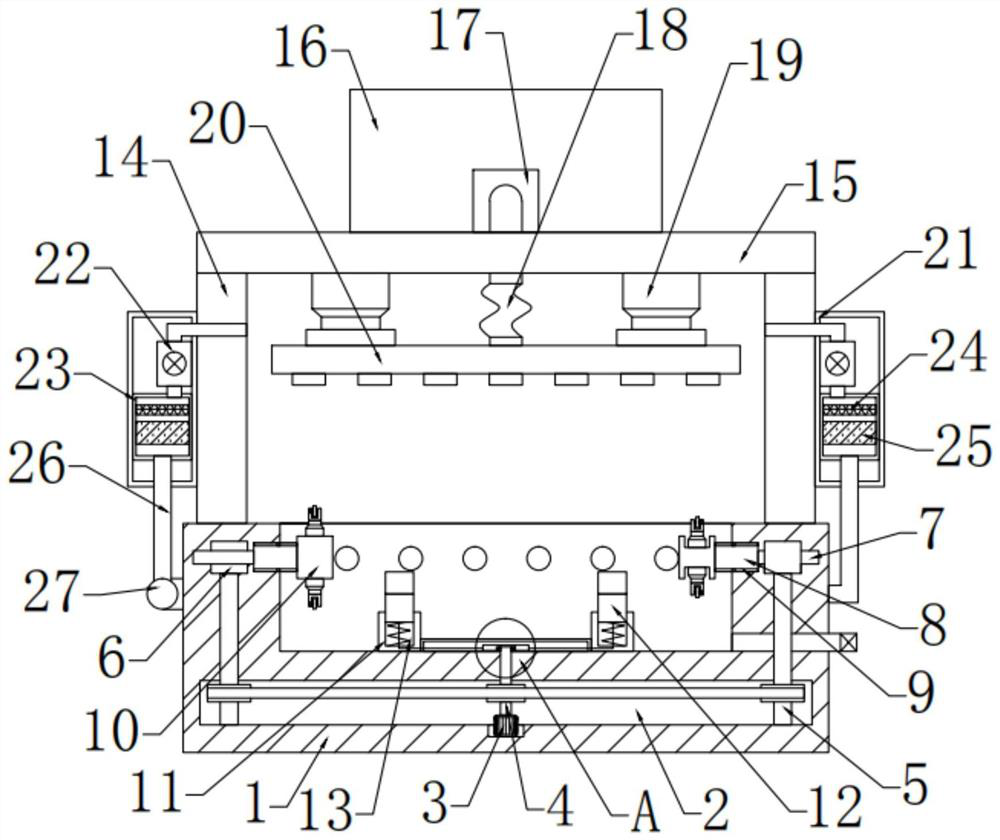

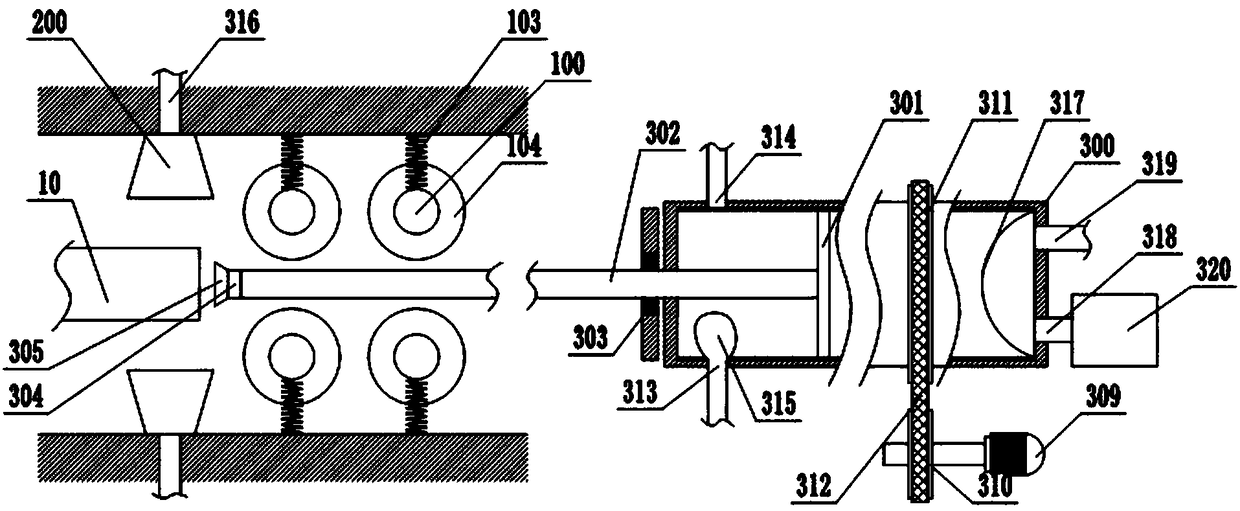

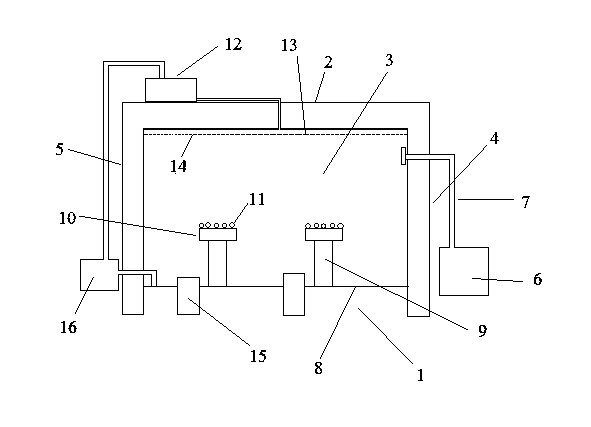

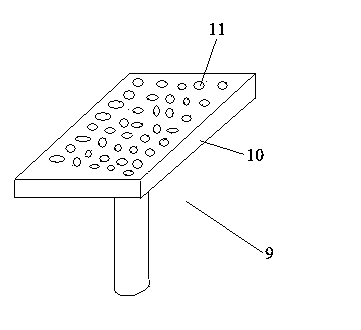

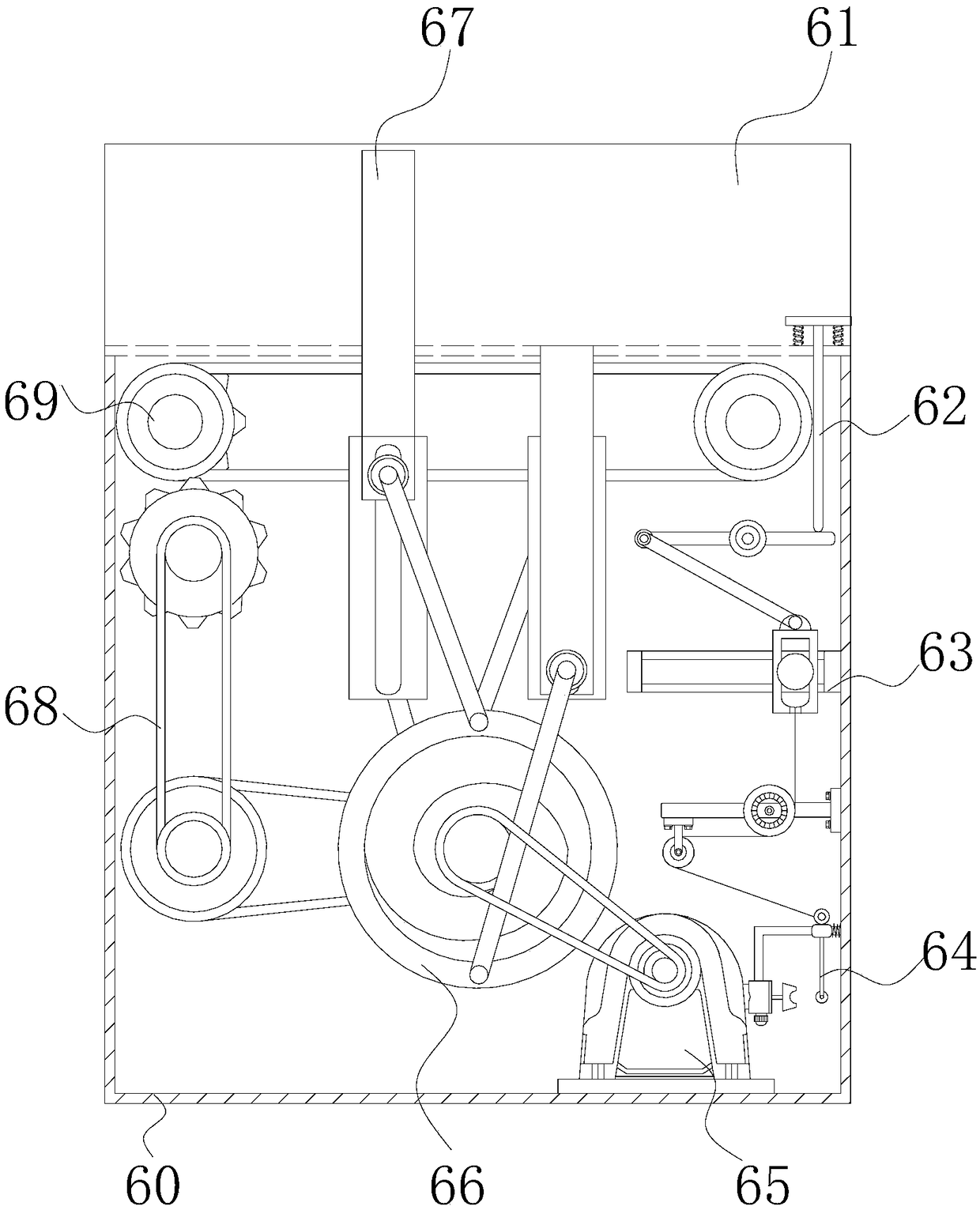

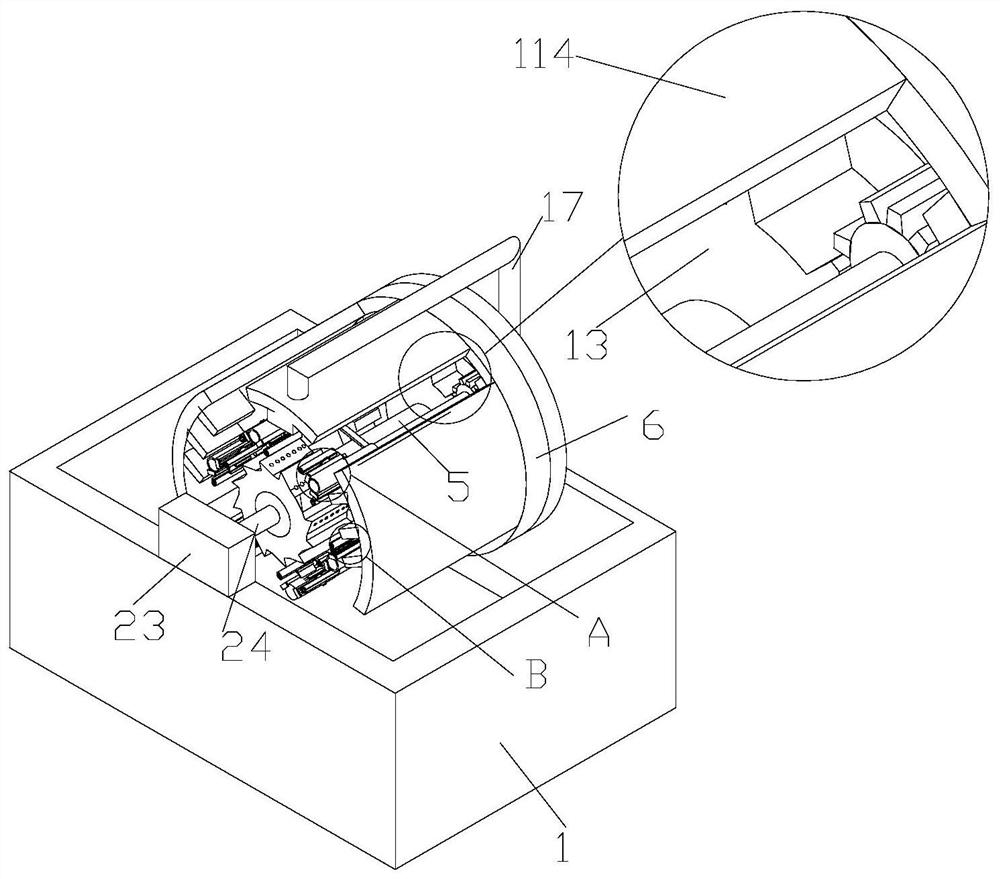

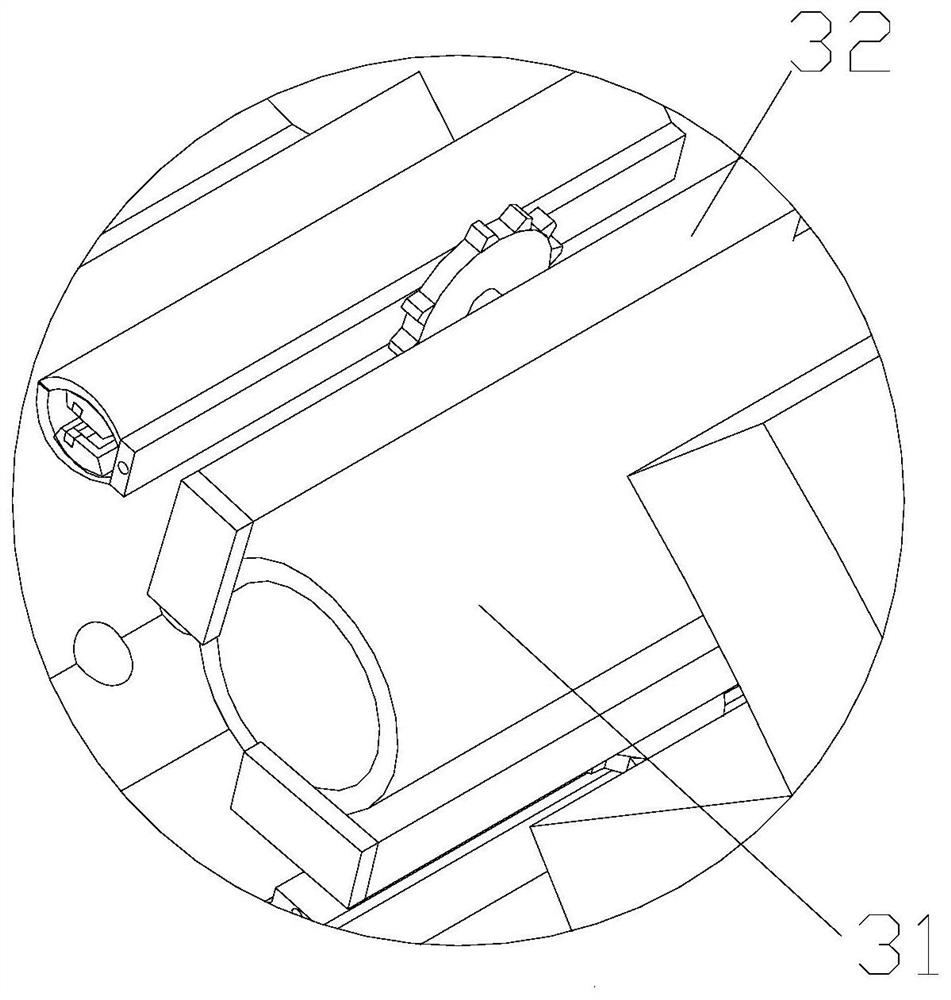

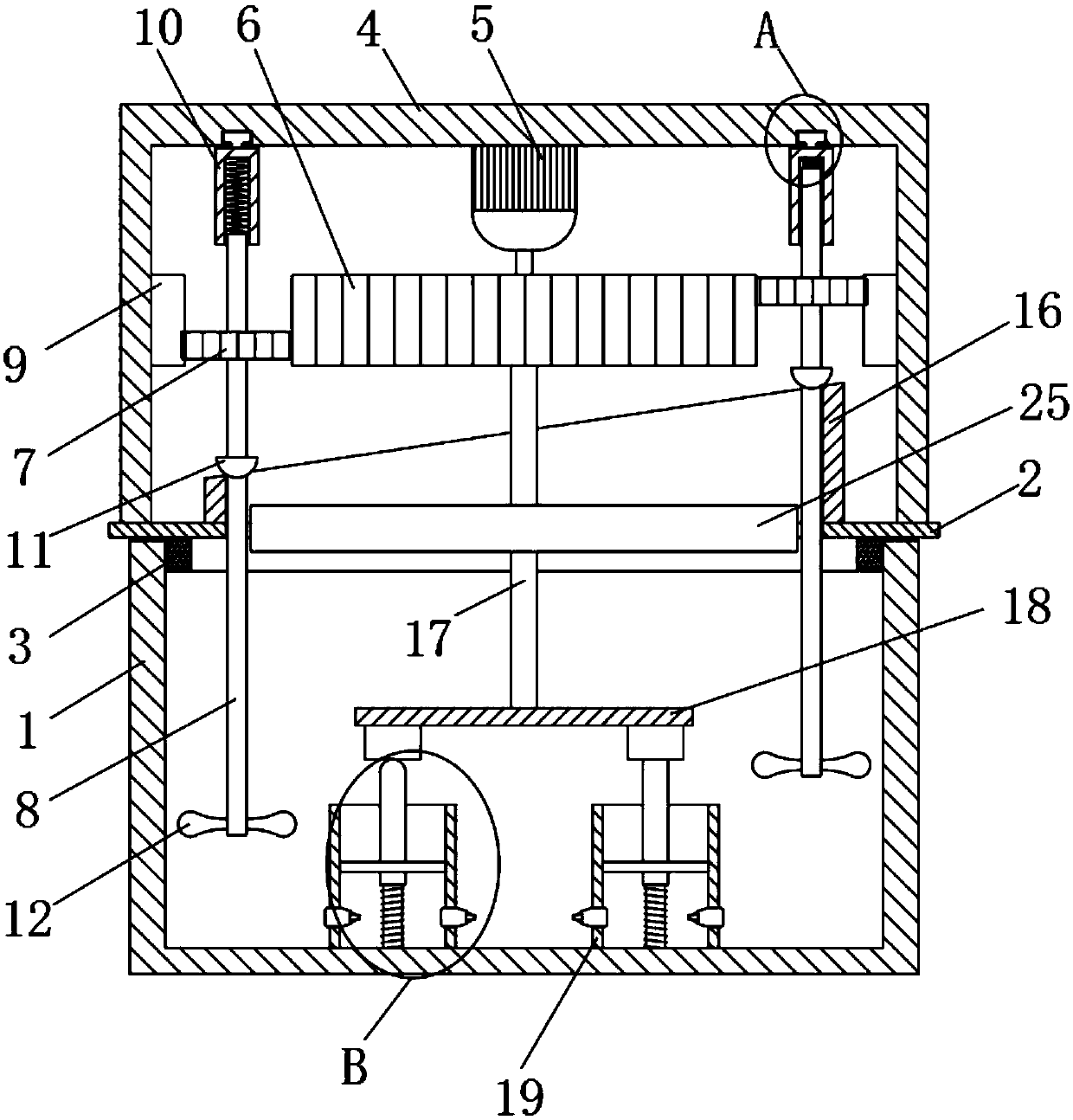

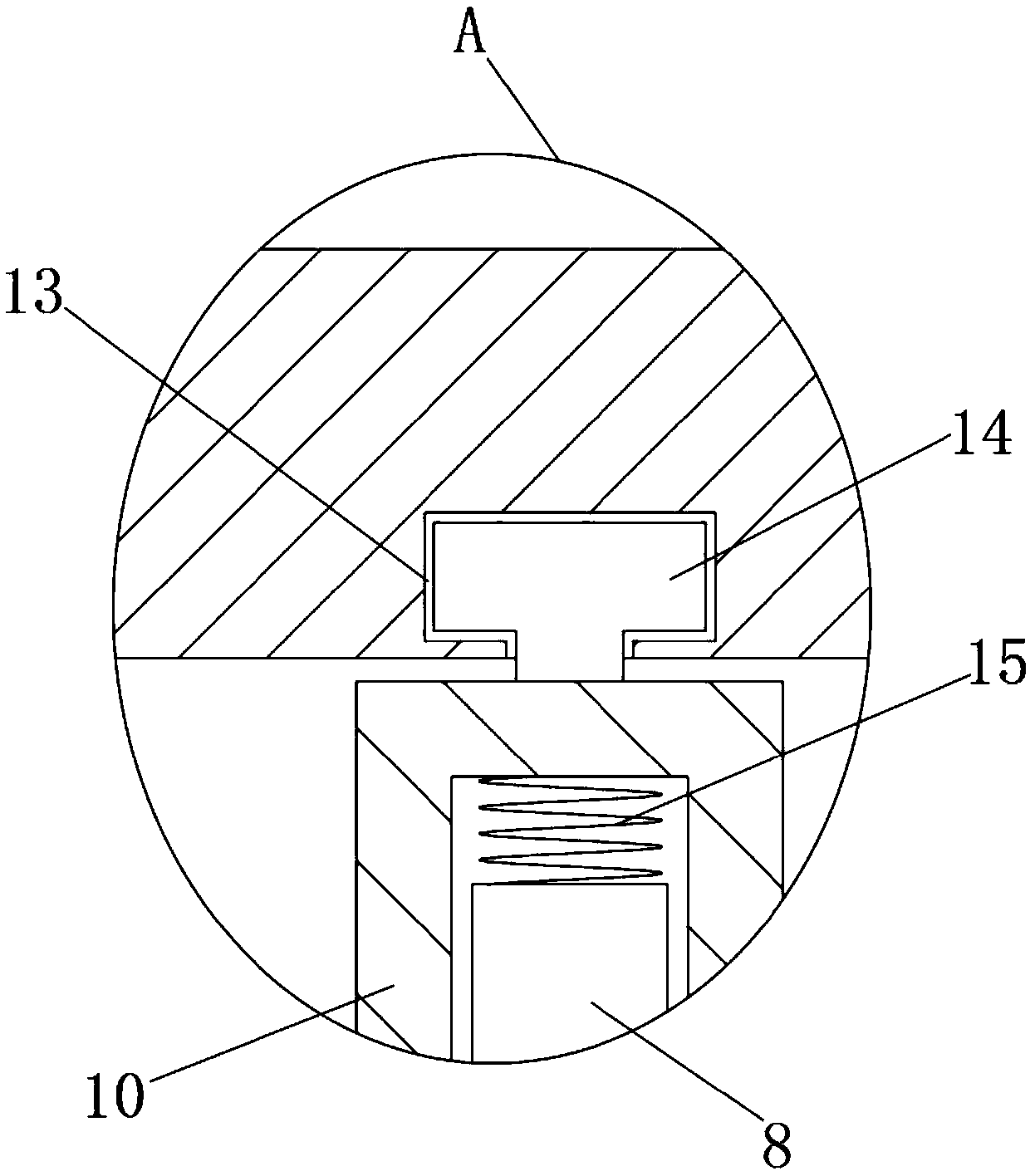

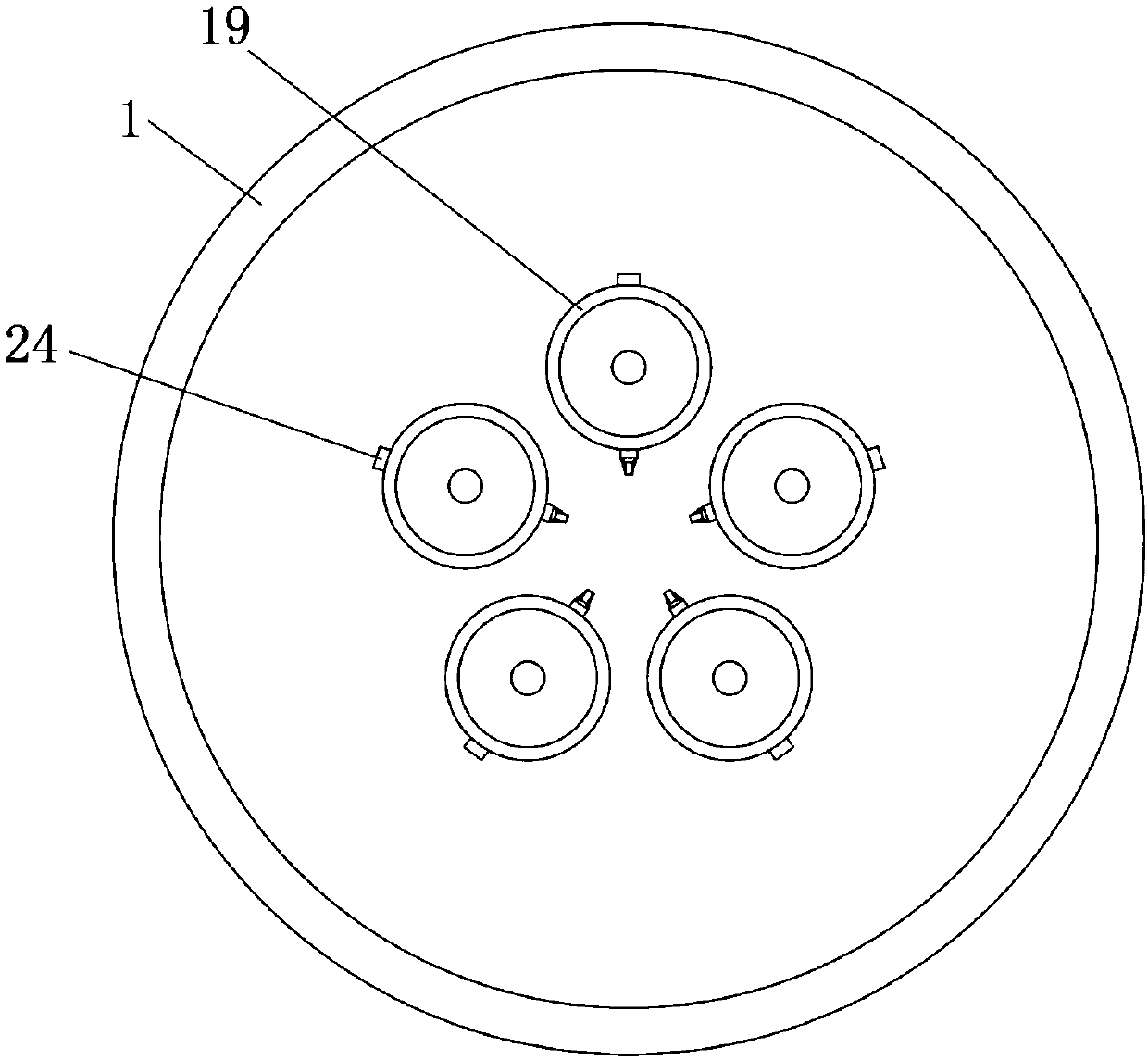

Device for spraying surface of cylindrical material with paint

InactiveCN110508430AFully paintedFast and efficient paint finishSpraying apparatusLacquerSpray nozzle

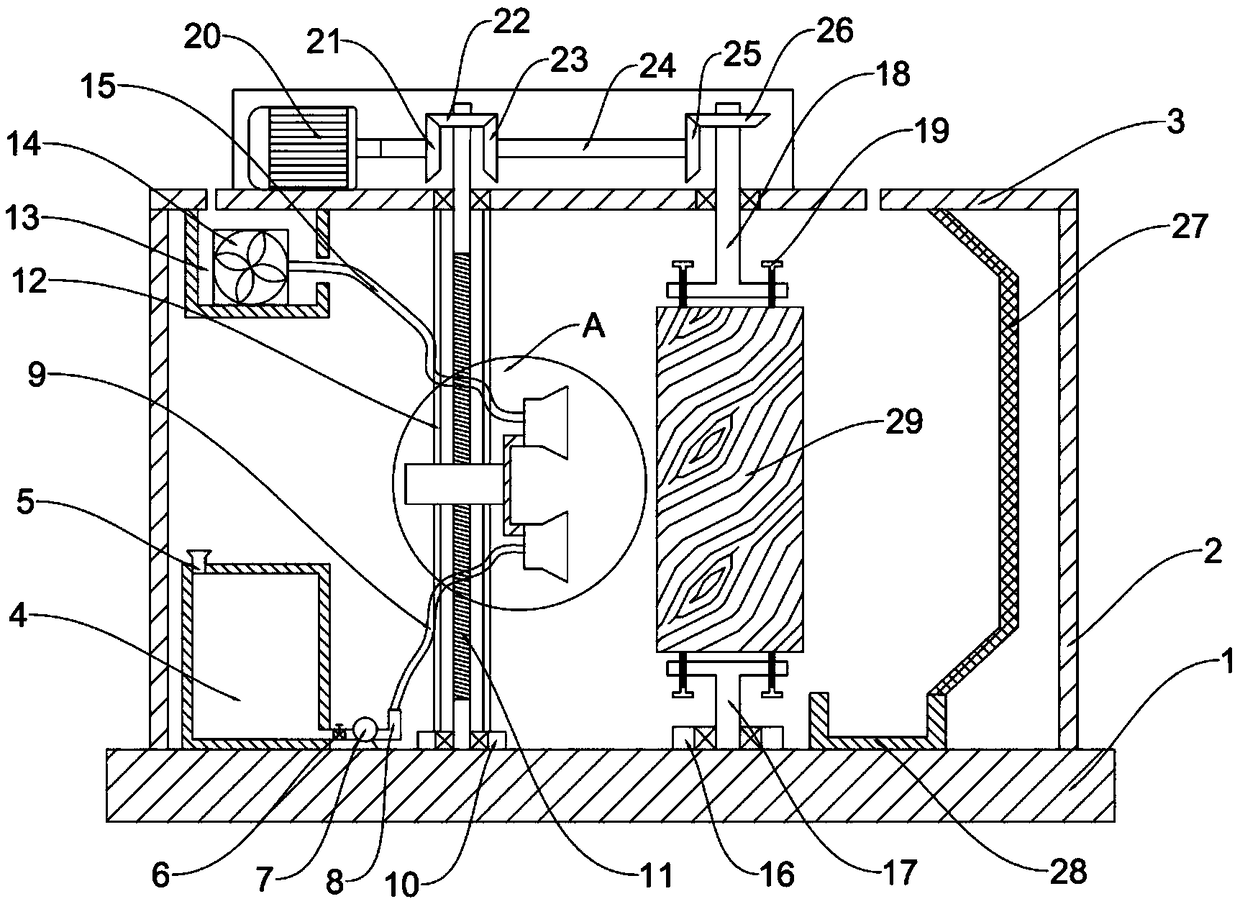

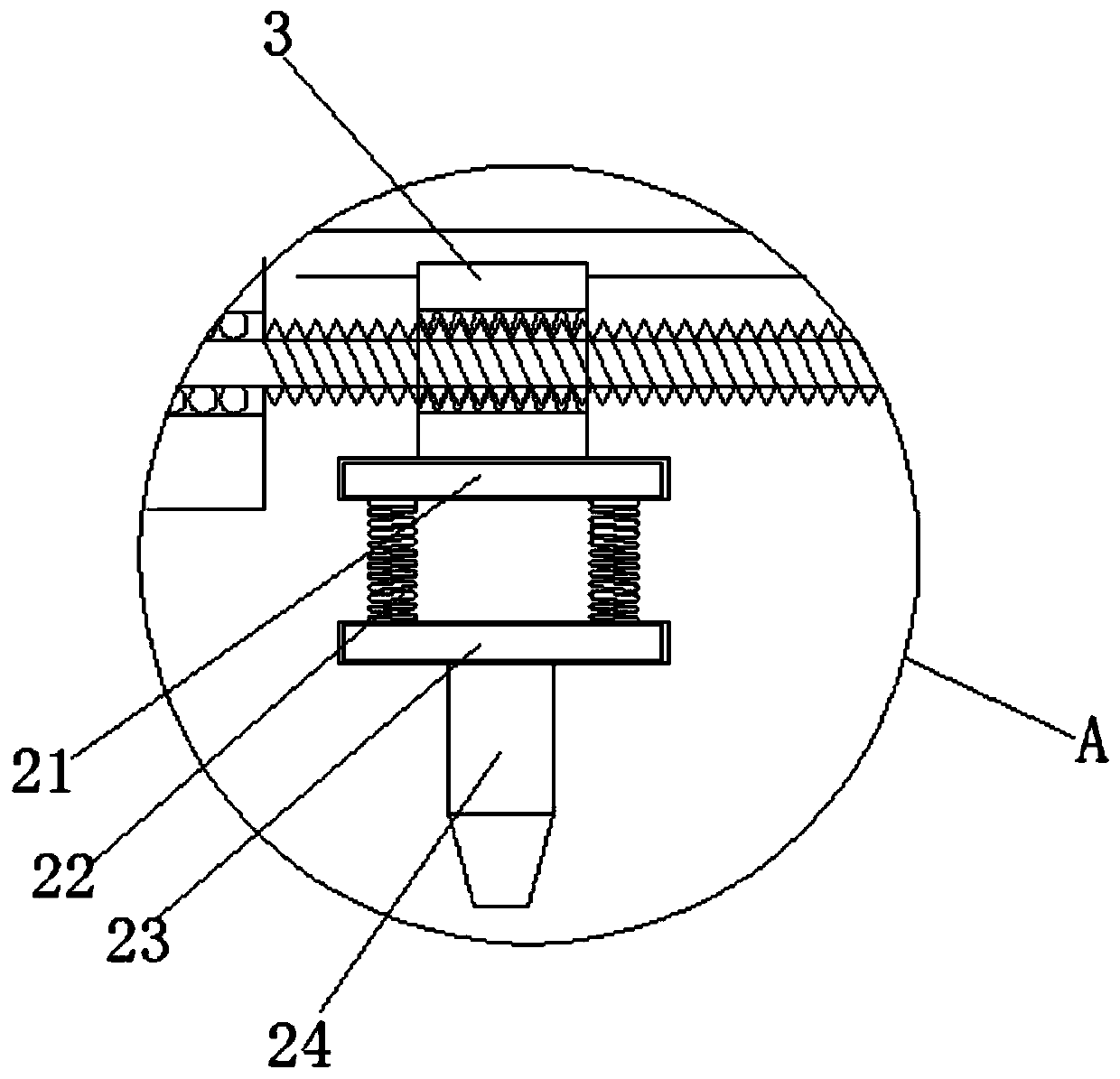

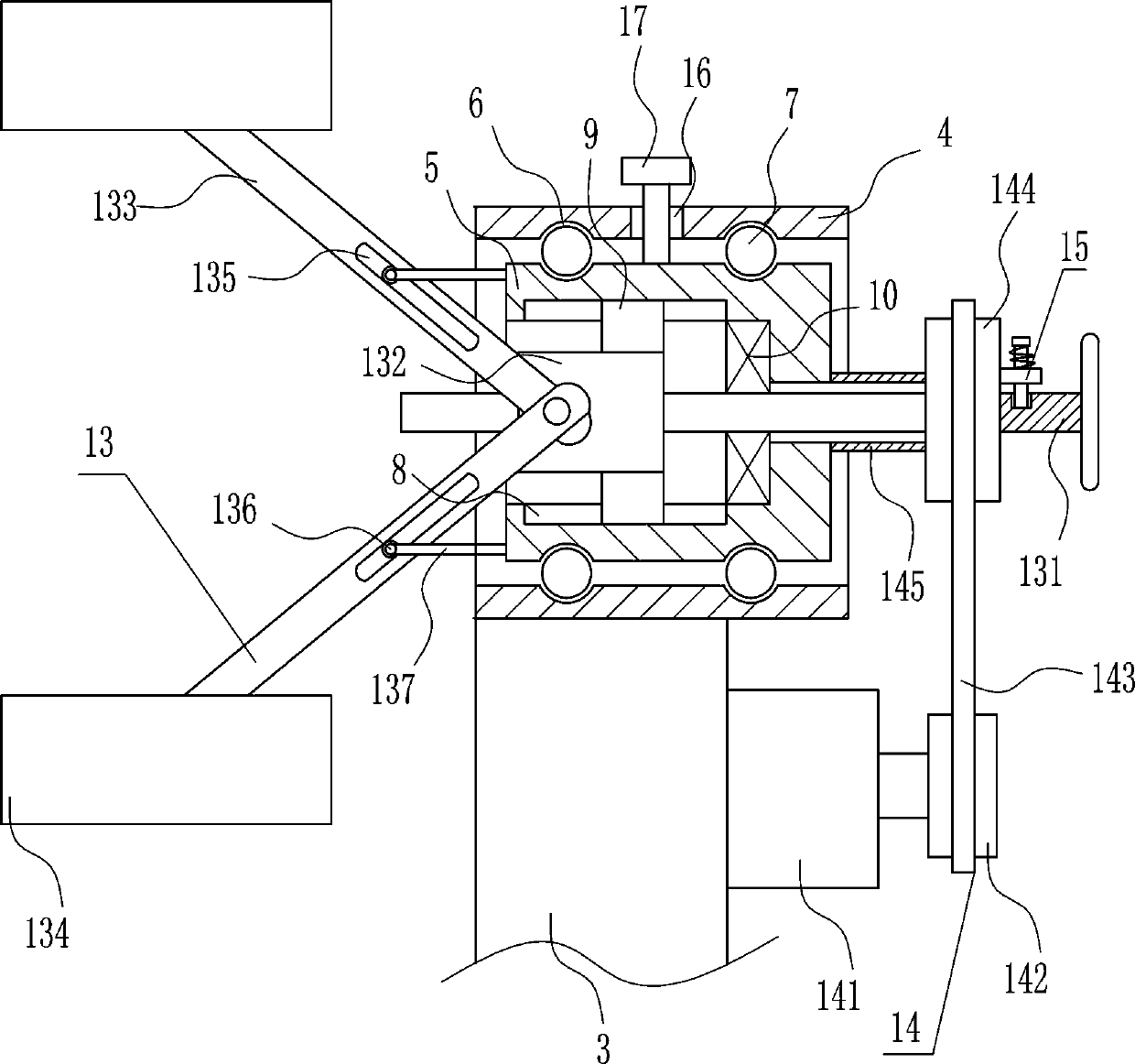

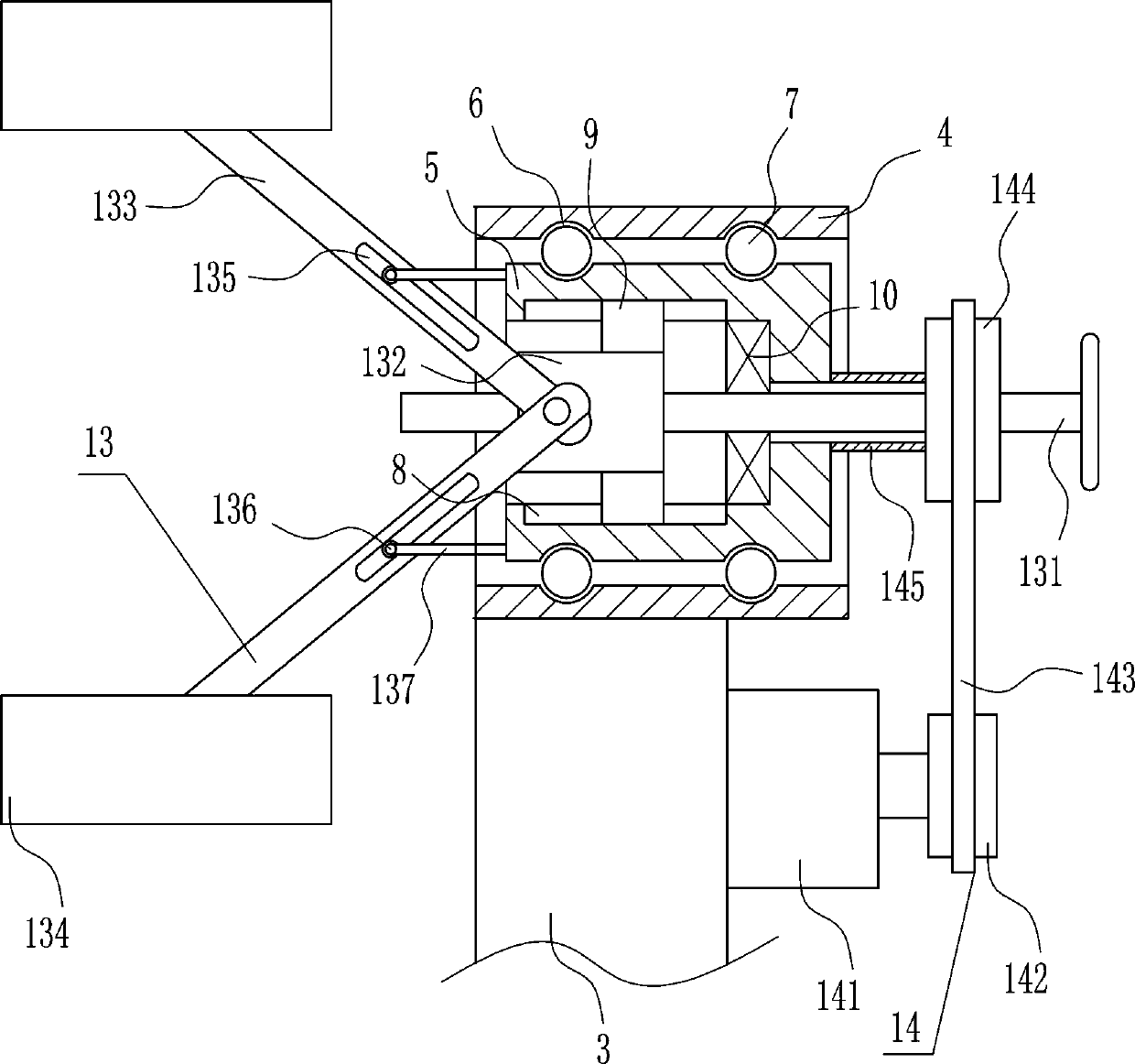

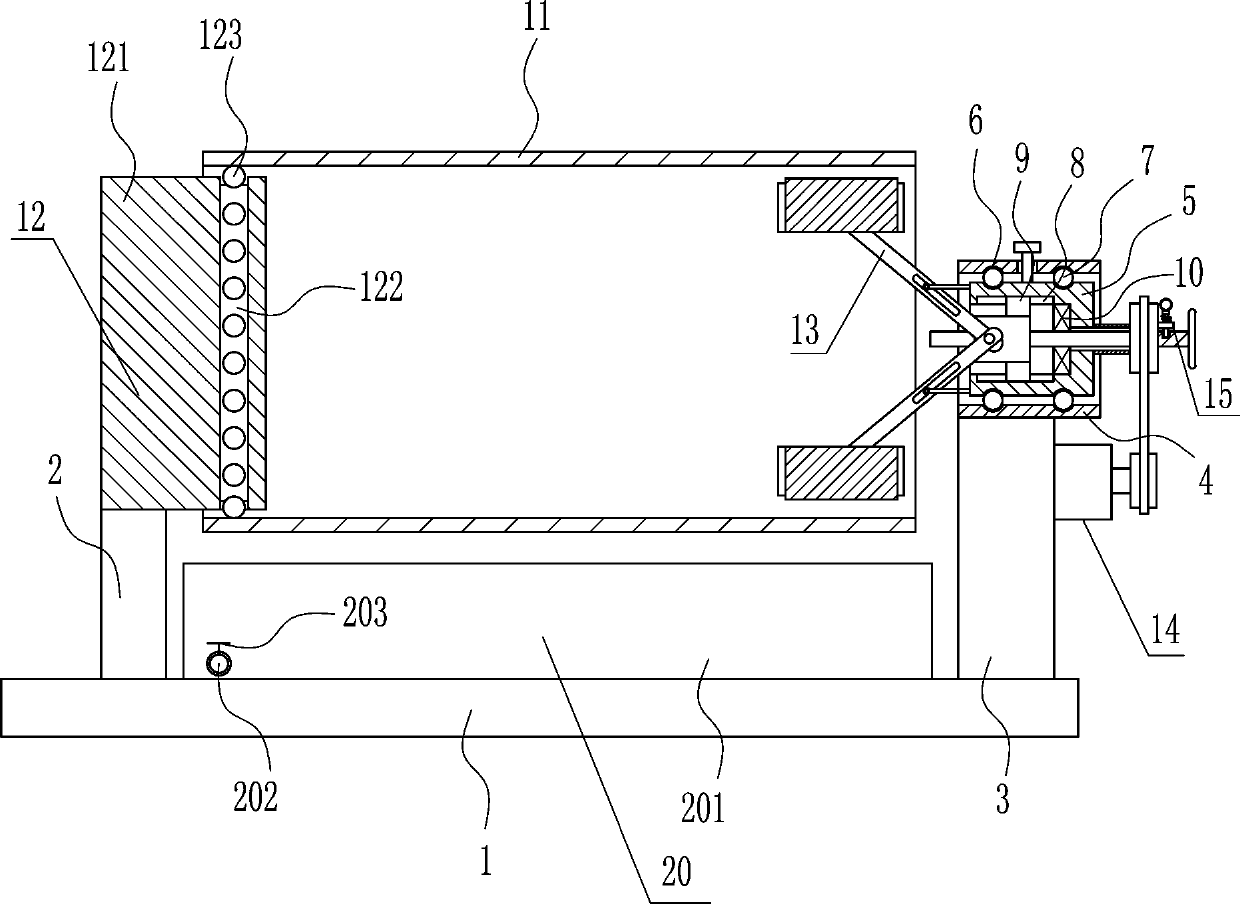

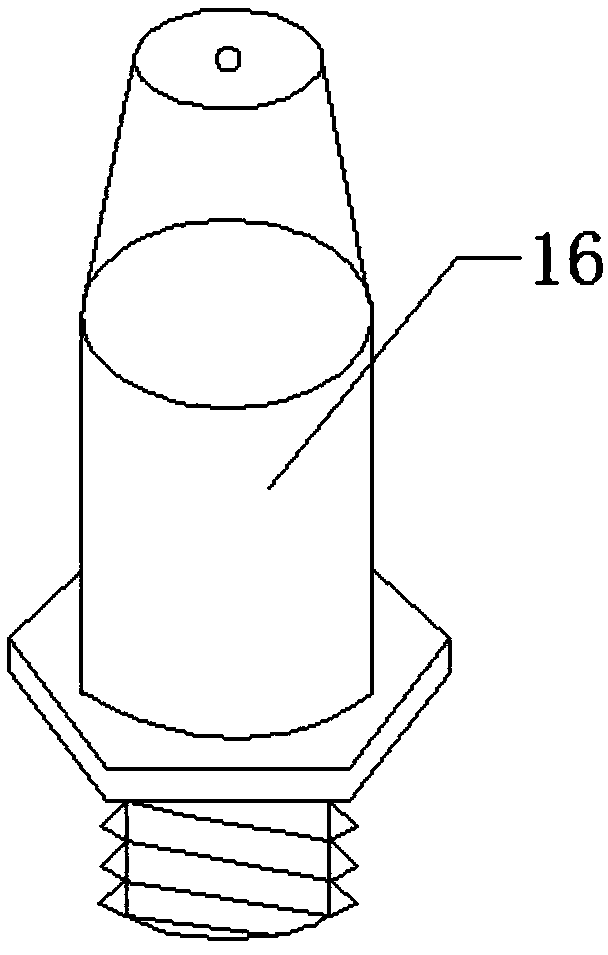

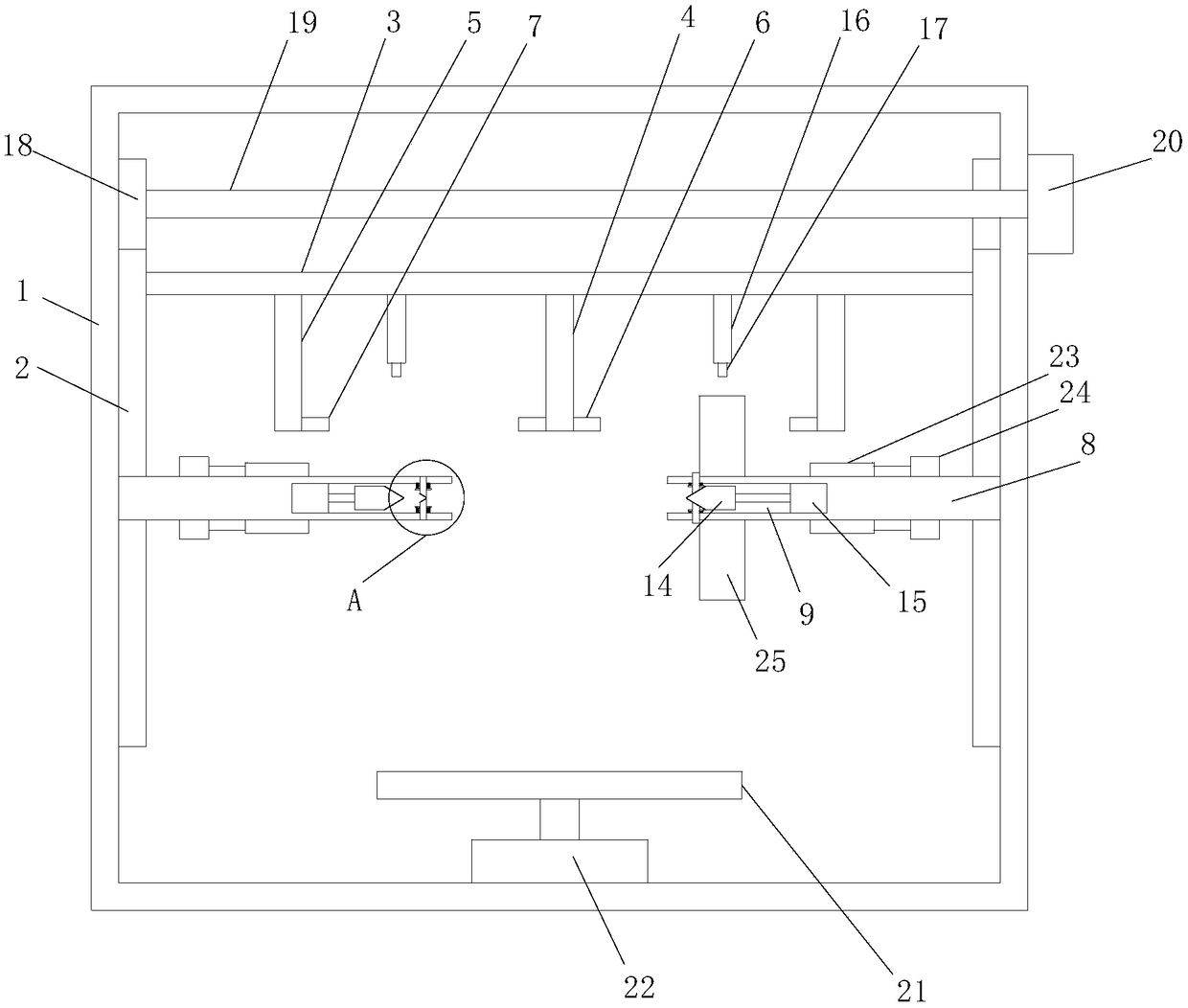

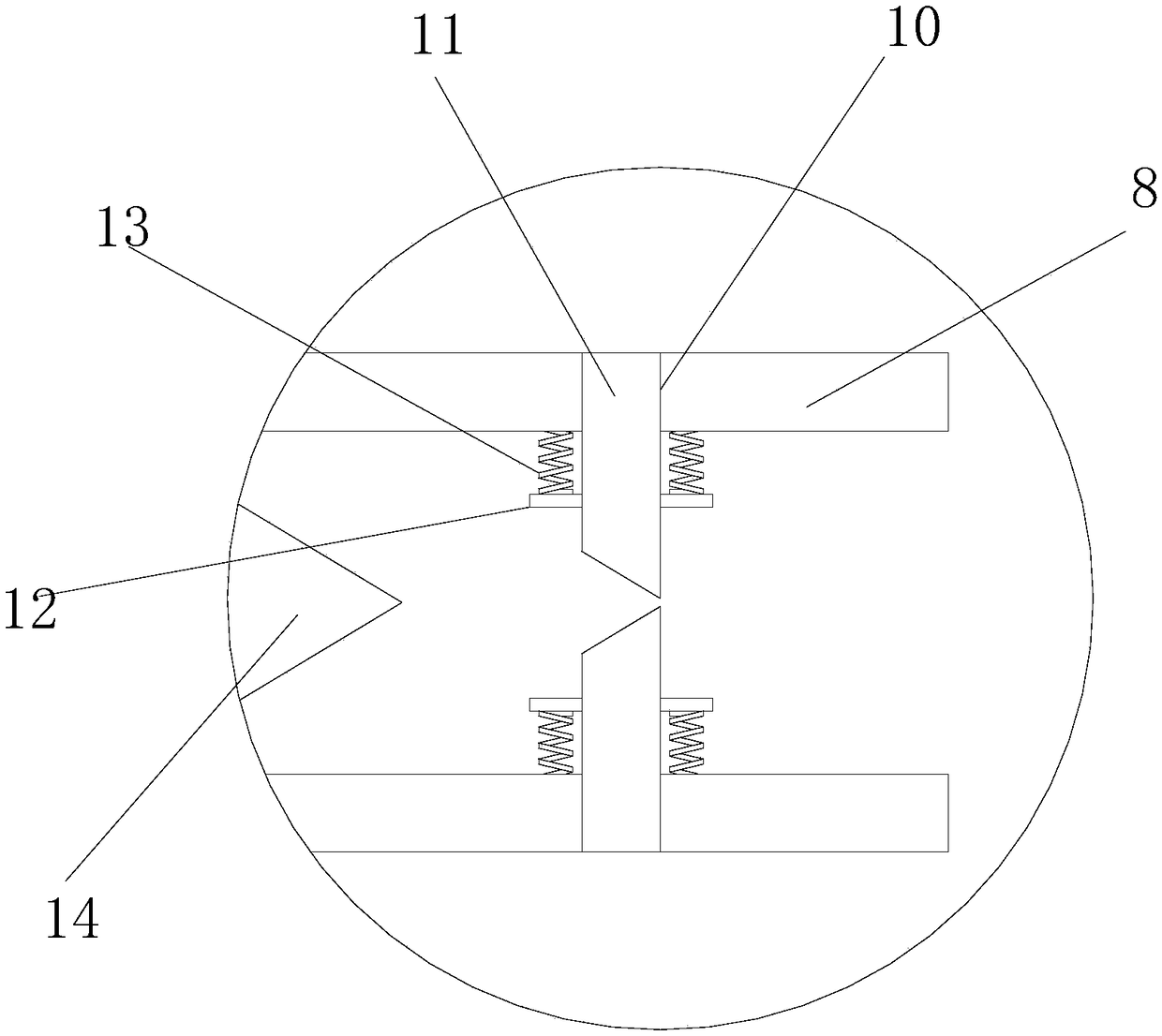

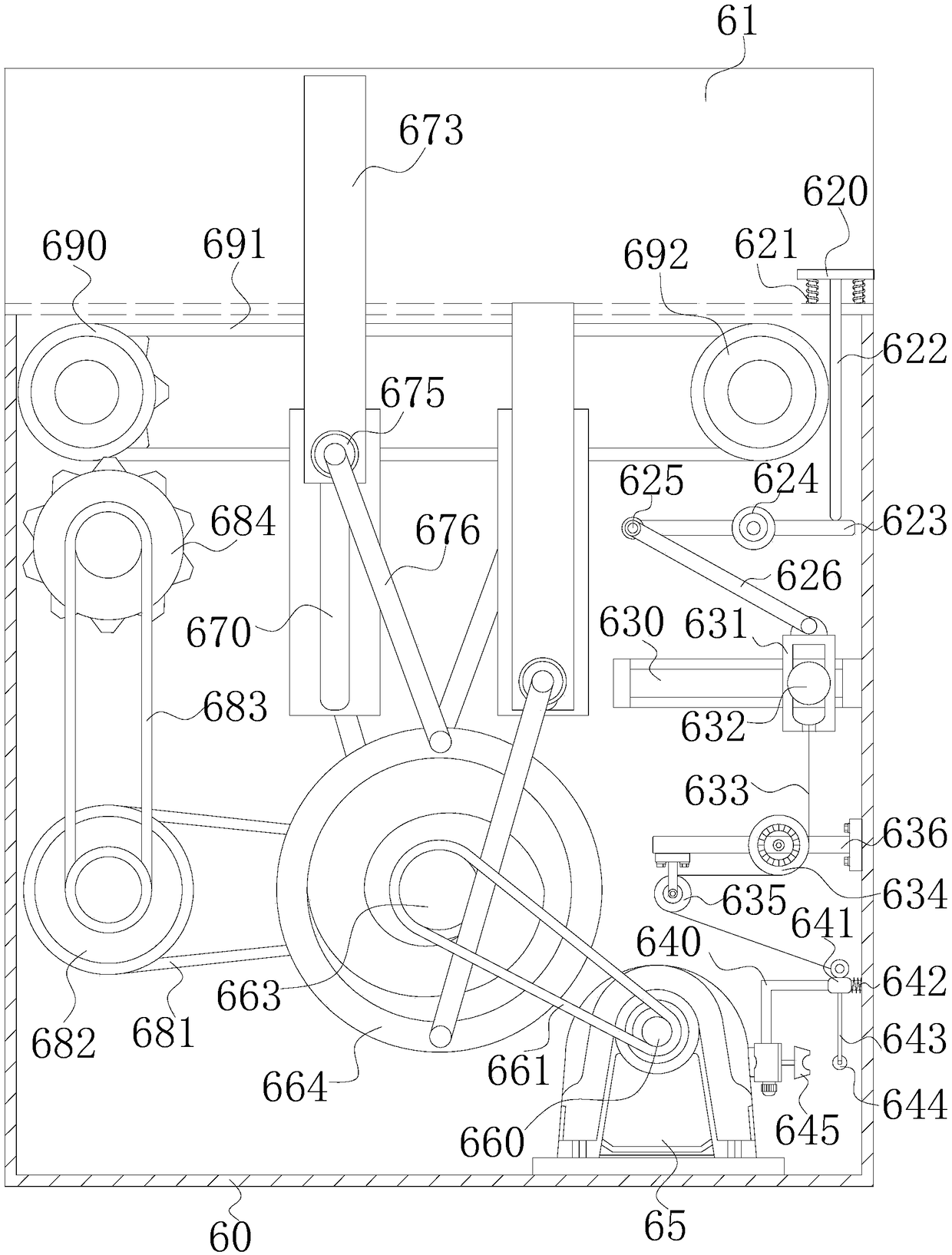

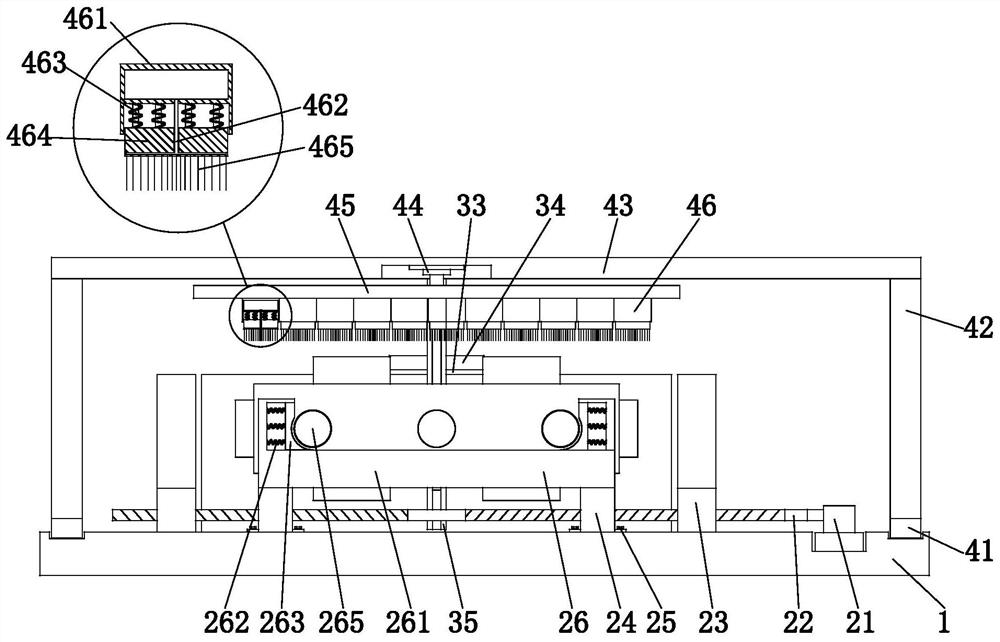

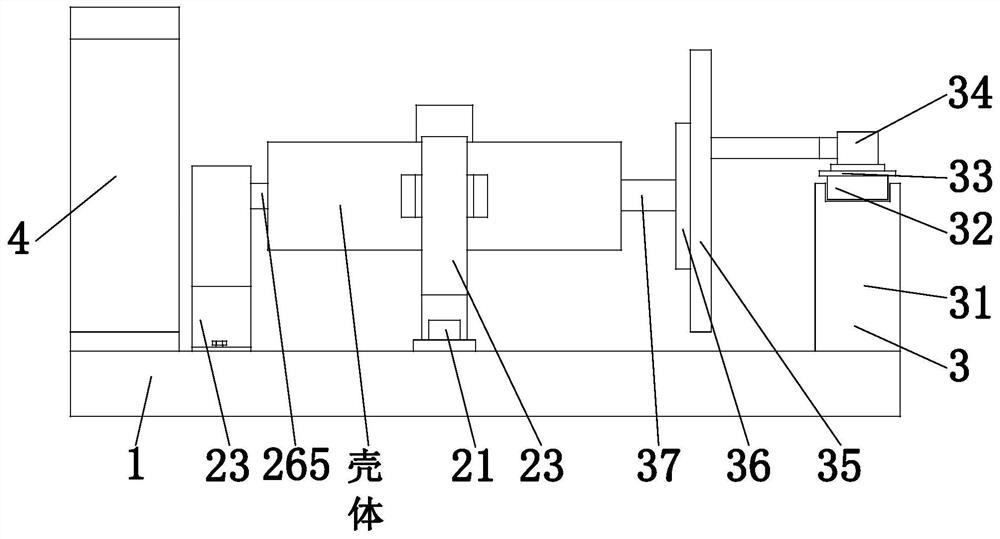

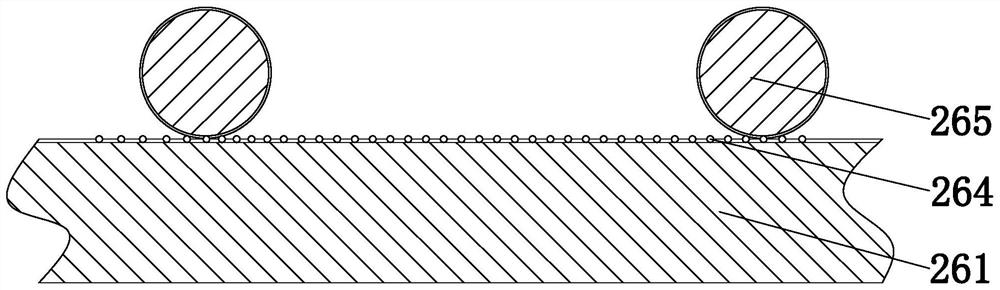

The invention discloses a device for spraying the surface of a cylindrical material with paint. The device comprises a housing, wherein a pressing chamber is formed in the housing and at the right endof the housing; a driving chamber is formed in the housing and at the left end of the housing; a driving mechanism for providing power for the device is arranged in the driving chamber; a lowering mechanism for pressing the material, to be sprayed with the paint, is arranged in the pressing chamber; a rotating mechanism for rotating the material, to be sprayed with the paint, is arranged in the housing and at the lower end of the housing; and a paint spraying mechanism for spraying the material with the paint is arranged in the housing. When the device works, the device utilizes the shape characteristic of the material to perform rotary paint spraying on the material; the device is designed with a moving spray nozzle and thus can spray the rotating material with the paint from the top down; and therefore, the device can not only fully spray the material with the paint but also compete the paint spraying of the whole material quickly and efficiently.

Owner:嵊州摩天自动化设备有限公司

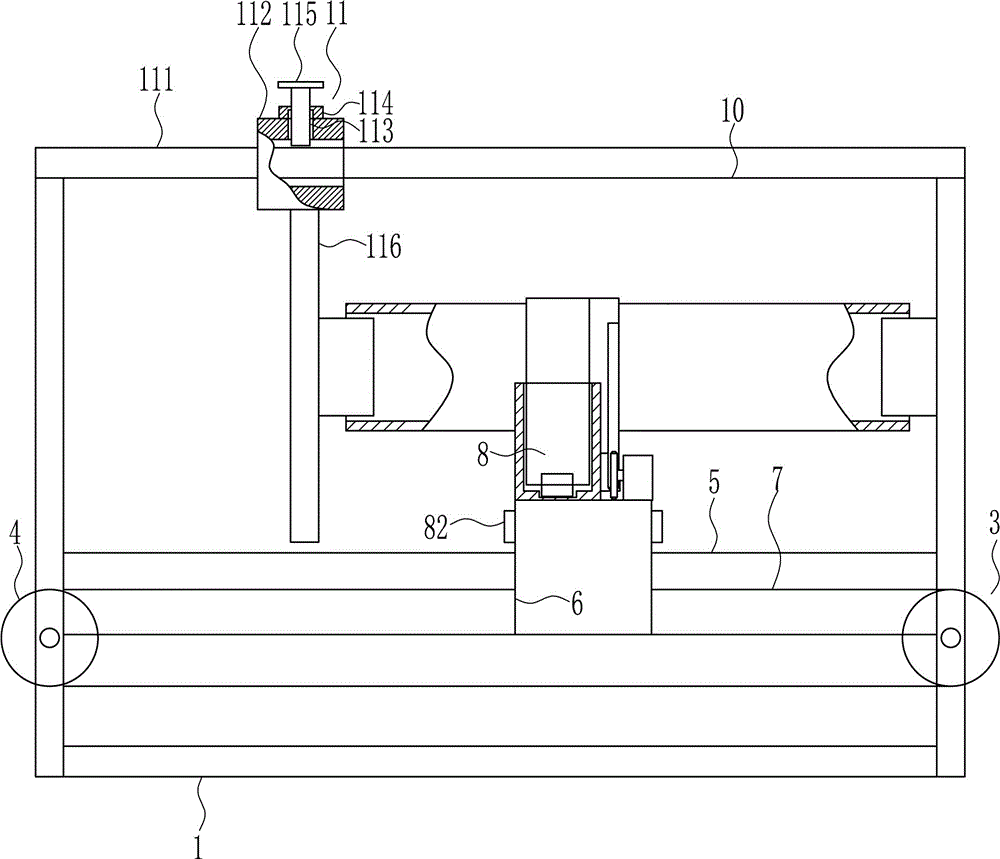

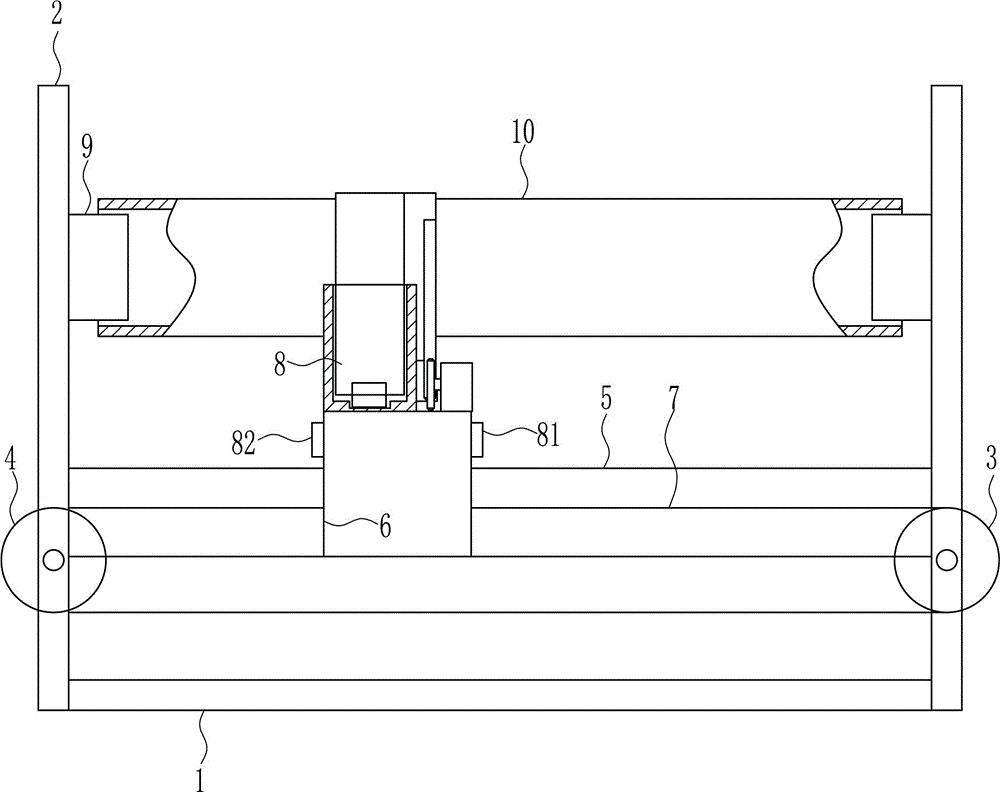

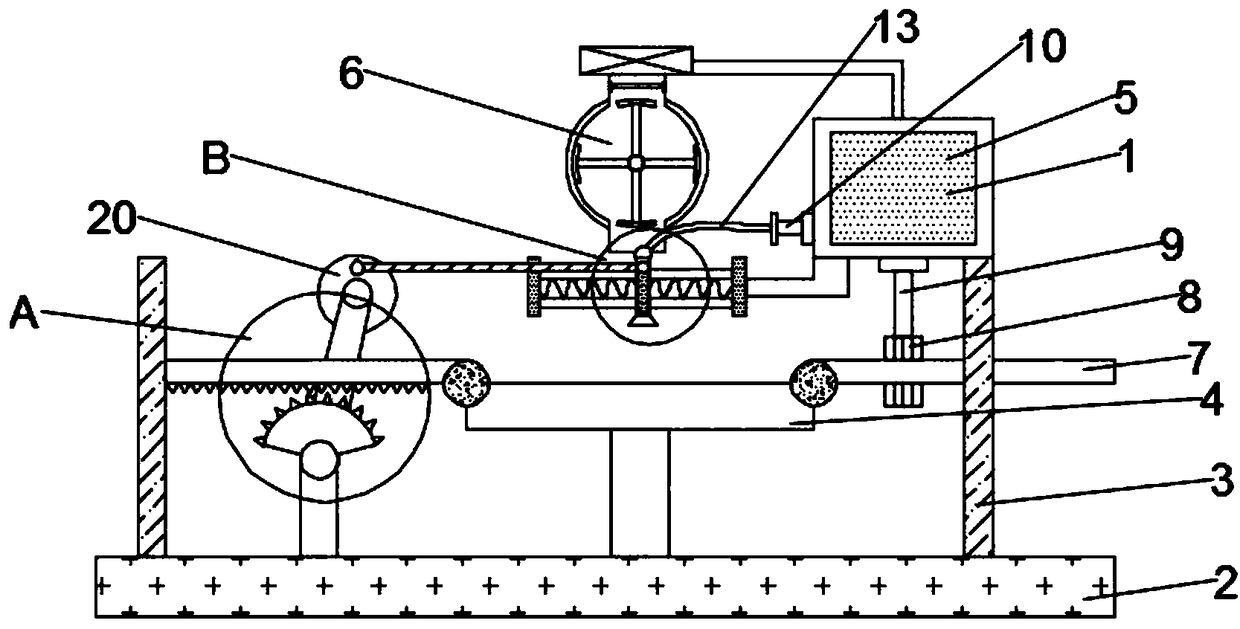

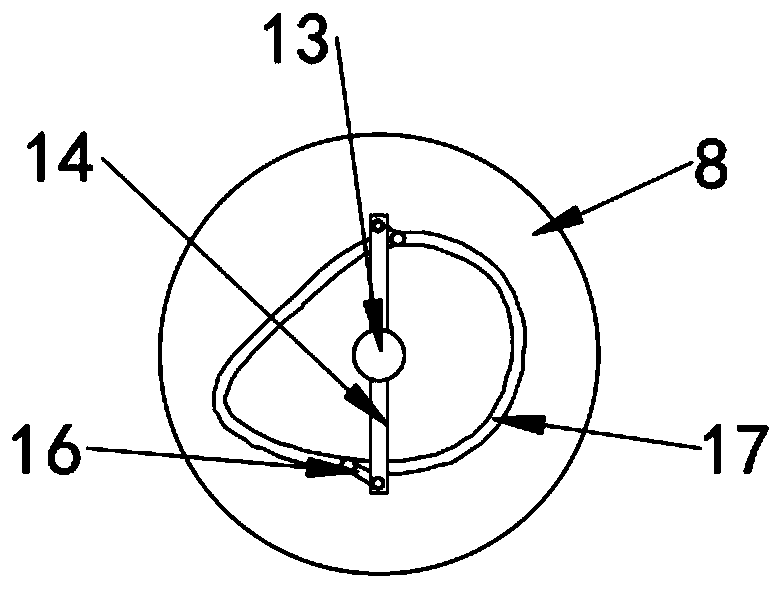

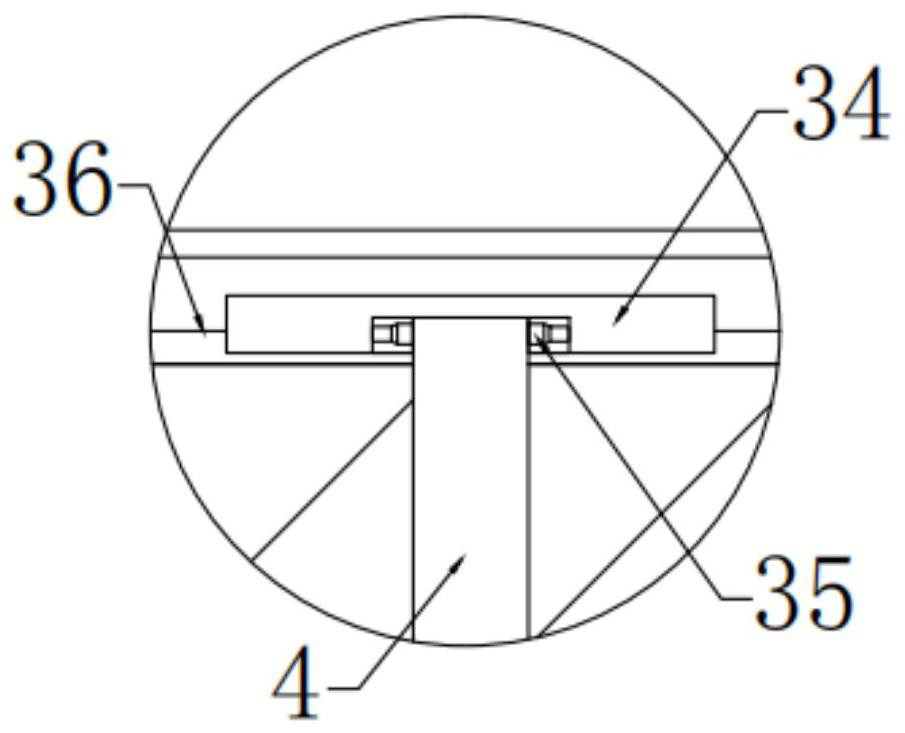

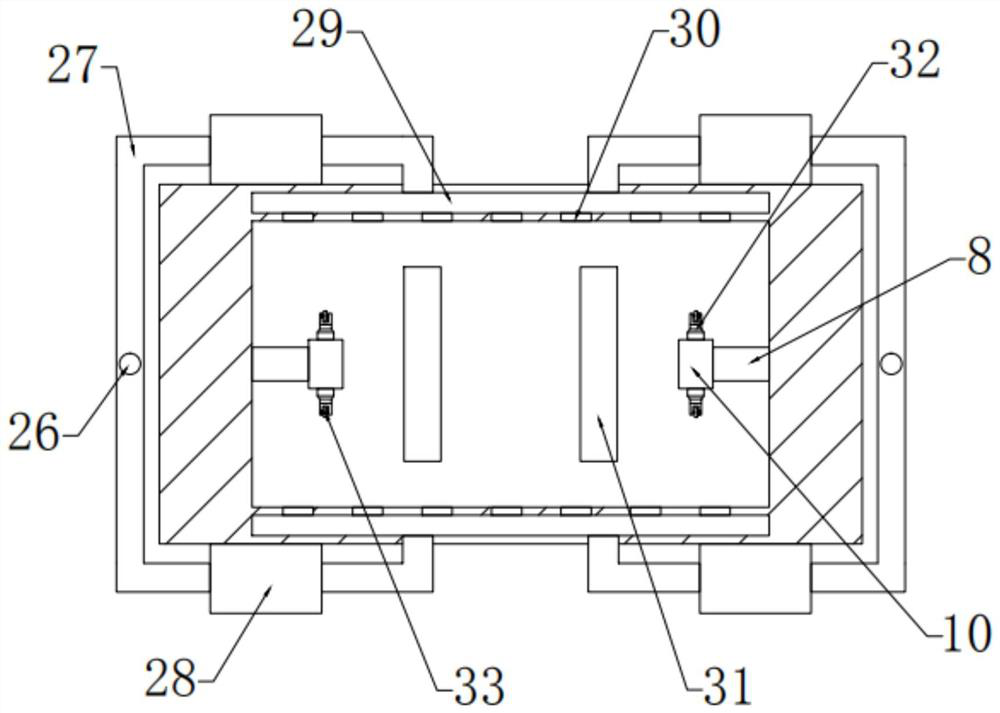

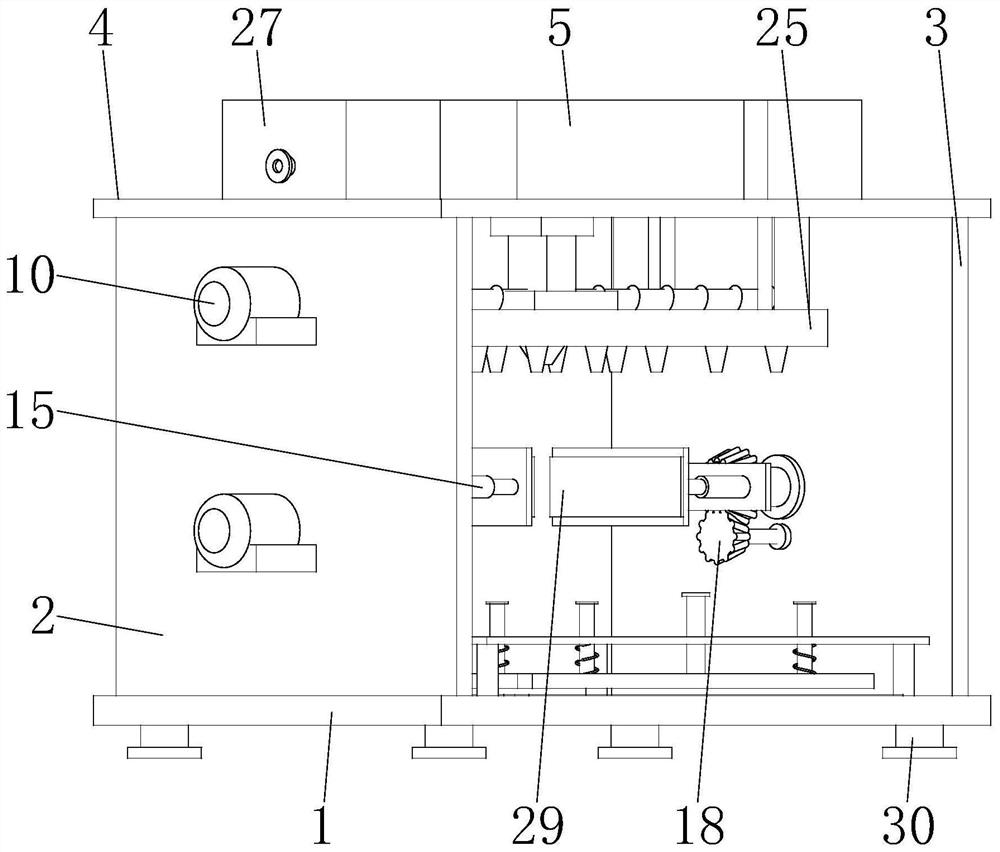

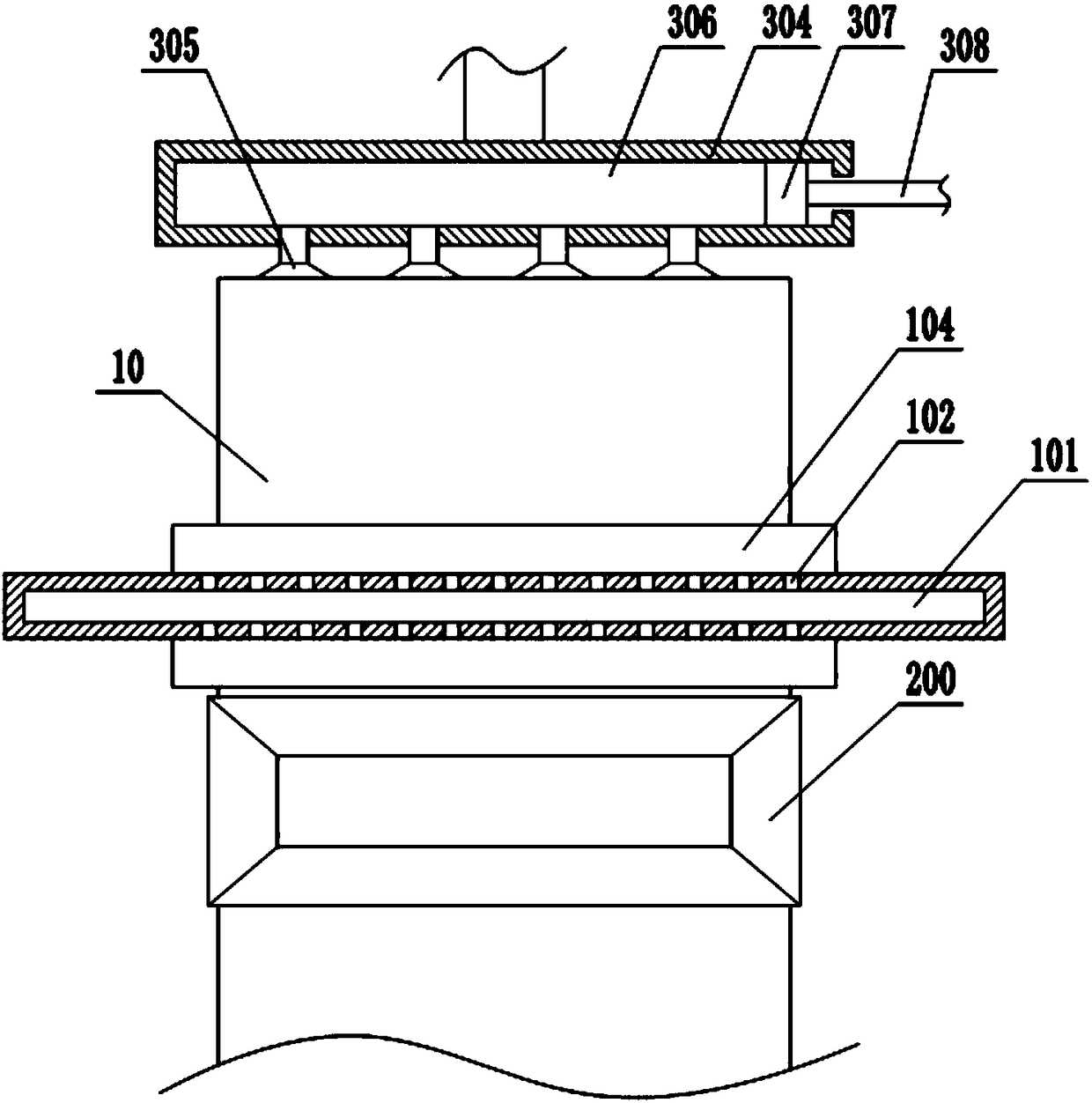

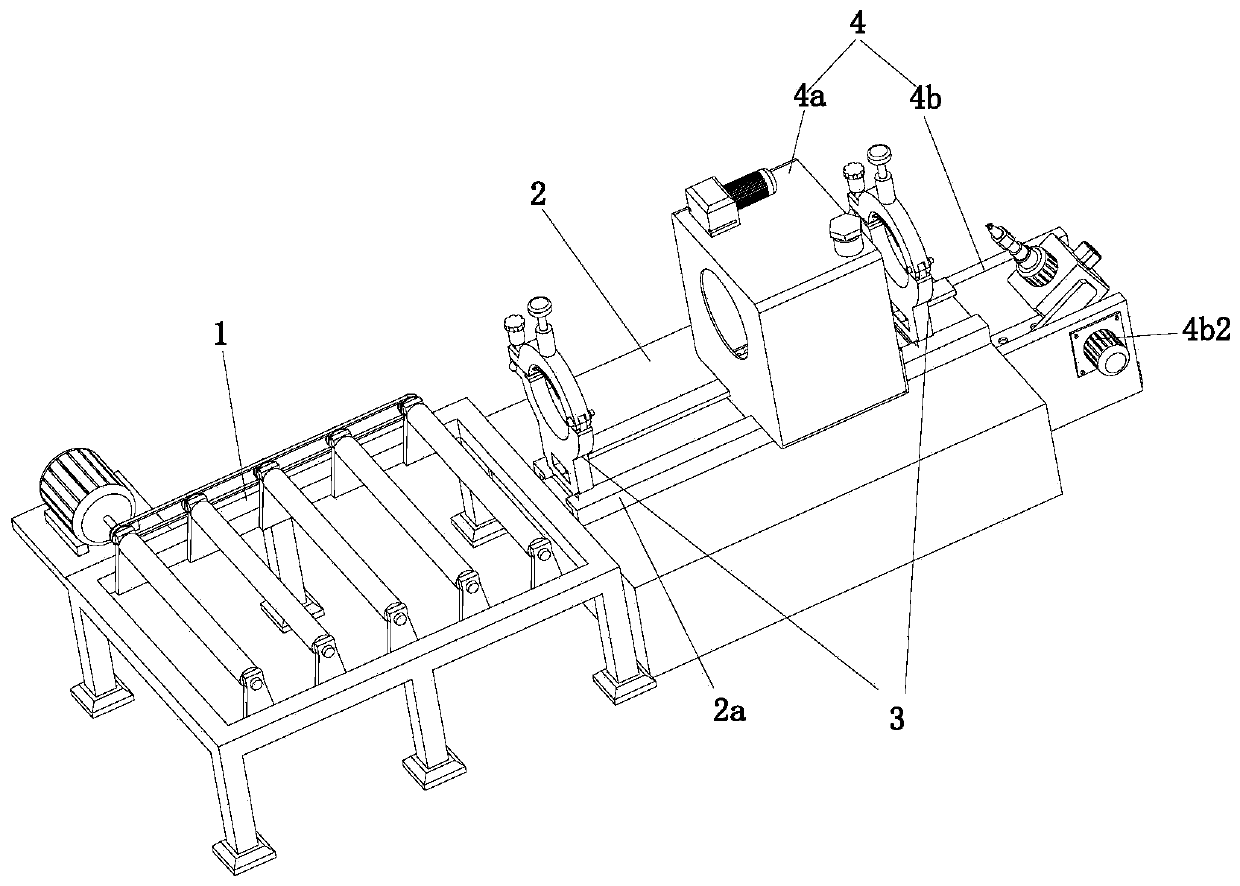

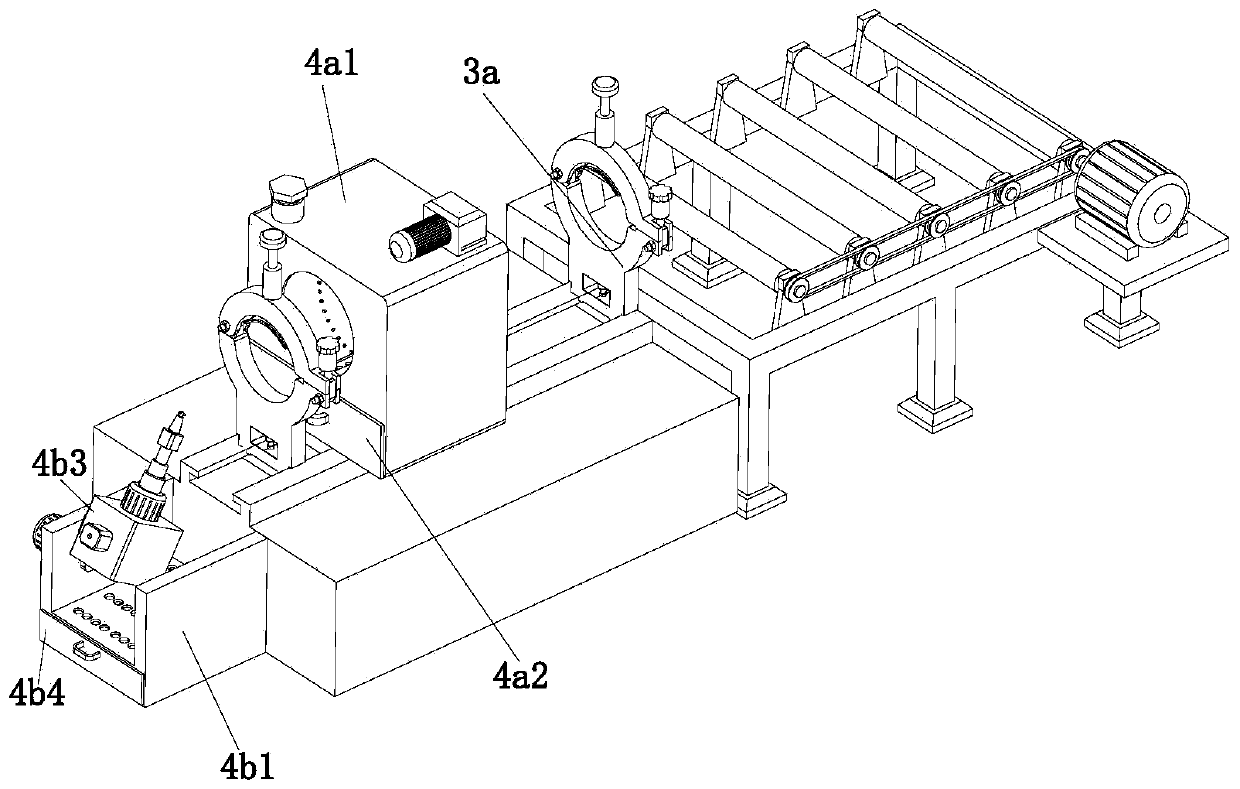

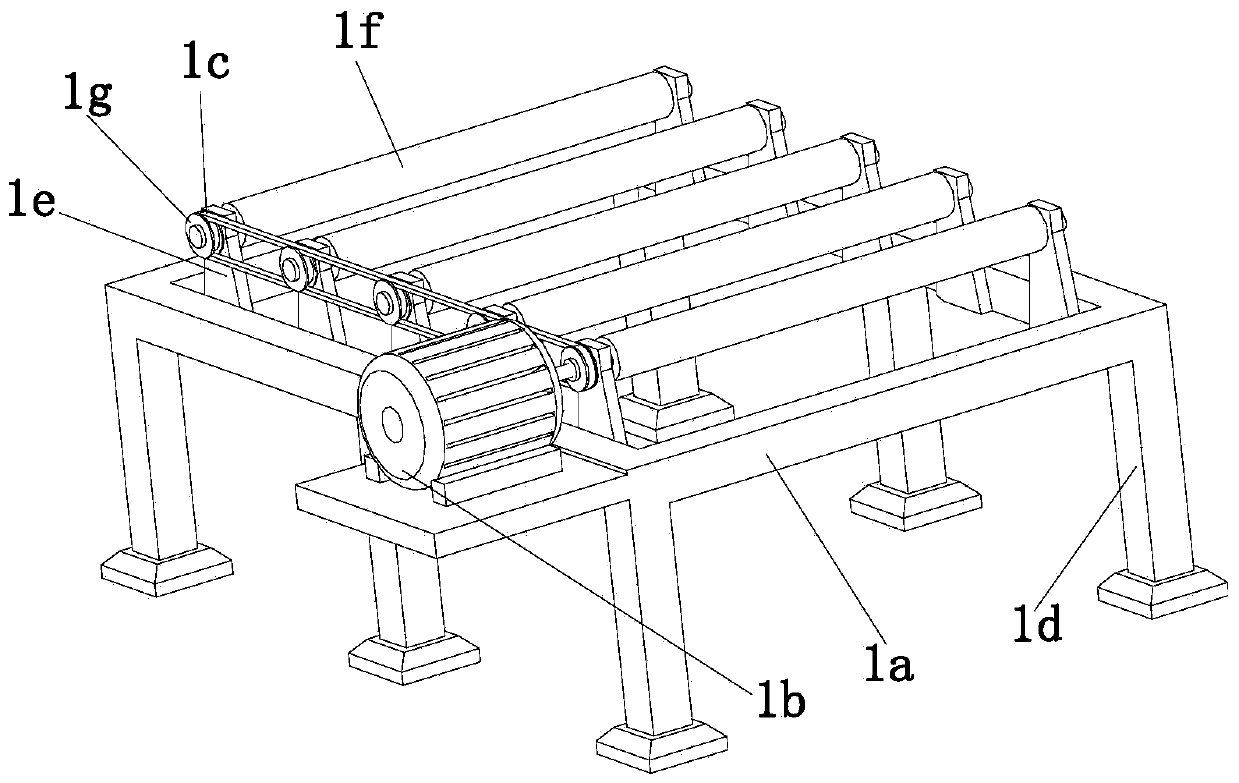

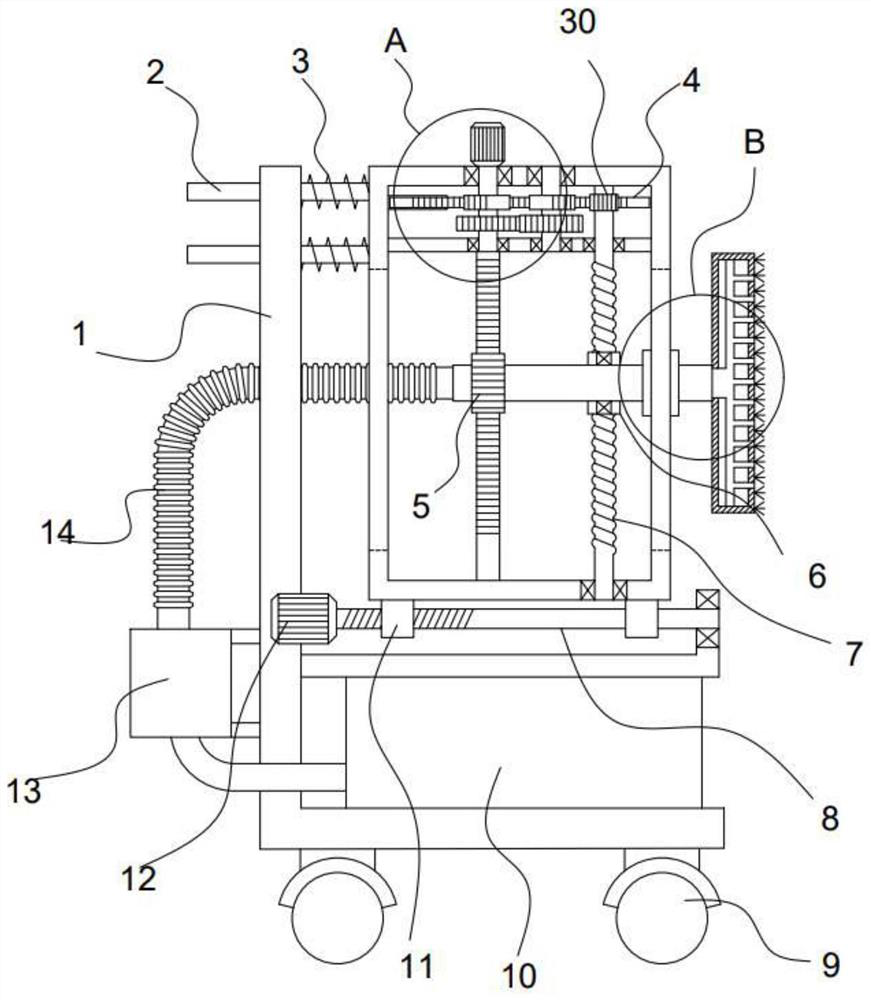

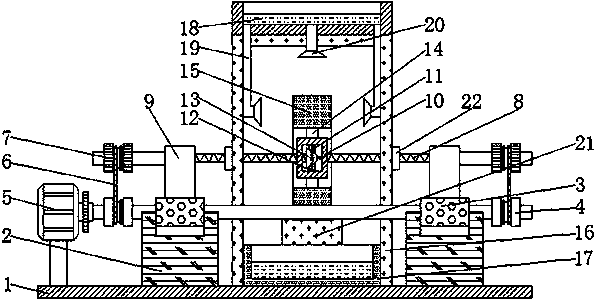

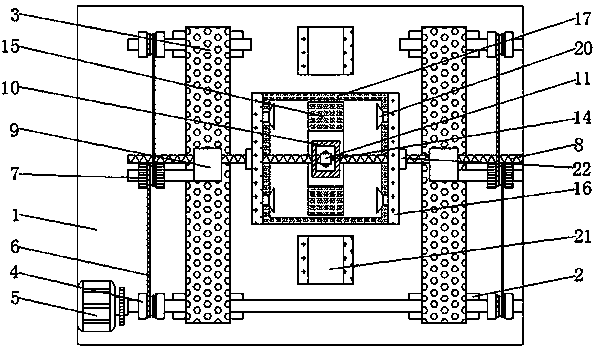

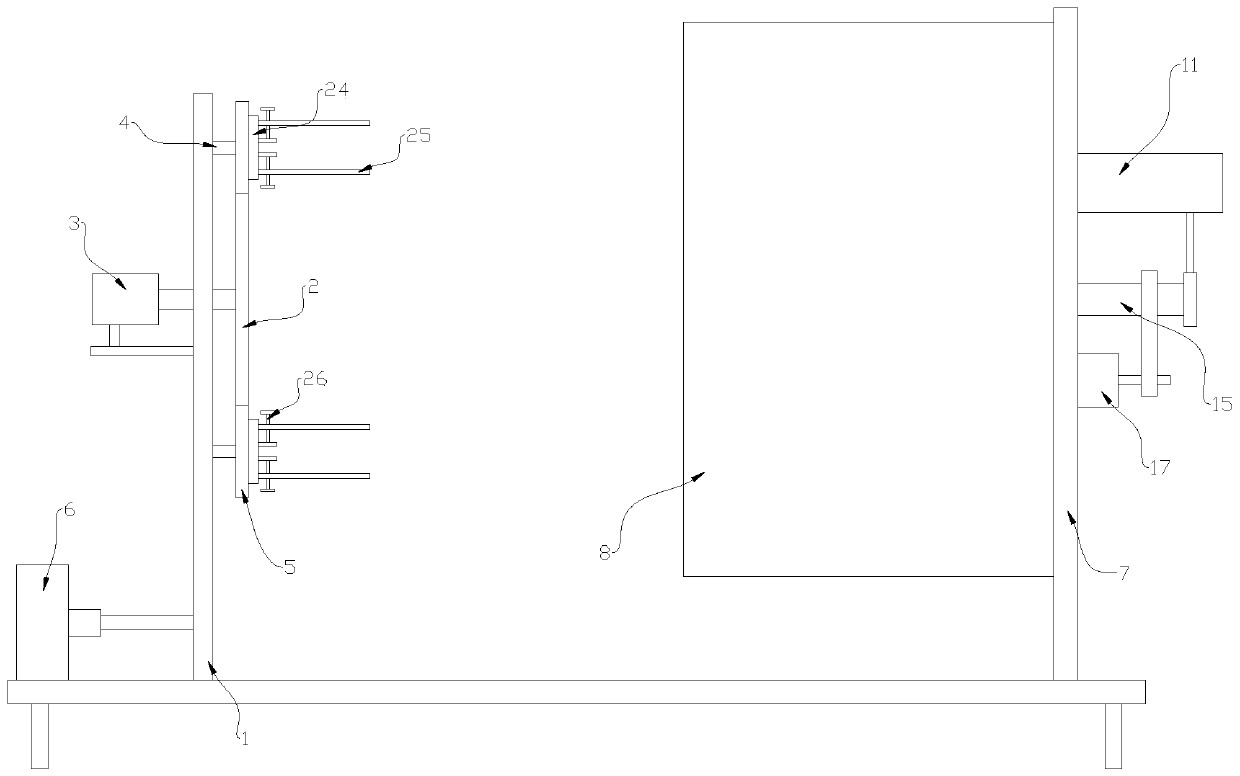

Industrial paint spraying equipment for surface of steel pipe

The invention relates to paint spraying equipment, in particular to industrial paint spraying equipment for the surface of a steel pipe. According to the industrial paint spraying equipment for the surface of the steel pipe, paint spraying is comprehensive, the paint spraying speed is high, and harm to workers in the paint spraying process is small. The industrial paint spraying equipment for the surface of the steel pipe comprises a base plate, supporting plates, a driving wheel, a driven wheel, a first sliding rail, a first sliding block and the like. The supporting plates are symmetrically mounted at the left end and the right end of the base plate in a welded mode. The driving wheel is rotatably connected to the front side of the lower portion of the supporting plate on the right side. The driven wheel is rotatably connected to the front side of the lower portion of the left supporting plate. The first sliding rail is connected between the supporting plates on the left side and the right side in a welded mode. By adoption of the paint spraying equipment, the effects of comprehensive paint spraying, high paint spraying speed, and little harm to the workers in the paint spraying process are achieved.

Owner:江苏新大高空工程有限公司

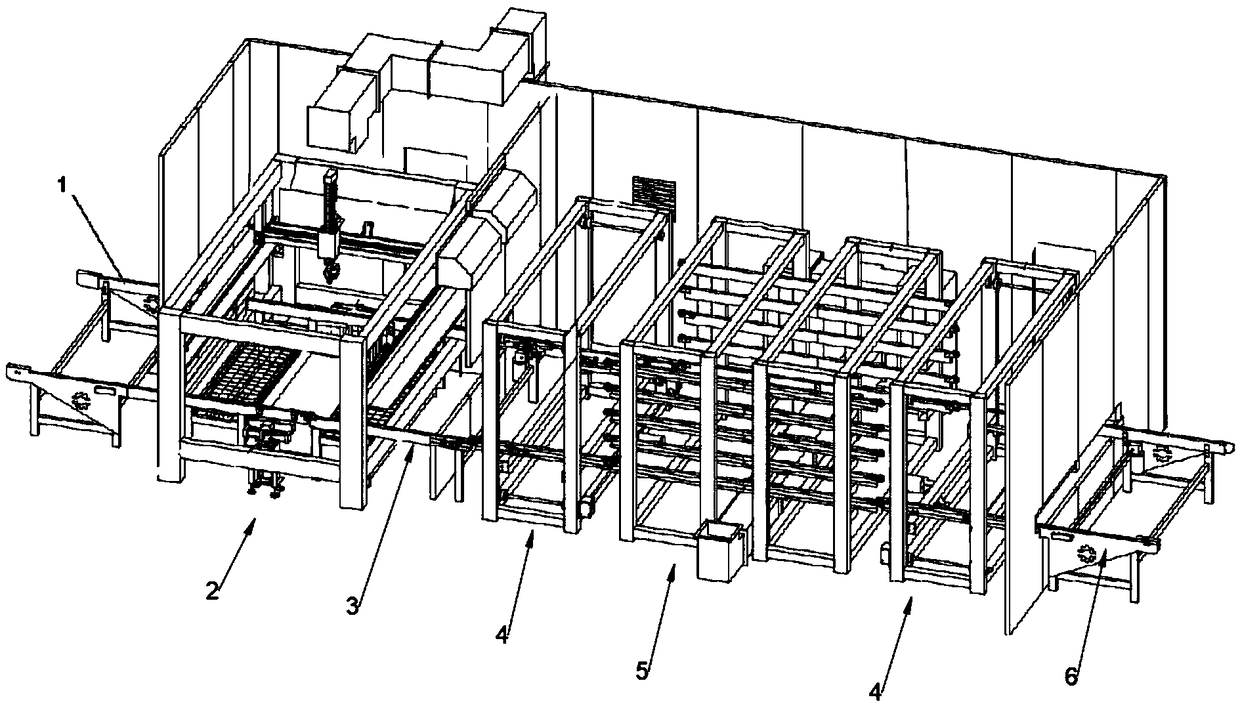

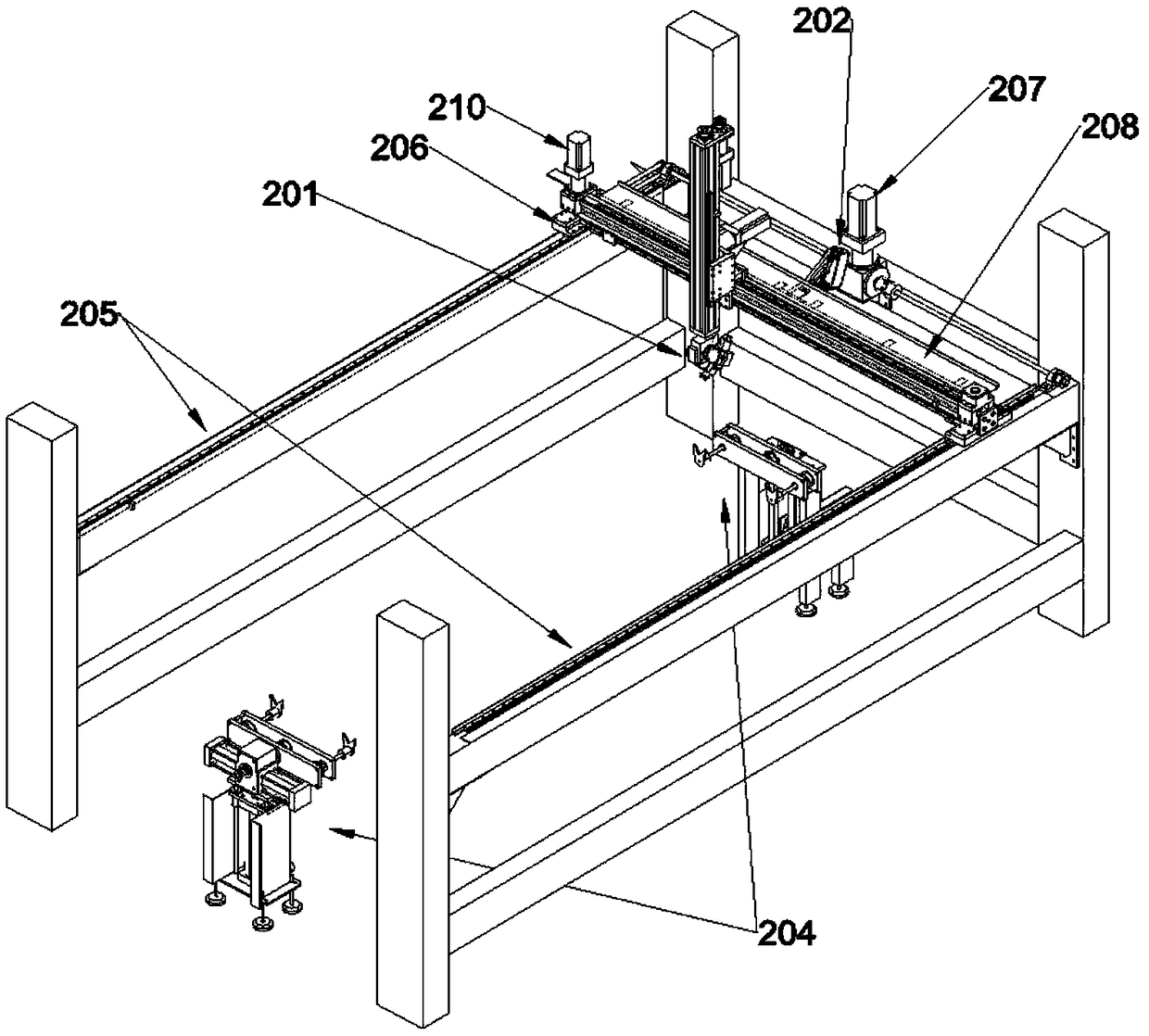

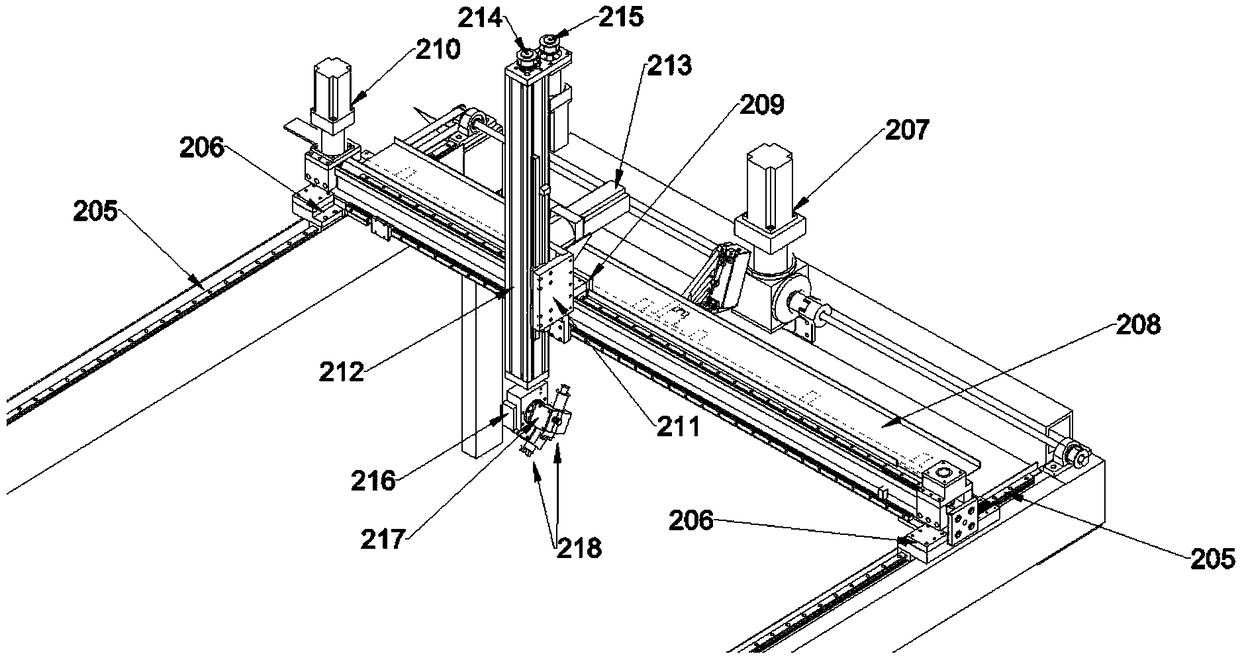

Full-automatic door panel painting equipment and method

PendingCN109433469AImprove spraying effectNo dead angle sprayingSpray boothsEngineeringSocial effects

The invention discloses full-automatic door panel painting equipment, and further discloses an automatic door panel painting method. The full-automatic door panel painting equipment comprises a feeding machine, a spray booth, a conveyor, a drying room, a discharging machine and a main controller. The feeding machine is used for conveying door panels to be painted into the spray booth. The spray booth is used for spraying the door panels to be painted. The conveyor is used for conveying painted door panels to the drying room. The drying room is used for drying the painted door panels. The discharging machine is used for transporting the dried door panels out of the drying room. The spray booth is internally provided with spray guns, a 3D laser scanner and a painting position, a pair of door-turning machines is arranged at both ends of the painting position, and the spray guns includes the large spray gun and the small spray gun. The automatic door panel painting method comprises the steps that the positioned door panels are first scanned by the 3D laser scanner, a painting route is planned, the small spray gun is used for accurately spraying the uneven or engraved positions, and then the large spray gun is used for comprehensively spraying the flat parts. The full-automatic door panel painting equipment is high in running speed, good in spraying effect and large in benefit improvement, pollution is minimized, and a good social effect is achieved.

Owner:龙口欧德珑精密机械制造有限公司

Wood surface treatment equipment for producing furniture

InactiveCN108745748AAchieving turbulent mixingAchieving cutting and mixingSpray boothsSurface finishingWood machining

The invention discloses wood surface treatment equipment for producing furniture. The wood surface treatment equipment comprises a machine body, a base, supporting stand columns, a paint stirring boxand a heating device, wherein the base is horizontally arranged at the bottom of the machine body, the two supporting stand columns are symmetrically welded on the upper surface of the base, the paintstirring box is fixedly welded at the upper end of the supporting stand column on the right side, the heating device is arranged in the middle of the upper portion of the machine body, a wood placingtable is correspondingly arranged below the heating device, and the wood placing table is fixedly arranged in the middle of the upper surface of the base and is characterized in that a first rack iswelded to the right section of the wood placing table, and a pressurizing pump is welded to the bottom of the left side wall of the paint stirring box. According to the wood surface treatment equipment for producing the furniture, pain spraying treatment can be rapidly carried out on the wood surface, the paint spraying effect is good, the paint surface is uniform, and the thickness is consistent;and the paint surface after paint spraying can be quickly dried, and then the quality of the furniture after wood processing is guaranteed.

Owner:清远市简居科技有限公司

Uniform paint spraying device for spraying paint to lifting hook

The invention discloses a uniform paint spraying device for spraying paint to a lifting hook, and belongs to the technical field of paint spraying devices. A rotary disc is mounted at the output end of a fourth drive motor, a clamping assembly is mounted on the top of the rotary disc, a filter net is arranged on the portion, located on the outer side of the rotary disc, of the top of a base, firstthreaded rods are mounted on the two sides of the top of the filter net through bearings, side plates are mounted on the two sides of the top of the filter net, a top plate is mounted on the tops ofthe side plates, a first drive motor is mounted on one side of the top of the top plate, the output end of the first drive motor and the tops of one group of first threaded rods are fixed, a driving transmission gear is mounted on the tops of the outer sides of one group of first threaded rods, a transmission belt sleeves the outer side of the driving transmission gear, a driven transmission gearis mounted on the tops of the outer sides of the other group of first threaded rods, and the driven transmission gear is engaged with the inner side of the transmission belt. The lifting hook is sprayed more sufficiently, uniformly and comprehensively, and the lifting hook is clamped more stably through the clamping assembly.

Owner:新乡市长江起重机械有限公司

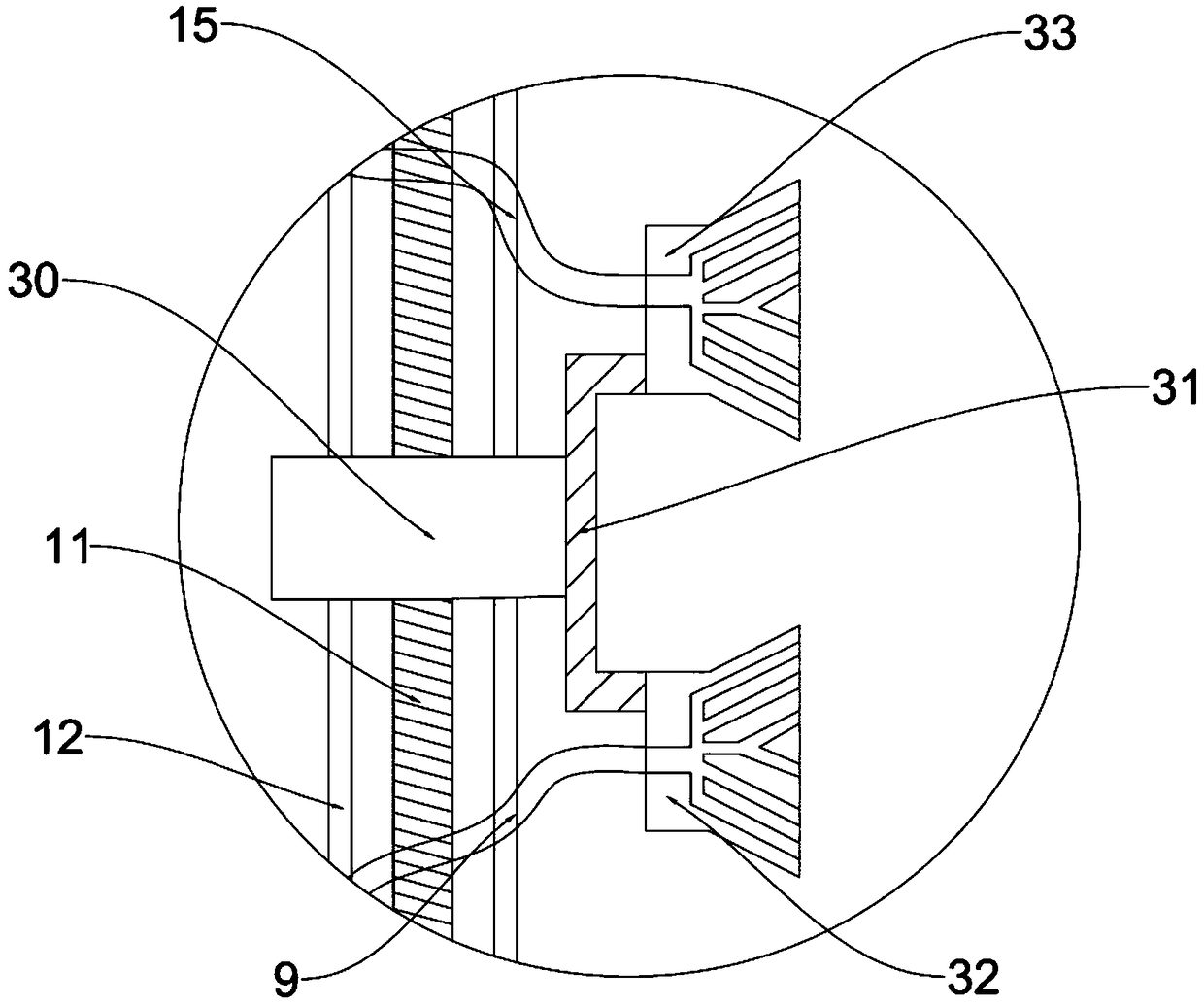

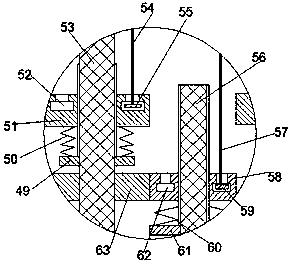

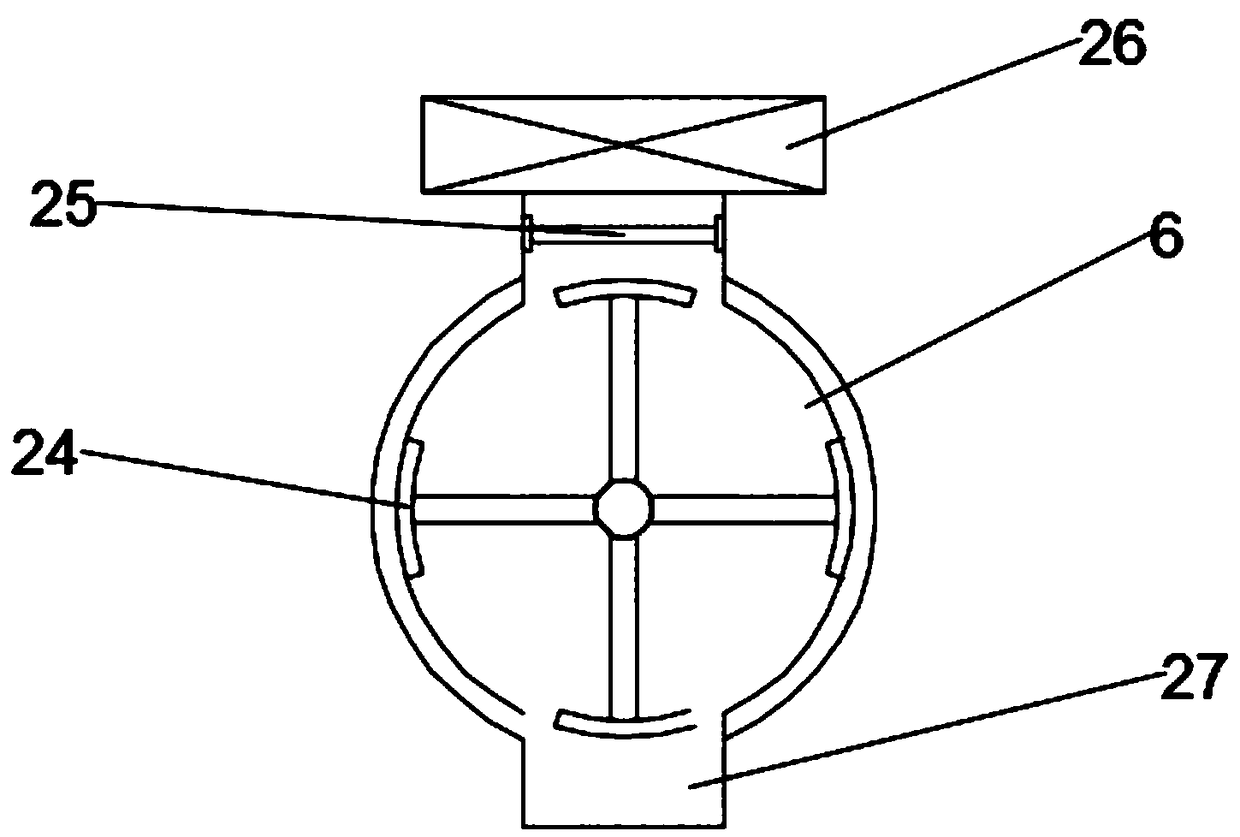

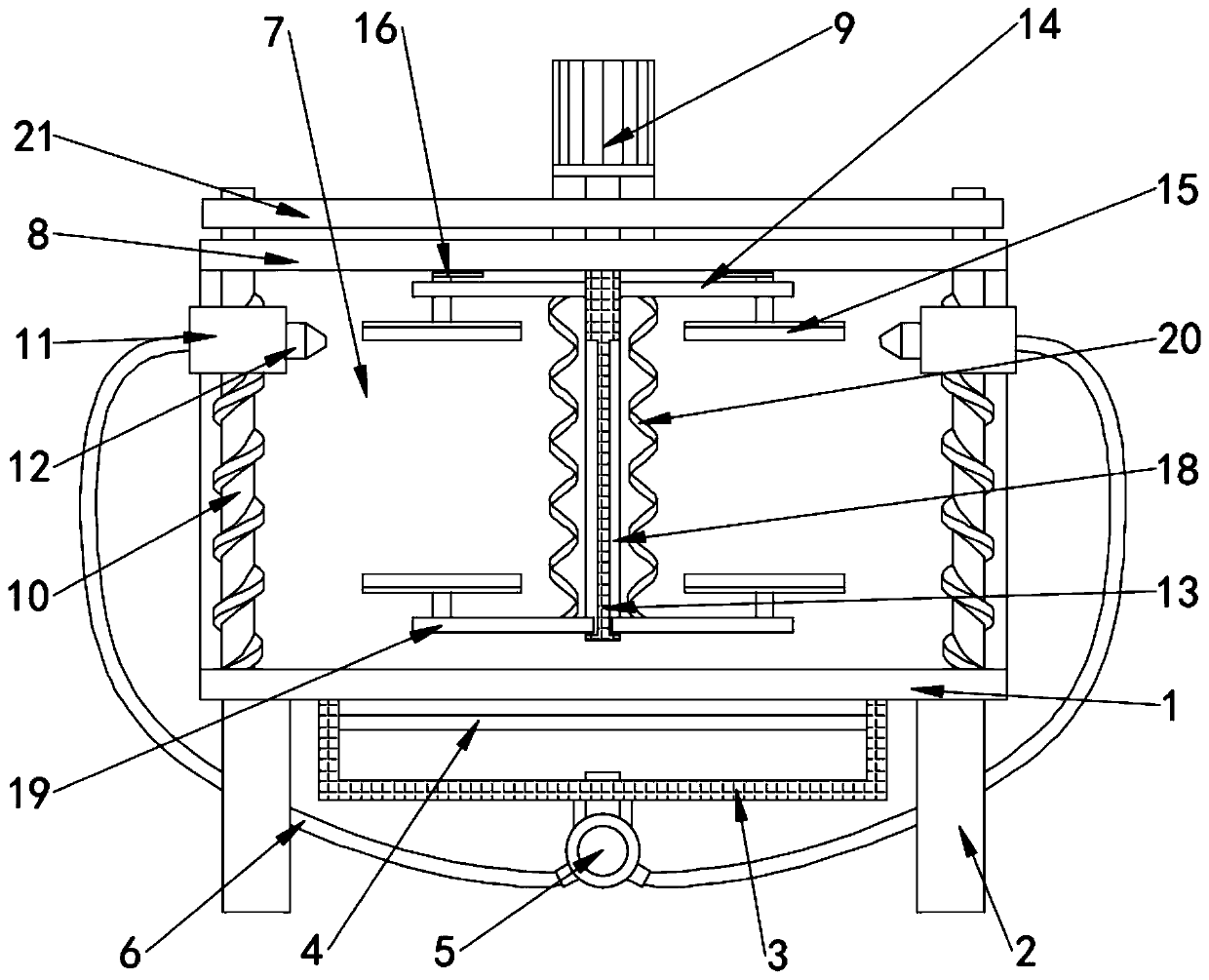

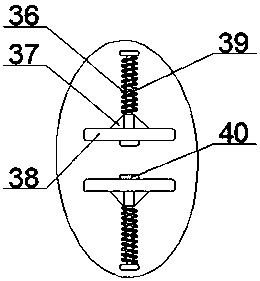

Supporting and fixing device for fire fighting pipeline paint coating

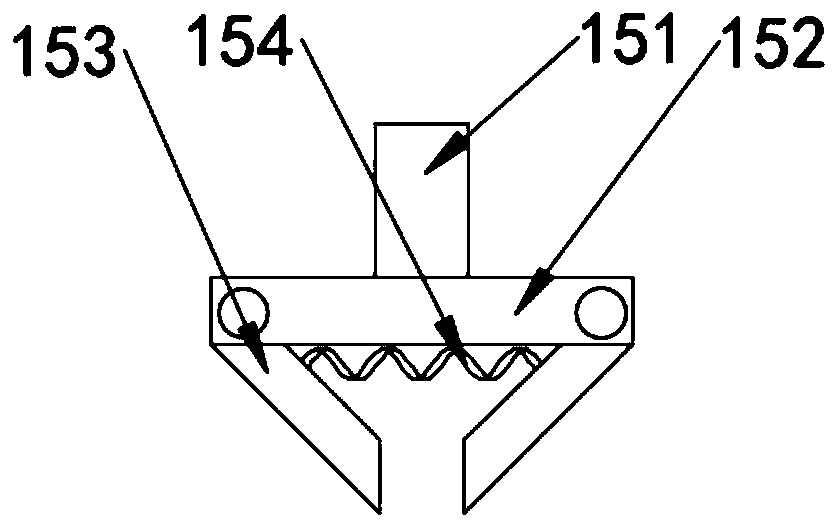

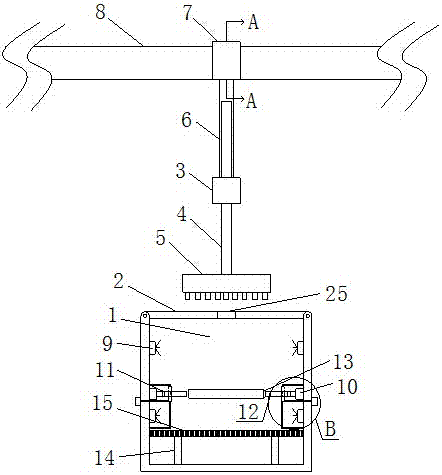

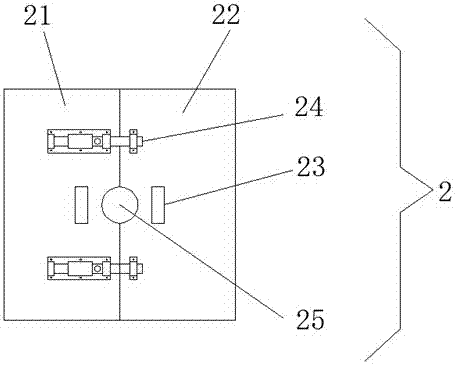

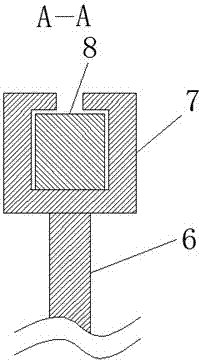

InactiveCN107639001ASmooth rotationFully paintedLiquid surface applicatorsCoatingsEngineeringCoating

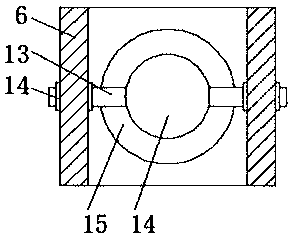

The invention relates to a supporting and fixing device, in particular to a supporting and fixing device for fire fighting pipeline paint coating. The supporting and fixing device for fire fighting pipeline paint coating aims at providing the supporting and fixing device for fire fighting pipeline paint coating with the advantages that a fire fighting pipeline can be supported and fixed, so that people can more comprehensively perform paint coating on the fire fighting pipeline, and paint falling in the paint coating process can also be collected and treated. In order to solve the technical problems, the invention provides the supporting and fixing device for fire fighting pipeline paint coating. The device comprises a bottom plate and the like, wherein a left support rod is arranged at the left side of the top of the bottom plate; the top end of the left support rod is provided with a supporting device; a right support rod is arranged at the right side of the top of the bottom plate;a round tube is arranged on the top end of the right support rod. Through the supporting device, the fire fighting pipeline can be supported; meanwhile, the smoothness is higher when the fire fightingpipeline rotates; the goal of supporting and fixing the fire fighting pipeline can be achieved; people can more comprehensively perform paint coating on the fire fighting pipeline; the effect of collecting and treating the paint falling in the paint coating process can also be achieved.

Owner:江苏申新工程有限公司

Painting device for electromechanical product maintenance

The invention discloses a painting device for electromechanical product maintenance. The painting device comprises a motor and a painting box; a rotating shaft is fixedly connected above the motor; arotating disc is connected above the rotating shaft through a bolt; a longitudinal extension rod is fixedly connected to the top end in the painting box; a transverse extension rod is fixedly connected to the right wall in the painting box; atomization nozzles are in threaded connection to the longitudinal extension rod and the bottom of the longitudinal extension rod; the right side of the painting box is fixedly connected with a painting tank; a circular discharge port with a diameter of 5 cm is formed in the right lower angle of the painting box; a waste paint box is mounted on the right side of the discharge port; the upper end of the painting box is fixedly connected with an air pump; an electromagnetic valve is mounted on the right side of the air pump; the right side of the electromagnetic valve is connected with an air pipe; and a control plate is fixedly connected to the left side of the painting box. The painting device for electromechanical product maintenance is simple in structure and convenient to manufacture, and adopts high-pressure painting and multidirectional painting to achieve better painting effect.

Owner:汝州市中鼎科技有限公司

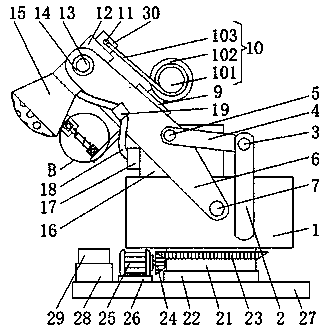

Automobile metal plate paint spraying robot convenient to operate

The invention discloses an automobile metal plate paint spraying robot convenient to operate. The robot comprises a shell, a second rotating shaft and a material barrel, a first driving device is arranged in the shell, moreover, the two ends of the first driving device extend out of the front surface and the back surface of the shell and are fixedly connected with the opposite surfaces of two first connecting rods, and moreover, the opposite surfaces of the top ends of the two first connecting rods are movably connected with the surfaces, far away from each other, of the right ends of two second connecting rods through two first pin shafts. According to the automobile metal plate paint spraying robot convenient to operate, through the mutual cooperation of the first driving device, the first connecting rods, the second connecting rods, third connecting rods, the first pin shafts, second pin shafts, third pin shafts, a spray head and a spraying cylinder, the two ends of a third rotatingshaft drive the two first connecting rods to rotate, the height of the spray head is controlled through the first driving device, so that ascending and descending of the spray head are realized, thenpaint spraying of the robot on automobile metal sheets with different heights is facilitated, and the paint spraying efficiency of the metal sheets is improved.

Owner:铜陵汇泽科技信息咨询有限公司

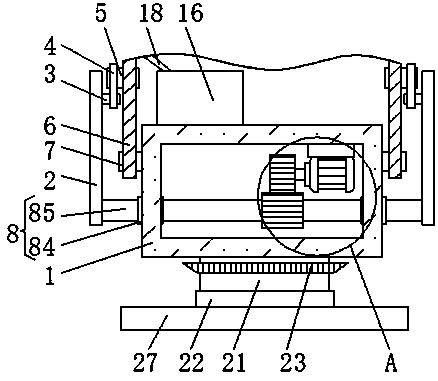

Paint spraying equipment for automobile hub coating production line

The invention provides paint spraying equipment for an automobile hub coating production line. The paint spraying equipment comprises a paint spraying box and a paint spraying mechanism and a supporting mechanism which are arranged in the paint spraying box; the paint spraying mechanism comprises two rotating discs, a power unit, a connecting rod, a first paint spraying column and two second paintspraying columns; the two rotating discs are rotatably installed on the inner walls of the two sides of the paint spraying box, the power unit is connected with the two rotating discs and drives thetwo rotating discs to rotate, the two ends of the connecting rods are connected with the two rotating discs separately, a first paint storing cavity is formed in the first paint spraying column, multiple first paint spraying heads communicating with the first paint storing cavity are arranged on the side, close to the rotating discs, of the second end of the first paint spraying column, a second paint storing cavity is formed in each second paint spraying column, and multiple second paint spraying heads communicating with the second paint storing cavities are arranged on the sides, close to the first paint spraying column, of the second ends of the second paint spraying columns; and the supporting mechanism comprises two supporting rods which are horizontally arranged and used for supporting a to-be-machined workpiece. According to the paint spraying equipment for the automobile hub coating production line, the paint spraying effect is good, the product quality is good, the working efficiency is high, and comprehensive paint spraying can be conducted on a hub.

Owner:ANQING LIUXI IND EQUIP

Paint spraying device for hardware production machining

The invention relates to the technical field of hardware machining devices, and discloses a paint spraying device for hardware production machining. The paint spraying device comprises a base. Supporting legs are fixedly installed at the four corners of the bottom of the base correspondingly. A paint tank is fixedly installed at the center of the bottom of the base. A filter screen is fixedly sleeved with the top of an inner cavity of the paint tank. The top of a liquid pump is fixedly sleeved with the center of the bottom of the paint tank. One ends of hoses are fixedly sleeved with the two ends of the bottom of the liquid pump correspondingly. According to the paint spraying device for hardware production machining, a lead screw and a rotating shaft can be driven to rotate at the same time by a motor through a chain, a flat nozzle on a movable platform can move up and down, paint can be sprayed on hardware parts conveniently from top to bottom, a movable groove rotates to drive the hardware parts on a fixing device to rotate, a rotating rod can rotate along a clamping groove, the hardware parts on the fixing device can accordingly rotate, paint is comprehensively sprayed on the hardware parts, and the paint spraying efficiency is improved.

Owner:江门市新会区祥誉金属制品有限公司

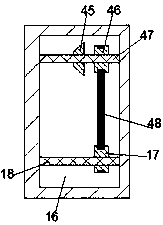

Fire fighting pipeline paint spraying device

InactiveCN111701750AEasy to fixFully paintedPretreated surfacesLiquid spraying apparatusStructural engineeringIndustrial engineering

The invention relates to the technical field of fire fighting equipment processing, in particular to a fire fighting pipeline paint spraying device. The fire fighting pipeline paint spraying device comprises a placement seat. A groove is formed in the top of the placement seat, a supporting mechanism is arranged on the inner side of the groove, fixing clamps are arranged on the left side and the right side of the supporting mechanism, and the fixing clamps are connected with a driving mechanism arranged on the inner side of the placement seat. The tops of the left end and the right end of theplacement seat are fixedly connected with fixed plates, the tops of the fixed plates are fixedly connected with a top plate, and the top plate is provided with a paint spraying mechanism. According tothe fire fighting pipeline paint spraying device, the fixing clamps are arranged, a second telescopic rod can enable an electric roller to be in stable contact with the inner wall of a fire fightingpipeline, the fire fighting pipeline can be rotated under the action of the electric roller, and the pipeline can be subjected to paint spraying in an all-round way, the uniformity of the paint spraying is ensured; and the driving mechanism is arranged, the distance between the fixing clamps on two sides is adjusted so that the device can fix fire fighting pipelines of different sizes.

Owner:陈永严

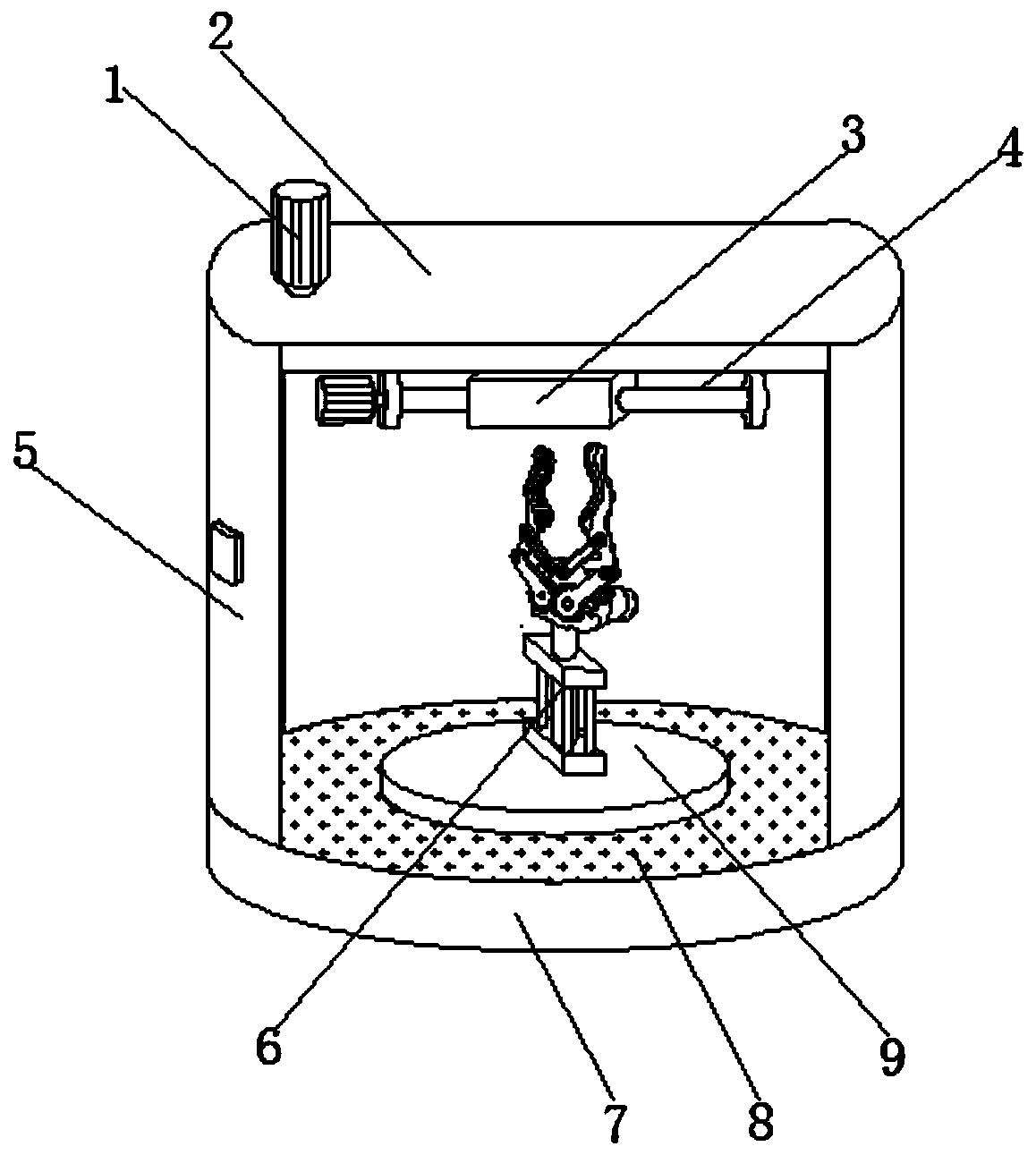

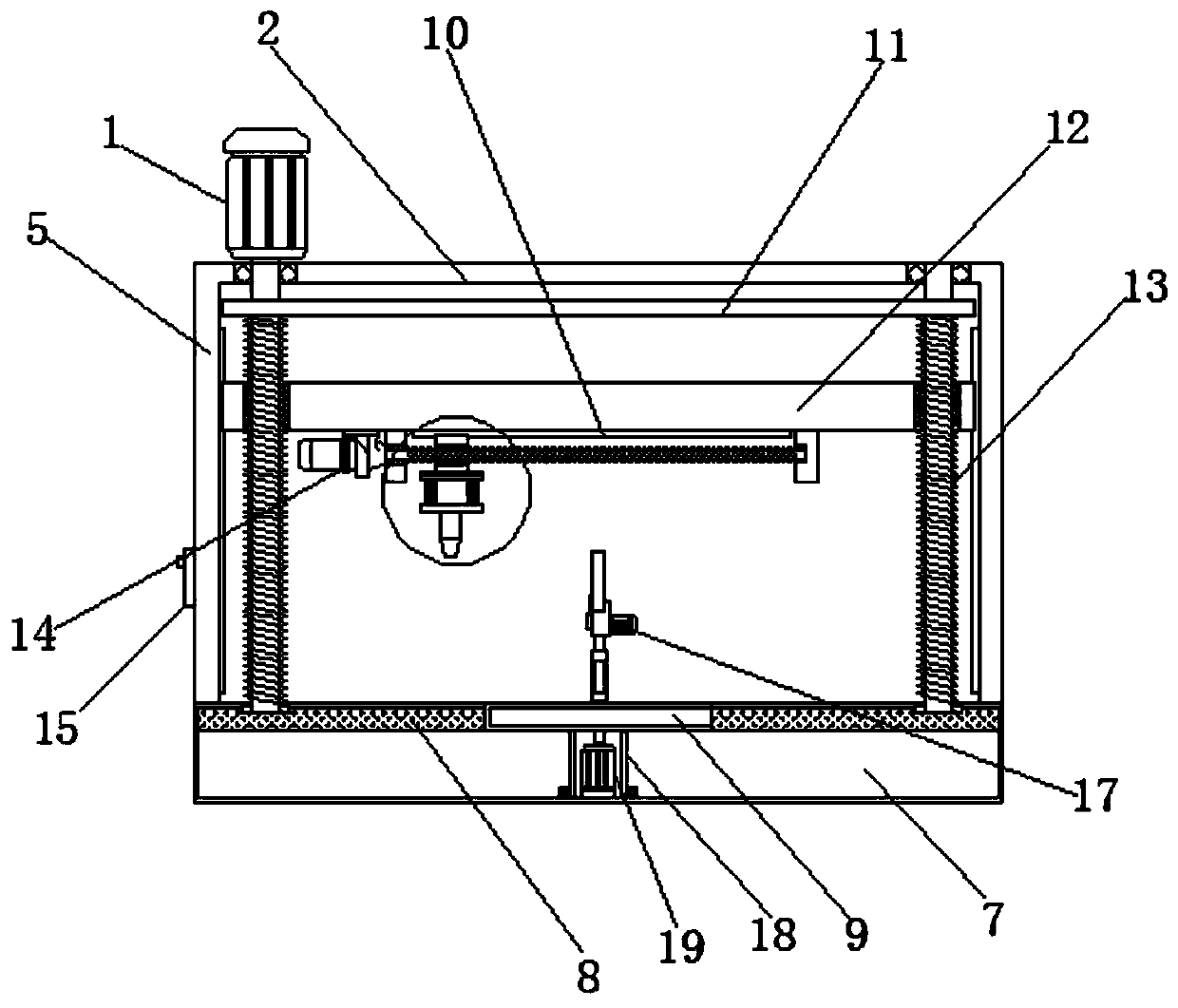

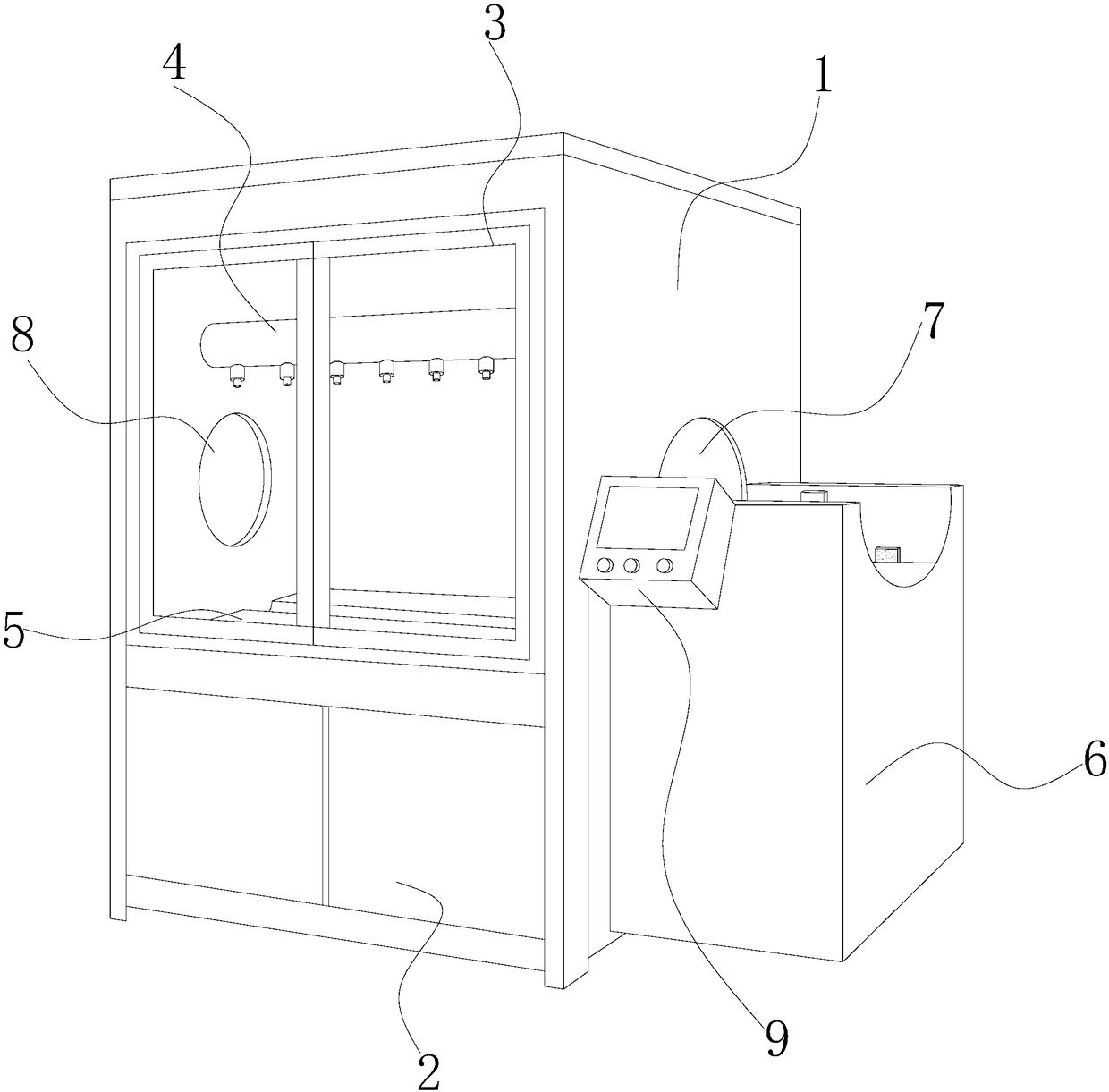

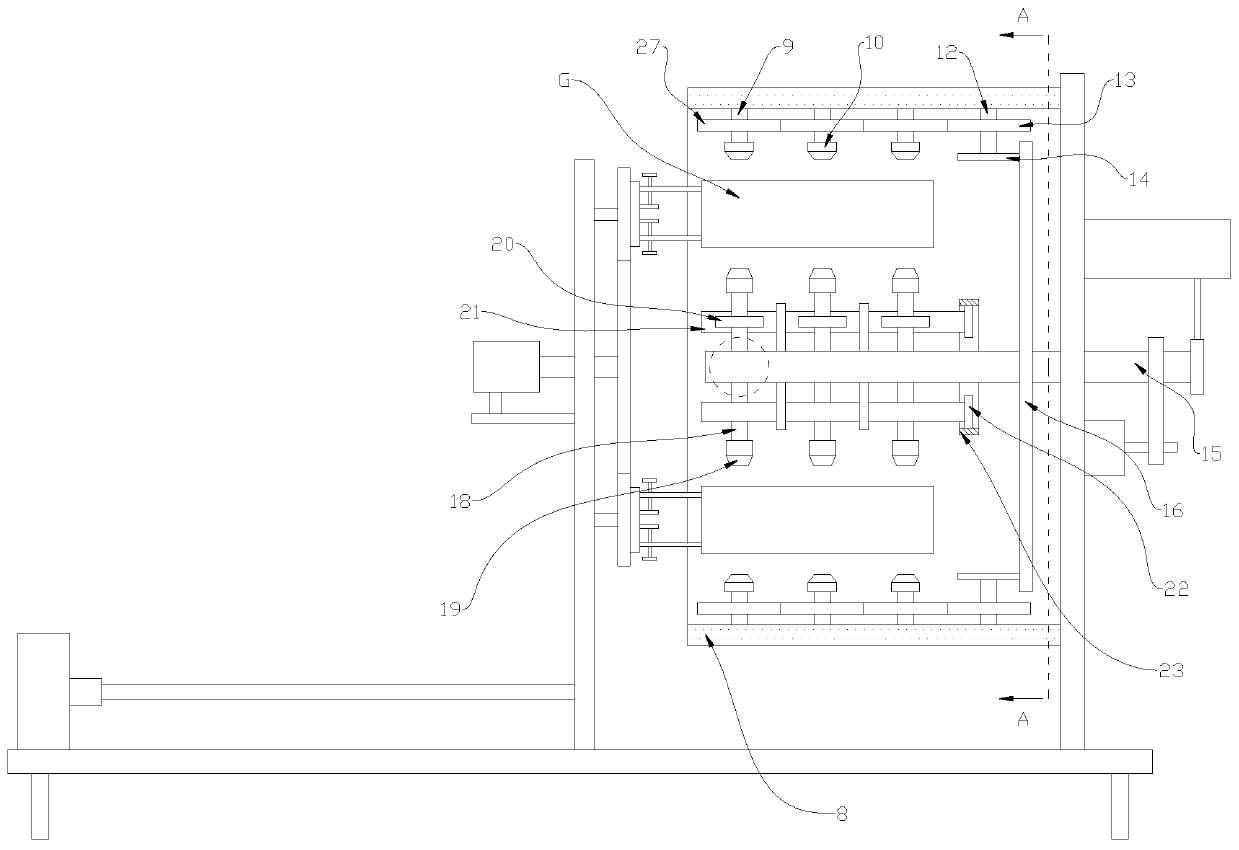

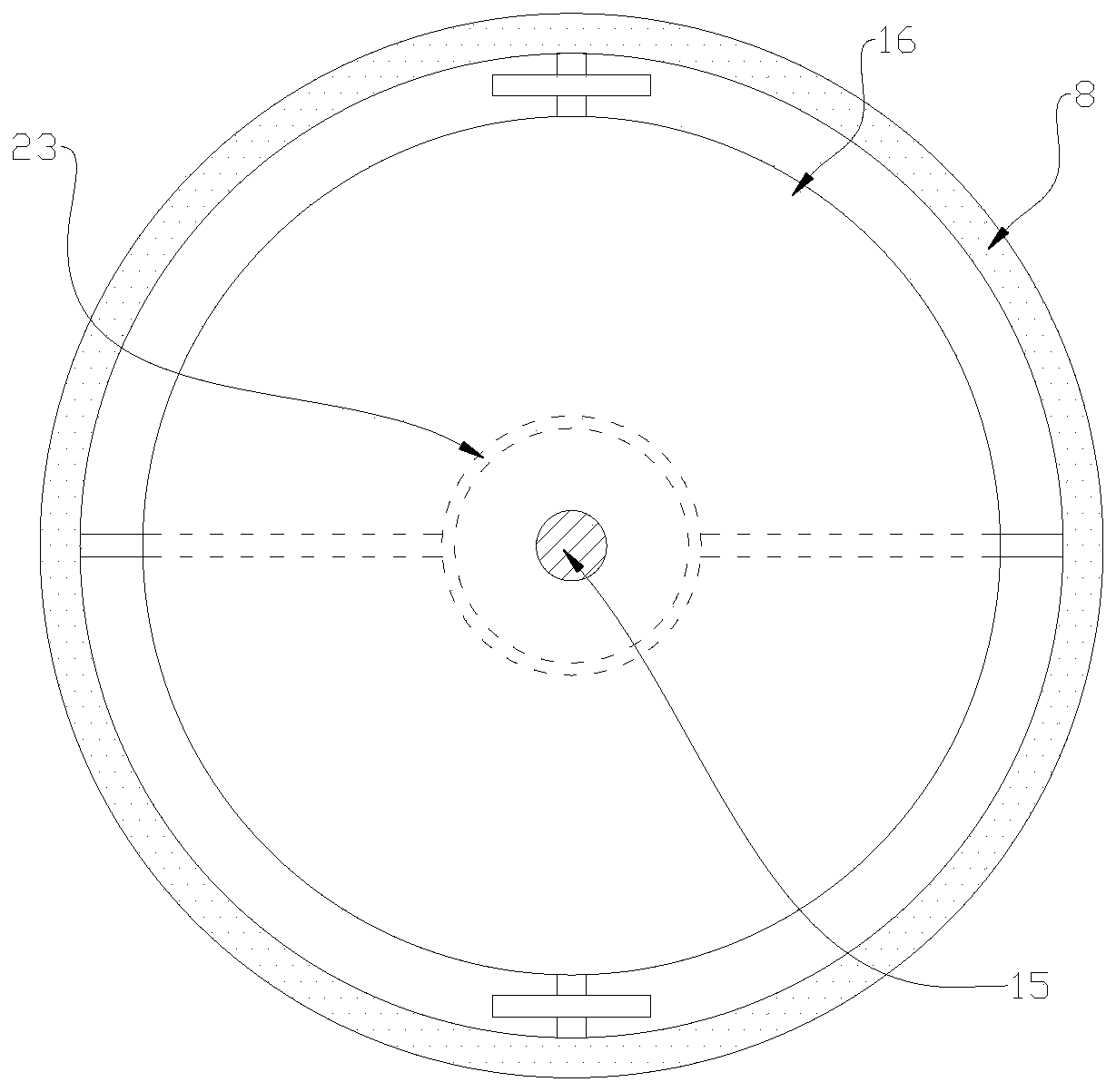

Paint spraying device for high-altitude air fan production and manufacturing and spraying method thereof

The invention belongs to the technical field of spraying equipment, and particularly relates to a paint spraying device for high-altitude air fan production and manufacturing and a spraying method. The paint spraying device comprises a workbench, wherein a left vertical plate and a right vertical plate are fixedly connected to the upper end of the workbench, a top plate is fixedly connected to theupper ends of the left vertical plate and the right vertical plate, a paint spraying box is fixedly connected to the upper end of the top plate, a guide groove is formed in the surface of the lower end of the top plate, a guide sliding block is connected to the inner wall of the guide groove in a sliding mode, a threaded block is fixedly connected to the surface of the lower end of the guide sliding block, and a spraying head is fixedly installed on the surface of the lower end of the threaded block. According to the paint spraying device, a gear disc, a motor and a connecting rod are arranged, so that a high-altitude air fan can be turned over in the spraying process of the device, and the overall spraying is more comprehensive; and a strip-shaped inserting groove, a strip-shaped inserting plate and a disposable film are formed and arranged, so that the workbench cannot be polluted by excessive paint generated in the spraying process, and the time required for later cleaning is saved.

Owner:JIANGSU JIUGAO ELECTRONICS TECH

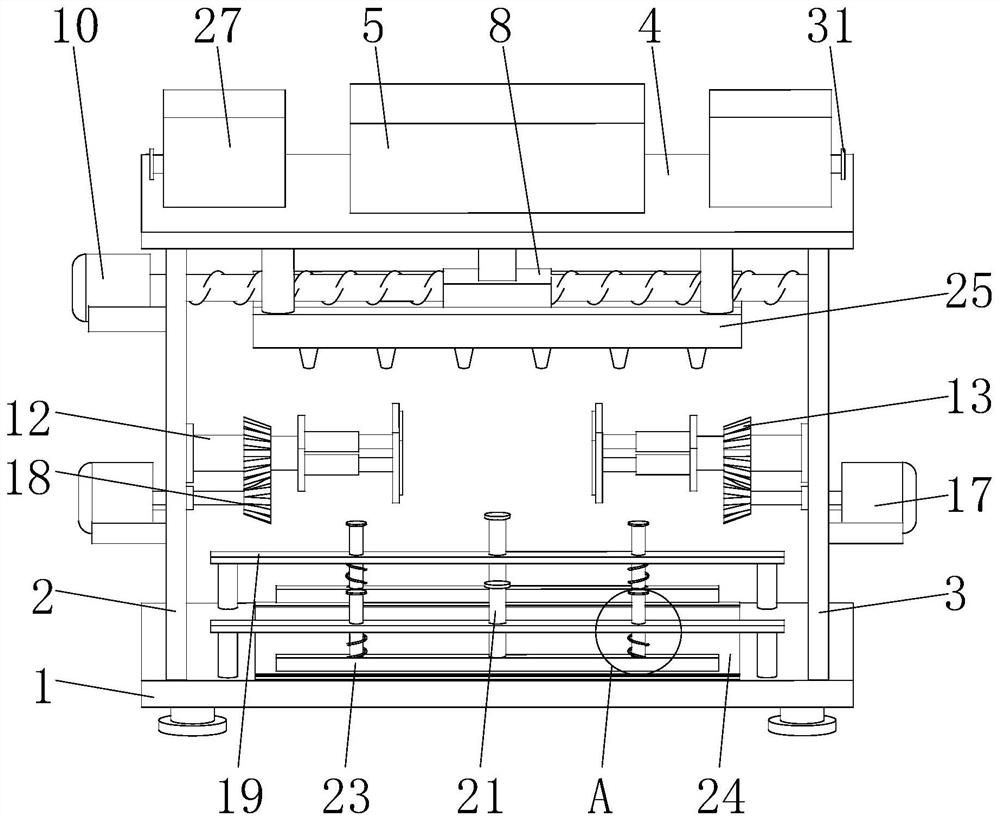

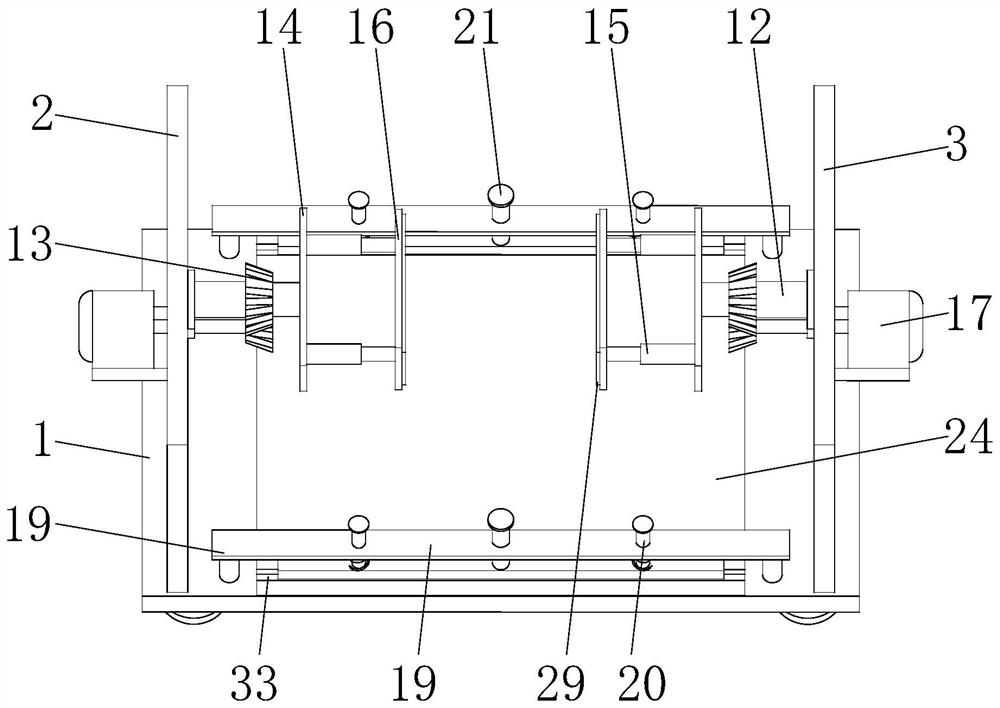

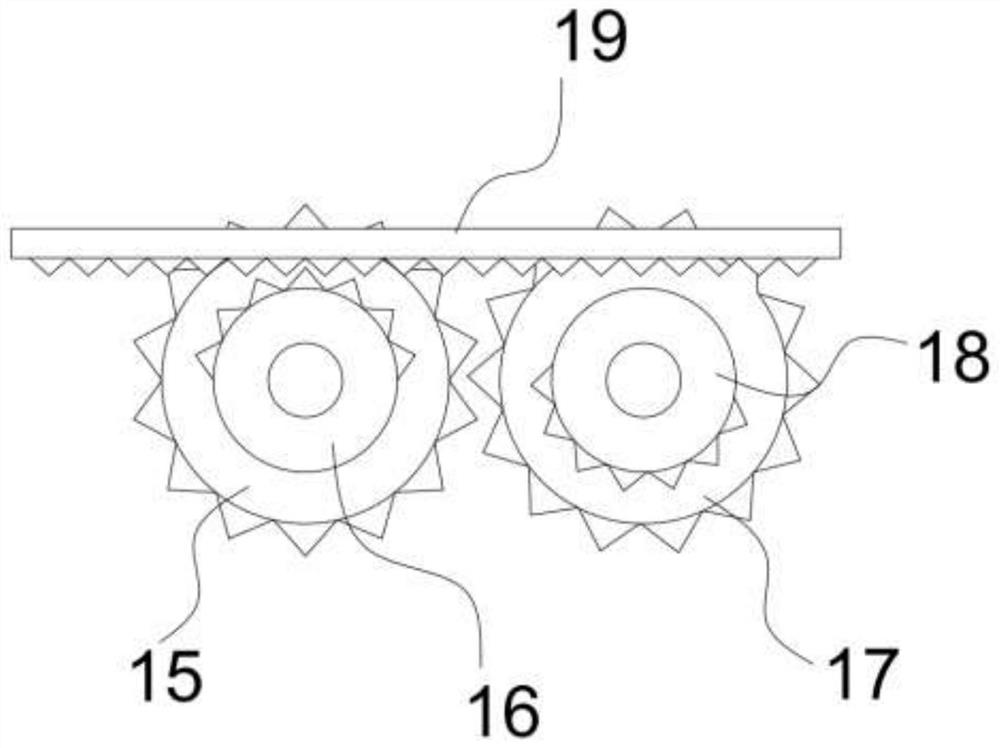

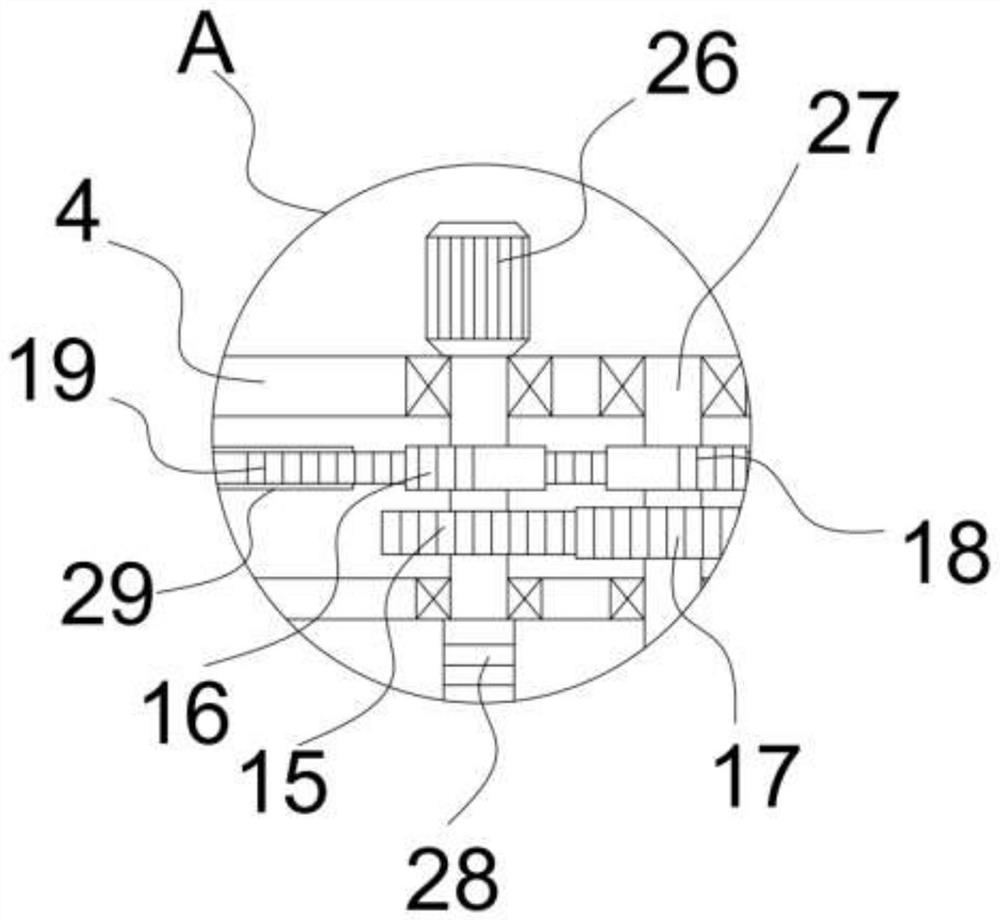

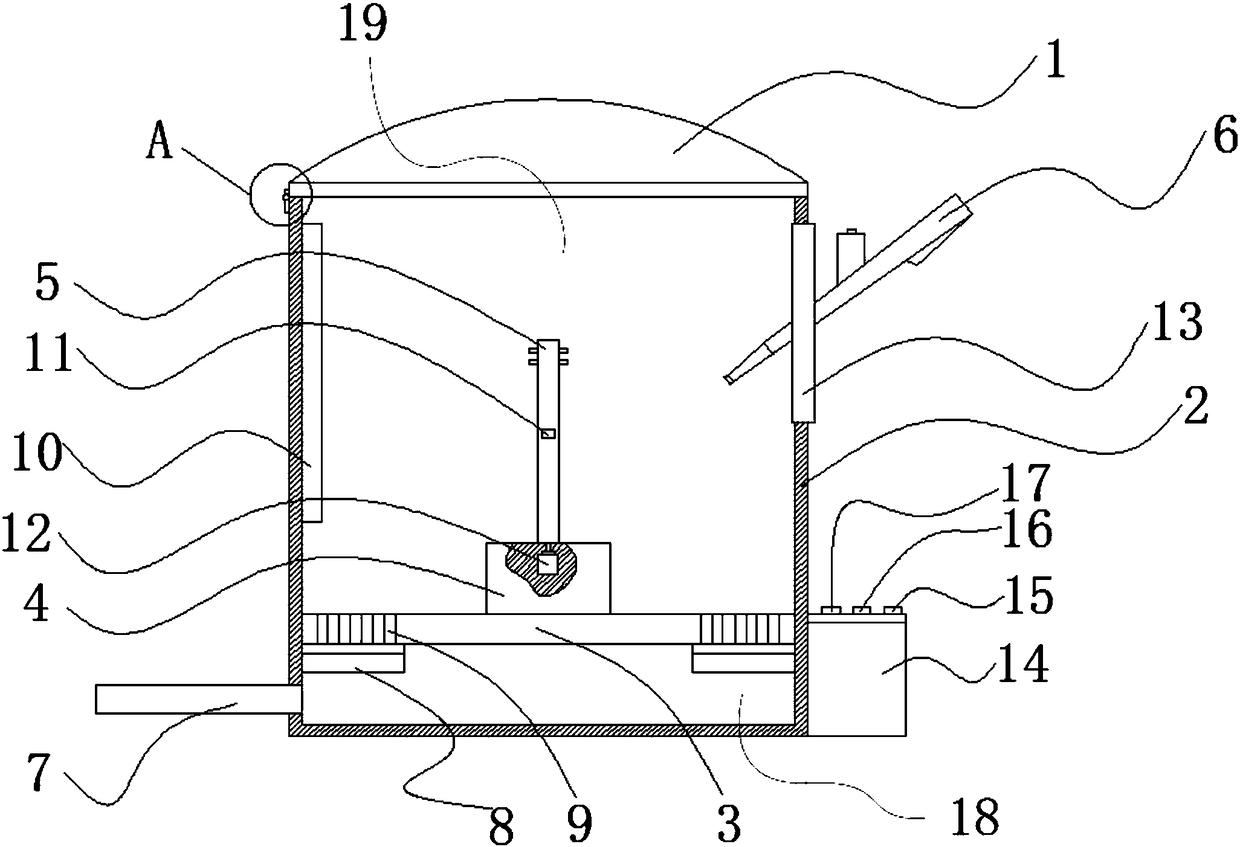

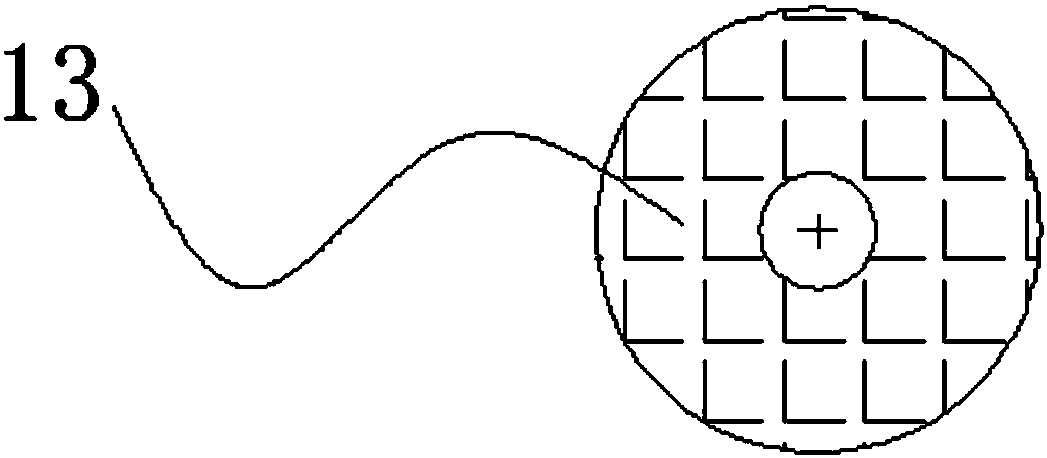

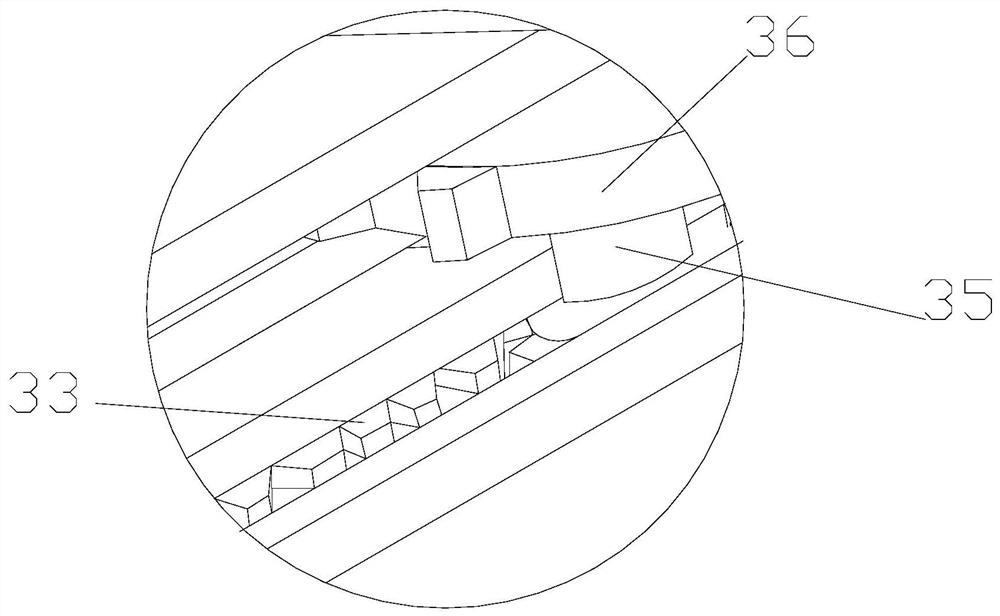

Carved wood plate double-sided paint brushing device

InactiveCN108311345AFully paintedFully contactedLiquid surface applicatorsCoatingsFuel tankBrush device

The invention relates to the technical field of paint brushing equipment, and particularly discloses a carved wood plate double-sided paint brushing device. The carved wood plate double-sided paint brushing device comprises a brushing mechanism, a dust suction mechanism and a power mechanism, wherein the brushing mechanism comprises a support shaft; the outer part of the support shaft is connectedwith a flexible sleeve; an oil cavity and an oil hole are formed inside the support shaft; the dust suction mechanism comprises a fan cover; the power mechanism comprises a piston tube; a piston is connected with the inner wall of the piston tube through screw threads; a piston rod spline is connected onto a machine frame; the end part of the piston rod is connected with a positioning rod; a suction disc is arranged on the positioning rod; a first air inlet one-way valve and a first air outlet one-way valve are arranged on the piston tube; a ventilated dust removal bag is arranged in the piston tube; a second air inlet one-way valve and a second air outlet one-way valve are arranged on the piston tube; the second air inlet one-way valve is connected with an oil storage box; the second airoutlet one-way valve is communicated with the oil cavity through a pipeline. After the technical scheme is adopted, the double-sided dust removal, brushing and drying treatment on a carved wood platecan be completed; the production work procedures of the carved wood plate can be reduced; the production efficiency of the carved wood plate is greatly improved.

Owner:CHONGQING XINNAN WOOD PROCESSING CO LTD

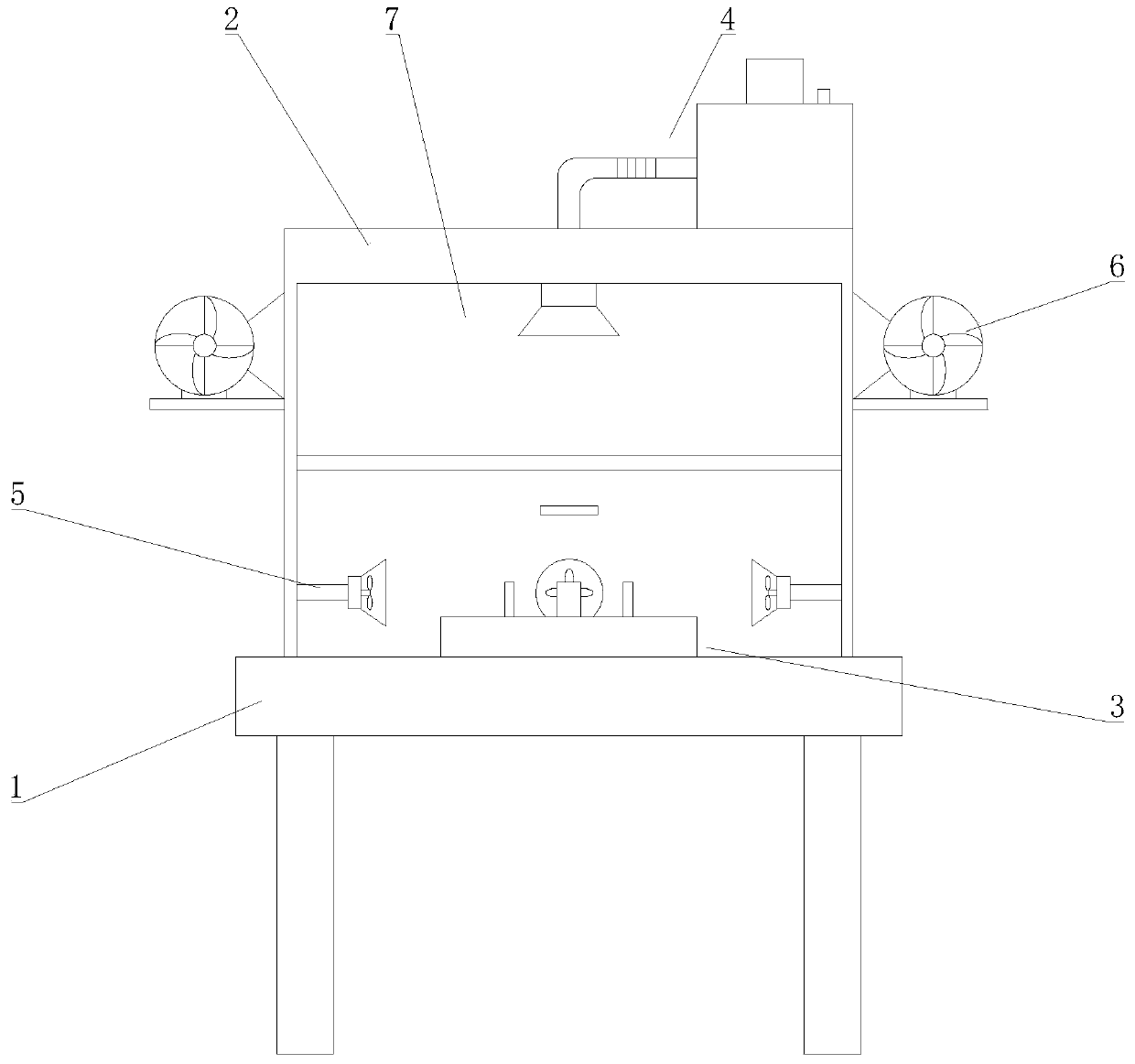

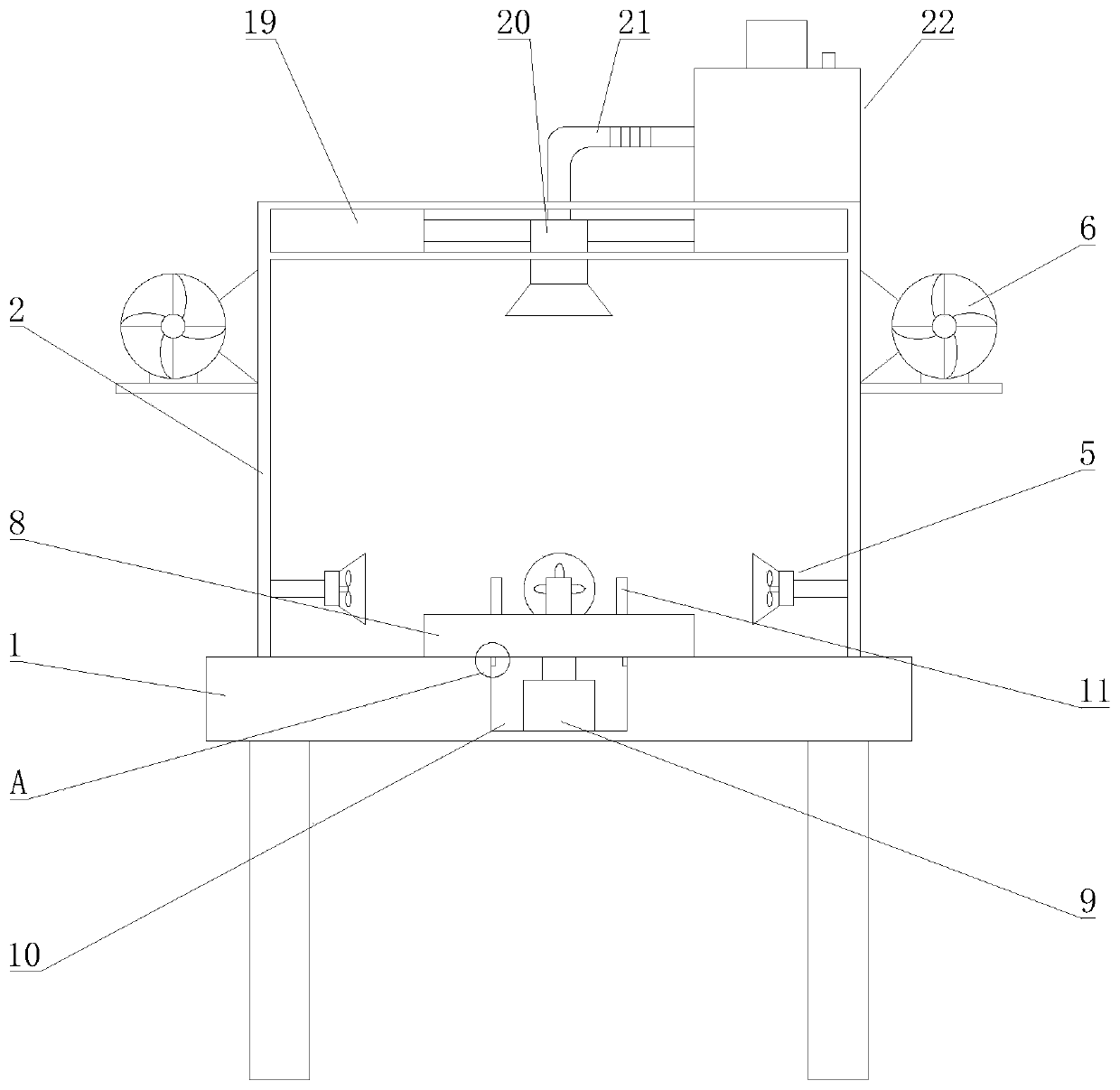

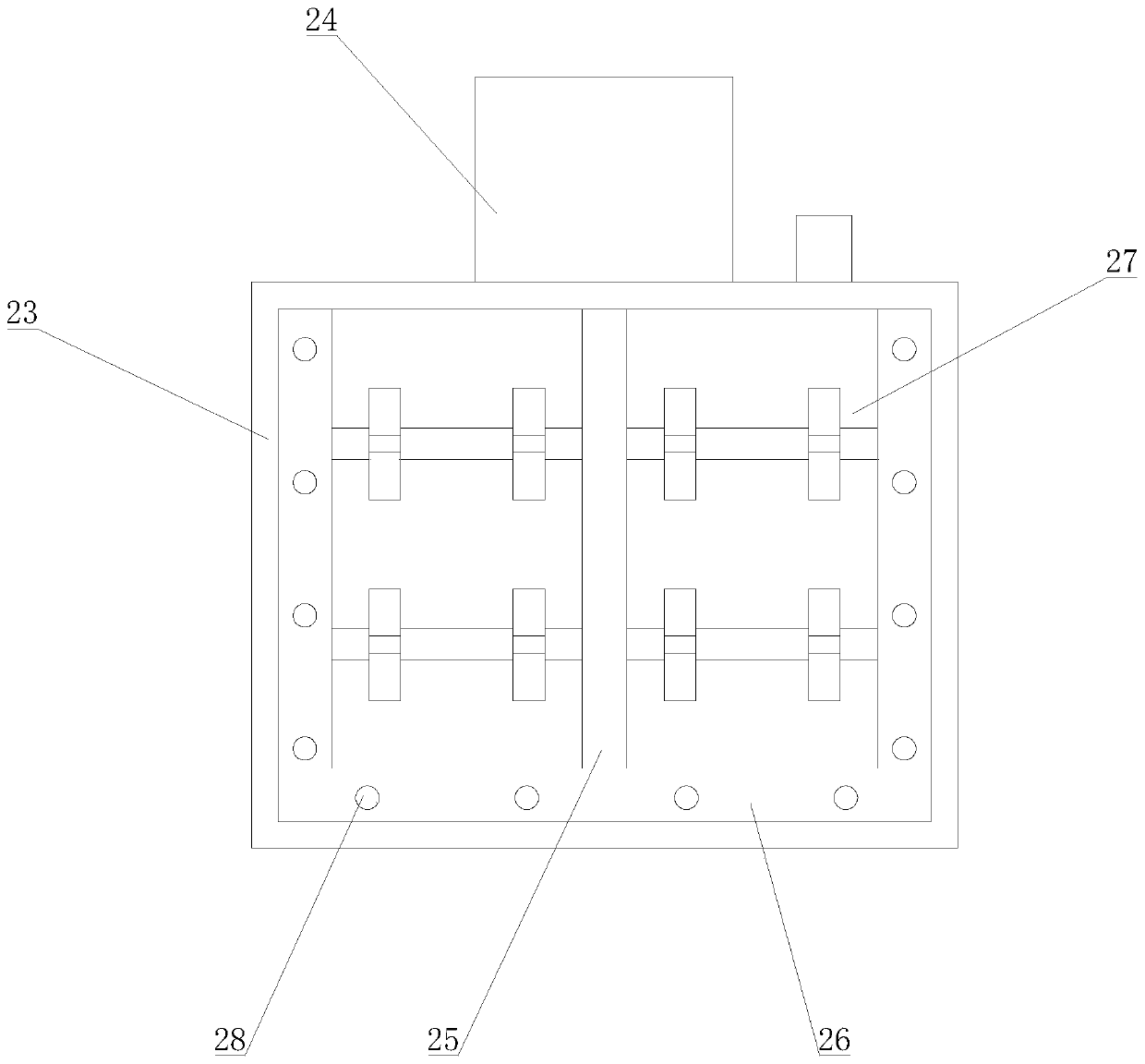

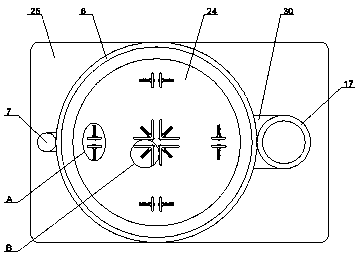

Electric box production machining device

The invention discloses an electric box production machining device. The electric box production machining device comprises an operation table, an isolation cover, a positioning assembly, a paint spraying assembly, a fan and an exhaust fan, wherein the isolation cover is arranged at the upper end of the operation table, the positioning assembly is arranged on the operation table, the paint spraying assembly is arranged on the isolation cover and located above the positioning assembly, the fan is arranged inside the isolation cover, and the exhaust fan is arranged outside the isolation cover. According to the electric box production machining device, paint processing equipment is arranged, so that paint is fully mixed, and the paint spraying effect is guaranteed; the positioning assembly isarranged, and an electric box board to be painted is fixed on a positioning table, so that the situation that the paint spraying efficiency and the paint spraying effect are reduced during paint spraying due to the fact that the electric box board to be painted is displaced is avoided; the positioning table rotates during paint spraying, so that paint spraying is uniform and comprehensive; the fan is arranged to supply air to the electric box board, a heating plate is electrified and heated, generated hot air is used for accelerating drying of the paint, and the drying speed is increased; andmeanwhile, the exhaust fan sucks off the peculiar smell of the paint and sends the peculiar smell to an external purification device for waste gas treatment, so that the pollution of the peculiar smell of the paint to the environment is avoided.

Owner:中合智腾建设有限公司

Open type spray booth

InactiveCN103769333AEasy to operateEasy accessLiquid surface applicatorsCoatingsEngineeringLower face

The invention relates to an open type spray booth. The open type spray booth comprises a spray chamber. The spray chamber is composed of a roof, a first wall body, a second wall body and a third wall body, wherein the second wall body and the third wall body are located on the two sides of the first wall body and connected with the first wall body. The open type spray booth further comprises an exhaust device which is located outside the spray chamber. An exhaust pipeline of the exhaust device passes through the second wall body and is communicated with the spray chamber. A water pool is formed in the lower face of the spray chamber. A rotating table for workpieces to be placed on is arranged on the water pool. By means of the open type spray booth obtained through the technical scheme, paint pollution produced in the spray process is reduced, the open type spray booth is convenient to use and operate for workers, and work efficiency is improved. According to the optimized technical scheme, protrusions are arrayed on a tabletop of the rotating table, the lower end of the first wall body and the upper end of the first wall body protrude more towards the inner portion of the spray chamber, the workpieces and the whole tabletop make point contact instead of face contact, and paint can be more comprehensively sprayed on the workpieces.

Owner:江苏新昌汽车部件有限公司

Wooden door paint spraying device with all-directional rotating function

The invention provides a wooden door paint spraying device with an all-directional rotating function. The wooden door paint spraying device comprises a workbench, wherein a first vertical plate is fixedly installed on one side of the top end of the workbench; a first rotating mechanism is installed on one side of the first vertical plate in a penetrating mode; electric sliding blocks are slidablyconnected to the interiors of two sliding grooves; the mounting parts of the two electric sliding blocks are fixedly connected with two first supporting columns through elastic columns; electric pushrods are embedded in the two first supporting columns; a threaded shaft is rotationally connected between two square connecting seats; and one end of the threaded shaft is fixedly connected with the output end of a stepping motor arranged on the surface of one of the square connecting seats. The wooden door paint spraying device has the beneficial effects that the first rotating mechanism and a second rotating mechanism are arranged, a worker only needs to rotate a hand wheel, then a wooden door can be rotated, the paint spraying surface is very convenient to replace, the operation is simple,time and labor are saved, meanwhile, the wooden door which is placed in a suspended mode is convenient to spray paint, and the situation that the paint spraying surface is in contact with the table surface, and consequently the paint spraying year is uneven is avoided.

Owner:广东博硕涂装技术有限公司

Wood paint spraying device for finishing engineering

The invention belongs to the technical field of finishing and decoration engineering, and particularly relates to a wood paint spraying device for finishing engineering. The wood paint spraying devicecomprises a base. A universal self-locking wheel is fixedly arranged at the bottom of the base. A first support and a second support are arranged at the bottom of the base. A paint spraying box is fixedly installed on the first support. An annular guide rail is arranged at the inner bottom of the paint spraying box. A processing platform is arranged above the annular guide rail. The inner bottomportion of the processing platform is provided with an annular sliding chute corresponding to the annular guide rail. The annular sliding chute is formed in the annular guide rail and is in sliding connection with the annular guide rail. A first clamping plate structure and a second clamping plate structure are arranged on the processing platform. A first motor is fixedly installed on one side ofthe paint spraying box. The wood paint spraying device for finishing engineering is stable in structure, simple to operate, scientific and reasonable in design, short in production period, low in manufacturing cost and convenient to move, can save a lot of time and energy of workers and make wood overturn automatically, and effectively improves the working efficiency.

Owner:安徽山水空间装饰股份有限公司

Appearance paint spraying equipment for laying of petroleum pipeline

The invention discloses appearance paint spraying equipment for laying of a petroleum pipeline. The appearance paint spraying equipment structurally comprises an equipment body, an equipment base, a visible window, a paint spraying device, a paint recycling tank, a rotary pushing device, a pipeline feeding port, a pipeline discharging port and an electric control box, wherein the equipment body isof a rectangular structure; the equipment base is arranged at the lower part of the equipment body; the equipment base and the equipment body are of an integrated structure; the visible window is arranged on the front surface of the equipment body; the visible window and the equipment body are movably connected through hinges; and the paint spraying device is horizontally arranged inside the equipment body. The appearance paint spraying equipment disclosed by the invention is equipped with the rotary pushing device; the rotary pushing device can be automatically started when the petroleum pipeline is placed in a semicircular groove; the petroleum pipeline can be rotationally pushed at a constant speed into the appearance paint spraying equipment for paint spraying, and then the one-time comprehensive uniform paint spraying operation can be achieved; and accordingly, the working efficiency of the appearance paint spraying equipment for laying of the petroleum pipeline can be effectively improved and the paint spraying uniformity can be improved.

Owner:河南天隆管道设备有限公司

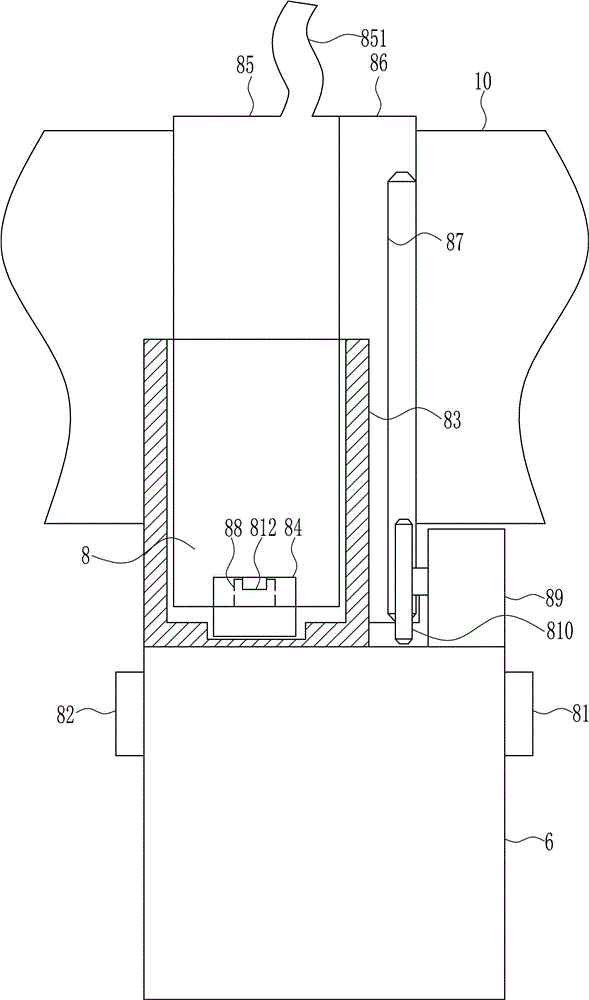

Steel pipe paint spraying machining device

InactiveCN111451044ASolve the problem of unable to automate transportationPrevent splashSpraying apparatusIndustrial engineeringSteel tube

The invention discloses a steel pipe paint spraying machining device. The device comprises a conveying mechanism, a supporting table, a fixing mechanism and a paint spraying mechanism, wherein the supporting table is located beside the conveying mechanism, the fixing mechanism is located on the supporting table, and a sliding table is arranged on the supporting table and fixedly connected with thesupporting table; and the paint spraying mechanism comprises an outer ring paint spraying assembly and an inner ring paint spraying assembly, wherein the outer ring paint spraying assembly is locatedon the sliding table and is in sliding fit with the sliding table, and the inner ring paint spraying assembly is located beside the supporting table and is fixedly connected with the supporting table. According to the device, through the arrangement of the conveying mechanism, the problem that in the paint spraying process of a traditional steel pipe paint spraying device, steel pipes need to beconveyed and fixed manually and cannot be automatically conveyed is solved; and through the arrangement of the specific outer ring paint spraying assembly, the problem that paint splashes everywhere and is wasted due to the fact that no object capable of blocking and recycling paint is arranged around when a traditional paint spraying device sprays paint is solved, and the problem that an inner ring of the traditional paint spraying device cannot spray paint mechanically and automatically is solved through arranging the inner ring paint spraying assembly.

Owner:杨丽萍

All-dimensional automobile door handle paint-spraying device

InactiveCN107413569AImprove painting efficiencyEvenly paintedLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention discloses an all-dimensional automobile door handle paint-spraying device which comprises a paint spraying chamber. An automobile door handle is clamped through sucking discs, each sucking disc is connected to a coupler through a clamp telescoping rod, and the other end of each coupler is connected to an output shaft of a motor; and the motors are driven to drive the sucking discs and the door handle to rotate, and therefore the paint spraying efficiency can be improved, and paint spraying can be conducted more evenly. When paint spraying is conducted, a top cover of the paint spraying chamber is opened, a lotus-shaped spray head enters the paint spraying chamber, and paint spraying work is conducted by a paint spraying machine through a paint spraying tube and the lotus-shaped spray head; and the all-dimensional automobile door handle paint-spraying device further comprises connecting wheels, fixed racks, ventilating pipes and air suction pumps. According to the all-dimensional automobile door handle paint-spraying device, pollution to the external environment and harm to bodies of working staff in the paint spraying process are avoided; after paint spraying is completed, harmful gas in the paint spraying chamber is blown away and diluted through fans and then absorbed through an adsorption plate containing granular active carbon, and therefore pollution is further reduced; and the sucking discs and the air suction pumps are adopted, and the door handle cannot be disengaged in the paint spraying process.

Owner:安徽汇泰车轮有限公司

Movable wall surface painting device for indoor decoration

InactiveCN112376862AImprove brushing effectRealize the rotation effectBuilding constructionsElectric machineryEngineering

The invention discloses a movable wall surface painting device for indoor decoration, and relates to the technical field of building decoration. The movable wall surface painting device comprises a moving frame, an output shaft of a driving motor II is in transmission connection with a height adjusting mechanism for driving a brushing mechanism to vertically ascend and descend, and the moving frame is provided with a translation mechanism for driving a transmission box to transversely move. According to the device, transverse movement adjustment can be conducted on the transmission box throughthe arranged translation mechanism, a brush on a rotating disc makes contact with the wall surface in an attached mode, enough pressing force is achieved during wall surface brushing, so that the paint brushing effect is improved; the arranged height adjusting mechanism can drive the rotating disc to vertically ascend and descend in a reciprocating mode under driving of the driving motor II, so that positions at different height of the wall surface can be fully and comprehensively coated with paint; and in the reciprocating ascending and descending process of the rotating disc, a rotating gear is connected with a vertical rack in an engaged mode, then the rotating effect of the rotating disc is achieved, and paint brushing of the wall surface is more sufficient and comprehensive.

Owner:丁廷兵

Painting device for plastic model part

InactiveCN108580150AImprove the effect of spray paintAvoid flowSpray boothsEngineeringMechanical engineering

The invention discloses a painting device for a plastic model part, and relates to the technical field of model tools. The device comprises a painting part, a gas exhausting part, a top cover, a housing, a supporting plate, a base and a fixing rod, wherein the top cover which is manufactured through a light transmission material is movably arranged on the top part of the housing; the supporting plate is arranged in the housing and divides the housing into the painting part and the gas exhausting part; the base is arranged on the supporting plate, and a driving device is embedded into the base;the fixing rod is arranged on the base and is fixedly connected to the driving device, so that the driving device is capable of driving the fixing rod to rotate; and the fixing rod is used for fixingthe plastic model part to be painted. With the adoption of the device, the angle and the direction of the part to be painted can be adjusted during painting, so that the painting can be universally carried out, and as a result, the painting effect is improved.

Owner:郑丽君

Hydraulic ball valve shell corrosion prevention treatment device

ActiveCN111890254ADecrease productivityAvoid damageLiquid surface applicatorsWork holdersBrush deviceIndustrial engineering

The invention relates to a hydraulic ball valve shell corrosion prevention treatment device comprising a bottom machine frame, a clamping and containing mechanism, a turnover mechanism and a brushingmechanism. The hydraulic ball valve shell corrosion prevention treatment device can solve the following problems of a hydraulic ball valve shell in the brushing process, wherein the problems include the problem a that in the process of conducting corrosion prevention treatment through traditional brushing, due to the fact that when the shell is clamped, one clamp can only correspond to one specification of shells, replacement of different clamps needs to be conducted correspondingly when polishing work is conducted on different specifications of shells, the process flow is tedious and the production cost is high, the problem b that due to the fact that in existing devices, generally surface brushing corrosion prevention treatment can only be conducted on a single side of the shell, when two sides of the shell need to be brushed, the direction of the shell needs to be changed multiple times, the consumed time is long and the work efficiency is low and the problem c that due to the factthat the length of the brushing execution end of an existing brushing device is fixed and the length of the brushing execution section cannot be regulated according to the length of the shell, the brushing effect can be poor and use is influenced.

Owner:JIANGXI HYDRAULIC PIECES

Car part paint-spraying device with even spraying function

The invention discloses a car part paint-spraying device with an even spraying function. The car part paint-spraying device comprises a base, a paint-spraying chamber is formed in the top of the base,and conveying belts are arranged on the two sides of the paint-spraying chamber correspondingly. Rotary shafts at the two ends of the conveying belts are rotatably connected with the top of a first fixing seat, one sides of the rotary shafts are sleeved with pulleys correspondingly, and a gear is arranged between every two pulleys. The pulleys and the gears are rotatably connected through connecting ropes. According to the car part paint-spraying device with the even spraying function, car parts can be subjected to comprehensive paint spraying, and the paint-spraying efficiency of the car parts is improved; and in the paint-spraying process, the car parts can rotate, thus paint spraying is even, face changing for paint spraying is not needed, the sprayed surface is prevented from being collided, the paint-spraying quality is improved, the paint-spraying time of the car parts is consistent, the paint-spraying color difference is avoided, the quality of the car parts is improved, paintsprayed to the outer sides of the car parts falls into a collecting tank, and using of the paint is reduced accordingly.

Owner:扬州起航机械有限公司

Chain machining method for uniform paint coating of chains

The invention discloses a chain machining method for uniform paint coating of chains. The method comprises the following steps of conducting assembling: assembling inner chain plates, outer chain plates, sleeves, pins and rollers into a chain; conducting heat treatment: charging the assembled chain into a heat treatment device for heat treatment; conducting shot blasting: blasting shots on the surface of the chain to form small pits through a shot blasting device; conducting paint coating: coating paint to the chain through a chain paint coating device; and conducting drying: drying the painted chain through a baking device. The chain machining method for uniform paint coating of the chains is simple in implementation. The surface of the chain can be painted uniformly. Thus, the number ofdefective products is reduced.

Owner:HANGZHOU ZICHENG BIOTECHNOLOGY CO LTD

Coating device for mildew preventive

InactiveCN107675384AAvoid coveringFully paintedTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsBristleEconomic benefits

The invention discloses a coating device for a mildew preventive. The device comprises a box. A drying cavity and a coating cavity are formed inside the box. A baffle is arranged between the drying cavity and the coating cavity. A hydraulic rod is arranged on the baffle for performing drying, a garment feeding door and a garment discharging door are hinged to the two ends of the box respectively,two rows of bristles are arranged inside the coating cavity, a belt is arranged between the upper row of bristles and the lower row of bristles for linkage, the bristles are driven by a motor, a firstconveyor belt is arranged between the bristles, a clothes placement frame is arranged on the first conveyor belt, the first conveyor belt is driven by a stepping motor, a mildew preventive solution is contained at the bottom of the coating cavity, a micro water pump is arranged in the mildew preventive solution, a water outlet of the micro water pump is provided with a guide pipe to the top of the coating cavity, a plurality of nozzles are evenly distributed on the guide pipe, the top and the bottom of the drying cavity are each provided with a fan, an electric heating wire is arranged in anair outlet of the fan, and a second conveyor belt is arranged inside the drying cavity. The surface of a garment can be rapidly coated with the mildew preventive, the efficiency is high, artificial contact is reduced, the production efficiency is improved while the safety is good, and therefore the economic benefits are increased.

Owner:FANCHANG QINGXIN WASHING CO LTD

Preparation method and preparation equipment of shell water-based coating material taking mesh macromolecules as film-forming material

InactiveCN111171649AReduce formaldehyde contentConvenient livingRotary stirring mixersTransportation and packagingMacromoleculeMicelle

The invention discloses a preparation method of a shell water-based coating material taking mesh macromolecules as a film-forming material. The method comprises the following steps: S1, putting a dispersing agent, shell powder and deionized water into a container with a stirring device, mechanically stirring for 1-2 hours, adding corresponding parts by weight of a filler, and continuously stirringfor 30-60 minutes to obtain a mixture. According to the invention, the water-based coating material has the advantages that a mesh macromolecule film-forming material is added into a water-based coating material, and spontaneously forms a shell-core micelle with a special three-dimensional space structure and high thermodynamic stability in a water phase, and diversified functional molecular groups are embedded into the surface of the micelle by combining with amplification of molecular modification, so that the mesh macromolecule film can be quickly cured to form a mesh-shaped structure under the induction of external fields such as heat, air and the like, shell powder is attached to holes to generate a function of adsorbing water and formaldehyde so as to reduce the formaldehyde contentin a decorated room, so that the room is beneficial for people to live in.

Owner:万喜人家环保科技有限责任公司

Equipment capable of simultaneously spraying paint on plurality of steel pipes

Owner:ANHUI TAIGE STEEL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com