Efficient paint spraying device of circular anti-collision barrel used for traffic bridge

A bridge-shaped, circular technology, applied in spraying devices, liquid spraying devices, and devices that apply liquid to surfaces, etc., can solve the problems of affecting work efficiency, uneven painting, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

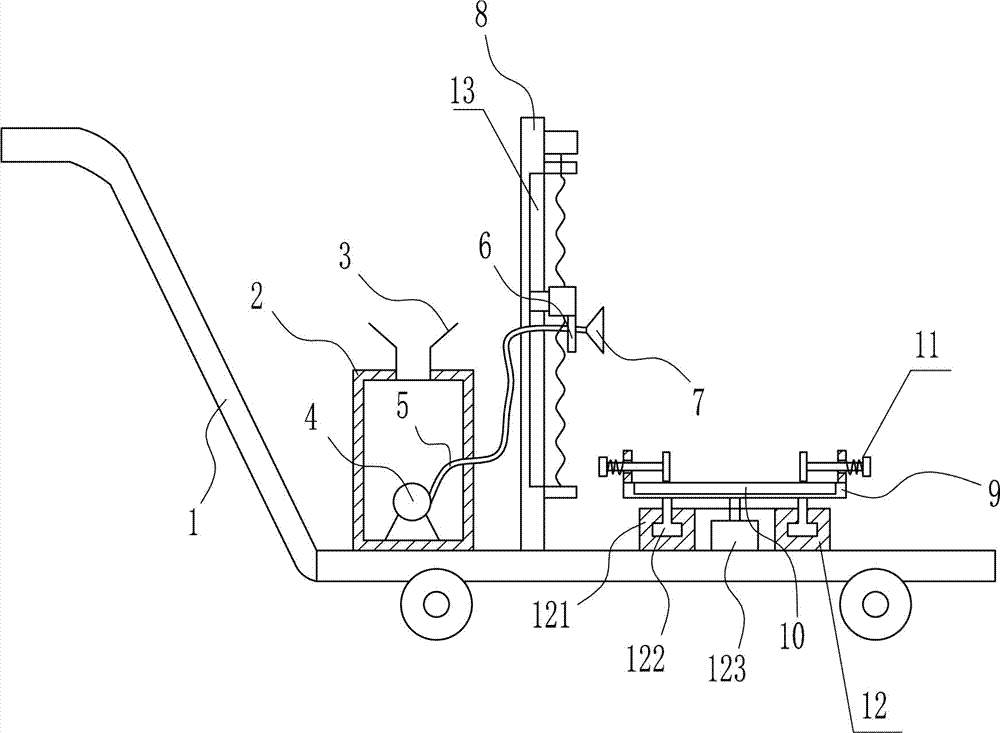

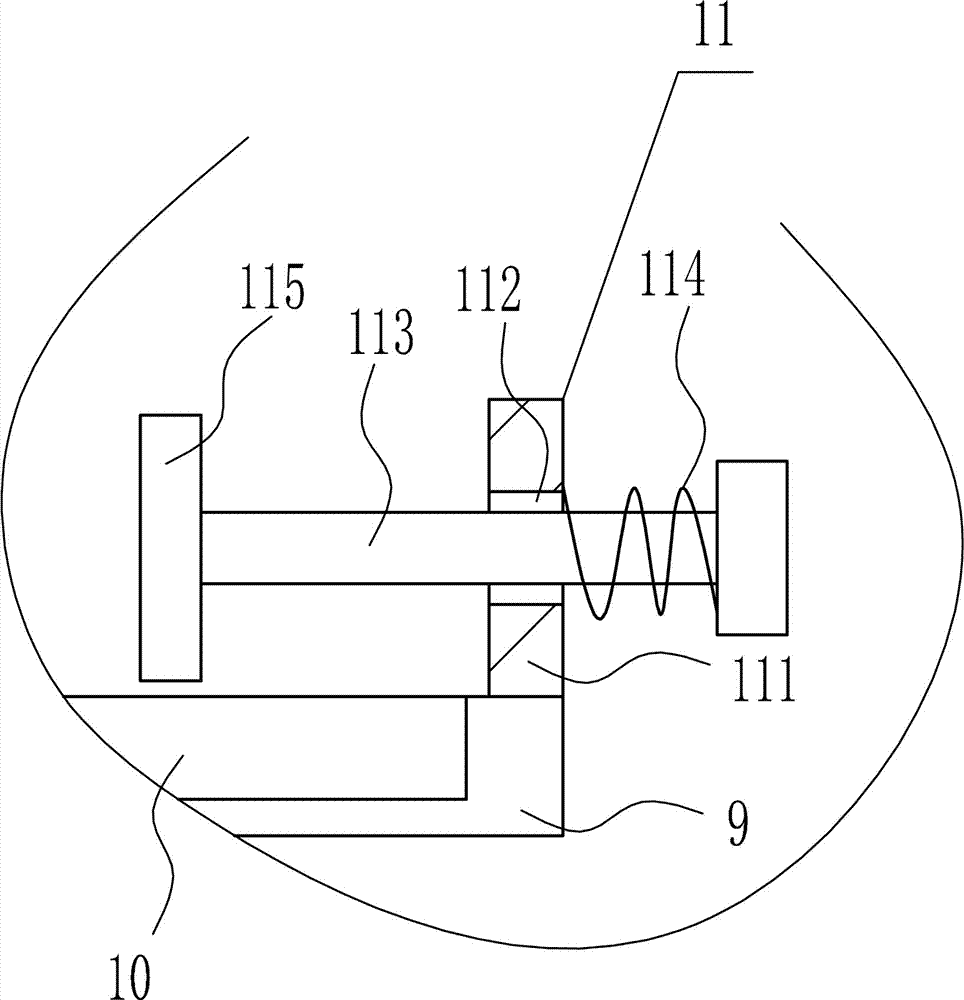

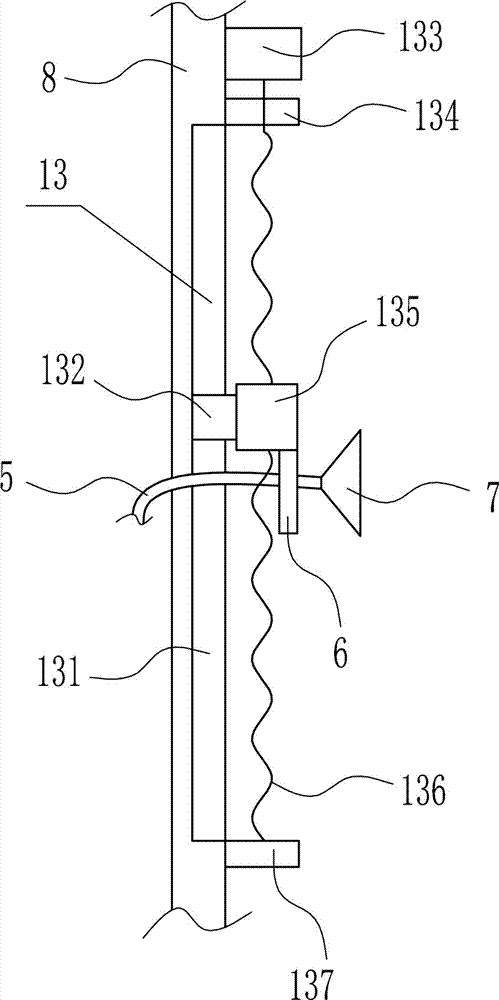

[0029] A kind of high-efficiency paint spraying device for circular anti-collision barrels for traffic bridges, such as Figure 1-5 As shown, it includes a trolley 1, a paint box 2, a lower hopper 3, a water pump 4, a discharge pipe 5, a first fixed sleeve 6, a first nozzle 7, a support plate 8, a placement plate 9, a fixing device 11, and a rotating device 12 and up and down moving device 13, a paint box 2 is installed on the left side of the top of the cart 1 through a bolt connection, and a lower hopper 3 is installed in the middle of the top of the paint box 2 through a bolt connection, and the lower hopper 3 communicates with the inside of the paint box 2, A water pump 4 is installed in the middle of the bottom of the paint box 2 through a bolt connection, and a support plate 8 is installed on the left side of the top of the cart 1 through a bolt connection. There is an up and down moving device 13, the first fixed sleeve 6 is connected to the up and down moving device 13...

Embodiment 2

[0031] A kind of high-efficiency paint spraying device for circular anti-collision barrels for traffic bridges, such as Figure 1-5 As shown, it includes a trolley 1, a paint box 2, a lower hopper 3, a water pump 4, a discharge pipe 5, a first fixed sleeve 6, a first nozzle 7, a support plate 8, a placement plate 9, a fixing device 11, and a rotating device 12 and up and down moving device 13, a paint box 2 is installed on the left side of the top of the cart 1 through a bolt connection, and a lower hopper 3 is installed in the middle of the top of the paint box 2 through a bolt connection, and the lower hopper 3 communicates with the inside of the paint box 2, A water pump 4 is installed in the middle of the bottom of the paint box 2 through a bolt connection, and a support plate 8 is installed on the left side of the top of the cart 1 through a bolt connection. There is an up and down moving device 13, the first fixed sleeve 6 is connected to the up and down moving device 13...

Embodiment 3

[0034] A kind of high-efficiency paint spraying device for circular anti-collision barrels for traffic bridges, such as Figure 1-5 As shown, it includes a trolley 1, a paint box 2, a lower hopper 3, a water pump 4, a discharge pipe 5, a first fixed sleeve 6, a first nozzle 7, a support plate 8, a placement plate 9, a fixing device 11, and a rotating device 12 and up and down moving device 13, a paint box 2 is installed on the left side of the top of the cart 1 through a bolt connection, and a lower hopper 3 is installed in the middle of the top of the paint box 2 through a bolt connection, and the lower hopper 3 communicates with the inside of the paint box 2, A water pump 4 is installed in the middle of the bottom of the paint box 2 through a bolt connection, and a support plate 8 is installed on the left side of the top of the cart 1 through a bolt connection. There is an up and down moving device 13, the first fixed sleeve 6 is connected to the up and down moving device 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com