Carved wood plate double-sided paint brushing device

A wood board and double-sided technology, which is applied in the field of double-sided painting devices for carved wood boards, can solve the problems of low production efficiency and achieve the effects of improving production efficiency, reducing production processes, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is a further detailed description through specific implementations:

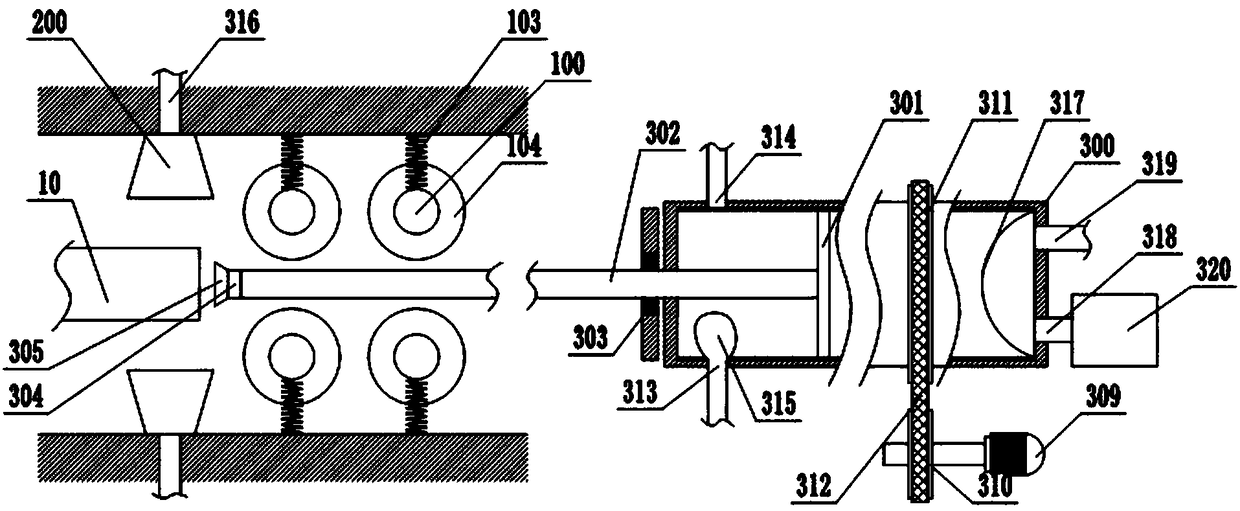

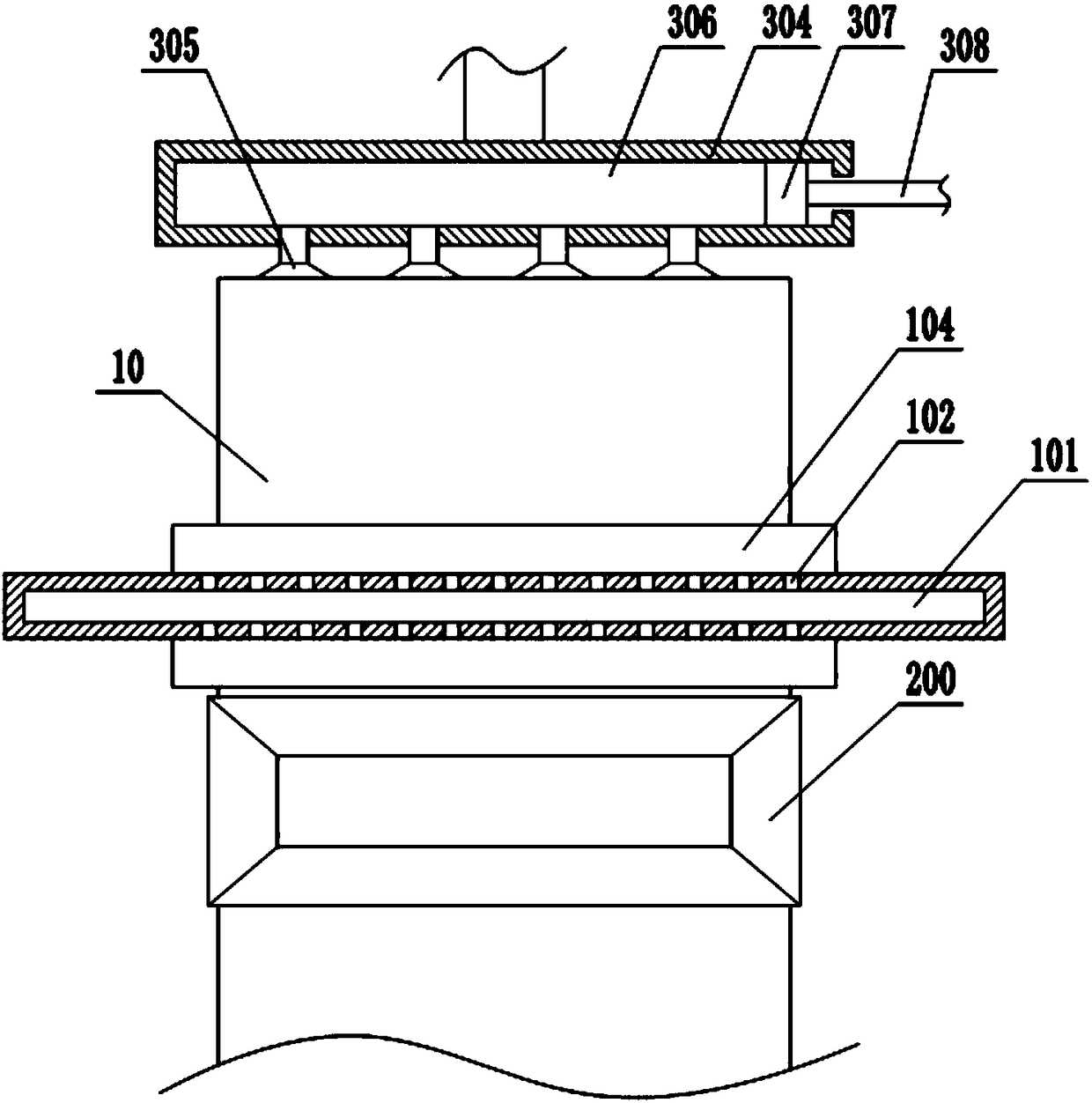

[0033] The reference signs in the drawings of the specification include: carved wood board 10, support shaft 100, oil cavity 101, oil hole 102, compression spring 103, sleeve 104, wind cover 200, piston cylinder 300, piston 301, piston rod 302, flower Key 303, positioning rod 304, suction cup 305, air pressure hole 306, sealing plug 307, pull rod 308, forward and reverse motor 309, driven pulley 310, driving pulley 311, belt 312, first air intake check valve 313, The first air outlet check valve 314, the dust bag 315, the pipe 316, the diaphragm 317, the second air inlet check valve 318, the second air outlet check valve 319, and the oil storage tank 320.

[0034] Such as figure 1 Shown as an embodiment of the present invention, a double-sided painting device for carved wooden boards is disclosed. The device includes a dust suction mechanism, a brushing mechanism, and a power mechanism. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com