Coating device for mildew preventive

An antifungal agent and brushing technology, which can be used in the processing of textile materials, the configuration of equipment for processing textile materials, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

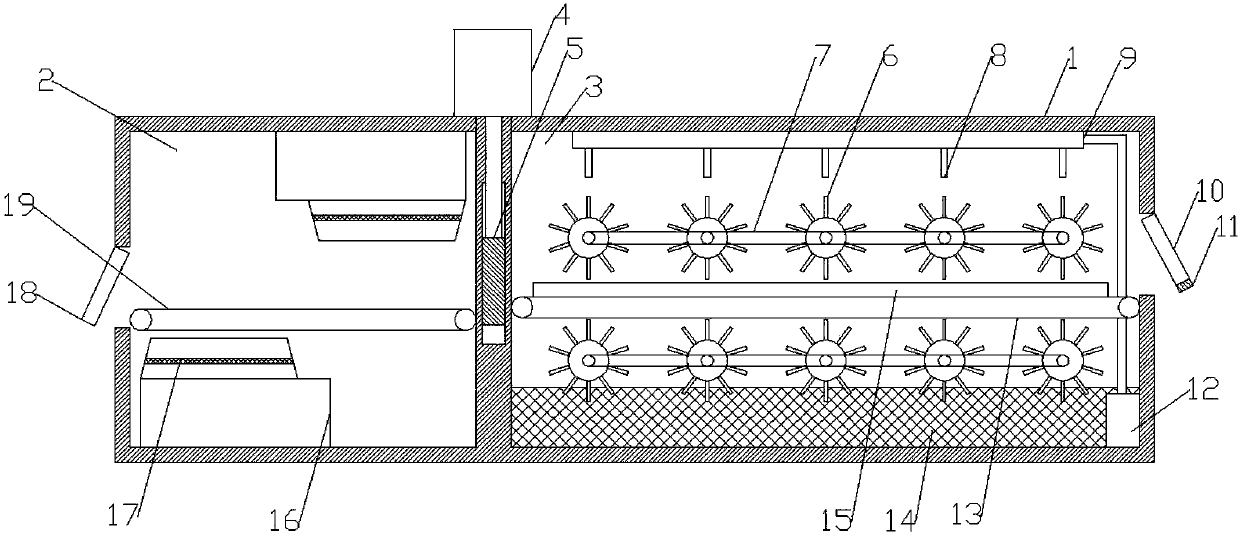

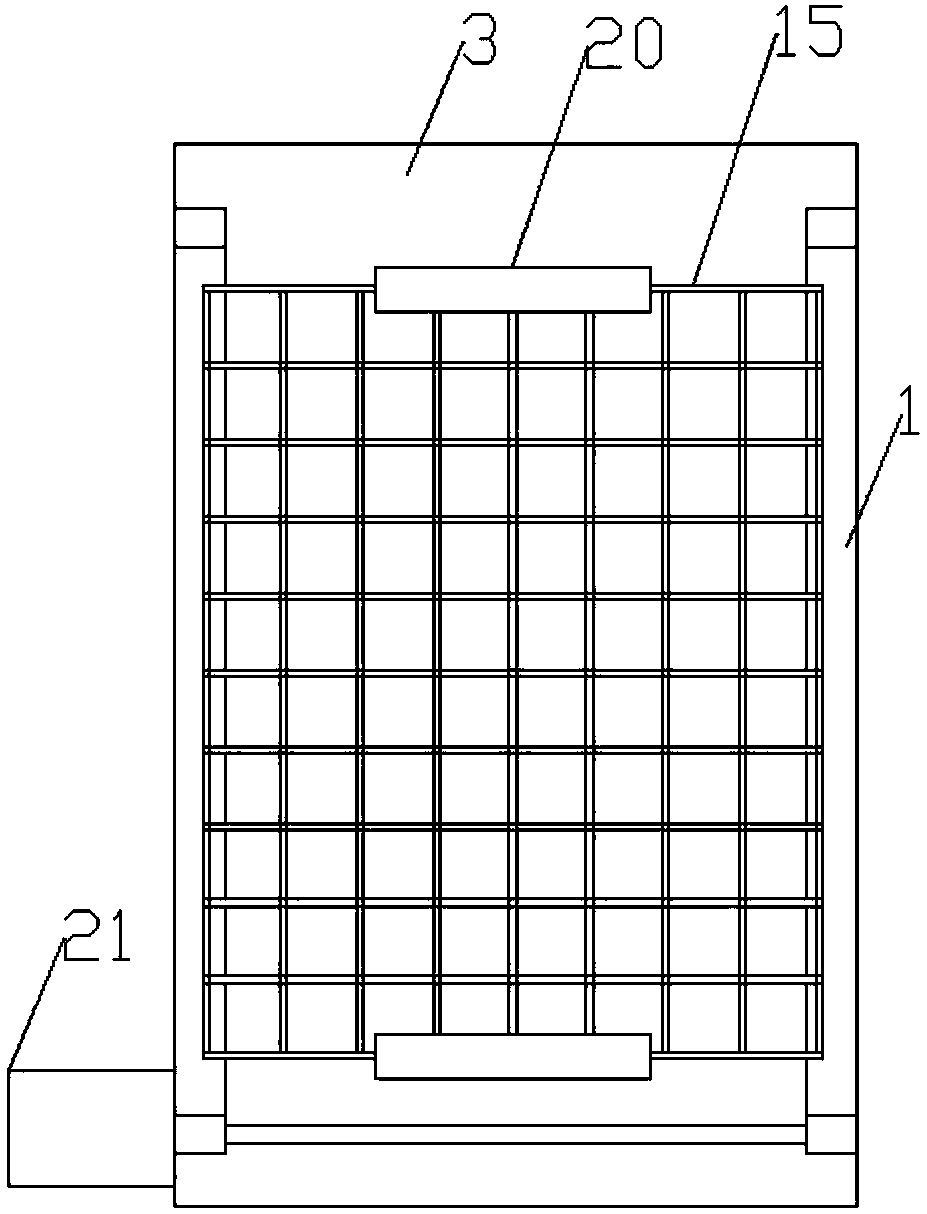

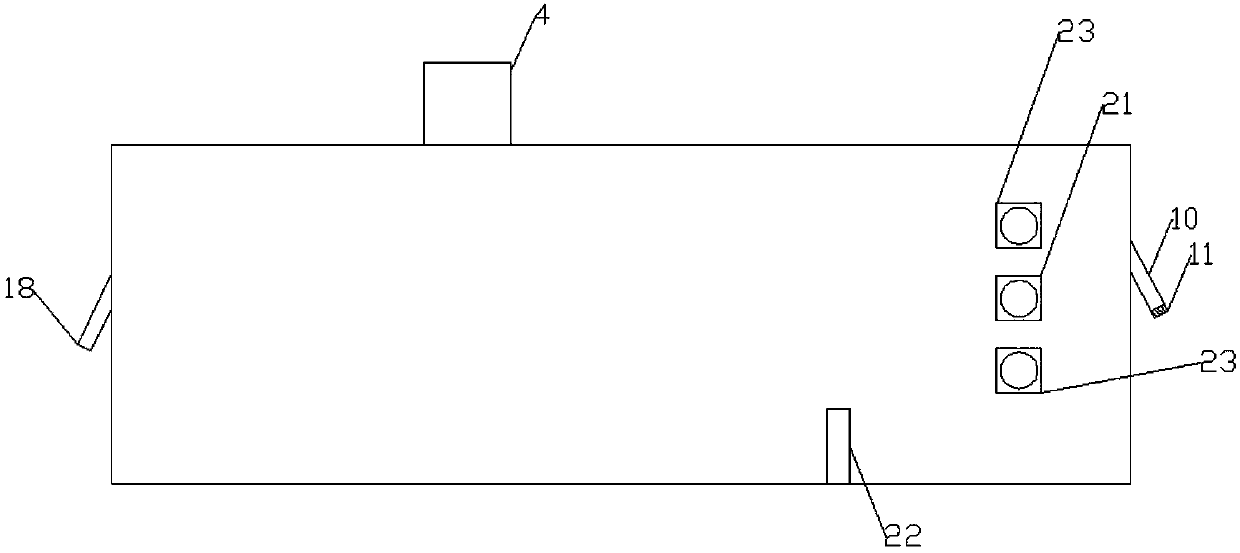

[0016] Figure 1-3 Show the specific embodiment of the present invention: a kind of antifungal agent brushing device, comprise box body 1, be provided with drying cavity 2 and brushing cavity 3 in described box body 1, described drying cavity 2 and brushing A baffle plate 5 is arranged between the cavities 3, and the baffle plate 5 is provided with a hydraulic rod 4 for driving, and the two ends of the box body 1 are respectively hinged with a clothes-in door 10 and a clothes-out door 18, and inside the brushing chamber 3 There are two rows of brushes 6, the upper row of brushes 6 and the lower row of brushes 6 are provided with a belt 7 linkage, the brushes 6 are driven by a motor 23, and a conveyor belt is arranged between the brushes 6 One 13, the conveyor belt one 13 is provided with a hanger 15, the conveyor belt one 13 is driven by a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com