Full-automatic door panel painting equipment and method

A kind of coating equipment and fully automatic technology, applied in the direction of spraying device, spray booth, etc., to achieve the effect of reducing personal contamination, overcoming human error, and good social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

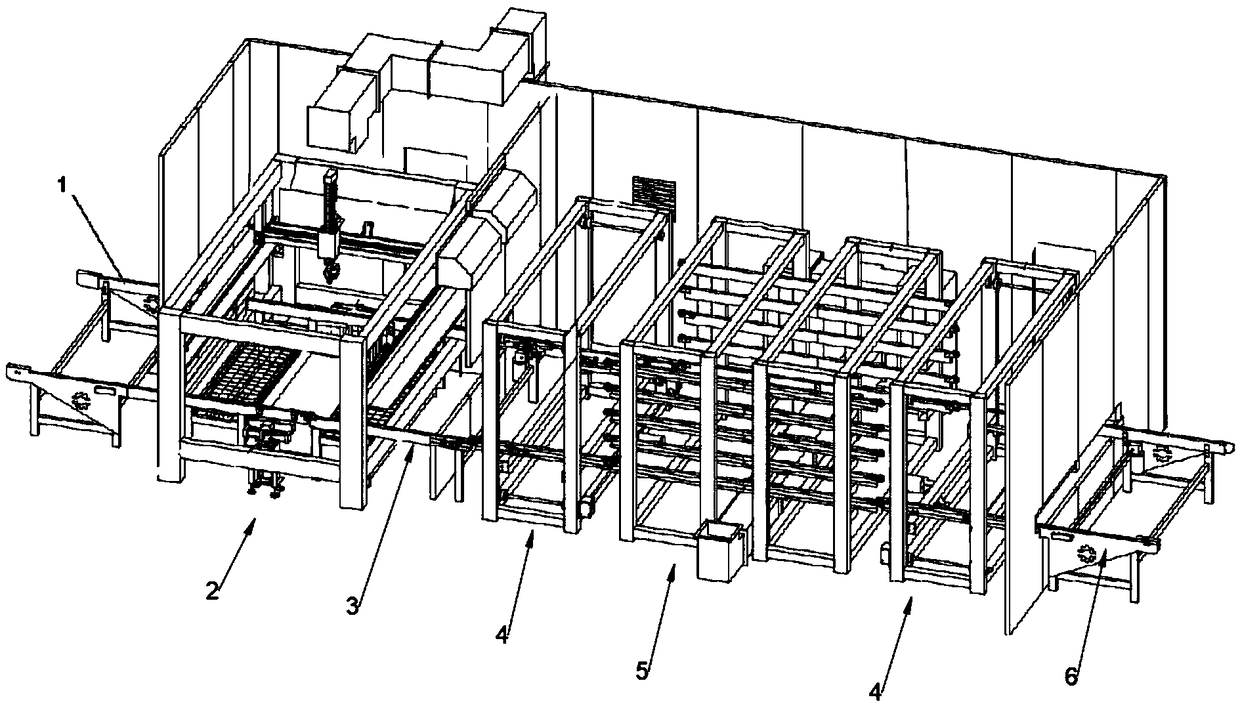

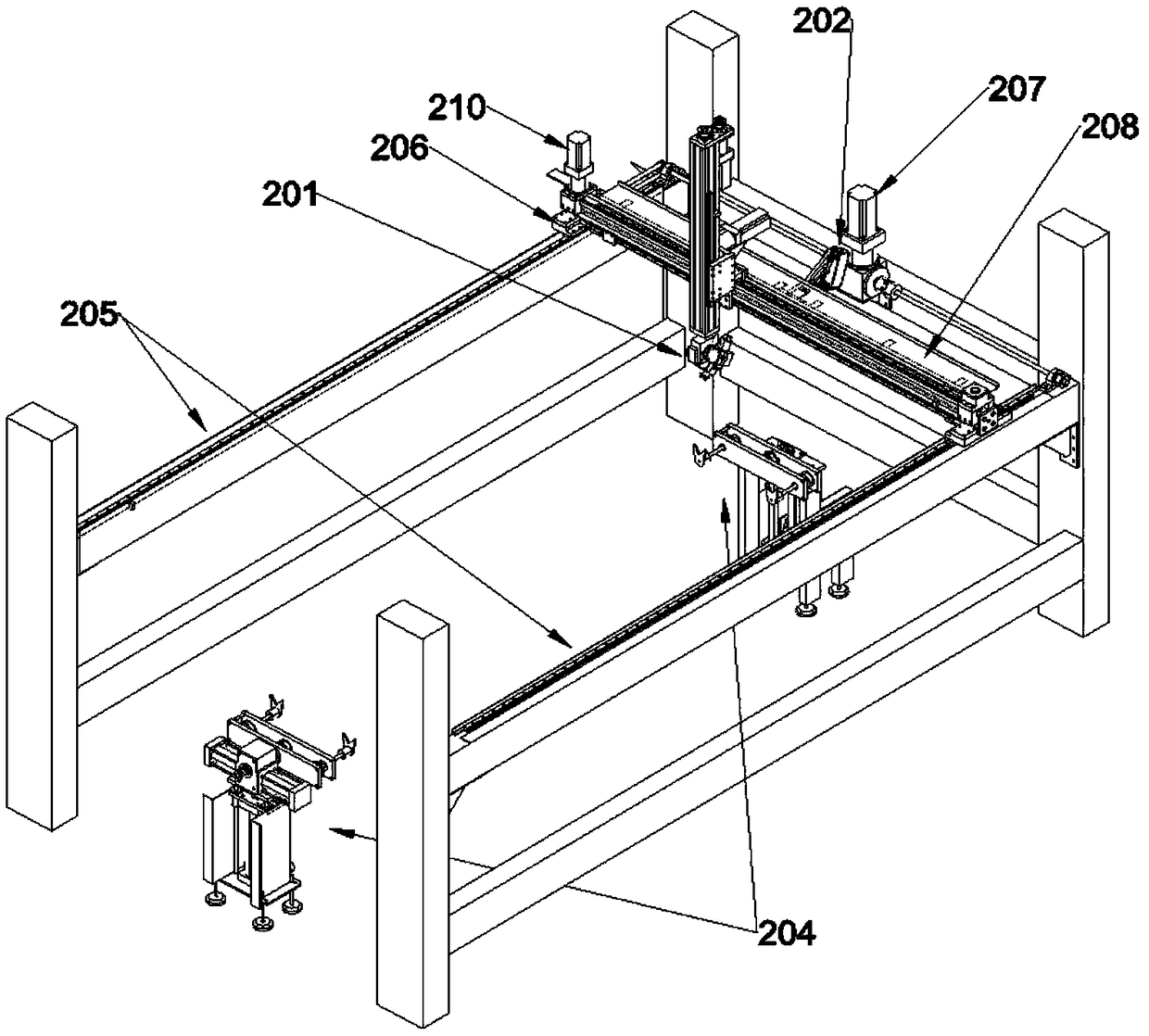

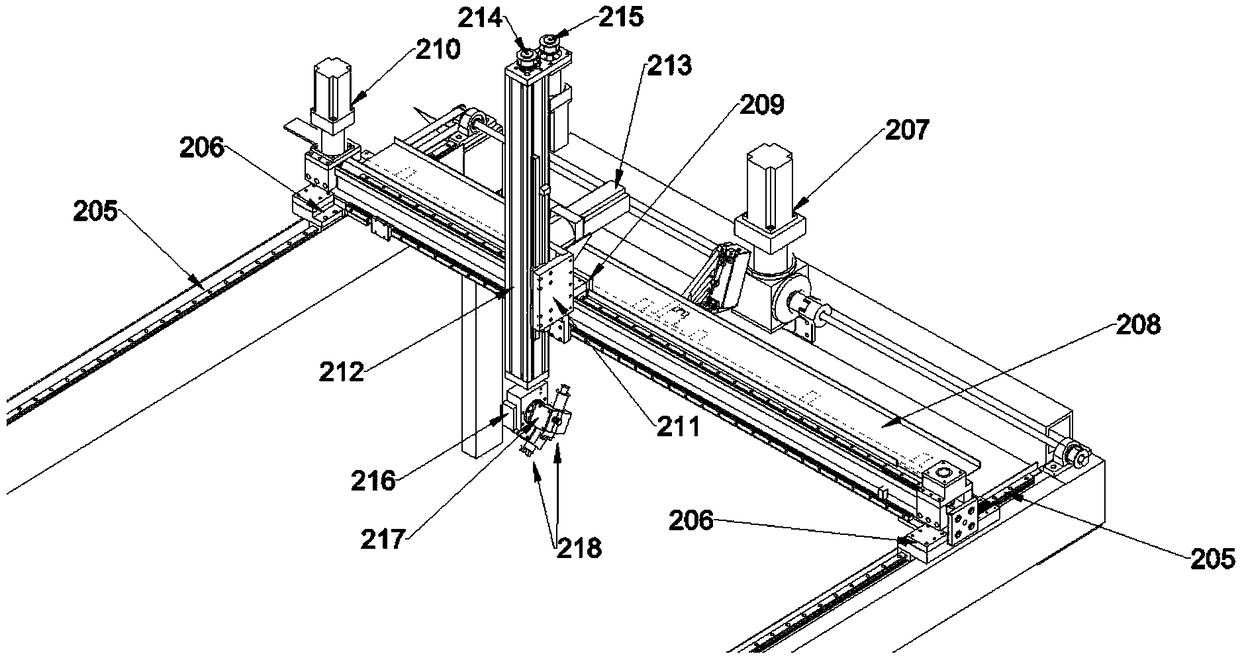

[0092] Please refer to figure 1 As shown, it is a schematic structural view of the automatic door panel coating equipment of the present invention. The automatic door panel coating equipment includes: a feeding machine 1, a painting booth 2, a conveyor 3, an elevator 4, a drying room 5, a feeding machine 6 and a main controller.

[0093] The feeder 1 is used to transport the door panel to be painted into the spray booth;

[0094] The spray booth 2 is used for spraying the door panels to be painted;

[0095] Conveyor 3 is used to transport the painted door panels to the drying chamber;

[0096] The drying chamber 5 is used for drying the painted door panels;

[0097] The unloading machine 6 is used to transport t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com