Open type spray booth

An open technology for spray booths, spraying equipment, coatings, etc., which can solve the problems of endangering the health of workers, inconvenient operation for workers, and damage to the paint layer on the surface of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

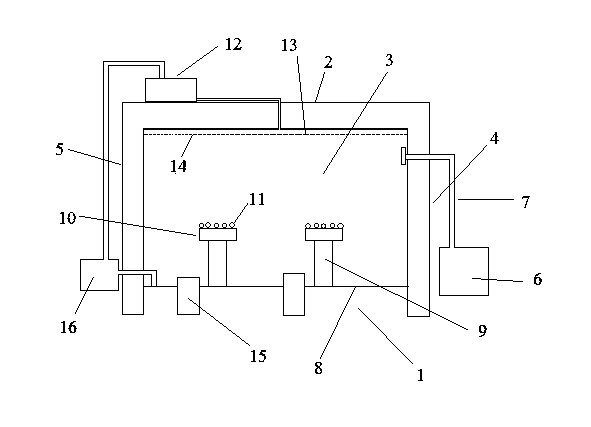

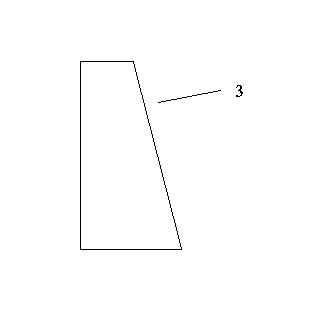

[0016] like figure 1 As shown, this open spray booth includes a spray booth 1, and the spray booth 1 is composed of a roof 2, a first wall 3 and a second wall 4 and a third wall that are located on both sides of the first wall 3 and are connected thereto. body 5 composition;

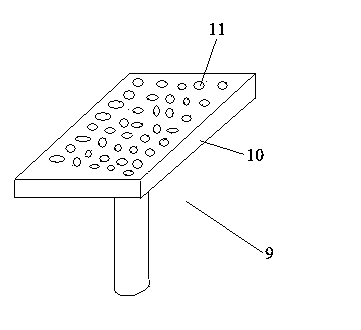

[0017] The outside of the spray booth 1 is provided with an exhaust device 6, and the exhaust pipe 7 of the exhaust device 6 communicates with the spray booth 1 through the second wall body 4, and is used to discharge harmful gases generated during painting. A pool 8 is provided below the chamber 1, and the pool 8 is used to absorb paint splashed during painting, and a turntable 9 for placing workpieces is installed on the pool 8, figure 1 There are two turntables in the middle, because the turntable 9 can realize 360-degree rotation, it is convenient for workers to spray the workpiece as a whole, eliminating the dead angle of spraying, and on the turntable 9, there are also protrusions, such as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com