Novel aluminum veneer pre-roll-coating production line and process technology

An aluminum veneer and production line technology, applied in the directions of coating, surface pretreatment, and devices for coating liquids on the surface, etc., can solve the problem that the pre-roll coating large-scale production line cannot play the best state, the defects and disadvantages are insurmountable, and the color is changed. Problems such as difficult patterns, to achieve the effect of outstanding energy saving advantages, simple and ingenious structure, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

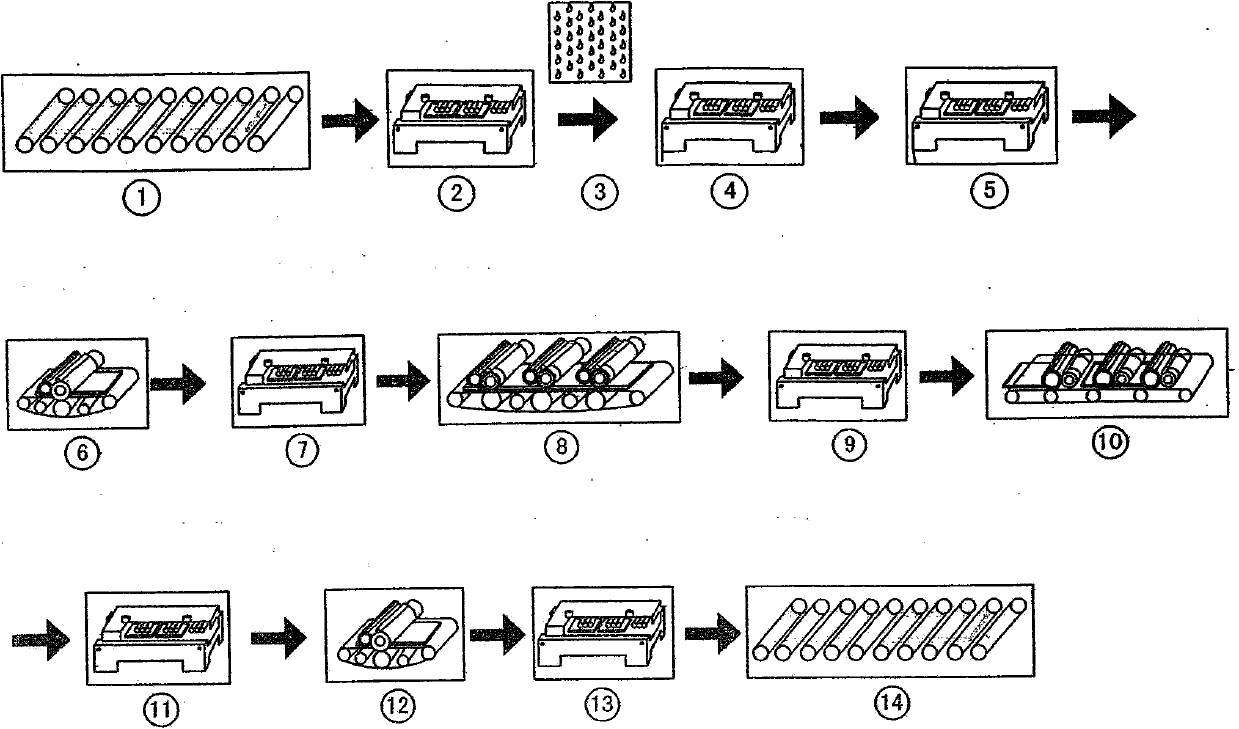

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 Shown:

[0066] A new type of aluminum veneer pre-roller coating production line, consisting of a front conveyor belt 1, an alkali washing machine 2, a cleaning machine 3, a chrome-free passivation device 4, an oven 5, a precision single-roller primer coater 6, and a far-infrared oven 7. Three-roll coater 8, far-infrared device 9, multi-color three-dimensional printing machine 10, far-infrared machine 11, precision single-roll varnish coater 12, curing oven 13, and rear conveyor belt 14;

[0067] The new aluminum veneer pre-roller coating production line has a front conveyor belt 1, an alkali washing machine 2, a cleaning machine 3, a chrome-free passivation device 4, an oven 5, a precision single-roller primer coater 6, and a far-infrared oven 7. Three-roller coater 8. Far-infrared device 9. Multi-color three-dimensional printing m...

specific Embodiment approach 2

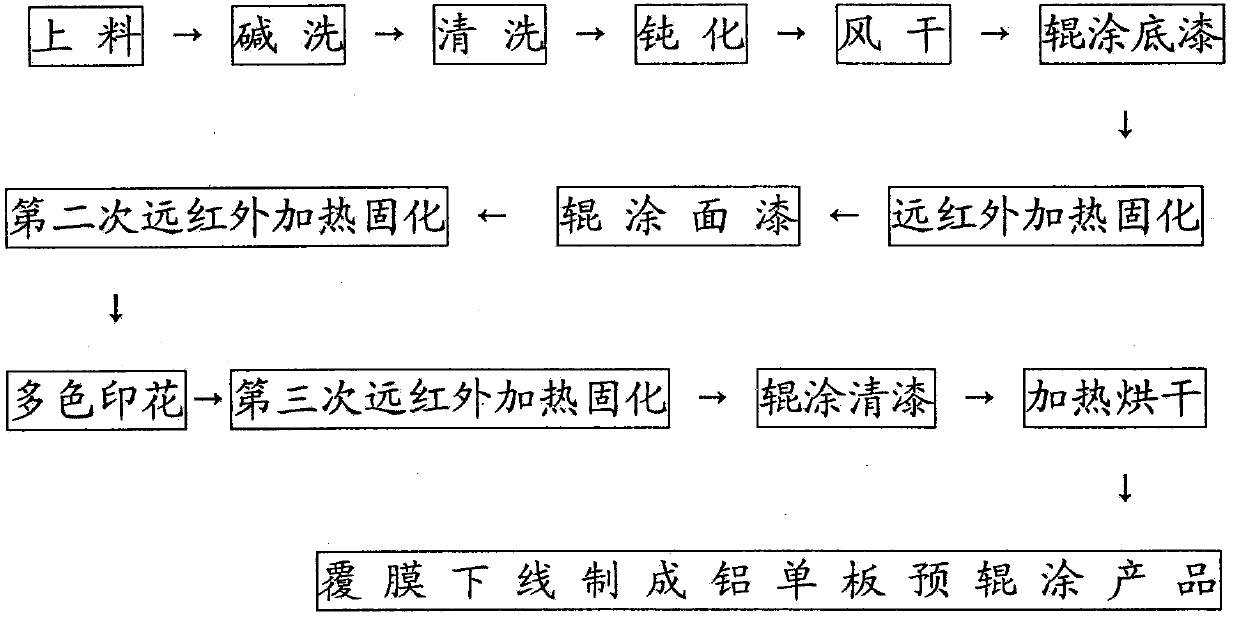

[0071] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 Shown:

[0072] A kind of process technology of the novel production line of pre-roller coating of aluminum veneer, apply described novel production line of pre-roller coating of aluminum veneer, the technological process of its production is:

[0073] (1) Loading: Manually lift the aluminum sheet and put it on the front conveyor belt 1 or adsorb it on the front conveyor belt 1 with a vacuum suction cup;

[0074] (2), alkali washing: wash the aluminum plate material with alkali washing machine 2;

[0075] (3), cleaning: cleaning the washed aluminum sheet material with cleaning machine 3;

[0076] (4), passivation: the chrome-free passivation device 4 is carried out to the chromium-free passivation treatment to the cleaned aluminum sheet material; promptly by the passivation product of chrome-free single component, generate a lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com