Patents

Literature

165 results about "Chromate free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy chromate-free passivation treatment method and aluminum alloy chromate-free passivation treatment fluid thereof

ActiveCN106086846AImprove corrosion resistanceImprove hydrophobicityMetallic material coating processesEnvironmental resistanceProtection layer

The invention relates to the technical field of metal surface anti-corrosion treatment, and provides an aluminum alloy chromate-free passivation treatment method and aluminum alloy chromate-free passivation treatment fluid thereof. The treatment fluid is composed of 0.5 to 10.0 g / L of titaniferous compounds, 0.1 to 8.0 g / L of zirconium salt, 0.1 to 10 g / L of fluoride, 0.5 to 20 g / L of oxidizing agents and 0.2 to 15 g / L of complexing agents, wherein the pH ranges from 3.6 to 4.5. Aluminum alloy is treated for 1 to 5 minutes at the room temperature in the chromate-free passivation treatment fluid, and then is subjected to chromate-free passive membrane sealing treatment for 60 seconds to 120 seconds at the room temperature in sealing treatment fluid composed of 1% to 15% of organosilane, 2% to 40% of water-soluble fluorocarbon emulsion and 65% to 97% of deionized water, so that a compound chromate-free passive membrane is formed on the surface of the aluminum alloy, and after the compound chromate-free passive membrane is dried, the compound chromate-free passive membrane with high corrosion resistance is obtained on the surface of the aluminum alloy and can be directly used as the terminal protection layer of the aluminum alloy; and the chromate-free passivation treatment fluid does not contain heavy metal ions such as chromium ions, and is non-toxic, harmless to human bodies or the environment, clean and friendly to the environment.

Owner:CRRC QINGDAO SIFANG CO LTD

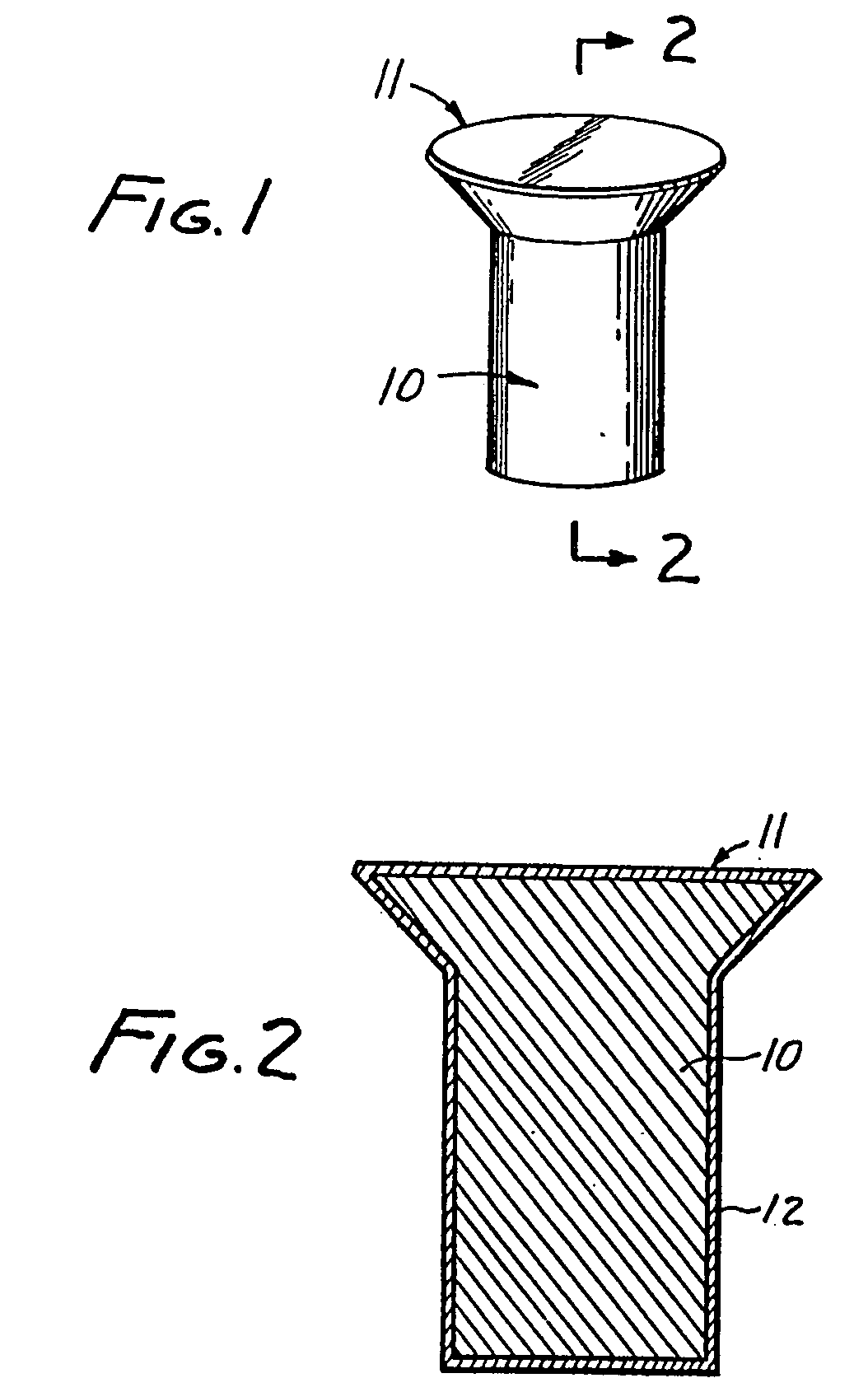

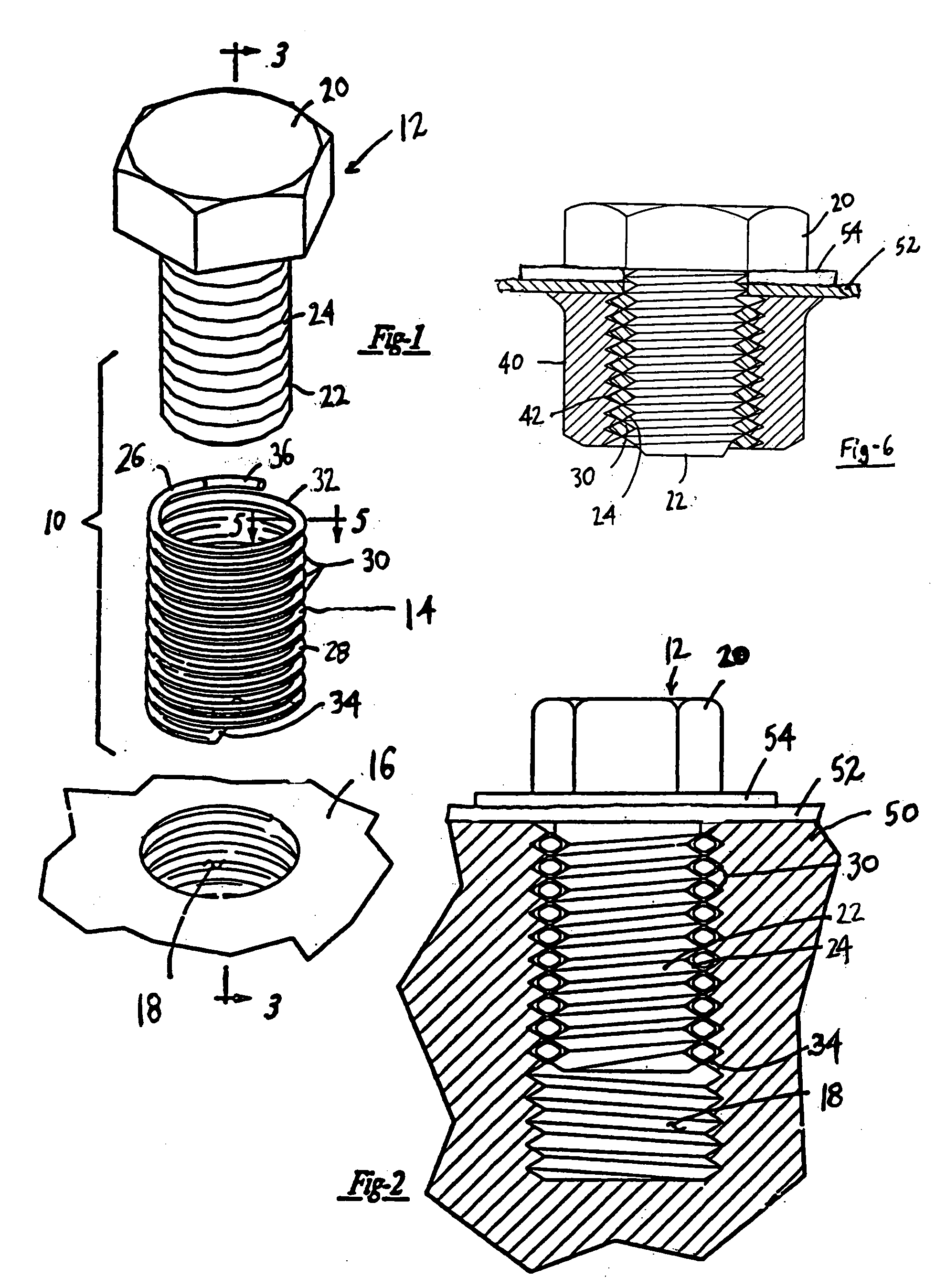

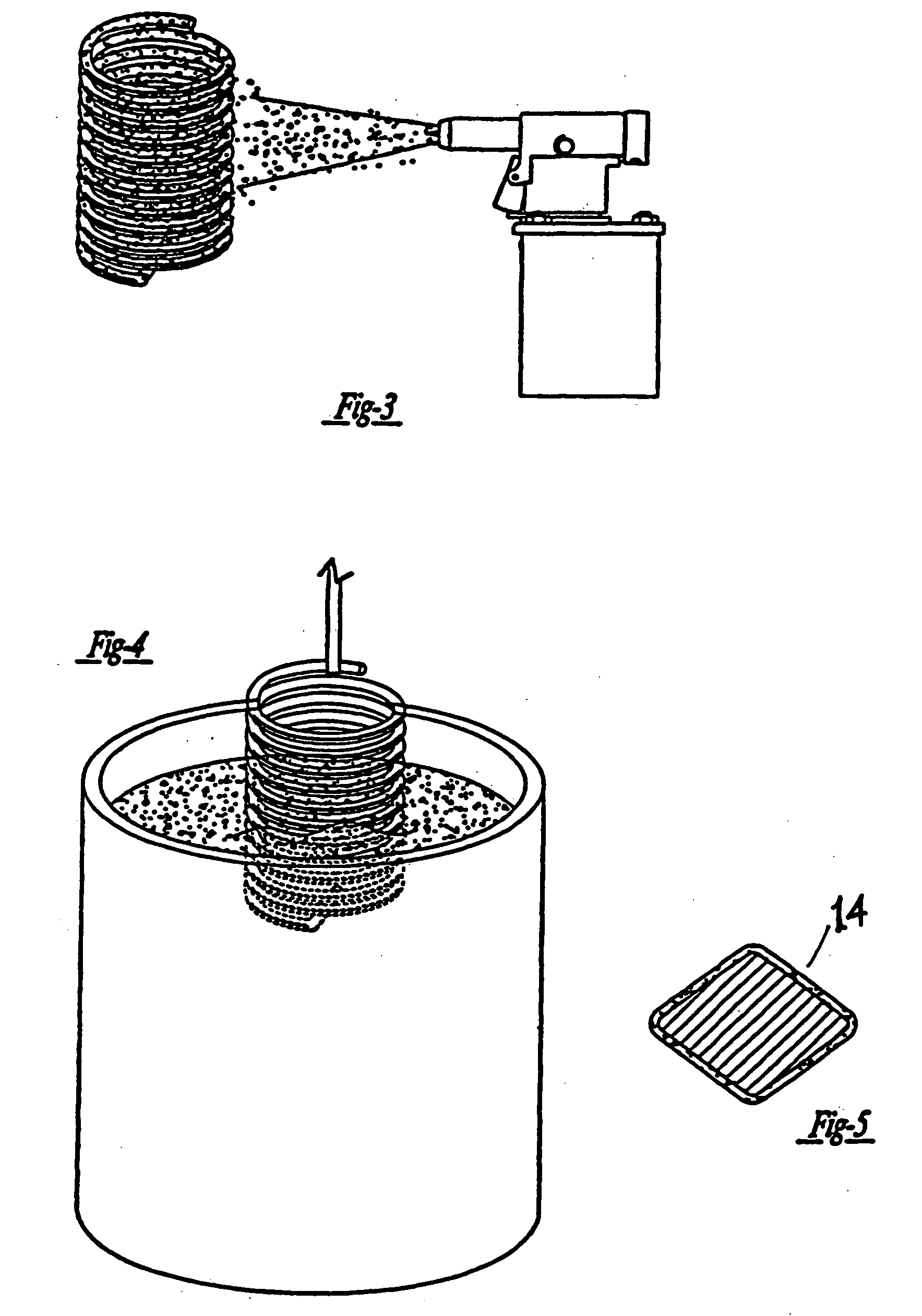

Chromate free corrosion resistant coating

ActiveUS20050151120A1Avoid corrosionIncrease resistancePinsOther chemical processesInterference fitPhenol

The chromate free corrosion resistant coating for a fastener contains corrosion inhibiting inorganic constituents, or a combination of inorganic and organic corrosion inhibiting constituents, suspended in a phenol-formaldehyde thermosetting resin. The coating material possesses high abrasion resistance, and provides good lubricity and relatively low friction, rendering it especially suited for use with interference-fit fasteners.

Owner:HI SHEAR

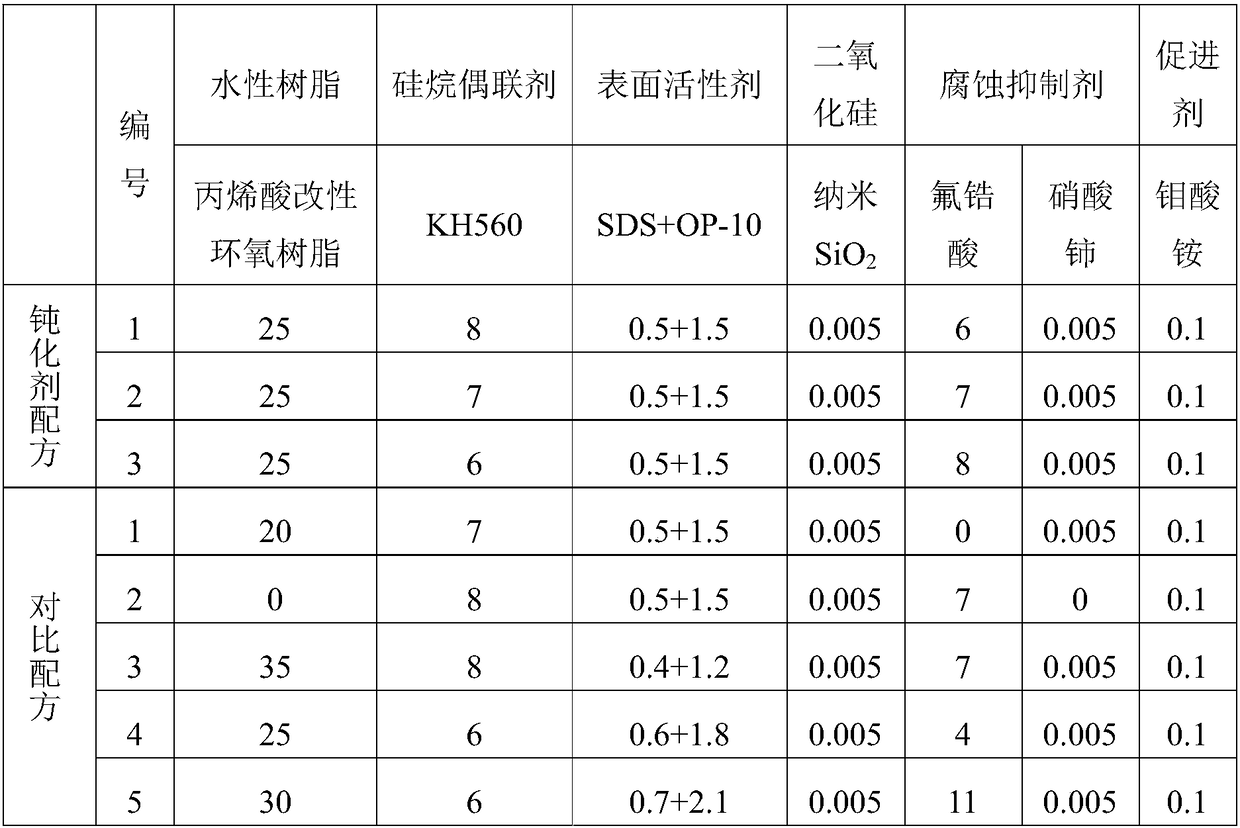

Chromate-free passivation agent for aluminum alloy

InactiveCN105779984AIncreasing the thicknessImprove compactnessMetallic material coating processesEpoxySilanes

The invention discloses a chromate-free passivation agent for an aluminum alloy. Per liter of chromate-free passivation agent is composed of, by mass, 10 mg to 300 mg of amino silane or / and epoxy silane, 1 mg-100 mg of dispersible nano particles, 10 mg-500 mg of a zirconium compound or / and a titanium compound, 1 mg-150 mg of metal ions, 10 mg-150 mg of fluoride, 1 mg-20 mg of a complexing agent, 75 mg-100 mg of organic phosphoric acid and the balance water; and the organic phosphoric acid is at least two of HEDP, HPMA, EDTMP, DTPMP, ATMP and PBTCA. According to the passivation agent, multiple kinds of organic phosphoric acid, multiple kinds of metal ions and multiple kinds of nano particles are chelated to the different degrees; on one aspect, the thickness and the compactness of a passivation film layer can be strengthened; and meanwhile, the passivation film layer (inorganic film layer) formed after chelation can show a color to a certain degree on the surface of the aluminum alloy.

Owner:NANJING KERUN LUBRICANTS

Compound chromate-free passivator capable of forming films rapidly and preparation method

InactiveCN108300988ANo pollution in the processClean manufacturingMetallic material coating processesCorrosion reactionPhosphoric acid

The invention provides a compound chromate-free passivator capable of forming films rapidly. The compound chromate-free passivator comprises water-dilutable resin, silicon dioxide, a surfactant, a corrosion inhibitor, an accelerant and water. The chromate-free passivator provided by the invention does not contain poisonous and harmful ingredients such as heavy metal, sodium nitrite, phosphoric acid and the like, is environment-friendly, pollution-free and clean in production, and is close to passivation effect of hexavalent chromate in the aspect of comprehensive performance such as corrosionresistance and reprocessing; and the passivator sufficiently utilizes the diversity of organic high-molecular polymers and the rapid forming characteristic of inorganic salt, so that a high-performance resin and zirconium-based oxide layer compound coating can be provided for metal surfaces, compound passivation film provides a double protection function for protection of metal surfaces, and the organic coating has a clear advantage of delaying initial-stage corrosion on the metal surfaces, so as to ensure that the metal surfaces have excellent corrosion resistance and then the adhesive forceof coating is improved.

Owner:长沙艾森设备维护技术有限公司

Metallic material having chromate-free-treated surface excellent in corrosion resistance, heat resistance, anti-fingerprint property, conductivity, coating property and black deposit resistance during

ActiveCN101228294AMeet the corrosion resistanceMeet heat resistanceMetallic material coating processesThin material handlingAdditive ingredientMetallic materials

The present invention provides a metal material with a non-chromate surface treatment, which can satisfy the corrosion resistance, heat resistance, fingerprint resistance, electrical conductivity, paintability and processing requirements that were difficult to achieve with the conventional non-chromate technology. Anti-blackening and other properties. The non-chromate surface-treated metal material of the present invention forms a composite film containing various components by applying and drying a water-based metal surface treatment agent on the surface of the metal material. The water-based metal surface treatment agent contains one The organic silane coupling agent (A) of amino group and the silane coupling agent (B) containing 1 glycidyl group in the molecule are mixed according to the ratio of solid content mass ratio [(A) / (B)] of 0.5 to 1.7. A silicon compound (W), at least one fluorine compound (X) selected from titanium hydrofluoride or zirconium hydrofluoride, phosphoric acid (Y) and a vanadium compound (Z).

Owner:NIPPON STEEL CORP

Chromate-free passivator and method for passivating aluminum or aluminum alloy surface

InactiveCN106756967AImprove bindingImprove corrosion resistanceMetallic material coating processesAdhesion forceMetallurgy

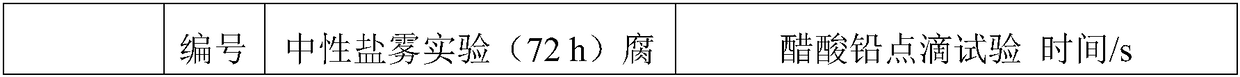

The invention provides a chromate-free passivator. The chromate-free passivator comprises the following components in a percent by weight: 77.3-93.8% of water, 5.0-20.0% of water-soluble resin, 0.1-1.0% of a coupling agent, 0.2-0.5% of a nanometer inorganic material, 0.5-1.0% of a complexing agent and 0.1-0.5% of an accelerant. When the chromate-free passivator provided by the invention is applied to the passivation of an aluminum or aluminum alloy surface, an obtained passivating film has excellent corrosion resistance and excellent bonding capability with a paint film and a powdery coating on the surface of a base material. Experimental results show that the corrosion resistance of the aluminum or aluminum alloy surface which is treated by using the chromate-free passivator is improved, the passivating film can resist salt mist for more than 72 hours, the wet film adhesion force of the paint film is improved, pressure cooker boiling can be withstood for more than two hours, and the quality of the formed film cannot be affected by environmental factors. The operation is simple, and the chromate-free passivator is suitable for site use.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

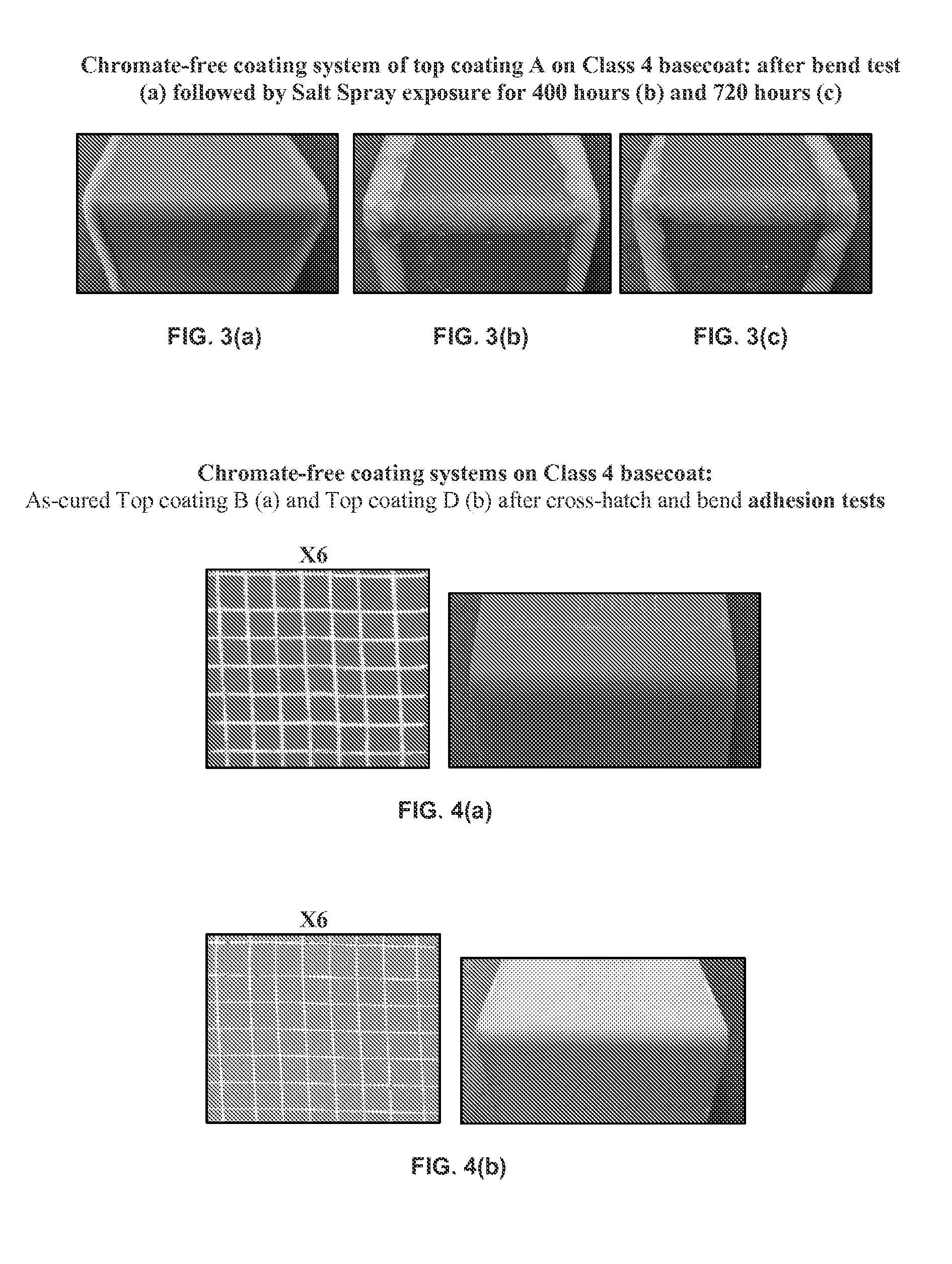

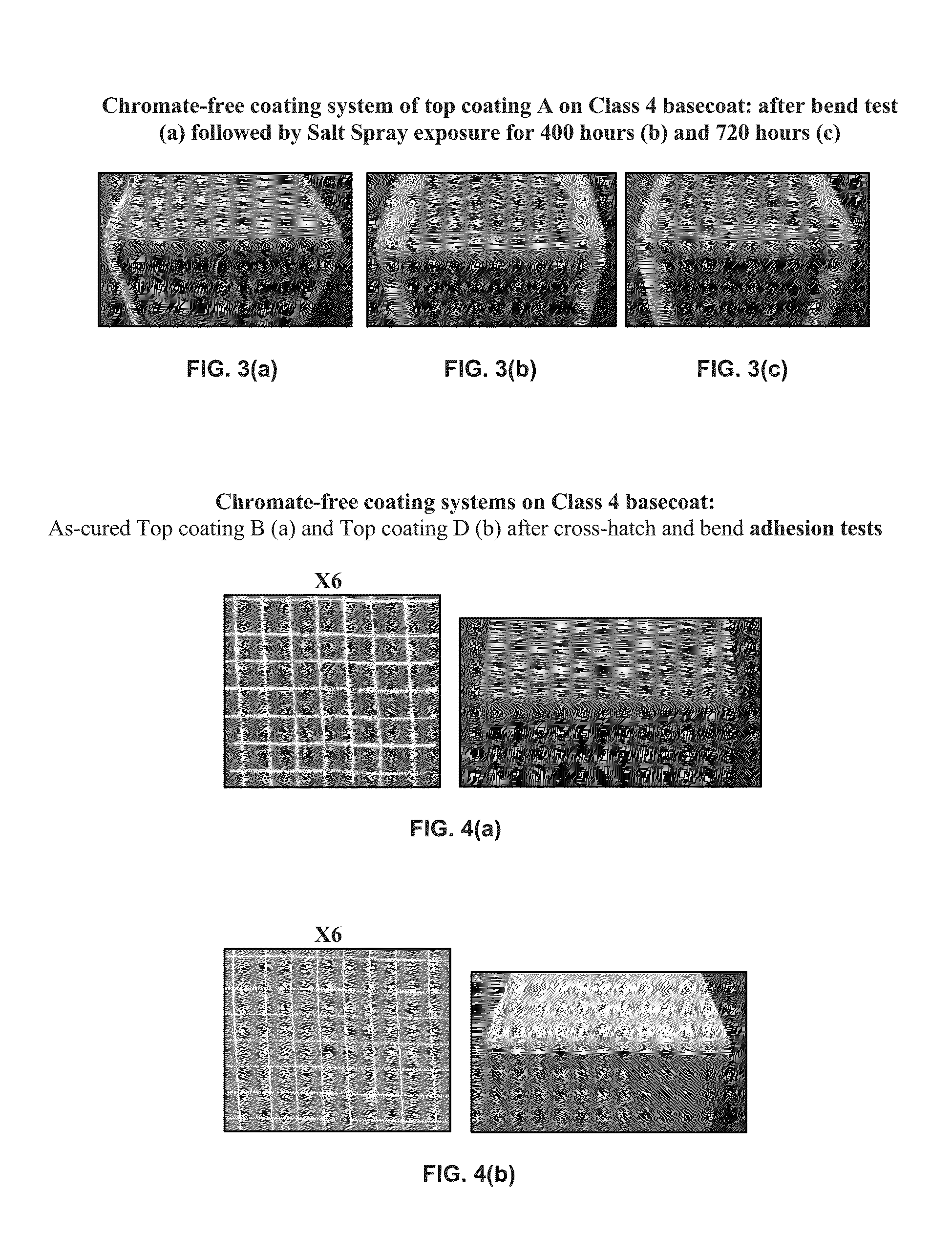

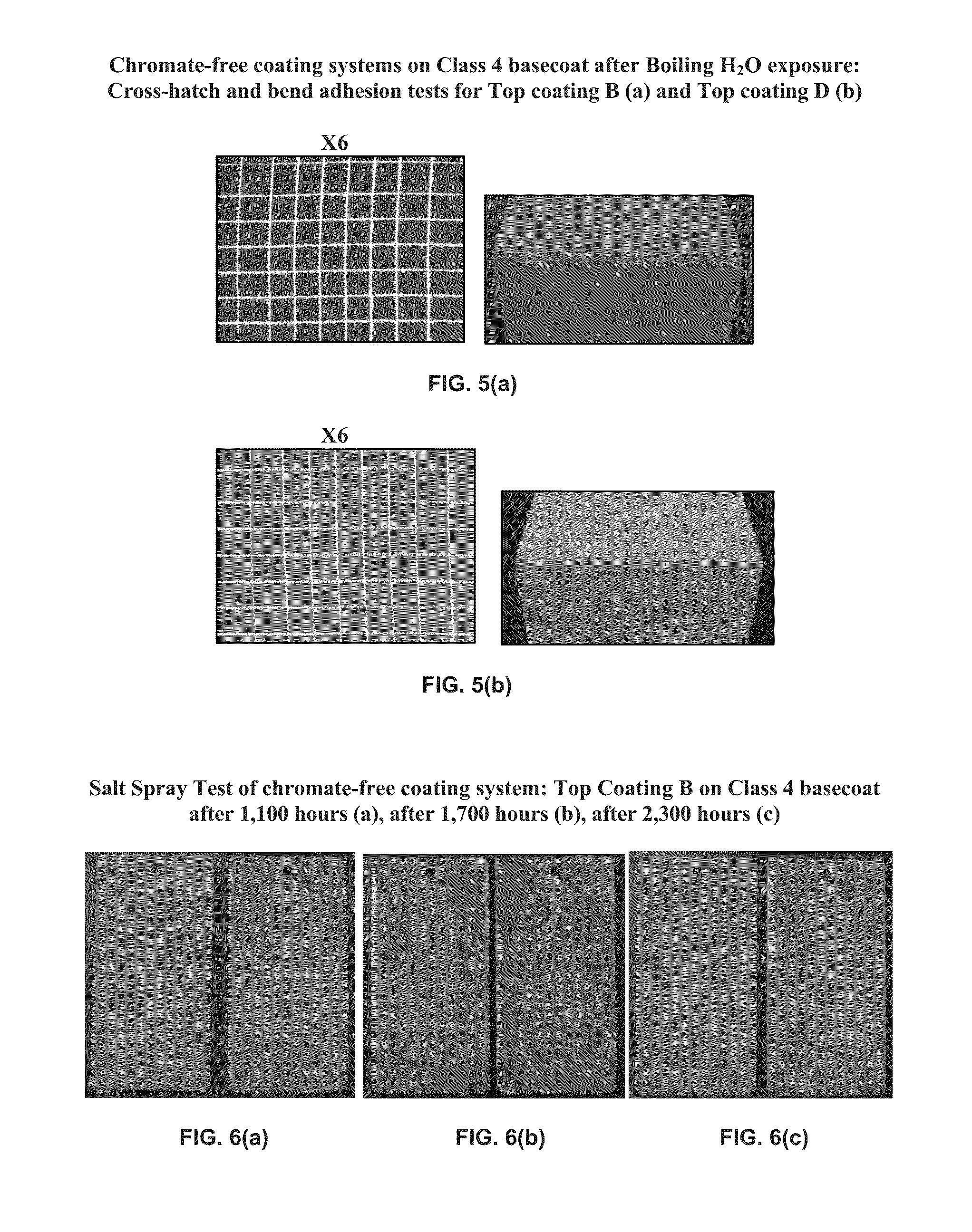

Chromate-free ceramic coating compositions

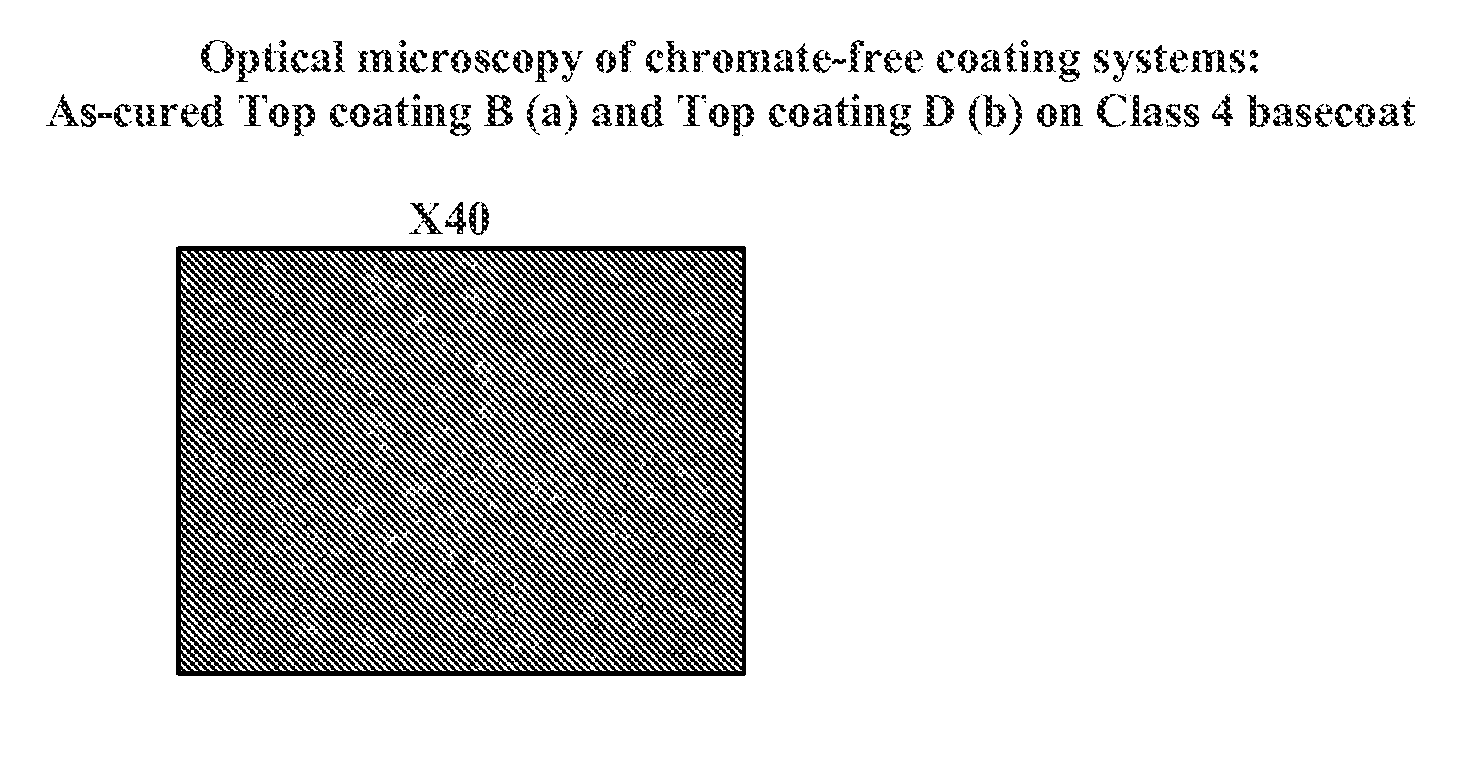

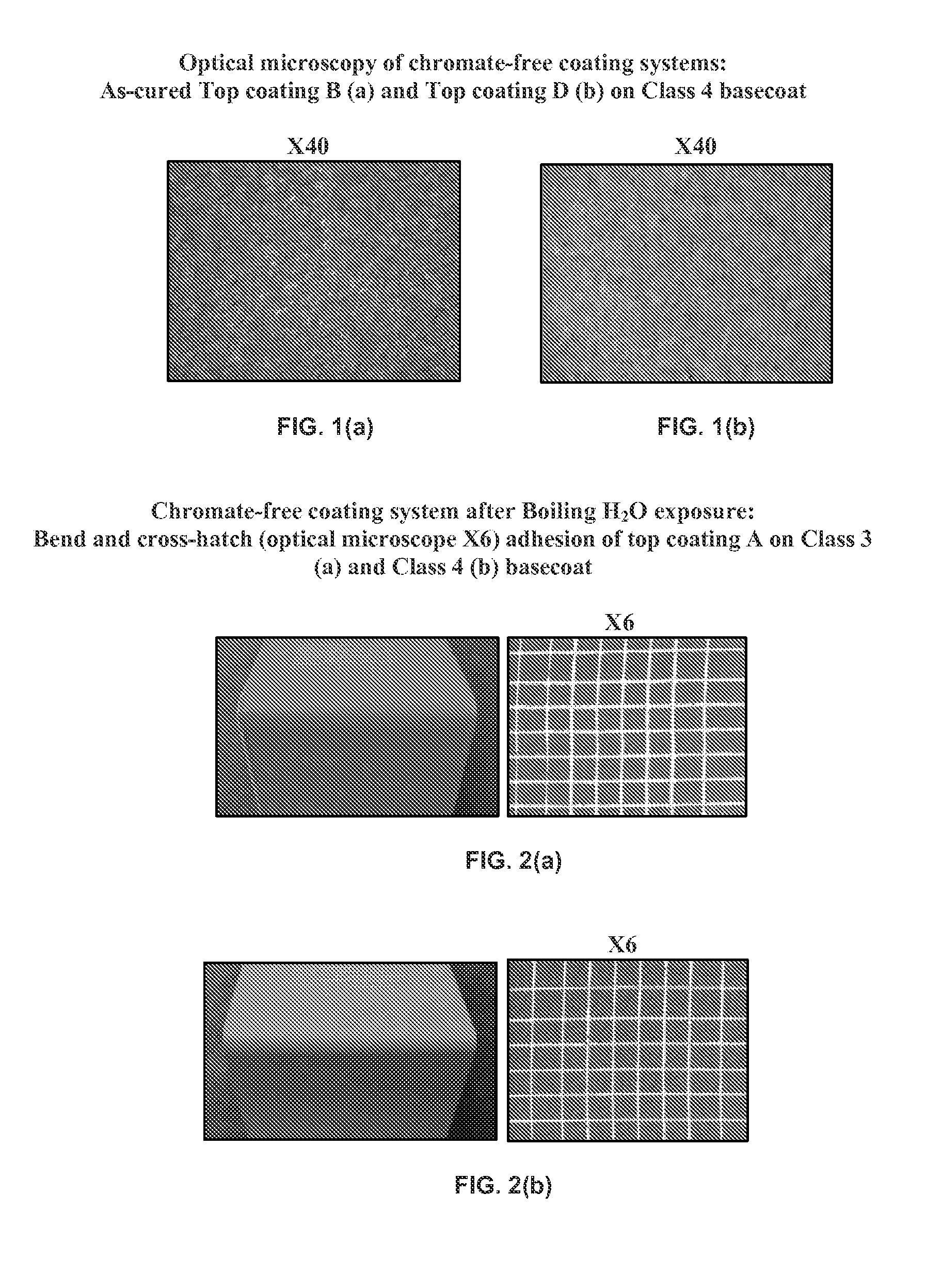

ActiveUS20150183998A1Improve corrosion resistanceImprove heat resistanceAlkali metal silicate coatingsAnti-corrosive paintsLithiumCoating system

A novel chromate-free multi-layer coating system composed of a lithium-doped potassium silicate binder based basecoat composition that is sealed with an aluminum phosphate-based top coat composition is described. The multi-layer coating system exhibits superior corrosion and heat oxidation resistance which can replace traditional chromate-containing coating systems.

Owner:PRAXAIR ST TECH INC

Rinsable metal pretreatment methods and compositions

InactiveUS20060151070A1Improve corrosion protectionImprove adhesionSolid state diffusion coatingPretreatment methodPhosphate

Chromate-free and metal phosphate free treatments and compositions for applying a conversion or passivation coating for metals, more particularly, steel, zinc coated steel, and aluminum surfaces. The methods of the invention comprise contacting the requisite metal surface with a treatment composition comprising a member or members comprising one or more Group IV B elements, fluoride, and phosphonic acid or phosphonate. Optionally, a silane may be added as a treatment component.

Owner:CHEMETALL CORP

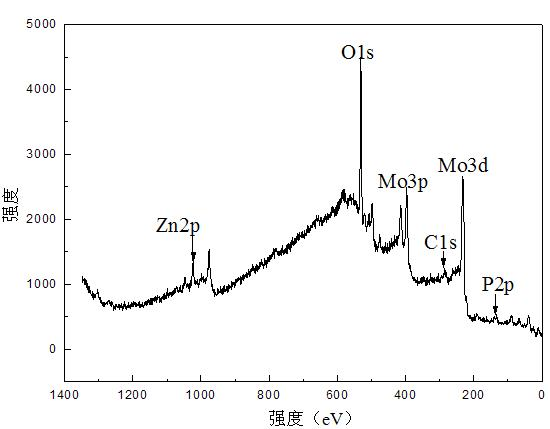

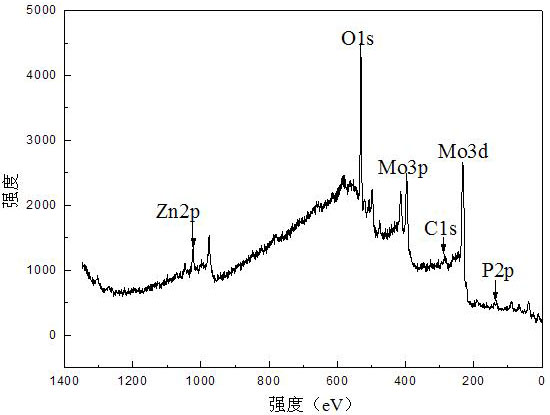

Blue write chromate-free passivation liquid of electrogalvanized layer and method for passivating electrogalvanized layer by adopting same

InactiveCN101906629AImprove compactnessImprove corrosion resistanceMetallic material coating processesElectrogalvanizationMolybdate

The invention relates to a blue write chromate-free passivation liquid of an electrogalvanized layer and a method for passivating the electrogalvanized layer by adopting the same, belonging to a chromate-free passivation liquid and a passivating method thereof. The invention solves the problem that the traditional passivation liquid contains toxic hexavalent chromium. The chromate-free passivation liquid contains molybdate, phosphate, sulfuric acid and organic matter. The passivating method comprises the steps of: dipping a treated galvanized steel sheet into the blue write chromate-free passivation liquid of the electrogalvanized layer with a temperature of 20-60 DEG C for passivating for 20-80s; and washing and drying to complete the process of passivating the electrogalvanized layer of the blue write chromate-free passivation liquid. The chromate-free passivation liquid does not contain the toxic hexavalent chromium and has good stability and stabilizing time exceeding 30 days.

Owner:HARBIN INST OF TECH

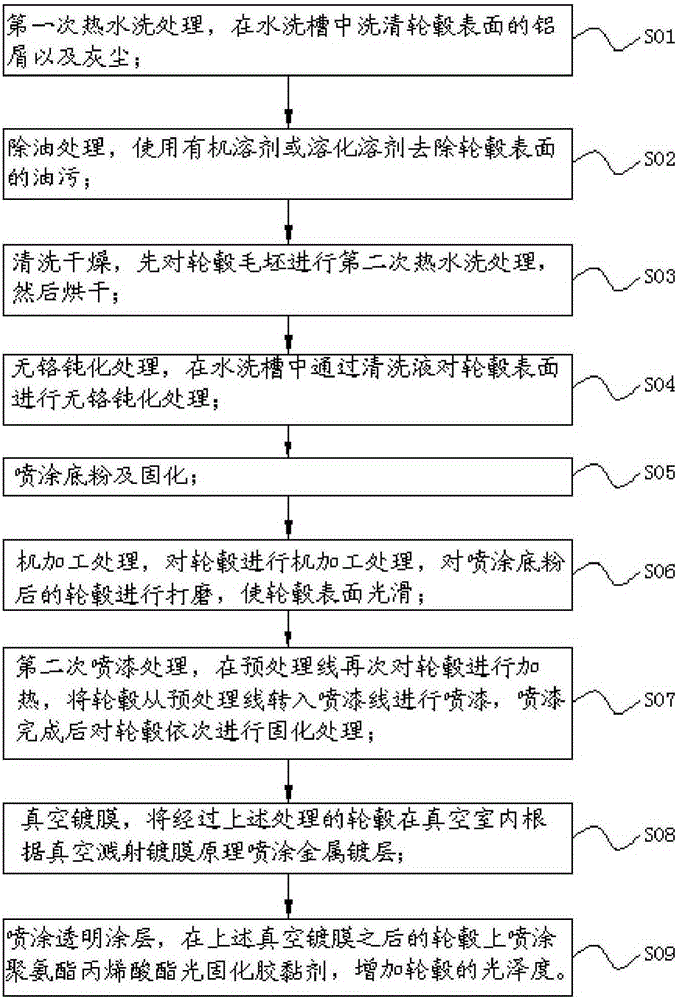

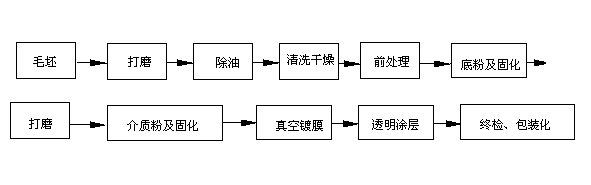

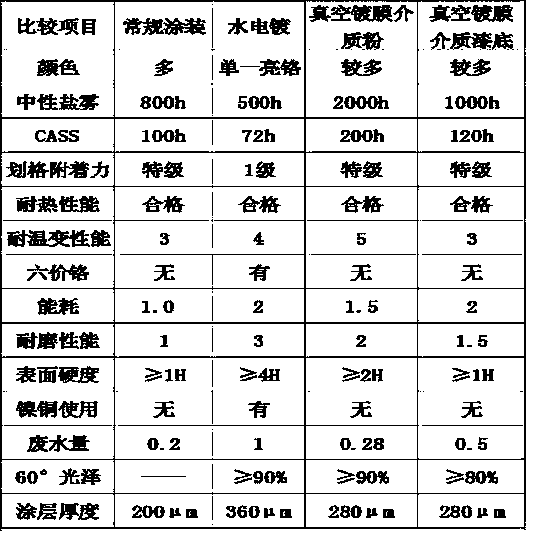

Automobile hub surface treatment process

InactiveCN105239069AImprove performanceImprove wear resistanceLiquid surface applicatorsVacuum evaporation coatingEngineeringBond Force

The invention relates to the technical field of automobiles, in particular to an automobile hub surface treatment process. The automobile hub surface treatment process comprises the following steps that first step of first-time hot water washing, the second step of oil removing treatment, the third step of cleaning and drying, the fourth step of chromate-free passivation treatment, the fifth step of bottom powder spraying and curing, the sixth step of machining treatment, the seventh step of second-time paint spraying, the eighth step of vacuum plating, and the ninth step of transparent coating spraying. According to the hub coating powder spraying paint spraying technology, the performance of a hub can be improved, the technology is simple, and the coating effect is good. By means of medium powder spraying and curing, the flatness, the glassines, the hardness and the corrosion resistance of the surface of the hub are improved, the surface of the hub is sealed, and the bonding force of a vacuum coating is improved. Through the transparent coating and high attaching force of the vacuum coating, the glossiness, the hardness, the abrasion resistance and the corrosion resistance of the hub are improved. The automobile hub surface treatment process is simple and low in energy consumption. The hardness and the corrosion resistance of the manufactured hub are high.

Owner:GUILIN HUASEN ELECTRIC POWER TECH CO LTD

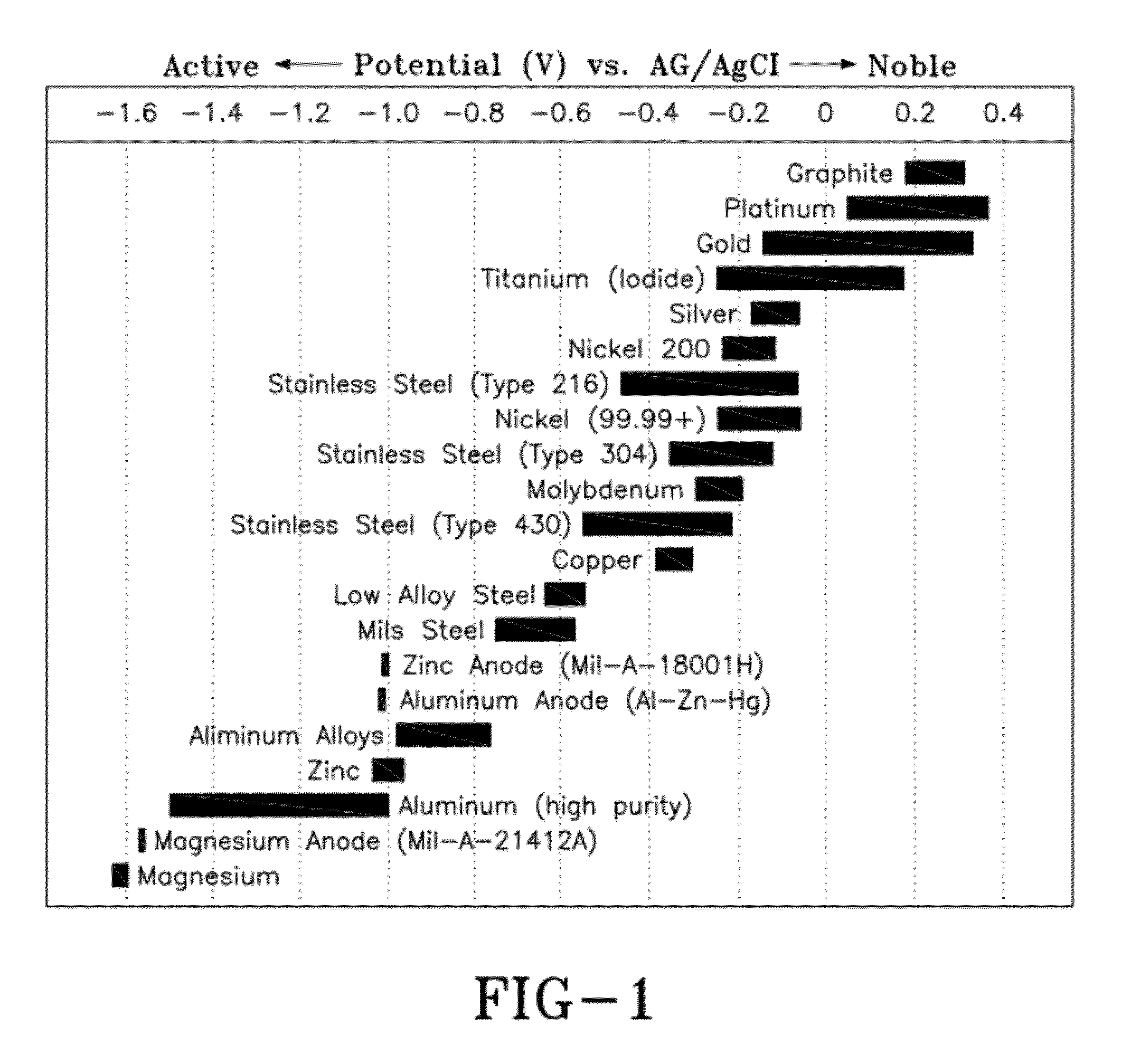

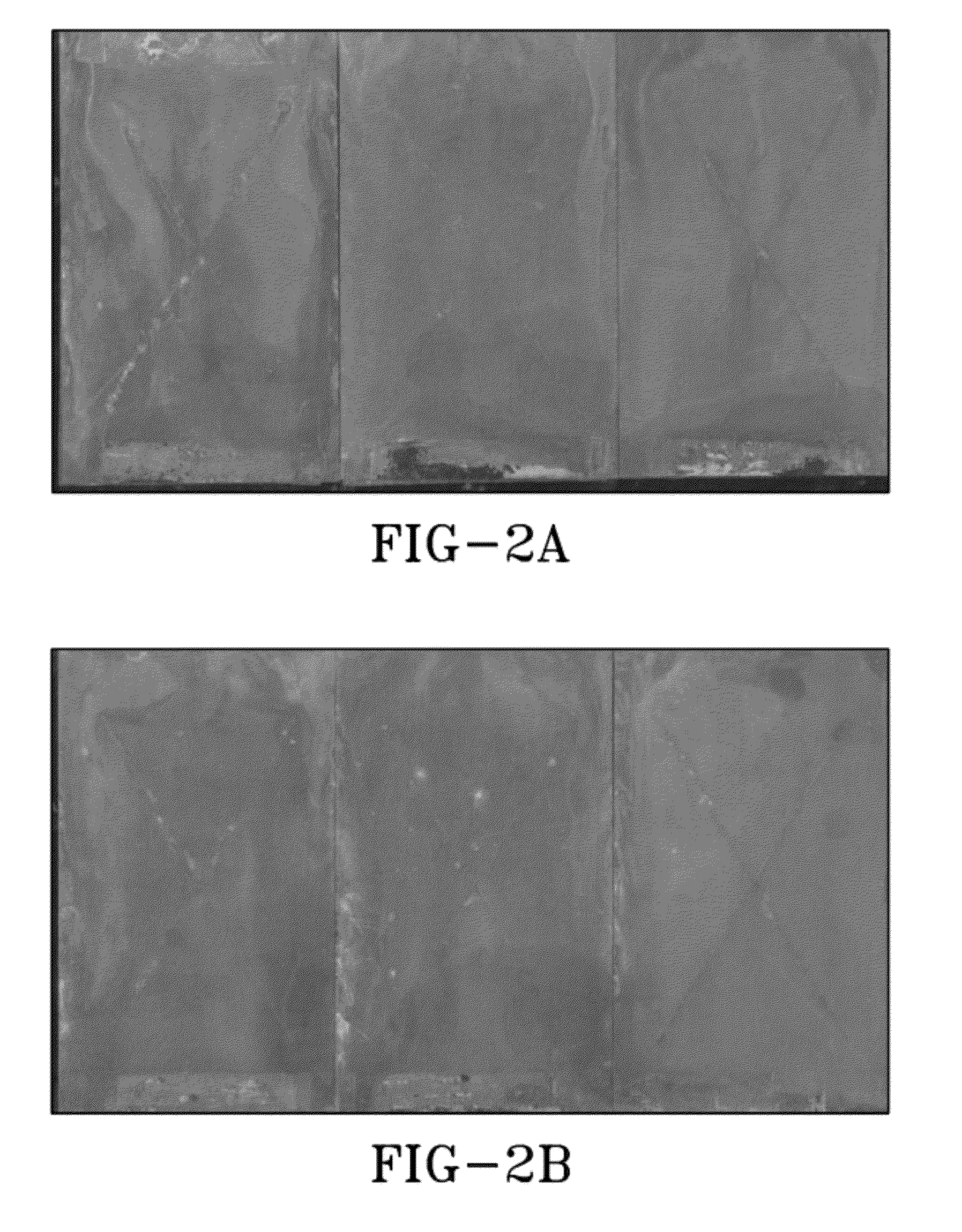

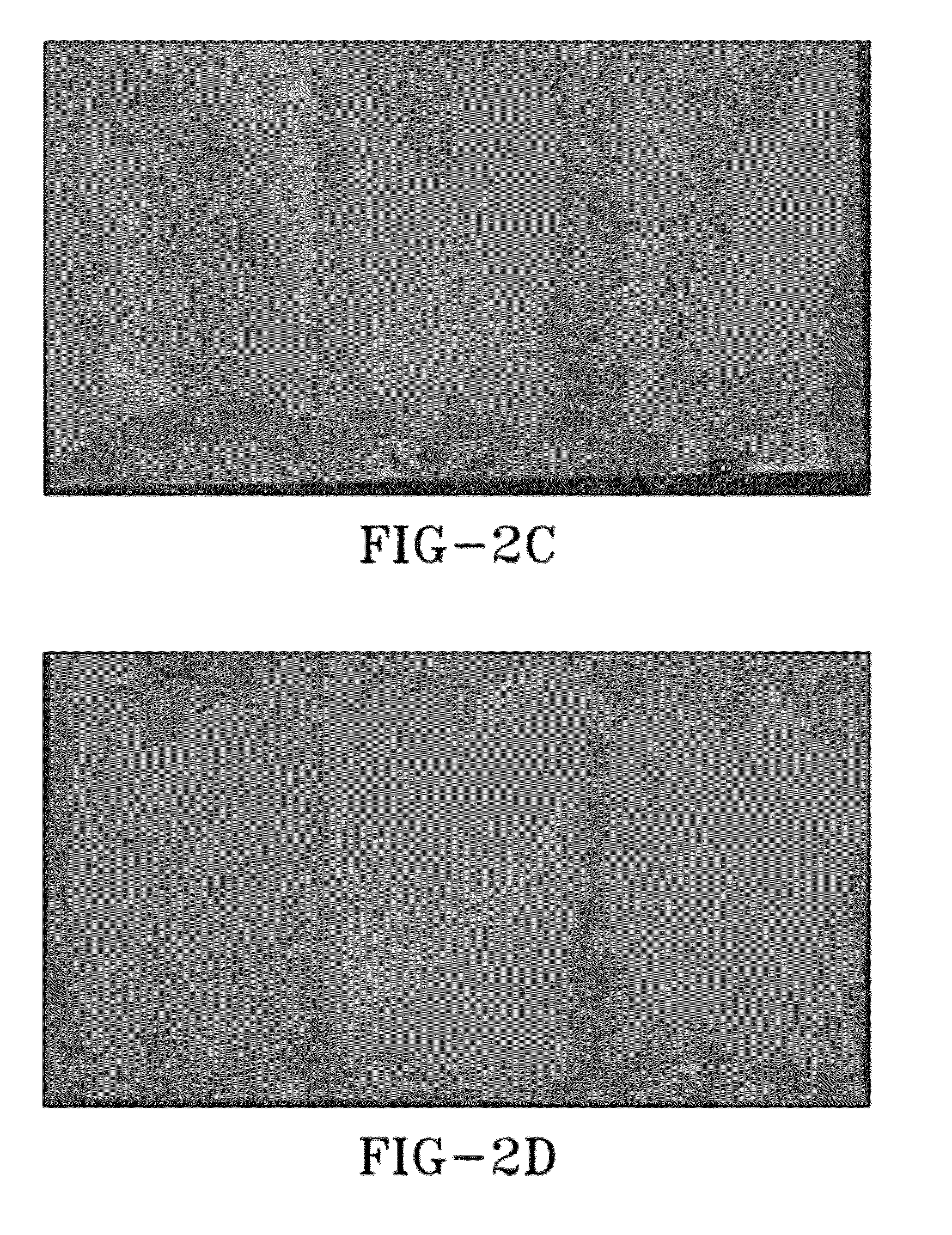

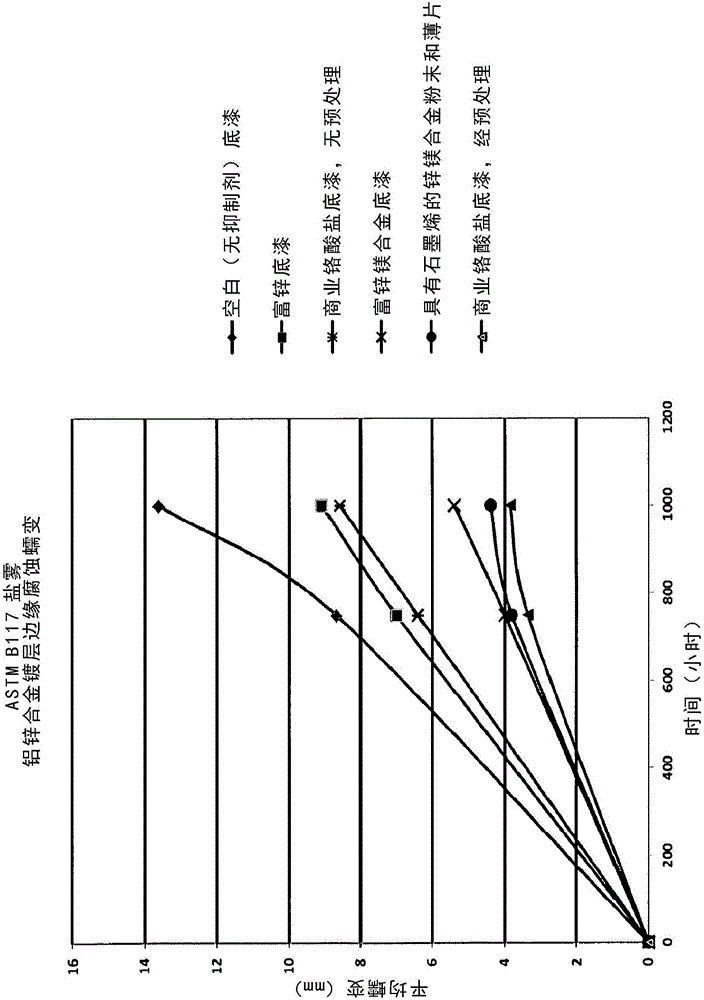

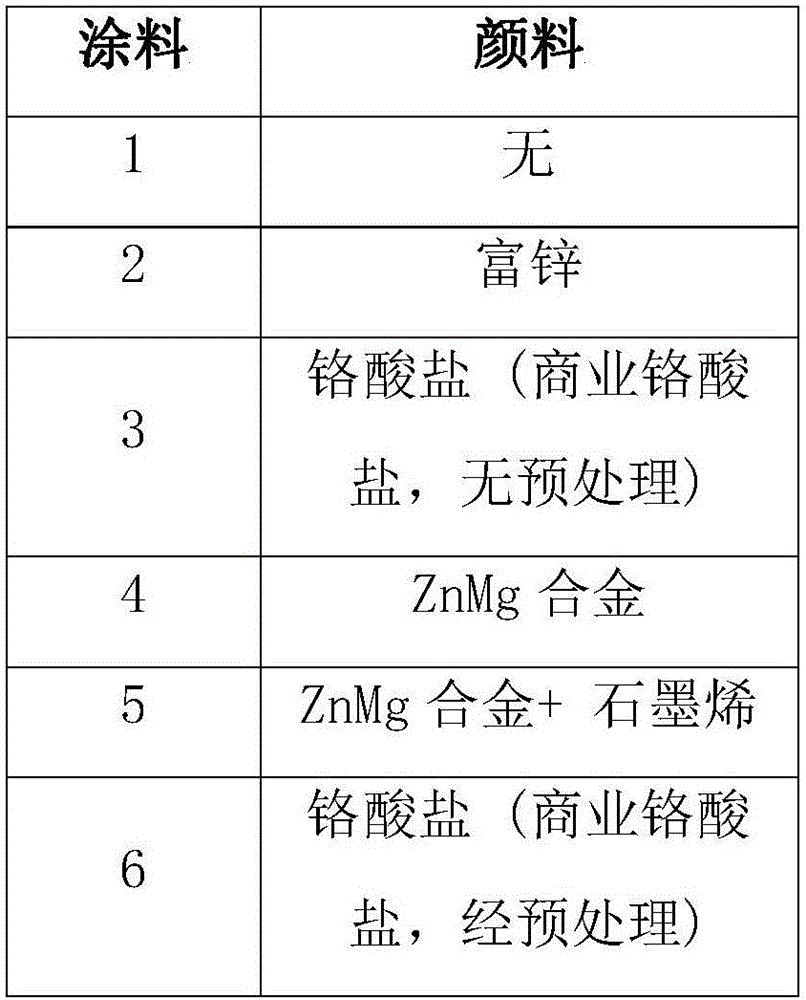

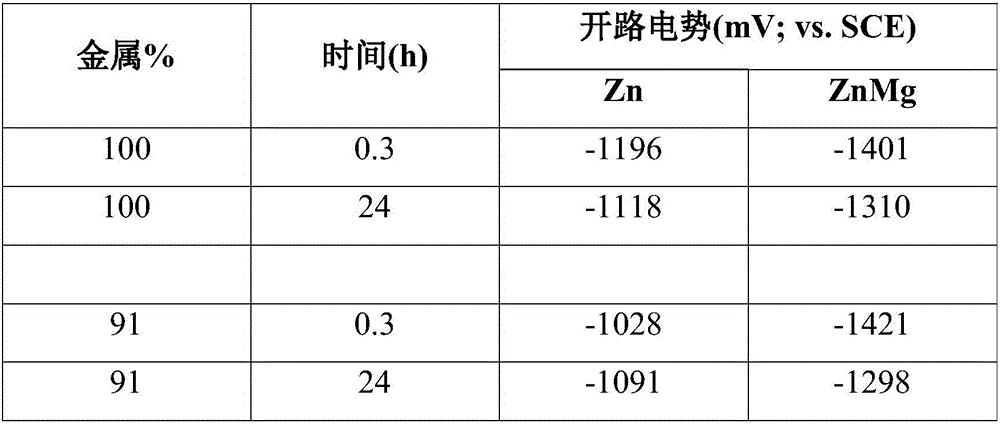

Active aluminum rich coatings

ActiveUS20120187343A1Low costWell mixedInorganic/elemental detergent compounding agentsBiocideIndiumOxygen

Chromate-free corrosion-inhibiting coating compositions comprising film-forming binders and galvanic aluminum alloy powders prepared in an oxygen (oxidizing), nitrogen (inert) or nitrogen-hydrogen (reducing) atmosphere having particle sizes ranging up to 100 microns. The aluminum alloy powders having the formula: aluminum-zinc-X (AlZnX) wherein X is an element selected from the group consisting of indium, gallium, tin and bismuth. Improvement in corrosion protection is obtained by the addition of chemical inhibitors such as an azole or talcite clay to the coating which further inhibits the self-corrosion of the aluminum alloy and extends the corrosion protection of the metal substrate being protected.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

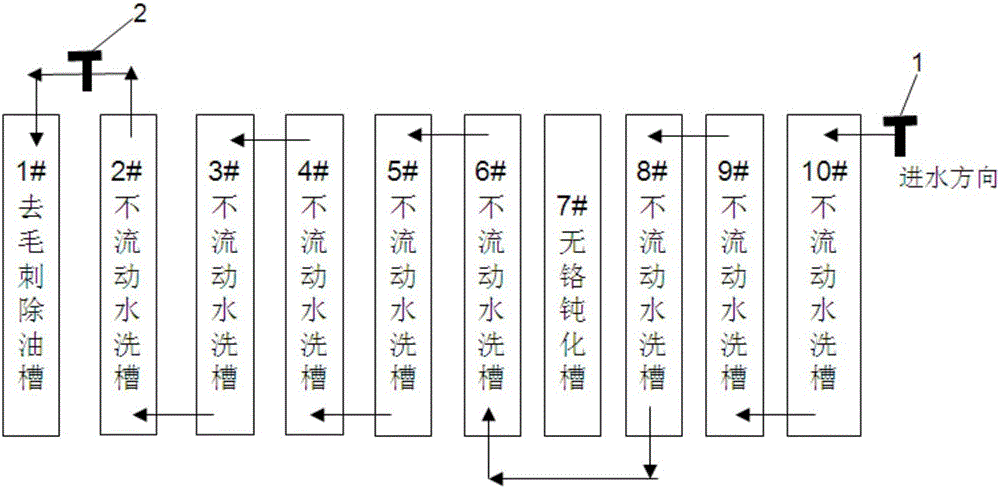

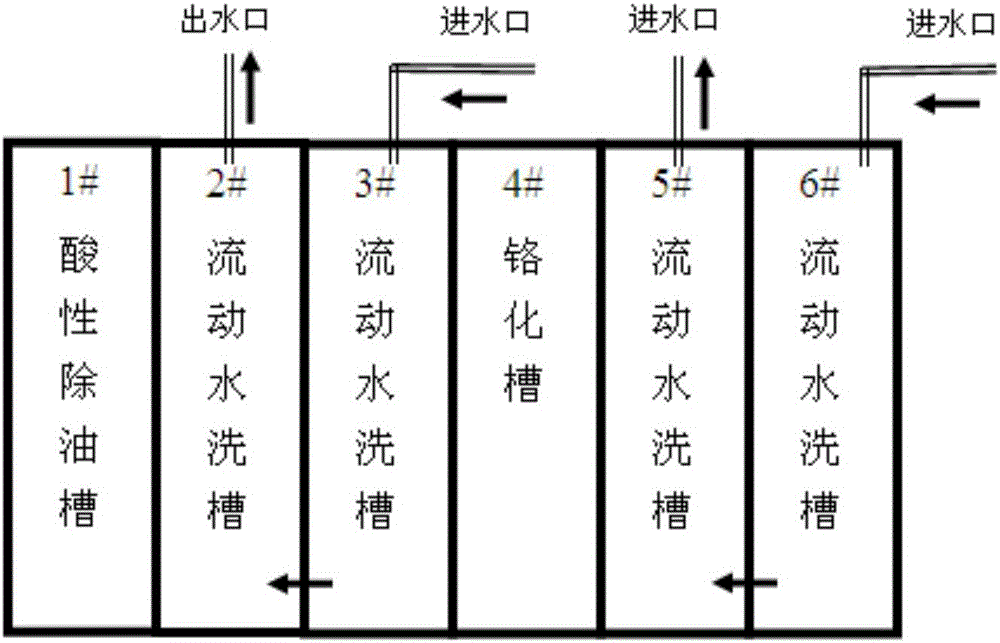

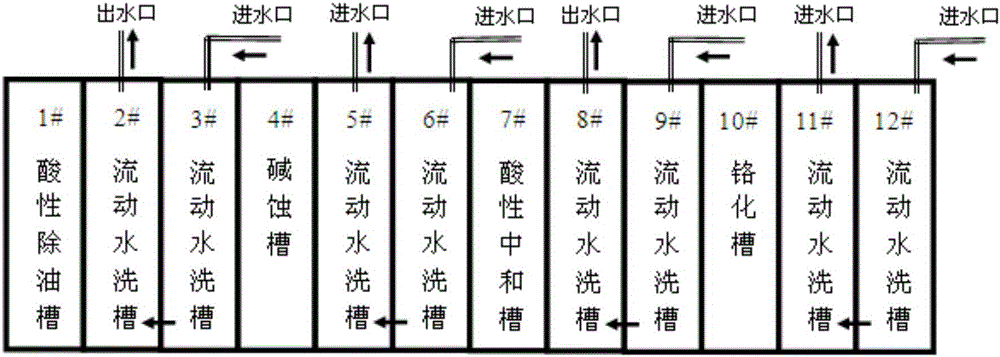

Aluminium alloy chromate-free overall agent compatibility treatment and wastewater zero discharge system

An aluminium alloy chromate-free overall agent compatibility treatment and wastewater zero discharge system comprises an agent compatible system and a series-opposing water-saving system, wherein the agent compatible system consists of a 1# deburring and degreasing bath and a 7# chromate-free passivation bath; the series-opposing water-saving system consists of a water washing compatible subsystem provided with not less than three non-mobile water washing baths, and an agent recycling subsystem provided with not less than one non-mobile water washing bath; the 1# deburring and degreasing bath, the water washing compatible subsystem and the agent recycling subsystem are in series-opposing arrangement on the whole, and a water inlet is formed in the starting end in the water flowing direction and connected with a water inflow channel by a water inflow control valve; and the 7# chromate-free passivation bath is arranged between the water washing compatible subsystem and the agent recycling subsystem. Due to the configuration of washing water series-opposing connection and agent retention and recycling on the basis of agent compatibility, the wastewater zero-discharge water-saving system is realized.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Chromate-free passivation solution for stainless steel

ActiveCN106756942AGood corrosion resistanceImprove use valueMetallic material coating processesMolybdateSulfate

The invention discloses a chromate-free passivation solution for stainless steel, and relates to a passivation solution. The chromate-free passivation solution for the stainless steel is specifically prepared from molybdate, tungstate, gallotannic acid, phytic acid, a silane coupling agent, a rare-earth sulfate, nano-modified packing, auxiliaries and water. The prepared passivation solution has the characteristics of being environmentally friendly, free of strong pungent odor and nontoxic, harm to personnel and the environment can be obviously reduced, the production cost is effectively reduced, and compared with similar products, the passivation speed of the chromate-free passivation solution is increased by about 35%; and the stainless steel treated with the chromate-free passivation solution is more excellent in corrosion resistance and high in use value.

Owner:ANHUI BAOHENG ADVANCED MATERIAL TECH CO LTD

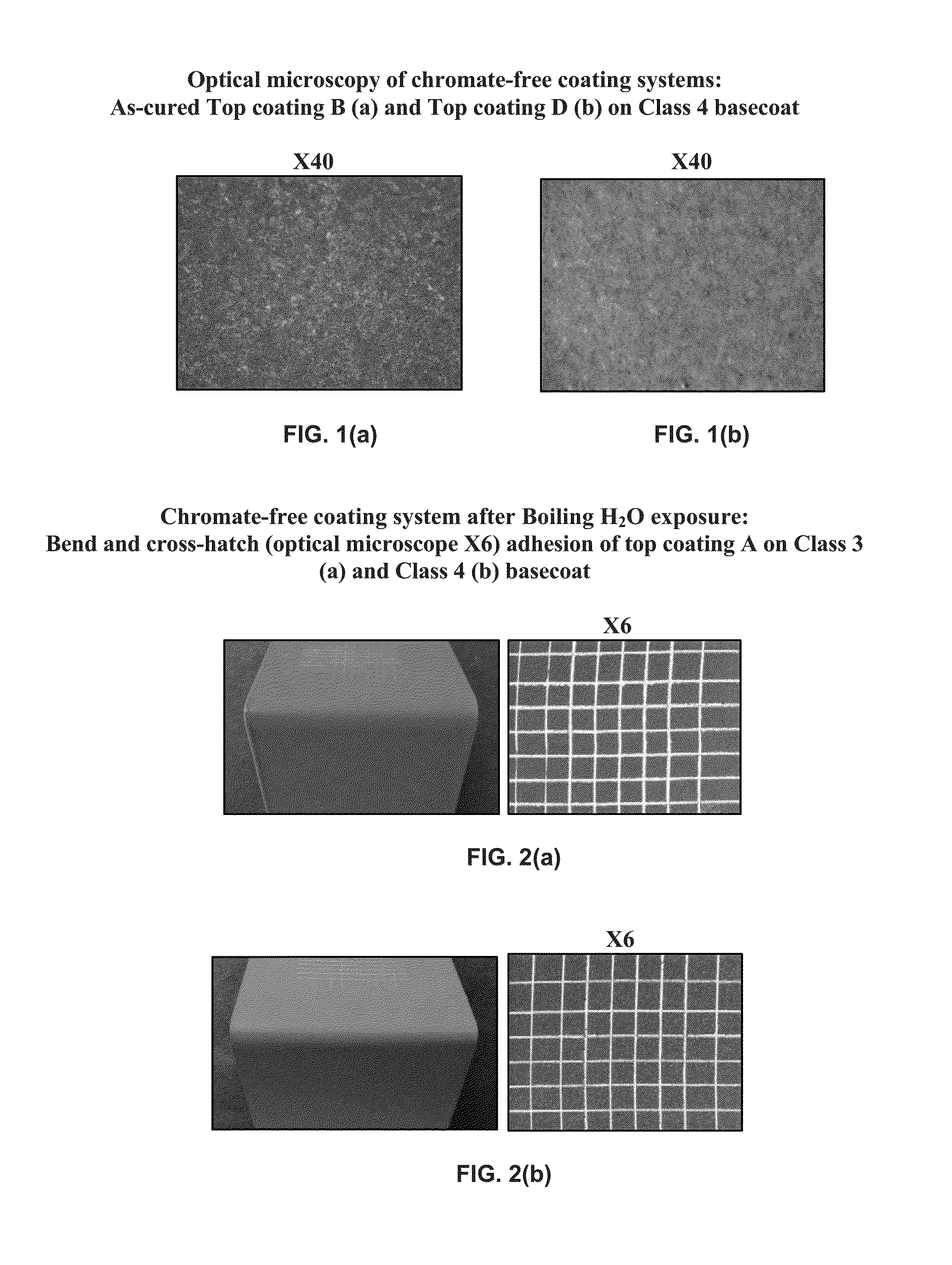

Chromate-free ceramic coating compositions

ActiveUS9394448B2Increase resistanceAlkali metal silicate coatingsAnti-corrosive paintsLithiumCeramic coating

A novel chromate-free multi-layer coating system composed of a lithium-doped potassium silicate binder based basecoat composition that is sealed with an aluminum phosphate-based top coat composition is described. The multi-layer coating system exhibits superior corrosion and heat oxidation resistance which can replace traditional chromate-containing coating systems.

Owner:PRAXAIR ST TECH INC

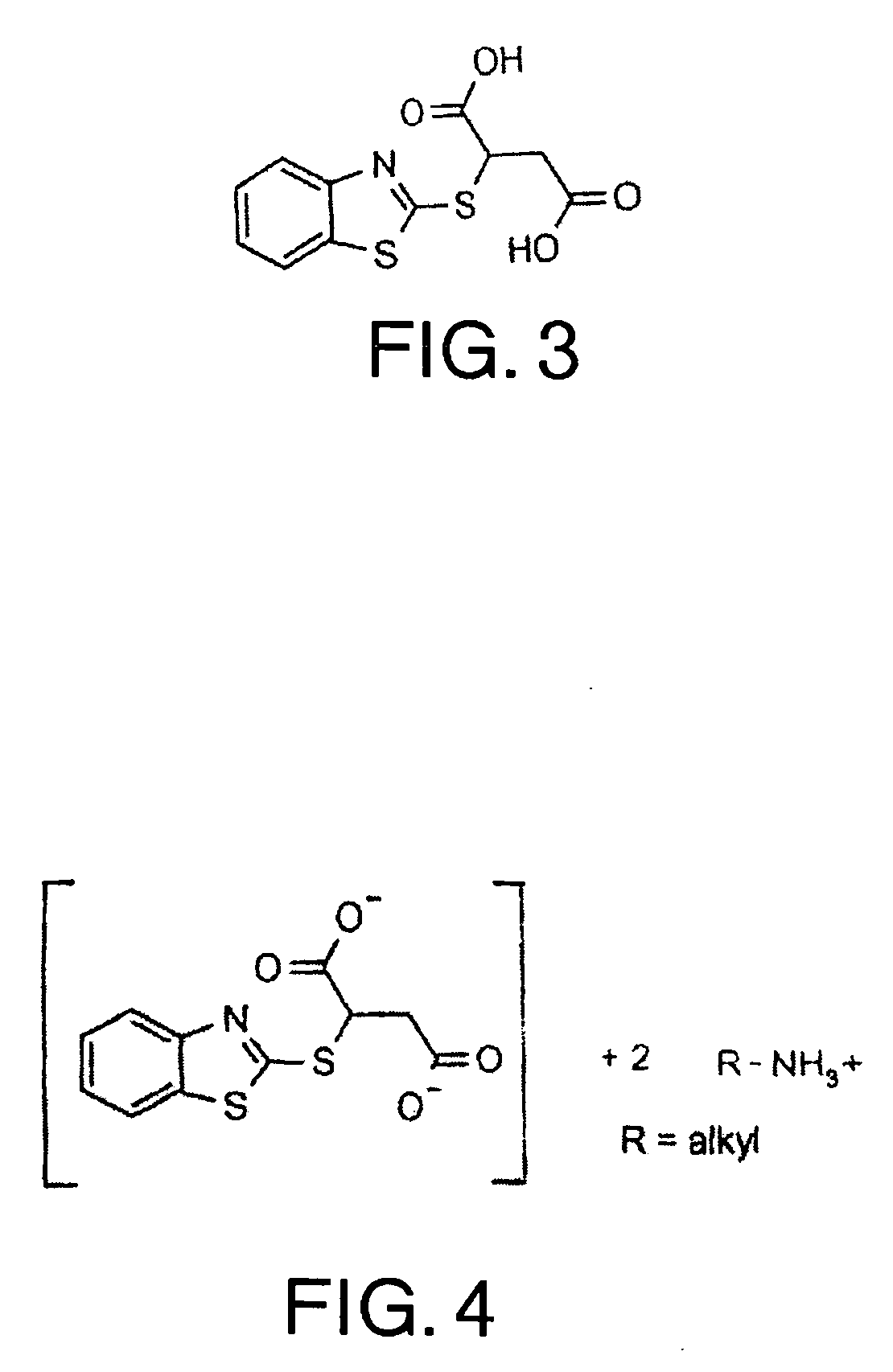

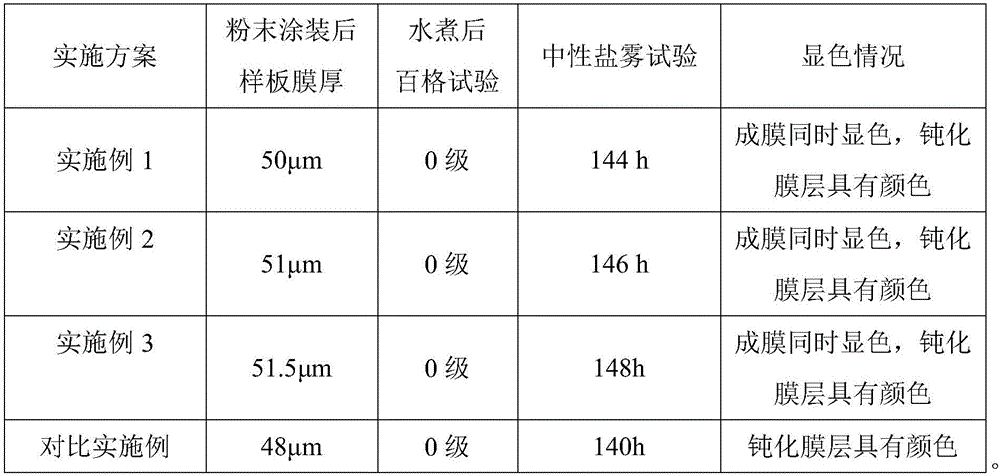

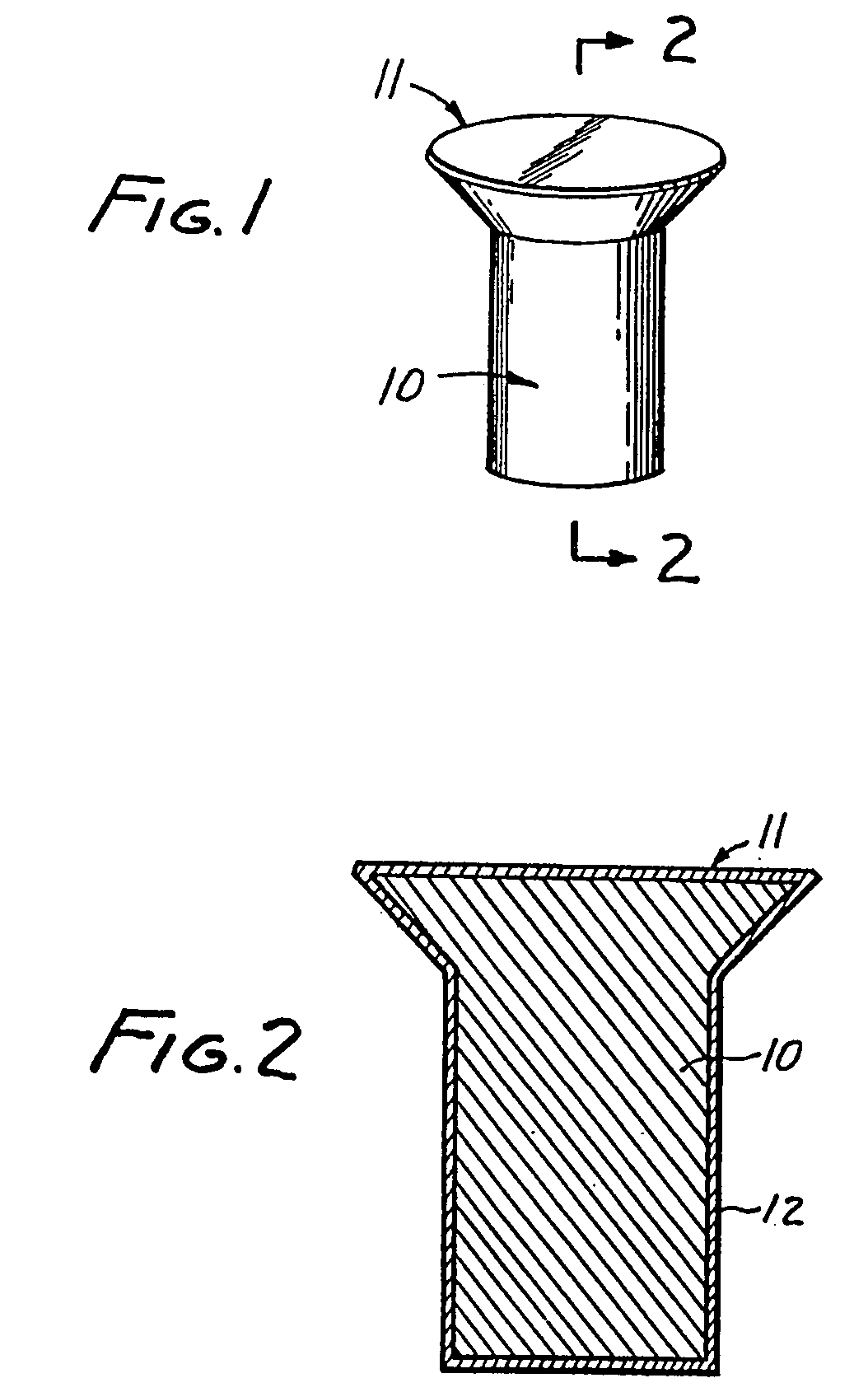

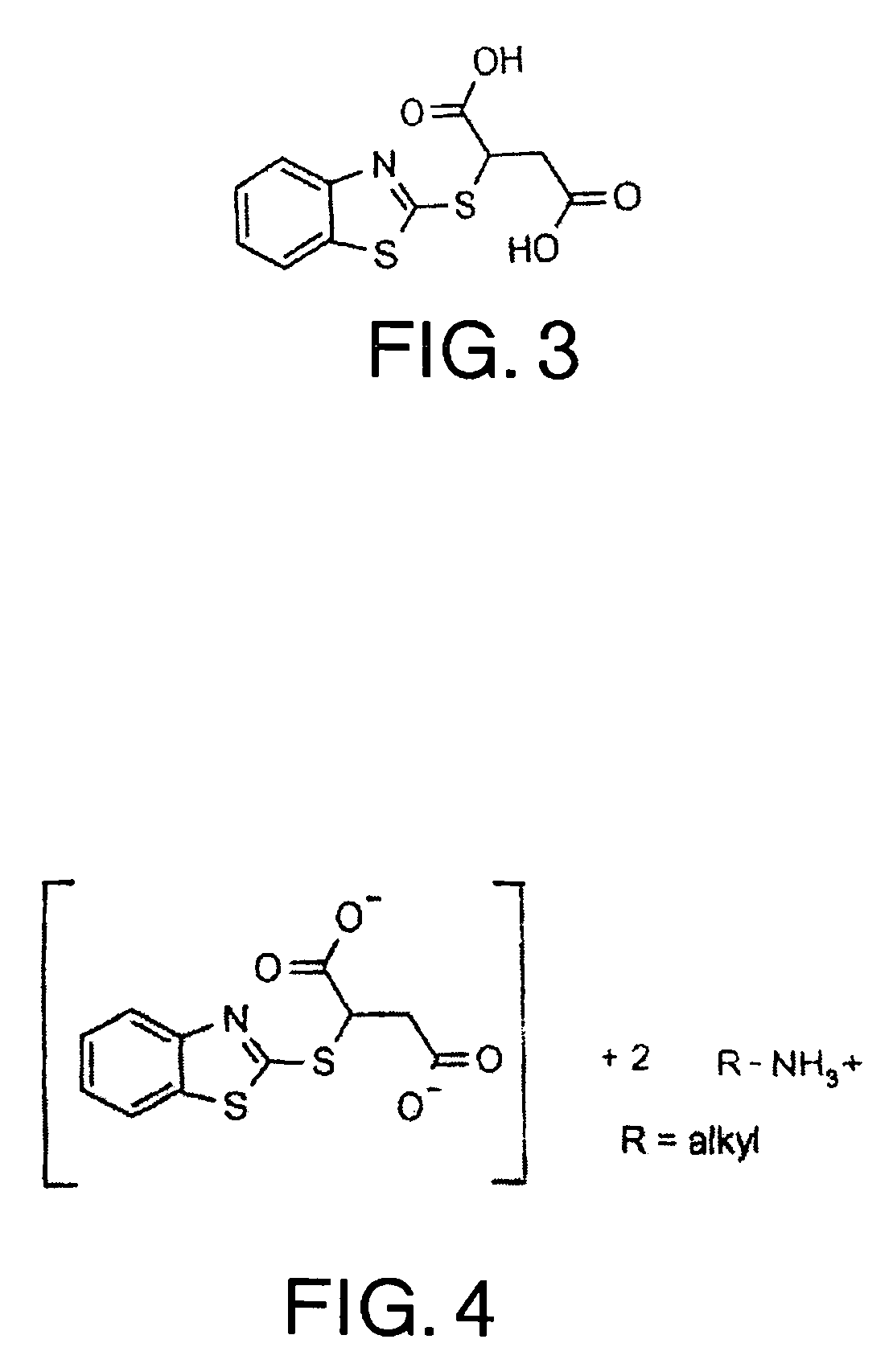

Chromate free waterborne corrosion resistant primer with non-carcinogenic corrosion inhibiting additive

ActiveUS20070228332A1Improve solubilityOther chemical processesAnti-corrosive paintsSolubilityChromate salt

A waterborne corrosion resistant primer composition is composed of a waterborne resin system; an optional curing agent; and a non-chromate containing corrosion inhibiting additive. The non-chromate corrosion inhibiting additive includes at least one of an anodic corrosion inhibitor, a cathodic corrosion inhibitor and a metal complexing agent. The metal complexing agent increases the solubility of at least one of the anodic and cathodic corrosion inhibitors.

Owner:RAYTHEON TECH CORP

Chromate-Free Surface Treated Metal Material with Excellent Corrosion Resistance, Heat Resistance, Fingermark Resistance, Conductivity, Coatability, and Blackening Resistance at the Time of Working

InactiveUS20090110921A1Satisfy corrosion resistanceLayered productsMetallic material coating processesAdditive ingredientPhosphoric acid

The present invention provides a metal material given a chrome-free surface treatment satisfying all of the requirements of corrosion resistance, heat resistance, fingermark resistance, conductivity, coatability, and blackening resistance at the time of working, which was difficult to achieve with conventional chromate-free technology. The chromate-free surface treated metal material of the present invention is comprised of a metal material on the surface of which is coated and dried an aqueous metal surface treatment agent comprising an organic silicon compound (W), obtained by blending a silane coupling agent (A) containing one amino group in its molecule and a silane coupling agent (B) containing one glycidyl group in its molecule in a solid weight ratio [(A) / (B)] of 0.5 to 1.7, at least one type of fluorocompound (X) selected from fluorotitanic acid or fluorozirconic acid, phosphoric acid (Y), and a vanadium compound (Z) so as to form a composite coating containing the different ingredients.

Owner:NIPPON STEEL CORP

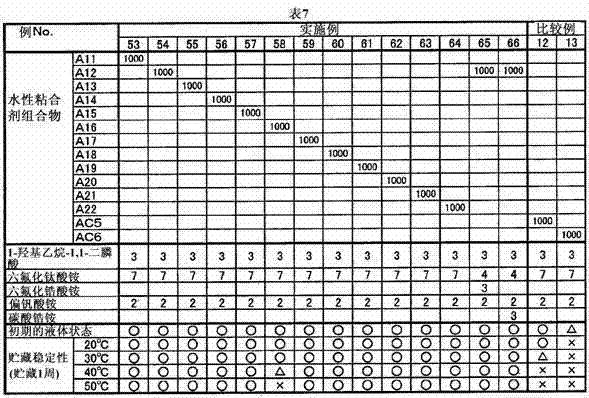

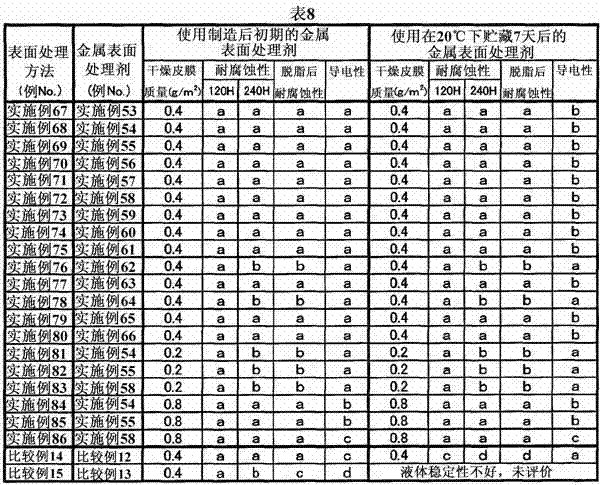

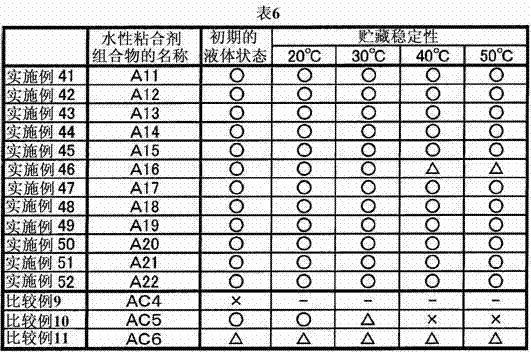

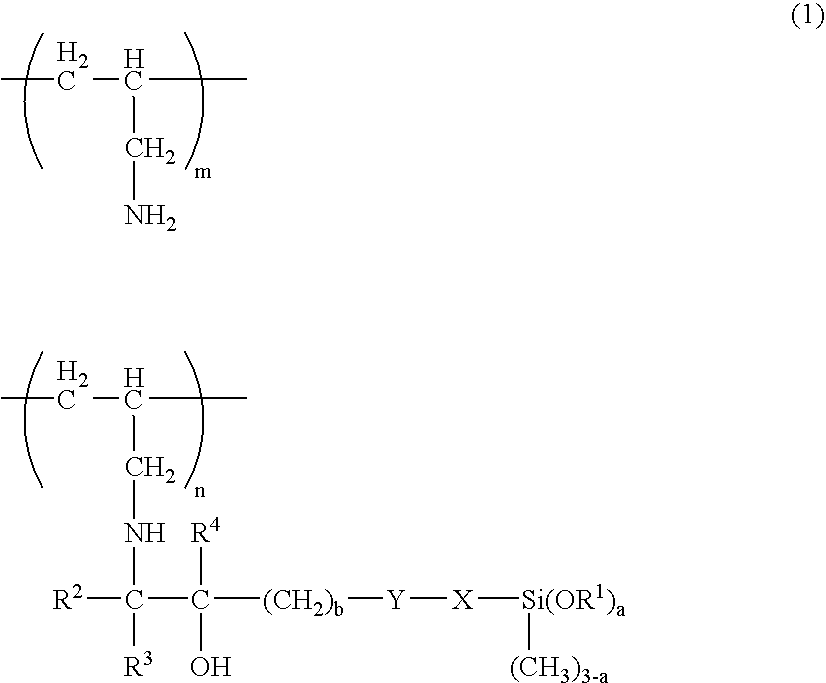

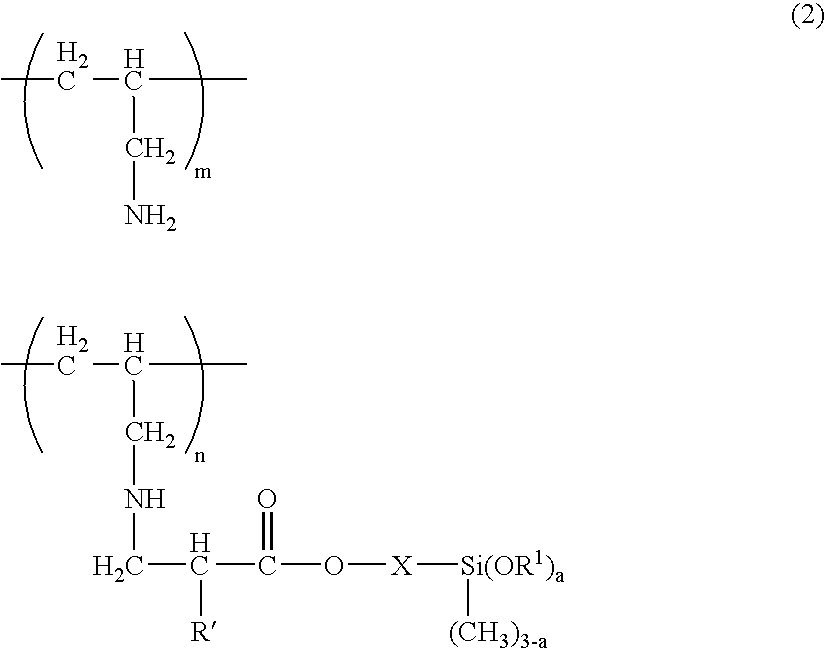

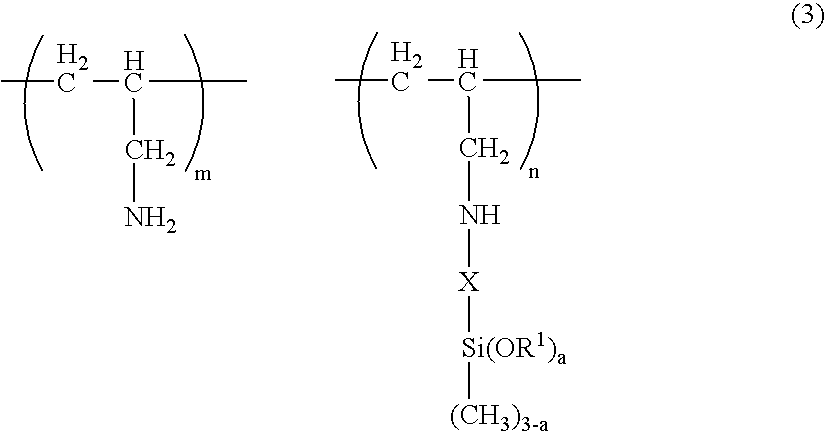

Aqueous binder composition for metal surface treatment agents

InactiveCN103946421AAvoid condensationImprove stabilityAnti-corrosive paintsMetallic material coating processesSiliconMetal

The present invention provides an aqueous binder composition for chromate-free metal surface treatment agents that have excellent coatability and liquid stability and are capable of forming a surface treatment film having excellent corrosion resistance, adhesiveness and electrical conductivity. This aqueous binder composition for metal surface treatment agents contains: a reaction product of a silane coupling agent containing an amino group and a silane coupling agent containing an epoxy group, or a reaction product of the above-described silane coupling agents and an alkoxysilane compound such as trialkoxysilane wherein a hydrocarbon group such as an alkyl group is directly bonded to a silicon atom; a specific acid compound; and water.

Owner:KANSAI PAINT CO LTD

Chromate-free passivation treatment process for aluminum profile material

InactiveCN105154861AExtend your lifeImprove surface strengthMetallic material coating processesOxidation resistantBiological activation

Disclosed is a chromate-free passivation treatment process for aluminum profile material. The chromate-free passivation treatment process specifically comprises the steps of ash removal, deslagging rinsing, oil removal degreasing, activation degreasing, rinsing, hot dip galvanizing, rinsing, chromate-free passivation and rinsing. The process is simple and orderly. Degreasing and galvanizing are added based on a traditional process, so that the life of the profile material is prolonged, and the surface strength of the profile material is increased; the profile material is oxidation-resistant for a long time; meanwhile, a layer of thin film is formed on the surface of the profile material, and the thin film protects the surface of the profile material effectively, so that the profile material is oxidation-resistant and corrosion-resistant. The process makes the chromate-free passivation treatment on the profile material more perfect.

Owner:ANHUI JINGCHANG ALUMINUM

Metal surface treating agent, surface treated steel material and treating method, and coated steel material and its production method

InactiveUS20080248317A1Good coating workabilityEfficiently providePretreated surfacesAnti-corrosive paintsSilyleneCarbon–carbon bond

A chromate-free metal surface treating agent which is well adapted for use with a metal-coated steel material is provided. This agent provides excellent workability, adhesion, and corrosion resistance when used as a pretreatment before providing an overcoat, for example, by applying a coating composition. A steel material which has been treated with such surface treating agent, and a method for treating a metal surface with such surface treating agent, as well as a coated steel material having an overcoat formed on the surface treated steel material, and its production method are also provided. The metal surface treating agent contains a compound which contains all of the following structures (a) to (c): (a) a straight chain and / or branched organic polymer skeleton formed by carbon-carbon bond optionally containing nitrogen atom between the carbon-carbon bond; (b) a primary, secondary, or tertiary amino group; and (c) a silyl group having a hydrolyzable group and / or hydroxy group bonded by silicon-carbon bond in one molecule and / or its (partial) hydrolysis and condensation product as its critical component, and this critical component is dissolved in water and / or an organic solvent.

Owner:SHIN ETSU CHEM IND CO LTD

Novel aluminum veneer pre-roll-coating production line and process technology

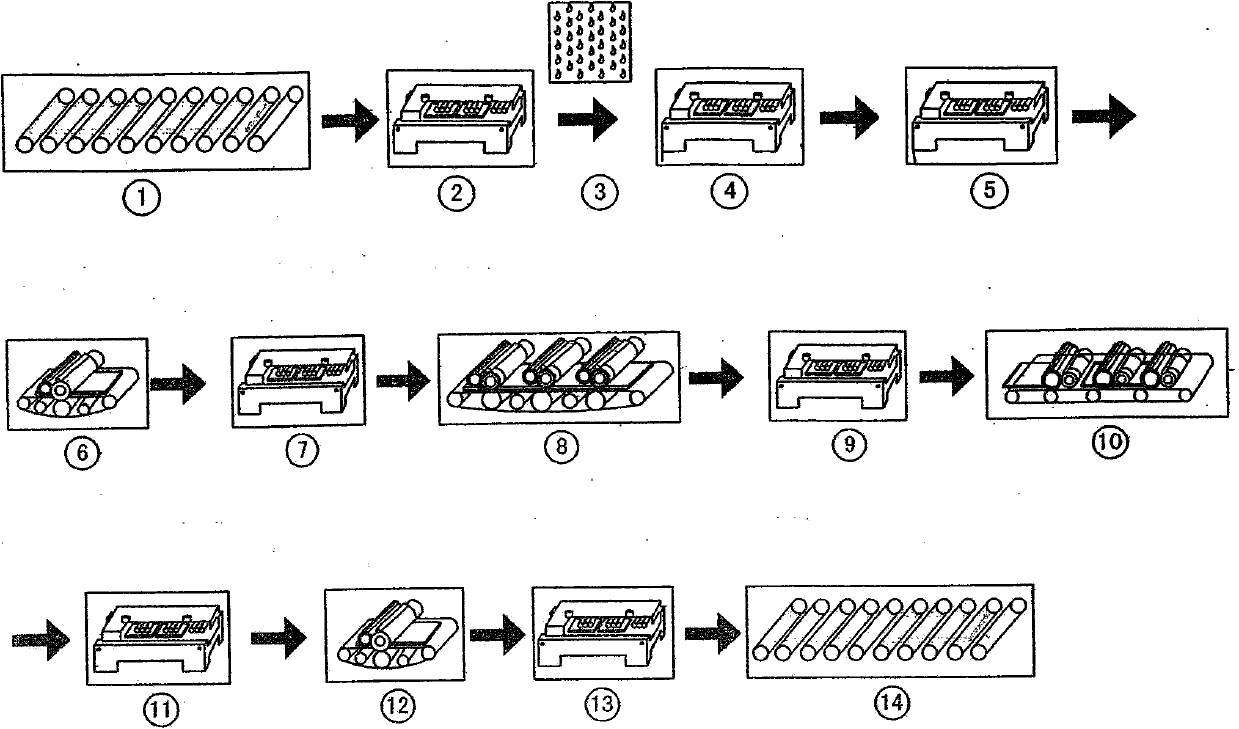

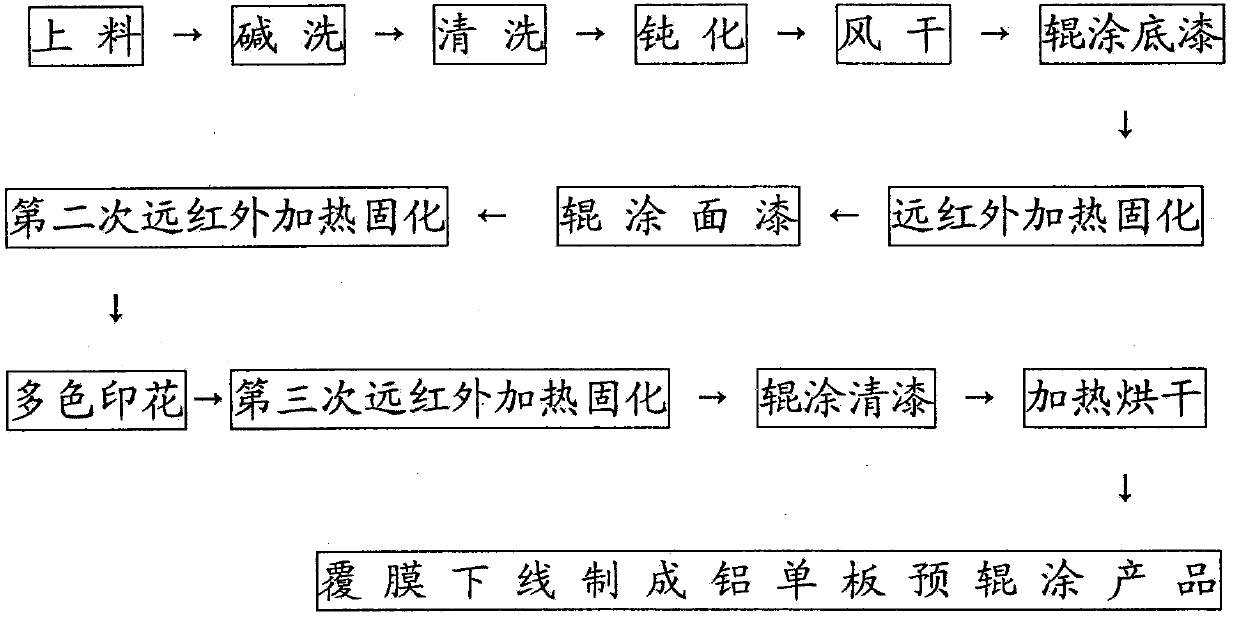

InactiveCN103990589AEasy to changeSolve problemsPretreated surfacesCoatingsProduction lineColor printing

The invention provides a novel aluminum veneer pre-roll-coating production line and a process technology and relates to the technical field of machinery. A series of key technologies including alkaline washing, cleaning, passivation, coating, printing and drying are adopted, and a front conveying belt, an alkaline washing machine, a cleaning machine, a chromate-free passivation device, a baking oven, a precise single-roller priming paint coating machine, a far infrared baking oven, a three-roller coating machine, a far infrared device, a multi-color stereoscopic printing machine, a far infrared machine, a precise single-roller priming paint coating machine, a curing baking oven and a rear conveying belt are sequentially placed to form the novel aluminum veneer pre-roll-coating production line. The process technology is that an aluminum veneer pre-roll-coating product is manufactured through feeding, alkaline washing, cleaning, passivation, air-drying, priming paint roll-coating, far-infrared heating and curing, finishing coat roll-coating, secondary far-infrared heating and curing, multi-color printing, third far-infrared heating and curing, varnish roll-coating, heating and drying and film coating and off-line operation. The novel aluminum veneer pre-roll-coating production line and the process technology are used for aluminum veneer roll-coating and are novel in concept, reasonable in design, simple and ingenious in structure, stable and reliable in effect and low in cost and facilitating manufacture, usage and popularization.

Owner:肇庆鑫盈装饰材料有限公司

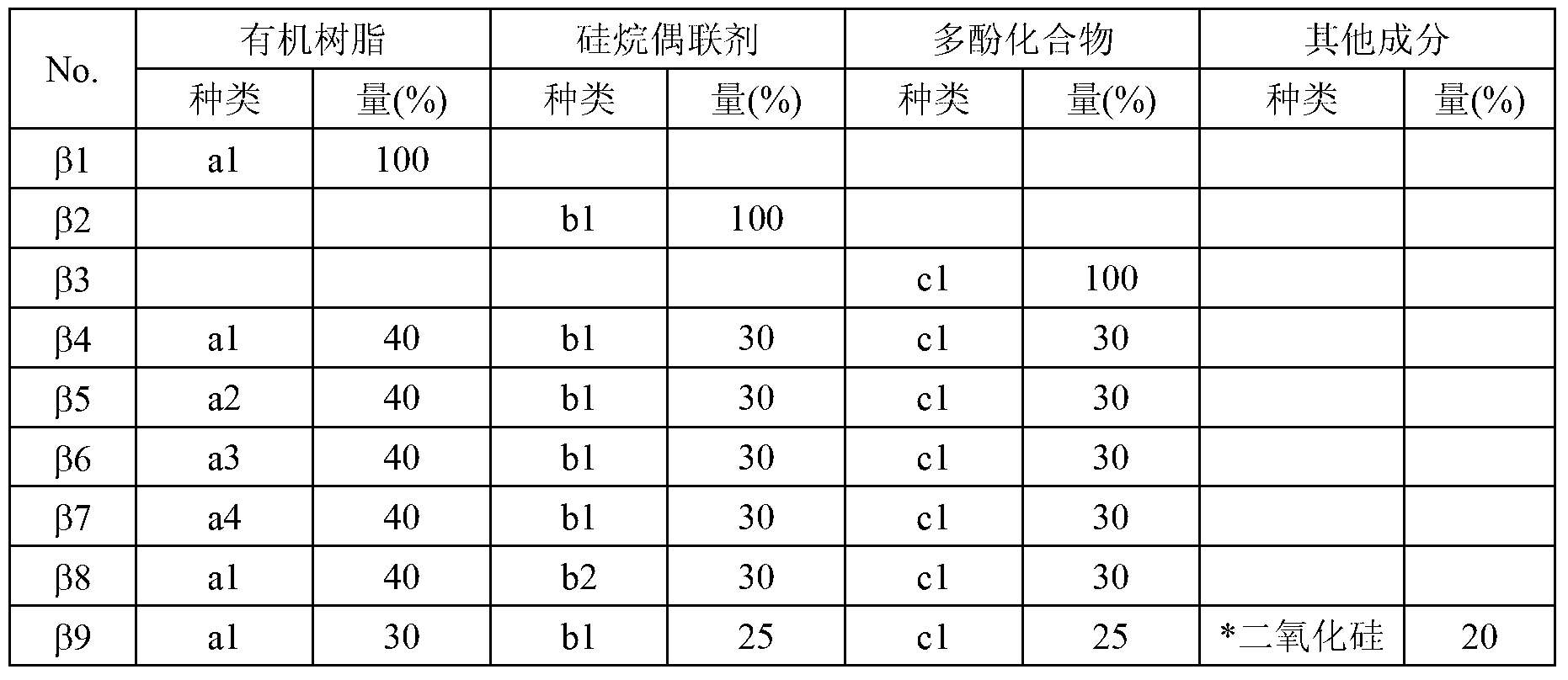

Chromate-free resin-composite vibration deadening material

ActiveUS20100126796A1Good shaping effectSmall environmental loadSpringsSynthetic resin layered productsInter layerAdhesive

Disclosed is a chromate-free resin composite damping material having a multilayer structure wherein a viscoelastic resin composition is interposed, as an intermediate layer, between metal plates. This chromate-free resin composite damping material is characterized in that (i) the viscoelastic resin composition is a thermosetting resin composed of an amorphous copolymerized polyester resin and a curing agent, and in that (ii) a chromate-free adhesive foundation film composed of 5-50% by mass of silica, 5-50% by mass of a polyester resin, 1-50% by mass of tannic acid and 0-30% by mass of a silane coupling agent is arranged on a metal plate surface which is in contact with the viscoelastic resin composition. This chromate-free resin composite damping material is excellent in durable adhesion.

Owner:NIPPON STEEL CORP +1

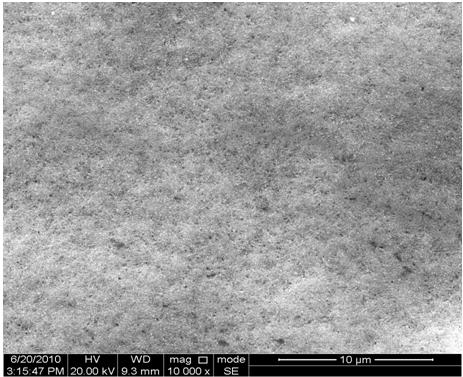

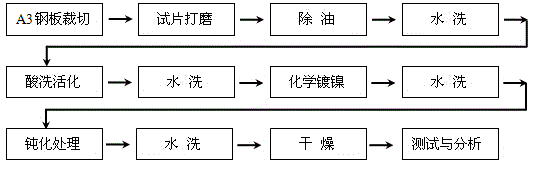

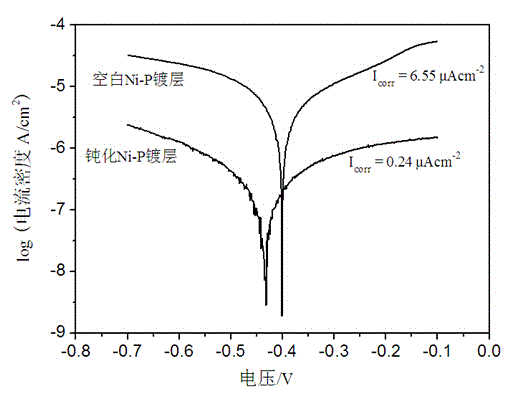

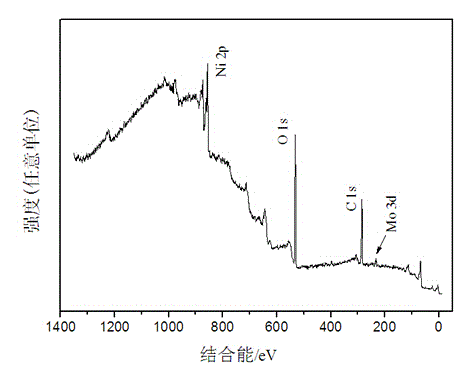

Chromate-free passivation method for chemically-plated Ni-P coating

ActiveCN104388920AImprove performanceGood resistance to oxidation and discolorationLiquid/solution decomposition chemical coatingCooking & bakingBuffering agent

The invention discloses a chromate-free passivation method for a chemically-plated Ni-P coating. The method comprises the following treatment steps of (1) preparing a chromate-free passivation solution, and sequentially adding 3-20g / L of sodium hydroxide, 1-10g / L of sodium carbonate, 10-60g / L of molybdate, 2-25g / L of film forming accelerant and 2-15g / L of buffering agent in distilled water; (2) carrying out chemical nickel plating on a substrate to be subjected to nickel plating; and (3) after ending the nickel plating operation, immediately cleaning a nickel-plated piece and carrying out passivation treatment on the nickel-plated piece, washing the nickel-plated piece twice after ending the treatment, and drying by blowing or baking. Through the passivation treatment, a layer of transparent passivation film can be formed on the surface of the Ni-P coating, so that the appearance of the coating is not influenced, and the anti-tarnish property and corrosion resistance of the coating are remarkably improved. Elements such as O, C, Ni and Mo can be detected in the passivation film. The chromate-free passivation method is relatively simple in process, simple and convenient to operate, low in cost, chromate-free, environment-friendly and capable of easily realizing industrialization.

Owner:SOUTH CHINA UNIV OF TECH

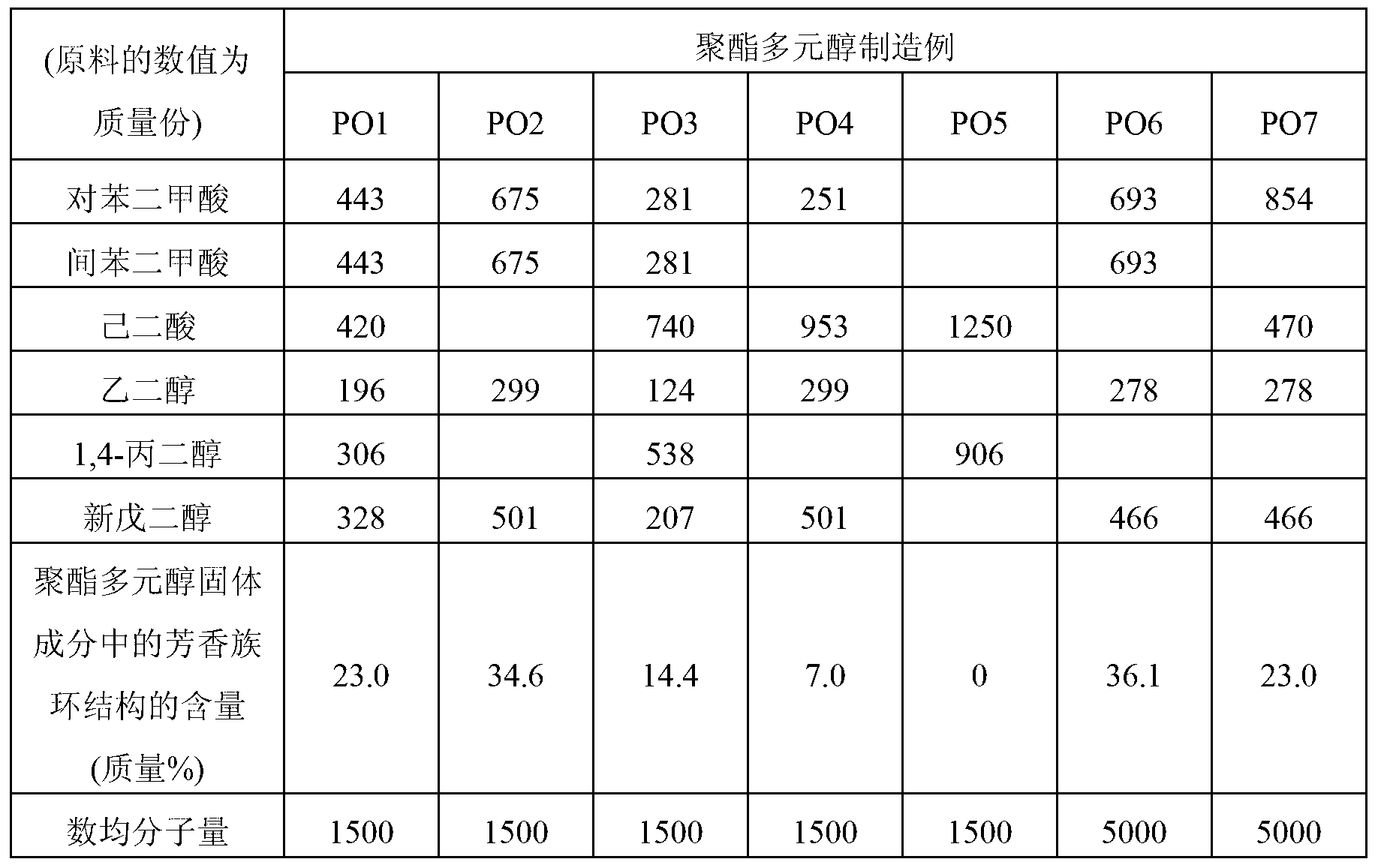

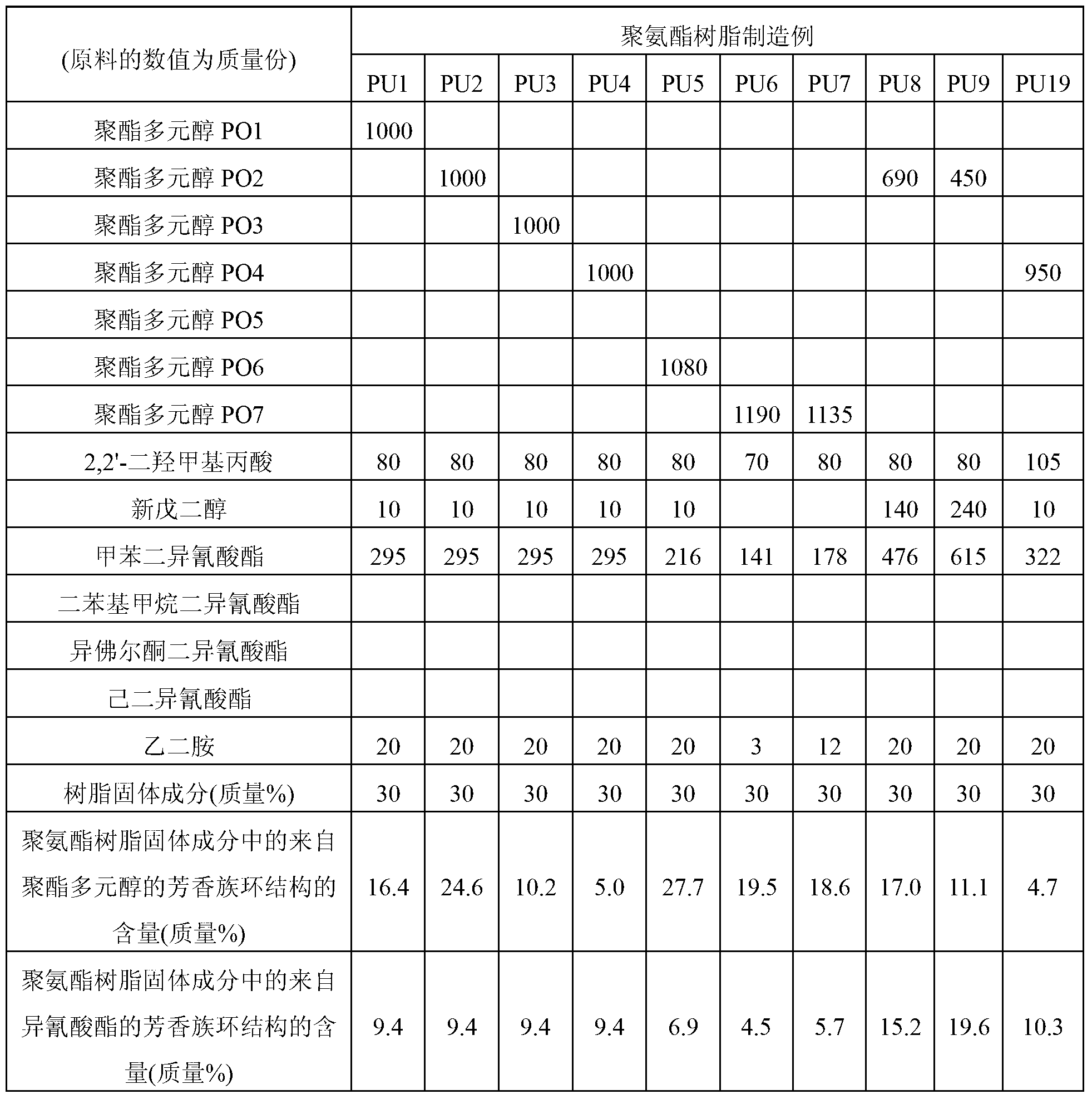

Colored and coated chromate-free metal sheet, and colored aqueous composition

ActiveCN103237658ACheap designStrong designSynthetic resin layered productsPolyurea/polyurethane coatingsPolyesterSilicon dioxide

The present invention provides a colored and coated chromate-free metal sheet which has, formed on at least one surface of a metal sheet, a colored coating film (alpha) that comprises a film-forming component comprising a polyurethane resin (A1) containing a urea group, a urethane group and a carboxyl group, a coloring pigment (B) and spherical silica particles (C) having an average particle diameter of 5-50 nm, wherein the polyurethane resin (A1) contains structural units each derived from a polyester polyol component (a) having an aromatic ring structure and structural units each derived from an isocyanate component (b) having an aromatic ring structure, each of the structural units derived from the isocyanate component (b) contains an aromatic ring structure, and the colored coating film (alpha) has a thickness of 2-10 mum, and wherein the metal sheet has excellent chemical resistance.

Owner:NIPPON STEEL CORP +1

Vacuum coating production process of automobile hub with high physical and chemical properties

InactiveCN103572203AImprove flatnessAccelerated corrosionVacuum evaporation coatingSputtering coatingVacuum chamberVacuum coating

The invention relates to a vacuum coating production process of an automobile hub with high physical and chemical properties. The production process comprises the following steps: (1) processing a hub blank; (2) inspecting and polishing the hub blank; (3) removing oil; (4) cleaning and drying; (5) carrying out pre-treatment; (6) spraying body powder and curing; (7) polishing; (8) spraying medium powder and curing; (9) vacuum coating: spraying a metal coating on the treated hub in a vacuum chamber according to a vacuum sputter coating principle; (10) preparing a transparent coating; and (11) finally inspecting and packaging, wherein the passivation coating is a chromate-free passivation coating and the metal coating is an aluminum film. According to the production process provided by the invention, the surface evenness and the corrosion resistance of the hub are improved, the evenness, the gloss, the hardness and the corrosion resistance of the surface of the hub are increased, the surface of the hub is sealed and metallized, and the hub has glossiness of water electroplating. The transparent coating has an adhesive force of a high vacuum coating. The production process provided by the invention is concise and low in energy consumption, and the prepared hub is high in hardness and strong in corrosion resistance.

Owner:NORD WHEEL MFG

Manganese-zirconium chromate-free passivating solution for surface treatment of aluminum alloy and method for manganese-zirconium chromate-free passivating treatment of surface of aluminum alloy

The invention discloses a manganese-zirconium chromate-free passivating solution for surface treatment of aluminum alloy and a method for manganese-zirconium chromate-free passivating treatment of the surface of aluminum alloy. The manganese-zirconium chromate-free passivating solution comprises the following components in mass-volume concentration: 0.01-10g / L of a permanganate, 0.01-10g / L of fluorozirconate or fluorozirconic acid, 0.01-4g / L of an accelerator and a pH value adjusting agent. A solvent used for preparing the manganese-zirconium chromate-free passivating solution is deionized water, and the pH value of the manganese-zirconium chromate-free passivating solution is adjusted to 3.0-6.8 due to the use amount of the pH value adjusting agent. The method comprises the following steps of soaking the aluminium alloy into the manganese-zirconium chromate-free passivating solution at the temperature of 5-40 DEG C or spraying the manganese-zirconium chromate-free passivating solution onto the aluminum alloy at the temperature of 5-40 DEG C, carrying out reaction on the manganese-zirconium chromate-free passivating solution and the aluminium alloy for 10-240 seconds, and then washing the aluminum alloy with water.

Owner:毛山红

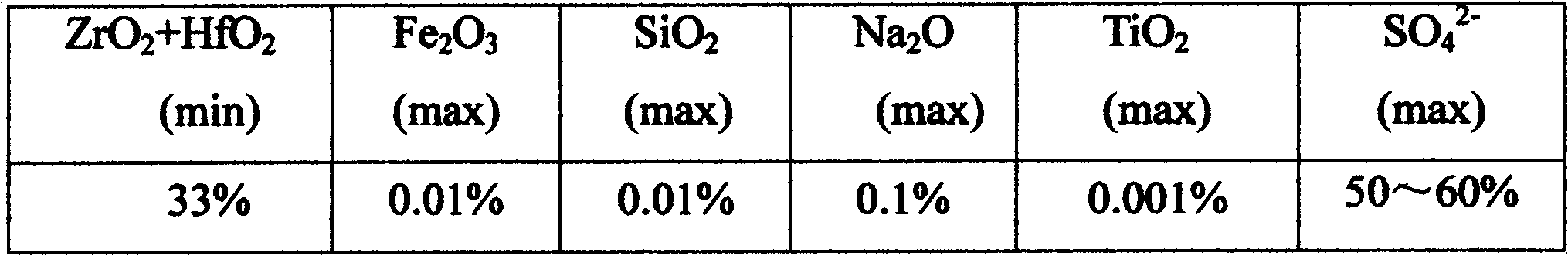

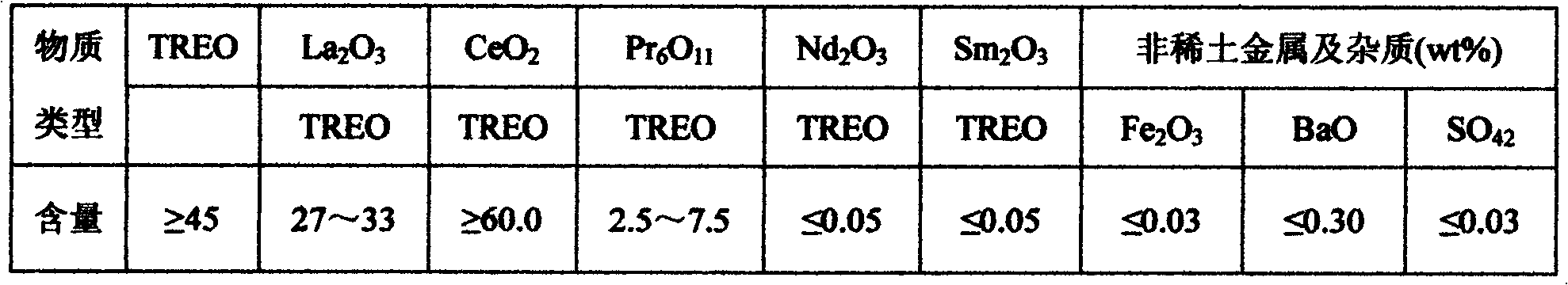

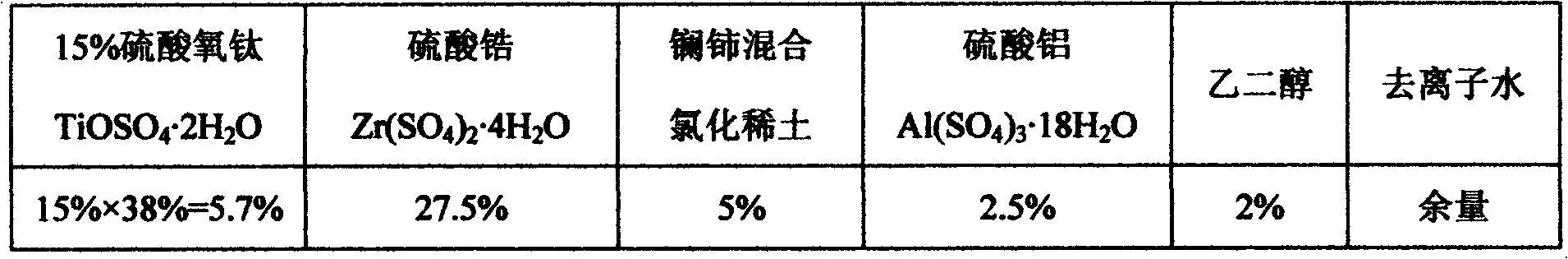

Chrome-free metal composite tanning agent and preparation method thereof

ActiveCN102321771AImprove performanceOvercome incapacityTanning treatmentAluminium chlorideRare earth

The invention discloses a chromate-free metal composite tanning agent, comprising the following ingredients: 27.5-37.5 wt% of tetravalent zircon salt, 2.0-5.0 wt% of trivalent aluminium salt, 2.5-10.0 wt% of 15-45 wt% tetravalent titanium salt, 2.5-7.5 wt% of La-Ce mixed chlorinated rare earth, 0-2.5 wt% of antifreezing agent, and 55-60 wt% of water, wherein, the tetravalent zircon salt is selected from zirconium sulfate, zirconium nitrate or zirconium chloride, the trivalent aluminium salt is selected from aluminium sulfate, aluminium chloride, aluminum potassium sulfate or aluminium ammonium sulfate, the tetravalent titanium salt is selected from titanyl sulfate, titanium sulfate or ammonium titanyl sulfate complex salt, the antifreezing agent is glycol, and the water is deionized water. The invention also discloses a preparation method of the chrome-free metal composite tanning agent. The chrome-free metal composite tanning agent has the advantages of good comprehensive properties, simple production technology, and environmentally friendly; and the preparation method is simple without special devices.

Owner:WENZHOU UNIVERSITY

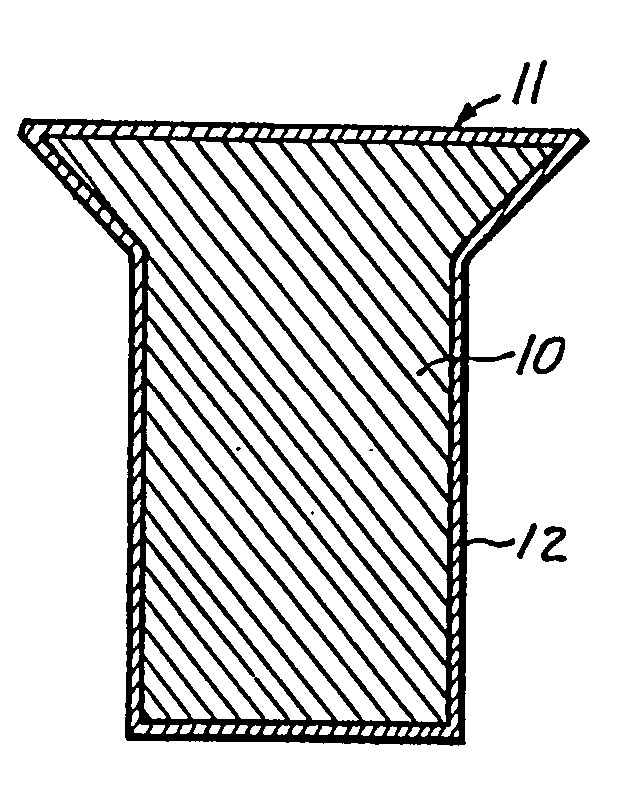

Chromate free corrosion resistant coating

ActiveUS7192639B2Increase resistanceImprove the lubrication effectPinsOther chemical processesInterference fitPhenol

The chromate free corrosion resistant coating for a fastener contains corrosion inhibiting inorganic constituents, or a combination of inorganic and organic corrosion inhibiting constituents, suspended in a phenol-formaldehyde thermosetting resin. The coating material possesses high abrasion resistance, and provides good lubricity and relatively low friction, rendering it especially suited for use with interference-fit fasteners.

Owner:HI SHEAR

Chromate free waterborne corrosion resistant primer with non-carcinogenic corrosion inhibiting additive

A waterborne corrosion resistant primer composition is composed of a waterborne resin system; an optional curing agent; and a non-chromate containing corrosion inhibiting additive. The non-chromate corrosion inhibiting additive includes at least one of an anodic corrosion inhibitor, a cathodic corrosion inhibitor and a metal complexing agent. The metal complexing agent increases the solubility of at least one of the anodic and cathodic corrosion inhibitors.

Owner:RTX CORP

Corrosion-resistant coating composition

The present invention provides a chromate-free coating composition having excellent corrosion resistance. The coating composition includes a binder system comprising a resin and a pigment system including a metal alloy pigment component and optionally, a carbonaceous component. Coated articles with the coating composition applied to at least a portion of a surface thereof are also provided.

Owner:SWIMC LLC

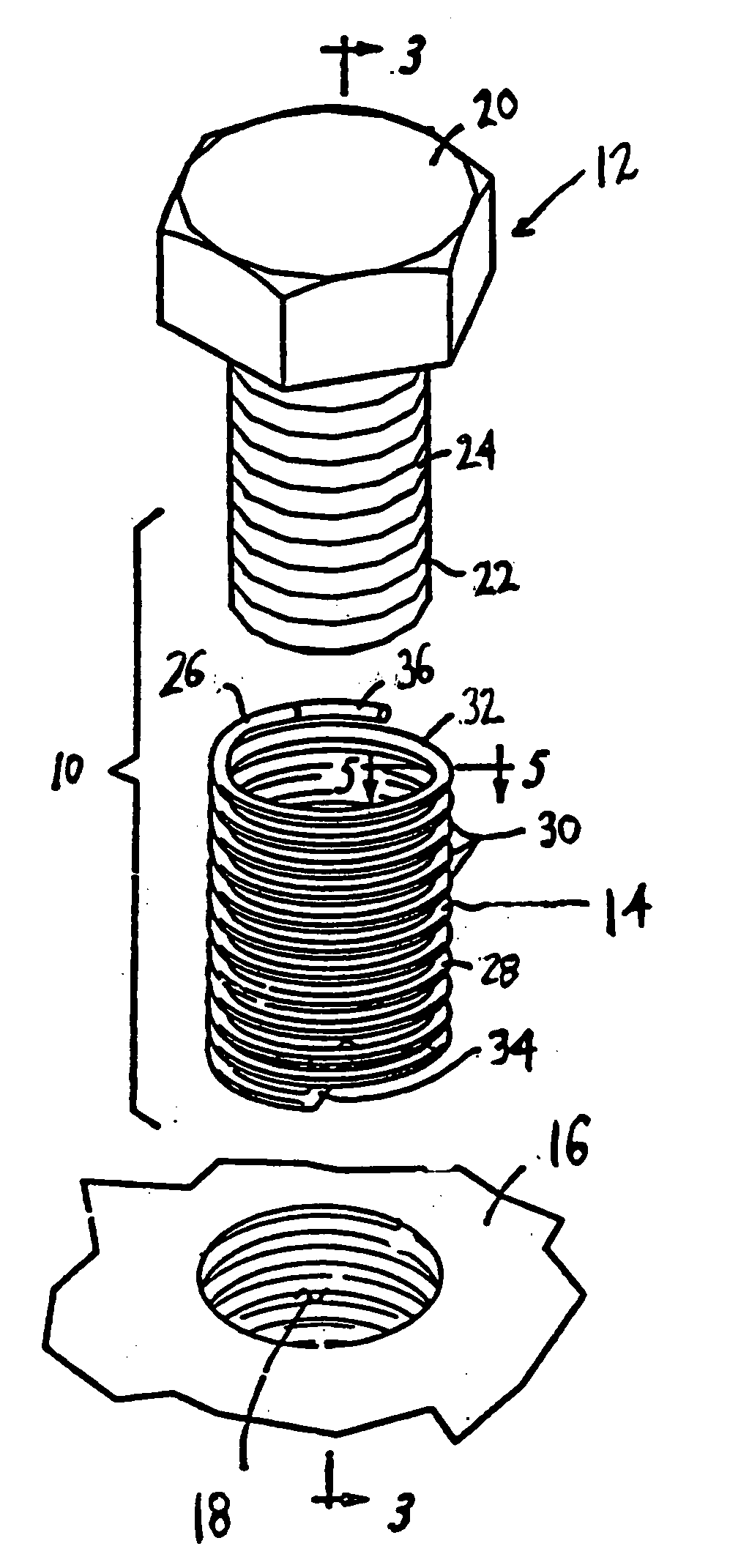

Chromate free fluoropolymer coated fastener inserts

Disclosed are fastener inserts for preventing galvanic corrosion in fastener assemblies by coating fastener inserts with a resin bonded chromate free fluoropolymer composition having an average viscosity of between about 20 to 30 seconds at 25° C. Also disclosed is a method for providing coated inserts as well as the coated inserts produced.

Owner:NEWFREY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com