Blue write chromate-free passivation liquid of electrogalvanized layer and method for passivating electrogalvanized layer by adopting same

A chromium-free passivation and electro-galvanizing technology, applied in metal material coating process and other directions, can solve the problem of toxic hexavalent chromium in passivation solution, and achieve the effect of increased density and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

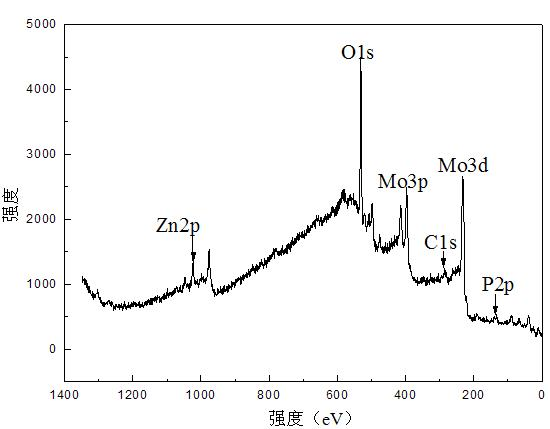

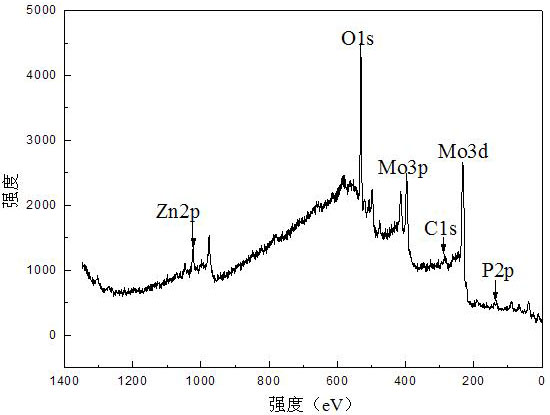

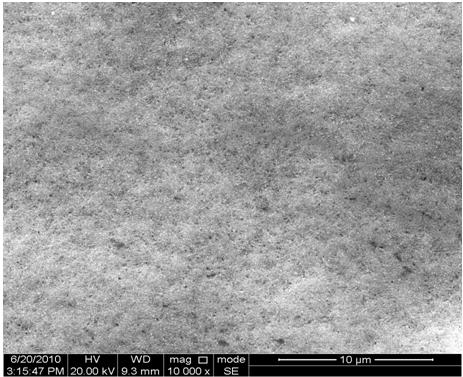

[0012] Specific embodiment 1: In this embodiment, the blue and white chromium-free passivation solution of the electro-galvanized layer is composed of molybdate, phosphate, sulfuric acid and organic matter. The concentration is 10g / L~50g / L, the concentration of phosphate is 5g / L~35g / L, the concentration of sulfuric acid is 1ml / L~10ml / L, the concentration of organic matter is 3g / L~30g / L, and the pH is 3~5.

[0013] The blue and white chromium-free passivation solution of the electro-galvanized layer in this embodiment does not contain highly toxic substances, and the passivation solution has good stability, and its stability time exceeds 30 days.

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molybdate is a mixture of sodium molybdate and ammonium molybdate, sodium molybdate or ammonium molybdate. Others are the same as the first embodiment.

[0015] In the present embodiment, when the molybdate is a mixture of sodium molybdate and ammonium molybdate, each component has an arbitrary ratio.

specific Embodiment approach 3

[0016] Specific embodiment three: This embodiment is different from specific embodiment one in that the phosphate is sodium phosphate. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com