Corrosion-resistant coating composition

A technology of corrosion resistance and composition, applied in the direction of anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: preparation coating composition

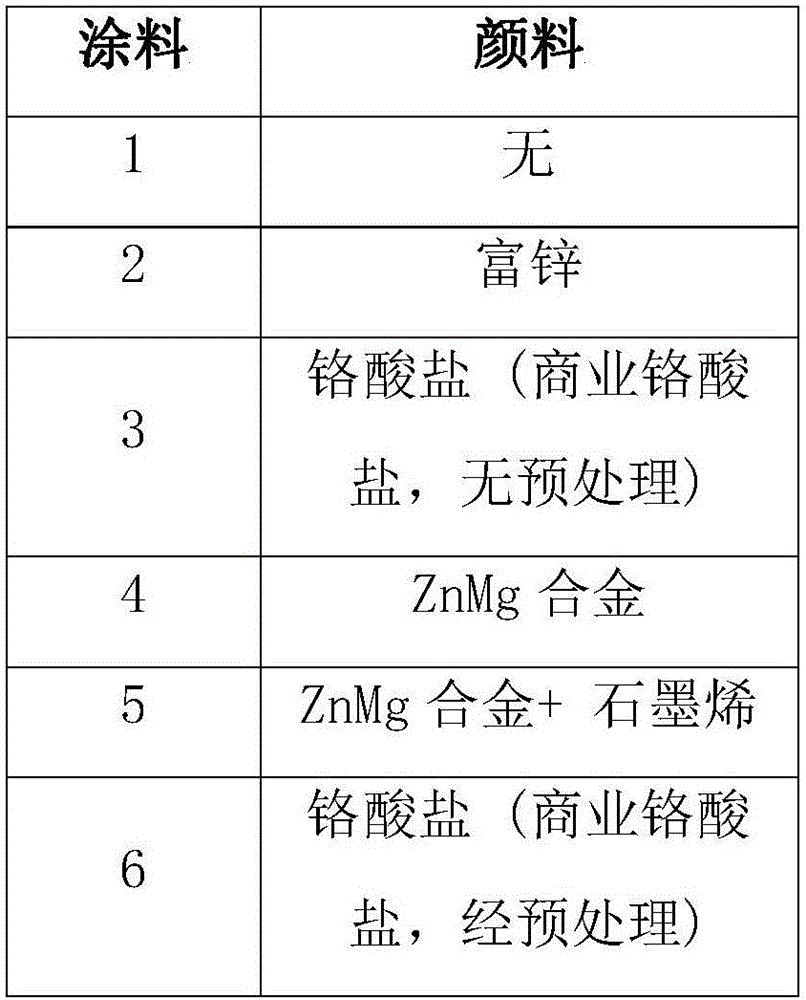

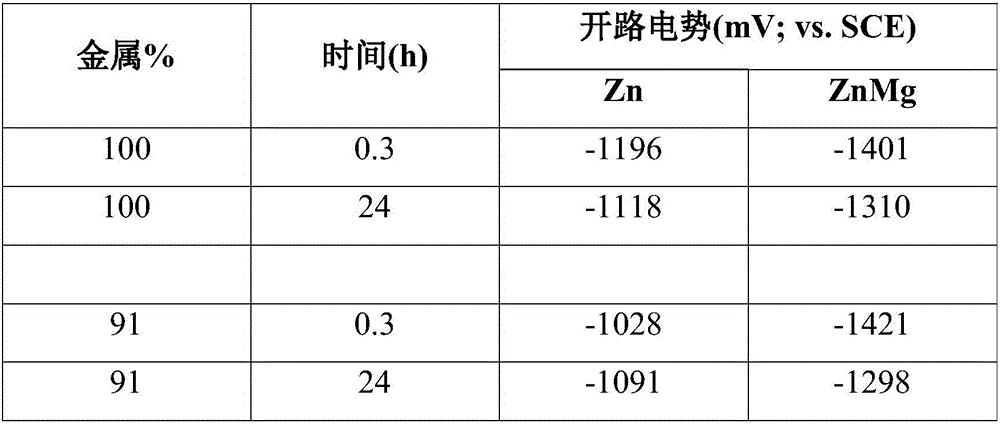

[0065] Coating compositions (#1 to #6) were prepared by combining the commercially available polyester binder resin components, melamine crosslinkers, and pigment systems shown in Table 1. The resin and crosslinker were blended together using standard mixing techniques known in the art, with a minimum level of leveling agent and amine catalyst (DABCO) to accelerate the crosslinking reaction. The blends were combined with the pigment systems shown in Table 1—to obtain coating compositions #1 to #5. Substrates (ie, galvanized metal panels; aluminum-zinc alloy coatings) were prepared by alkaline cleaning and no pretreatment was applied to the panels other than those indicated. The coating composition was applied to metal panels using standard application methods at a dry film thickness of approximately 0.2-0.3 mils and cured at 296°C (565°F) for 18-28 seconds (depending on line speed and oven design) to Peak metal tempera...

Embodiment 2

[0068] Embodiment 2: performance test

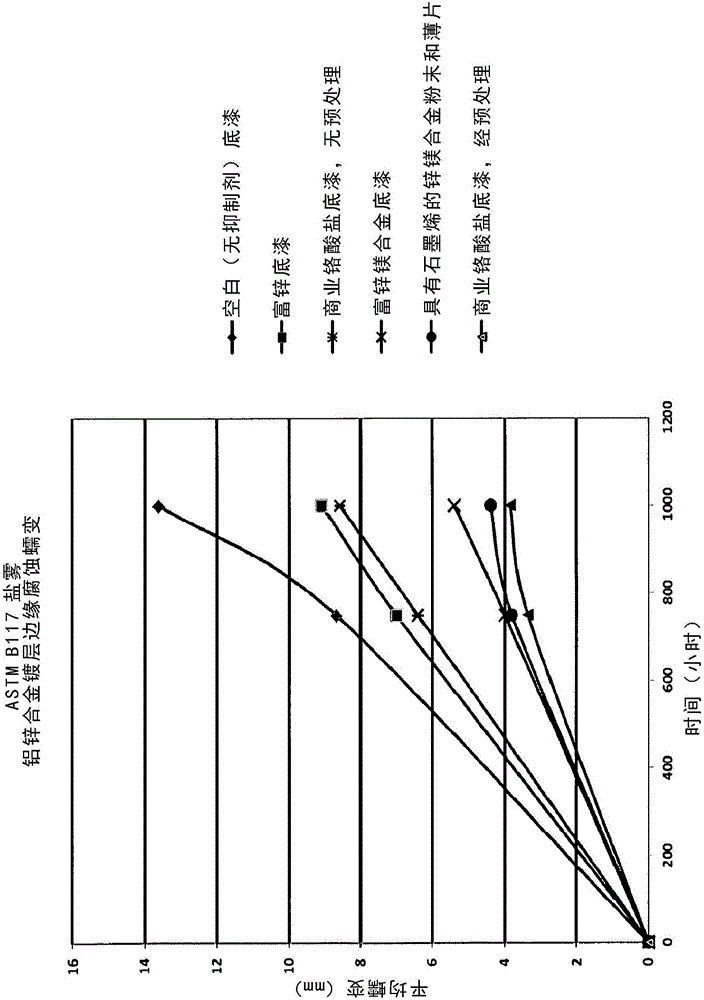

[0069] Salt spray test

[0070] The coating composition of Example 1 was coated on metal test panels, baked and edge burrs were trimmed, and then exposed to salt spray according to ASTM B117 method. Corrosion was assessed by measuring the amount of edge corrosion creep. An average creep of about 5 mm or less after 1000 hours of salt spray exposure is the desired creep limit. figure 1 The results for the coatings from Table 1 are shown in . From figure 1 As can be seen in the ZnMg alloy primers show significantly improved creep results relative to other coating compositions and comparable to pretreated industry standard commercial chromate standard primers. In addition, if figure 1 As shown in , ZnMg alloy pigments with graphene exhibit better corrosion resistance than coatings containing only ZnMg alloy pigments.

[0071] flexibility test

[0072] The coating compositions of Example 1 (especially those containing ZnMg alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com