Automobile hub surface treatment process

A technology for surface treatment and automobile wheel hub, which is applied in the coating process of metal materials, the device for coating liquid on the surface, coating and other directions, which can solve the problems of difficult treatment, consumption of precious metals, and high degree of environmental damage, so as to improve the wheel hub. performance, increase flatness, and the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

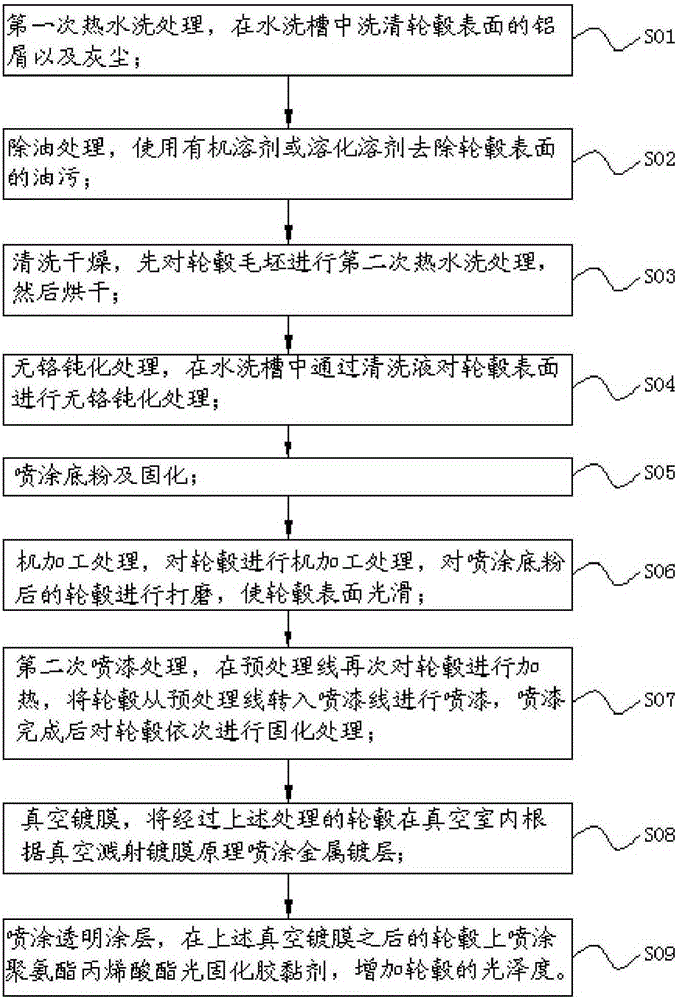

[0024] like figure 1 Shown, the present invention comprises the following steps:

[0025] S01, the first hot water washing treatment, wash the aluminum chips and dust on the surface of the wheel hub in the washing tank;

[0026] S02, degreasing treatment, using organic solvent or melting solvent to remove the oil on the surface of the hub;

[0027] S03, cleaning and drying, firstly carry out the second hot water washing treatment on the wheel hub blank, and then dry it;

[0028] S04, chromium-free passivation treatment, the chromium-free passivation treatment is carried out on the surface of the wheel hub through the cleaning solution in the washing tank;

[0029] S05, spraying primer and curing;

[0030] S06, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com