Chrome-free metal composite tanning agent and preparation method thereof

A non-chromium metal, compound tanning agent technology, applied in small raw hide/large raw hide/leather/fur treatment, tanning treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Tanning leather has problems such as low shrinkage temperature and leather stiffness, which achieves the effects of less environmental pollution, simple production process and good overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

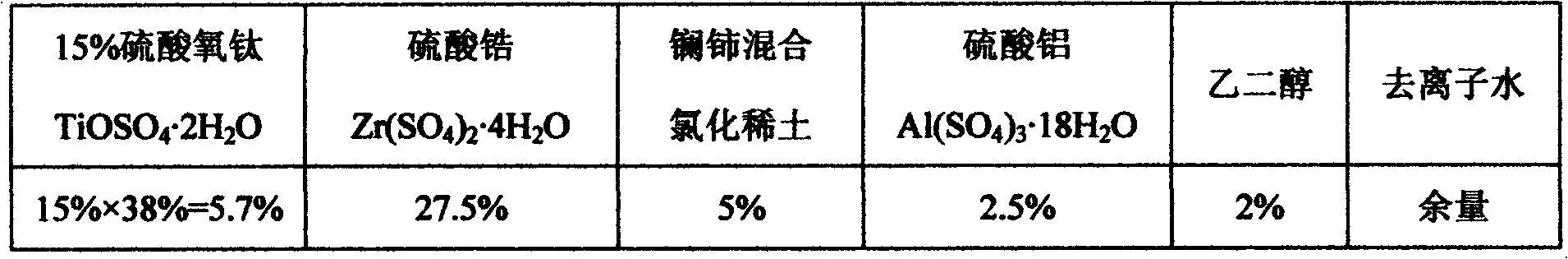

[0054] In the reactor with stirring, add 170.0g normal temperature deionized water, then add 30.0g titanyl sulfate (TiOSO 4 2H 2 (0) and stirred at room temperature for about 4 hours to obtain a colorless or slightly yellow transparent titanyl sulfate aqueous solution with a mass percent of titanyl sulfate solid tanning agent of 15.0%.

Embodiment 2

[0056] In the reactor with stirring, add 140.0g normal temperature deionized water, then add 30.0g titanyl sulfate (TiOSO 4 2H 2 0), stirring at normal temperature for about 2h, after the uniform dispersion of titanyl sulfate system becomes thinner, then add 30.0g of titanyl sulfate, continue stirring at normal temperature, the total stirring needs about 10h, to obtain titanyl sulfate solid tanning agent A colorless or light yellow transparent titanyl sulfate aqueous solution with a mass percentage of 30.0%.

Embodiment 3

[0058] Add 330.0g normal temperature deionized water in the reactor with stirring, then add 70.0g titanium oxysulfate (TiOSO 4 2H 2 0), stirred at normal temperature for about 2 hours, after the uniform dispersion system of titanyl sulfate became thinner, then added 100.0 g of titanyl sulfate, stirred at normal temperature for about 2 hours, and after the uniform dispersion system of titanyl sulfate became thinner, added 100.0 g titanyl sulfate, continue to stir, the total stirring time needs about 36h, namely obtain the colorless or light yellow transparent titanyl sulfate aqueous solution of 45.0% mass percentage of titanyl sulfate solid tanning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com