Chromate-free passivator and method for passivating aluminum or aluminum alloy surface

A chromium-free passivator and mixture technology, which is applied in the coating process of metal materials, can solve the problems of poor passivation film quality and low paint film adhesion, and achieve improved anti-corrosion performance, improved wet film adhesion, The effect of excellent binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

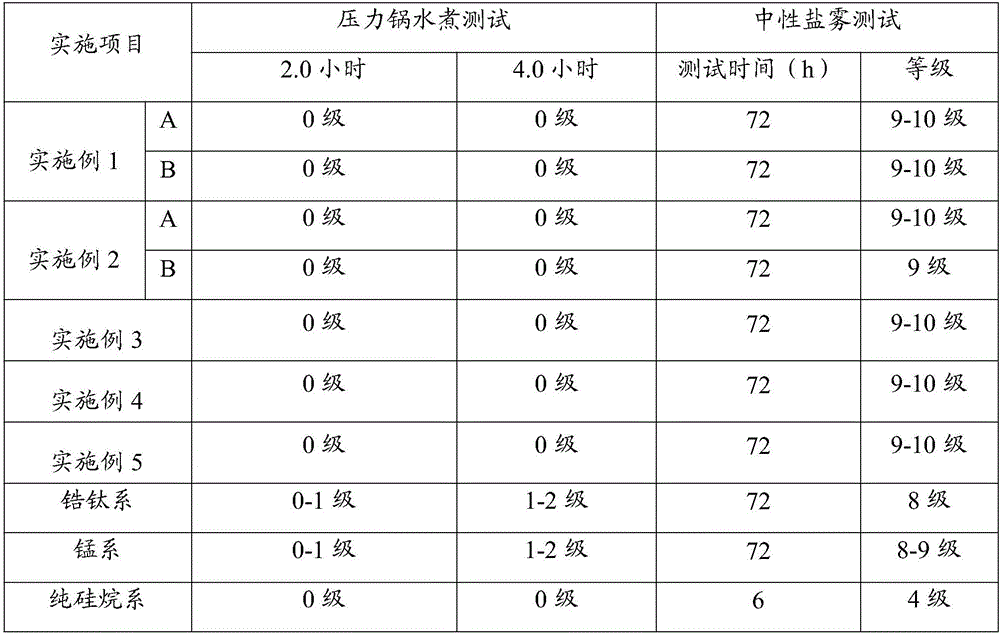

Examples

preparation example Construction

[0030] The present invention has no special limitation on the preparation method of the chromium-free passivating agent, and the technical scheme for preparing the composition well-known to those skilled in the art can be adopted. In the present invention, the preparation method of the chromium-free passivating agent is preferably mixing the raw materials described in the above technical scheme, more preferably comprising the following steps:

[0031] The accelerator is mixed with the first part of water to obtain an accelerator solution;

[0032] The accelerator solution is sequentially mixed with a modified water-soluble resin, a coupling agent and a nano-inorganic material to obtain a mixed material liquid;

[0033] Under the condition of stirring, the remaining water is added to the mixed material liquid.

[0034]In the present invention, the stirring rate is preferably 300-500 r / min, more preferably 350-450 r / min; the stirring time is preferably 10-30 min, more preferabl...

Embodiment 1

[0051] Prepare passivation solution according to the formula of chromium-free passivator, the content of each component in the passivator is: water 829kg, organosilicon modified acrylic resin 150.0kg (solid content 20wt%, weight average molecular weight 15000), KH-5605.0 kg, nano-titanium dioxide 3.0kg, phytic acid 8.0kg, nitric acid 5.0kg;

[0052] First, add nitric acid and phytic acid into 500.0kg of water, after stirring evenly, add organic silicon-modified acrylic resin, KH-560 and nano-titanium dioxide in turn, and then add the remaining water under the condition of stirring, and stir evenly;

[0053] Mix the above-mentioned passivating agent with the passivation bath solution according to the concentration of 1% and 10% by mass, and set aside;

[0054] Use sulfuric acid and hydrofluoric acid to prepare a degreasing solution, control the free acid value in the degreasing solution to about 15, immerse the standard aluminum alloy test panel (10×20cm) in the degreasing solu...

Embodiment 2

[0059] Prepare passivating solution according to the formula of chromium-free passivating agent, the content of each component in the passivating agent is: water 829.0kg, organosilicon modified acrylic resin 100kg (solid content 25wt%, weight-average molecular weight 10000), waterborne polyurethane 50kg (solid content 30%, weight average molecular weight 25000), KH-792 5kg, nano titanium dioxide 3kg, phytic acid 8kg, nitric acid 5kg, acetic acid 3kg;

[0060] Add nitric acid, phytic acid and acetic acid into 500kg of water according to the above-mentioned addition amount, after stirring evenly, add KH-792, silicone modified acrylic resin, water-based polyurethane and nano-titanium dioxide in sequence, and then add the remaining water under the condition of stirring, and stir Evenly enough;

[0061] Mix the above-mentioned passivating agent with a passivating bath solution at a concentration of 1% by mass, and set aside;

[0062] Degrease and wash the standard aluminum alloy t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com