Colored and coated chromate-free metal sheet, and colored aqueous composition

A chromate-free, metal plate technology, applied in the direction of metal layered products, coatings, synthetic resin layered products, etc., can solve the problems of insufficient adhesion, discoloration, coating film dissolution, etc., to achieve chemical resistance Excellent performance, reduced energy costs, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] The present invention is further illustrated by examples. However, the present invention is not limited to the following examples.

[0130] (1) metal plate

[0131] Table 1 shows the types of metal plates used. A mild steel plate with a plate thickness of 0.5 mm was used as a base material of the plated metal plate. Regarding the SUS plate, a ferritic stainless steel plate (steel composition: C: 0.008 mass%, Si: 0.07 mass%, Mn: 0.15 mass%, P: 0.011 mass%, S: 0.009 mass%, Al: 0.067 mass%, Cr: 17.3% by mass, Mo: 1.51% by mass, N: 0.0051% by mass, Ti: 0.22% by mass, the balance being Fe and unavoidable impurities). Alkaline degreasing treatment on the surface of the metal plate, washing and drying before use.

[0132] Table 1

[0133] No.

Metal plate (thickness 0.5mm, double-sided plating)

M1

Electro-galvanized steel sheet (coating weight 20g / m 2 )

M2

Hot-dip galvanized steel sheet (coating weight 60g / m 2 )

M3

Alloyed ...

manufacture example PO1

[0147]

[0148] Nitrogen gas was introduced into a reaction vessel equipped with a thermometer, a nitrogen introduction pipe, and a stirrer, and 443 parts by mass of terephthalic acid, 443 parts by mass of isophthalic acid, 420 parts by mass of adipic acid, 196 parts by mass of ethylene glycol, and 1 , 306 parts by mass of 4-butanediol, 328 parts by mass of neopentyl glycol, and 0.5 parts by mass of dibutyltin oxide were stirred. Next, while introducing nitrogen gas, the temperature was raised to 230° C., and polycondensation reaction was performed at this temperature for 15 hours until the acid value became 1 or less to obtain polyester polyol PO1.

manufacture example PO2

[0149]

[0150] According to the raw material composition shown in Table 6, polyester polyols PO2-PO7 were obtained by the procedure similar to manufacture example PO1. In either preparation, the amount of dibutyltin oxide is 0.5 parts by mass.

[0151] Table 6 also shows the number average molecular weight (polystyrene conversion value measured by GPC) of polyester polyols PO1 to PO7 and the content of aromatic ring structures in the solid content of polyester polyols PO1 to PO7 (mass % ). It should be noted that the content of the aromatic ring structure in the solid content of these polyester polyols PO1 to PO7 is obtained by substituting the denominator {solid content mass (g) of polyurethane resin (A1)} in the above formula [1] Calculated as {solid content mass (g) of polyester polyol}.

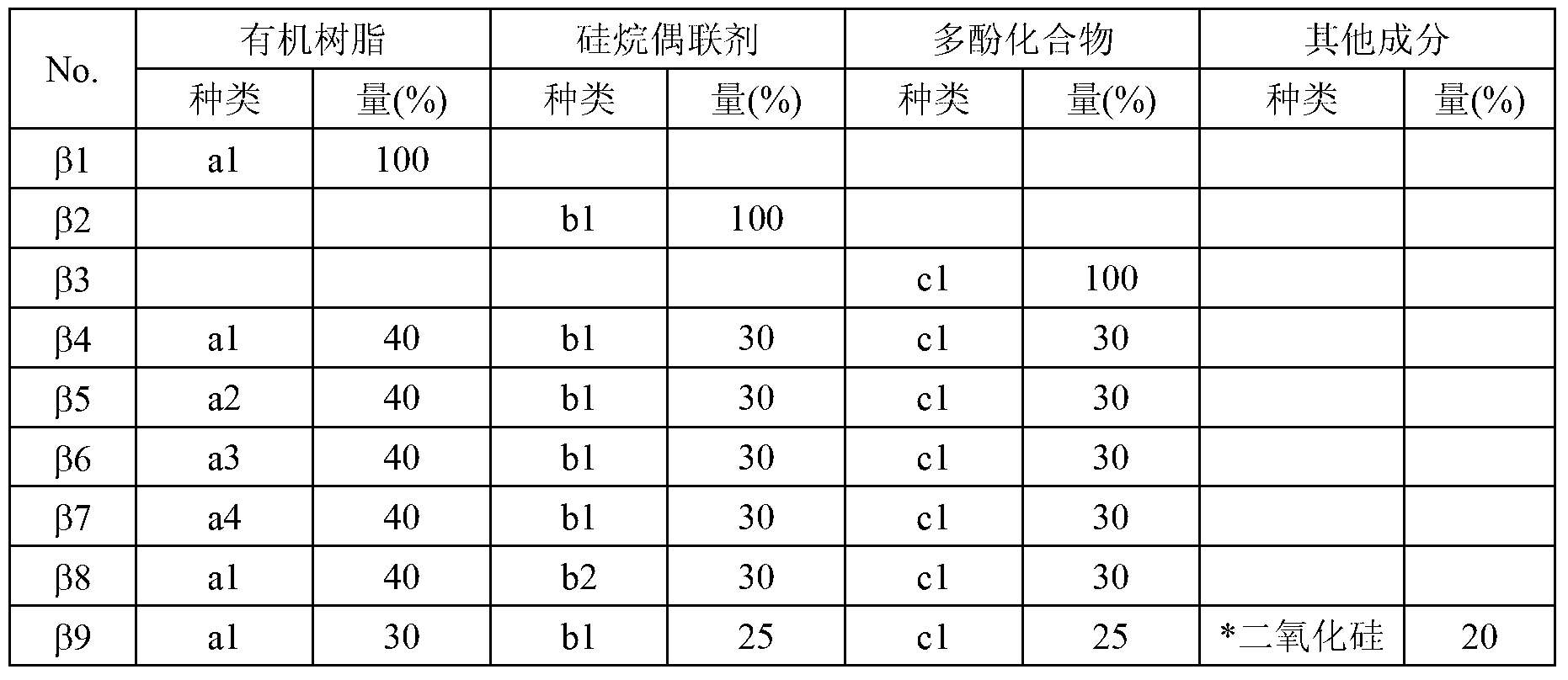

[0152] Table 6

[0153]

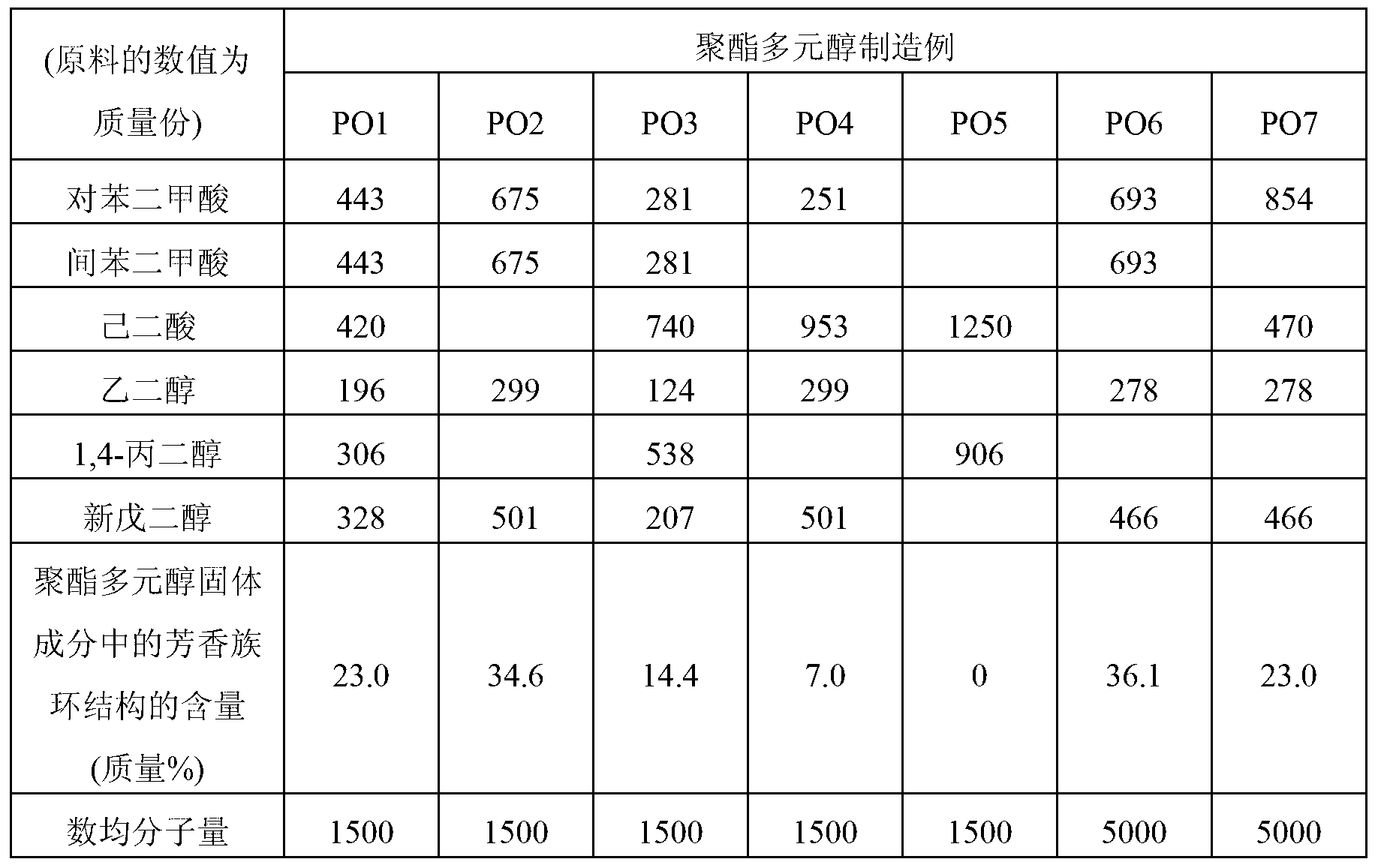

[0154] (Preparation of aqueous dispersion of polyurethane resin)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com