Chromate-free passivation agent for aluminum alloy

A chromium-free passivator and aluminum alloy technology, which is applied in the coating process of metal materials, can solve the problems of passivation effect hexavalent chromium technology gap and troubles, and achieve the goal of improving physical bonding ability, enhancing thickness and density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

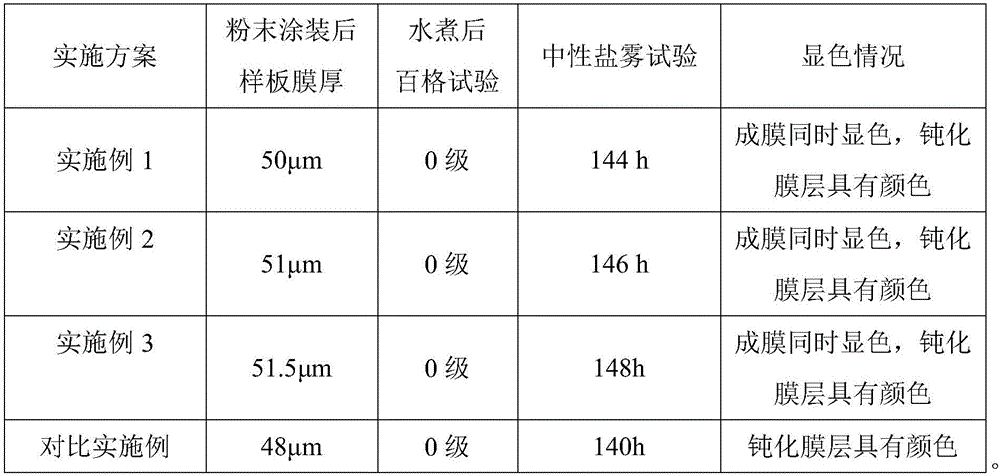

Examples

Embodiment 1

[0021] A chromium-free passivator suitable for aluminum alloys, consisting of the following components: 200ppm N-methyl-γ-aminopropyltrimethoxysilane, 40ppmγ-glycidyloxypropylmethyldiethoxysilane , 40ppm nano-scale SiO 2 Particles, 10ppm nanoscale ZrO 2 Particles, 250ppm potassium fluozirconate (calculated as zirconium), 200ppm fluotitanic acid (calculated as titanium), 100ppm cerium nitrate (calculated as cerium), 40ppm cobalt nitrate (calculated as cobalt), 100ppm sodium fluoride, 10ppm sodium citrate , 25ppm ATMP, 50ppm HEDP, 30ppm non-ionic surfactant and water balance.

Embodiment 2

[0023] A chromium-free passivator suitable for aluminum alloys, consisting of the following components: 50ppm γ-aminopropyltriethoxysilane, 100ppm γ-(2,3-glycidyloxy)propyltrimethoxysilane, 30ppm Nanoscale TiO2 particles, 20ppm nanoscale CeO 2 Particles, 50ppm nano-sized SiO 2 Particles, 120ppm 45% fluozirconic acid (calculated as zirconium), 60ppm potassium fluotitanate (calculated as titanium), 10ppm copper nitrate (calculated as copper), 50ppm cerium nitrate (calculated as cerium), 60ppm cobalt nitrate (calculated as cobalt) , 150ppm potassium fluoride, 15ppm oxalic acid, 50ppm HEDP, 30ppm HPMA, 50ppm non-ionic surfactant and water balance.

Embodiment 3

[0025] A chromium-free passivator suitable for aluminum alloys, consisting of the following components: 240ppmN, N-diethyl-γ-aminopropyltrimethoxysilane, 60ppm2-(3,4-epoxycyclohexyl)ethyl Triethoxysilane, 40ppm nano-sized SiO 2 Particles, 30ppm nano TiO 2 Particles, 30ppm nano-sized CuO nanoparticles, 250ppm potassium fluozirconate (calculated as zirconium), 250ppm fluotitanic acid (calculated as titanium), 90ppm cerium nitrate (calculated as cerium), 60ppm cobalt nitrate (calculated as cobalt), 150ppm fluorine Sodium chloride, 10ppm sodium citrate, 10ppm succinic acid, 50ppmEDTMP, 20ppmPBTCA, 30ppmHPMA, 30ppm nonionic surfactant and water balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com