Chromate-free passivation method for chemically-plated Ni-P coating

A chromium-free passivation and chemical plating technology, applied in liquid chemical plating, coating, metal material coating process, etc., can solve the problems of insufficient moisture and heat resistance, human and environmental toxicity, oxidation and discoloration of chemical nickel plating layer, etc. , to achieve the effect of good discoloration resistance, excellent corrosion resistance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

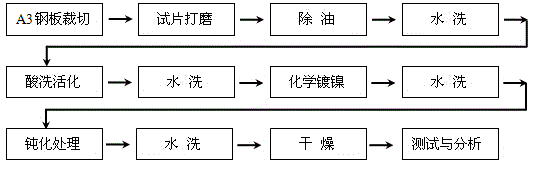

[0038] Electroless Ni-P coating molybdate passivation process of the present invention comprises the steps:

[0039] (1) Sample preparation: use low-carbon steel (A3) as the plating substrate for electroless nickel plating, cut the steel plate into 20×50×3mm samples, and punch holes at one end of the sample for hanging;

[0040] (2) Pre-plating treatment: The cut steel sheet is processed according to the following process, grinding → degreasing → water washing → activation → water washing. Among them, sandpaper of different grain sizes is used for grinding step by step from low to high (500#→1000#→1500#); degreasing is alkaline degreasing at room temperature for 10 minutes; activation uses 5.0% HCl solution, activation at room temperature for 10-30s , after cleaning with distilled water, electroless plating is carried out;

[0041] (3) Electroless nickel plating is carried out on the steel sheet, and the plating solution used is composed of: NiSO 4 ·6H 2 O 28g / L, NaH 2 PO ...

Embodiment 2

[0049] Step (1)-(3) is the same as embodiment 1.

[0050] (4) Preparation of passivation solution: prepare 1000ml of passivation solution, put 700ml of distilled water in a clean beaker, add in order:

[0051] NaOH 6.0g Na 2 CO 3 3.0g

[0052] Na 2 MoO 4 2H 2 O 40.0g C 6 h 5 o 7 Na 3 2H 2 O 8.0g

[0053] Na 2 S 2 o 8 7.0g

[0054] (5) Preparation of passivation film: After the test piece is plated, it is immediately subjected to passivation treatment after being washed with distilled water. During the treatment, the temperature of the passivation solution is 75°C, and the passivation time is 20 minutes. After the passivation treatment, the test piece is immediately rinsed and dried or dried to complete the passivation treatment.

Embodiment 3

[0056] Steps (1)-(3) are the same as in Example 1.

[0057] (4) Preparation of passivation solution: prepare 1000ml of passivation solution, put 700ml of distilled water in a clean beaker, add in order:

[0058] NaOH 4.0g Na 2 CO 3 7.0g

[0059] Na 2 MoO 4 2H 2 O 35.0g C 6 h 5 o 7 Na 3 2H 2 O 6.0g

[0060] NaClO 5.0g

[0061] (5) Preparation of passivation film: After the test piece is plated, it is immediately subjected to passivation treatment after being washed with distilled water. During the treatment, the temperature of the passivation solution is 60°C, and the passivation time is 25 minutes. After the passivation treatment, the test piece is immediately rinsed and dried or dried to complete the passivation treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com